Micron-sized monodispersed porous silica microsphere and preparation method thereof

A technology of porous silicon dioxide and silicon dioxide, applied in the directions of silicon dioxide, silicon oxide, nanotechnology, etc., can solve problems such as application field limitations, and achieve low cost of raw materials, adjustable particle size and pore structure, and acceptable conditions. Strong control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of Silica Microspheres Using Polymethylsilsesquioxane Microspheres as a Template

[0025] (1) Add 20 g of methyltrimethoxysilane to 100 mL of deionized water, add 0 μL of hydrochloric acid solution at pH 1, and stir and react at room temperature for 1 h to obtain a polysilsesquioxane hydrolyzate;

[0026] (2) Add 10 μL of concentrated ammonia water to the polysilsesquioxane hydrolyzate, stir evenly, let it stand for 4 hours, filter to remove the mother liquor, collect the microspheres, wash with 95% ethanol, and obtain the polysilsesquioxane gel microspheres. ball;

[0027] (3) Disperse 1 g of polysilsesquioxane gel microspheres in 10 mL of 80% ethanol according to the mass volume ratio of 0.1, and mix well;

[0028] (4) Add sodium hydroxide to the mixed solution obtained in step (3) to make the concentration 0.05M, mix well, shake and react in a water bath at 70°C for 10 hours, filter to remove the solvent, and wash the microspheres alternately with 95% et...

Embodiment 2

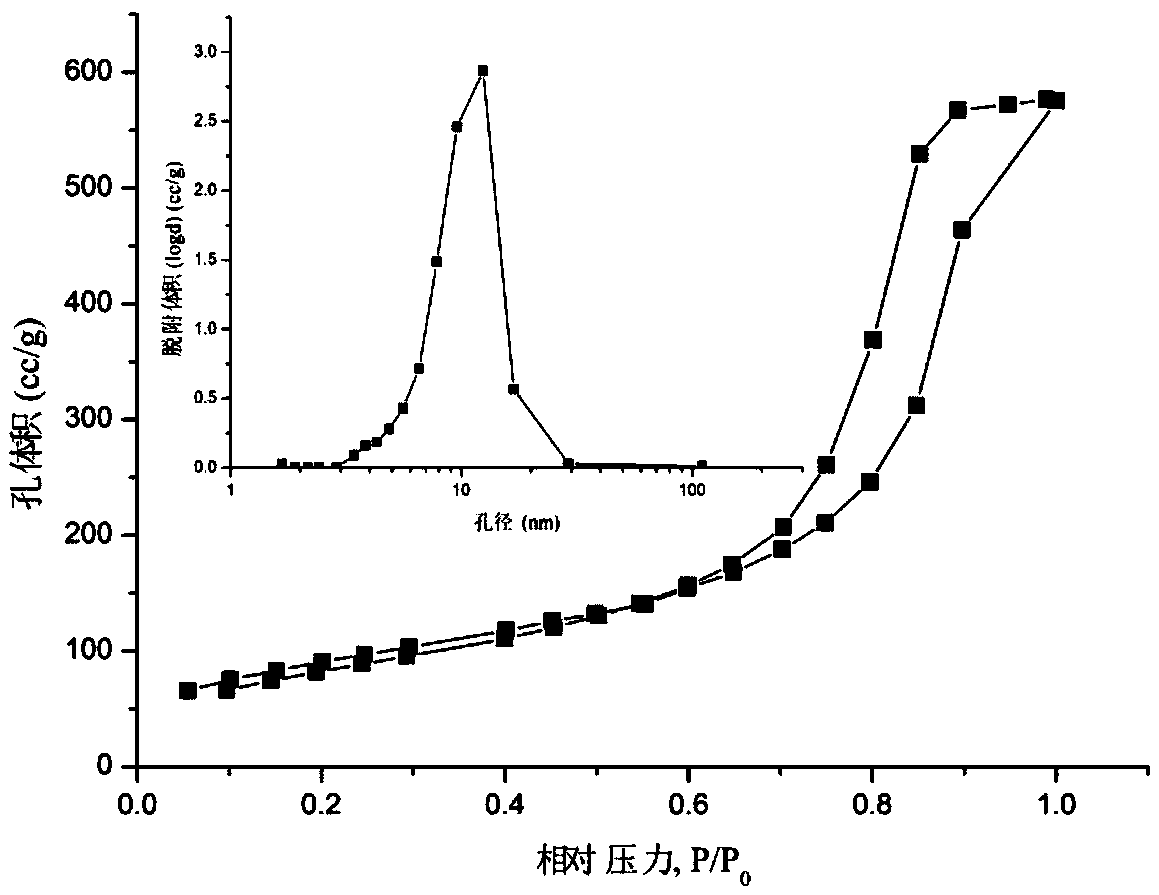

[0032] Preparation of silica microspheres with different pore sizes using polymethylsilsesquioxane microspheres as template

[0033] (1) Add 20 g of methyltrimethoxysilane to 100 mL of deionized water, add 0 μL of hydrochloric acid solution at pH 1, and stir and react at room temperature for 1 h to obtain a polysilsesquioxane hydrolyzate;

[0034] (2) Add 10 μL of concentrated ammonia water to the polysilsesquioxane hydrolyzate, stir evenly, let it stand for 4 hours, filter to remove the mother liquor, collect the microspheres, wash with 95% ethanol, and obtain the polysilsesquioxane gel microspheres. ball;

[0035] (3) Disperse 1 g of polysilsesquioxane gel microspheres in 10 mL of 80% ethanol according to the mass volume ratio of 0.1, and mix well;

[0036] (4) Add sodium hydroxide to the mixed solution obtained in step (3) so that the concentrations are 0.01 and 0.025M respectively, mix well, shake and react in a water bath at 70°C for 10 hours, filter to remove the solven...

Embodiment 3

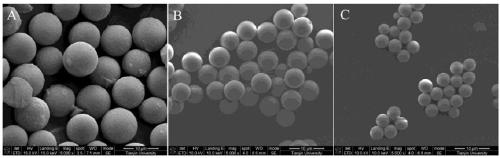

[0042] Preparation of silica microspheres with different particle sizes using polymethylsilsesquioxane microspheres as template

[0043] (1) Add 20 g of methyltrimethoxysilane to 100 mL of deionized water, add 0 μL of hydrochloric acid solution at pH 1, and stir and react at room temperature for 1 h to obtain a polysilsesquioxane hydrolyzate;

[0044] (2) Add 5, 20, and 50 μL of concentrated ammonia water to the polysilsesquioxane hydrolyzate, stir evenly, let stand for 4, 3, and 2 hours respectively, filter and remove the mother liquor, collect the microspheres, wash with 95% ethanol, Obtain polysilsesquioxane gel microspheres of different particle sizes;

[0045] (3) Disperse 1 g of polysilsesquioxane gel microspheres in 10 mL of 80% ethanol according to the mass volume ratio of 0.1, and mix well;

[0046] (4) Add sodium hydroxide to the mixed solution obtained in step (3) so that the concentrations are 0.05, 0.1, and 0.6M respectively, mix well, shake and react in a water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com