High-performance heat-insulation bricks for building and preparation method thereof

An insulating brick and high-performance technology, applied in the field of insulating bricks, can solve the problems of large waste of resources and energy of insulating bricks, limit the development of insulating brick technology, and low compressive strength of insulating bricks, and achieve good application prospects, high practical value, and high quality. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

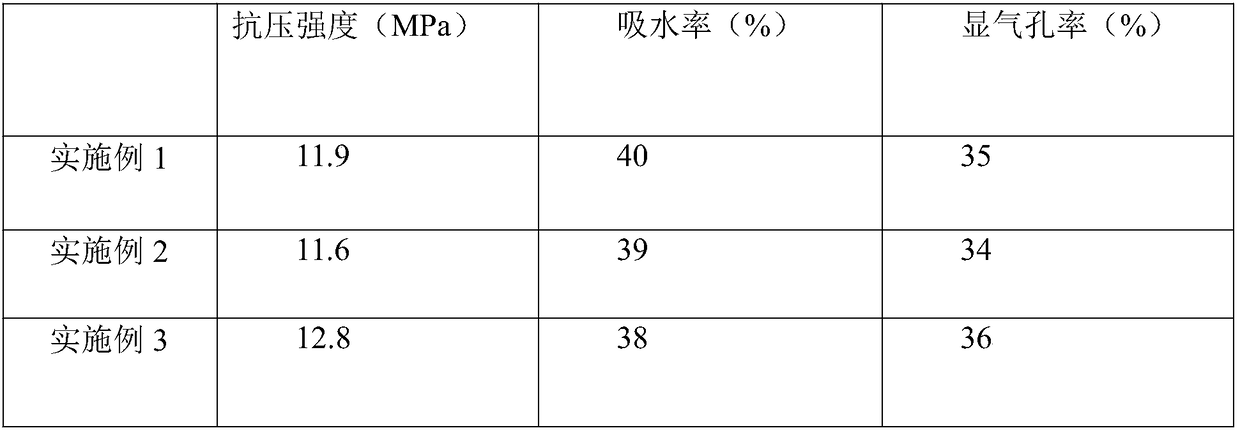

Examples

Embodiment 1

[0030] A kind of building high-performance insulating brick of the present embodiment comprises the raw material of following parts by weight:

[0031] 34 parts of modified fly ash, 28 parts of polymer microspheres, 22 parts of Portland cement, 16 parts of bentonite, 14 parts of kaolin, 20 parts of wood fiber, 16 parts of glass microspheres, 8 parts of refractory clay, and 4 parts of defoaming agent 4 parts, 4 parts of filler.

[0032] The modified fly ash of this embodiment is to pulverize the fly ash to a particle size of less than 1 mm, add it to water and stir for 35 minutes at a stirring speed of 350 r / min, then add a dilute inorganic acid solution to it, continue stirring for 1 hour, and then centrifuge to obtain the modified fly ash. The upper suspension, the suspension is sent to an oven to dry for 12 hours, and the modified fly ash is obtained.

[0033] The polymer microspheres in this embodiment are a mixture of silica microspheres and alumina microspheres in a weig...

Embodiment 2

[0042] A kind of building high-performance insulating brick of the present embodiment comprises the raw material of following parts by weight:

[0043] 40 parts of modified fly ash, 30 parts of polymer microspheres, 26 parts of Portland cement, 20 parts of bentonite, 18 parts of kaolin, 24 parts of wood fiber, 18 parts of glass microspheres, 10 parts of refractory clay, and 6 parts of defoaming agent 8 parts, 8 parts of filler.

[0044] The modified fly ash of this embodiment is to pulverize the fly ash to a particle size of less than 1 mm, add it to water and stir for 45 minutes at a stirring speed of 450 r / min, then add a dilute inorganic acid solution to it, continue stirring for 2 hours, and then centrifuge to obtain the modified fly ash. The suspension in the upper layer is sent to an oven to dry for 24 hours to obtain the modified fly ash.

[0045] The polymer microspheres in this embodiment are a mixture of silica microspheres and alumina microspheres in a weight ratio...

Embodiment 3

[0054] A kind of building high-performance insulating brick of the present embodiment comprises the raw material of following parts by weight:

[0055] 36 parts of modified fly ash, 29 parts of polymer microspheres, 24 parts of Portland cement, 18 parts of bentonite, 16 parts of kaolin, 22 parts of wood fiber, 17 parts of glass microspheres, 9 parts of refractory clay, and 5 parts of foam reducing agent 6 parts, 6 parts of filler.

[0056] The modified fly ash of this embodiment is to pulverize the fly ash to a particle size of less than 1 mm, add it to water and stir for 40 minutes at a stirring speed of 400 r / min, then add a dilute inorganic acid solution to it, continue stirring for 1.5 hours, and then centrifuge Take the suspension in the upper layer, and send the suspension into an oven to dry for 18 hours to obtain the modified fly ash.

[0057] The polymer microspheres in this embodiment are a mixture of silica microspheres and alumina microspheres in a weight ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com