Method for preparing silver powder in continuous mode

A continuous method, silver powder technology, applied in the field of silver powder with uniform particle size, can solve the problems of ubiquitous intermittent reaction, numerous production processes, unstable quality, etc., to achieve good dispersibility, uniform particle size and adjustable particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

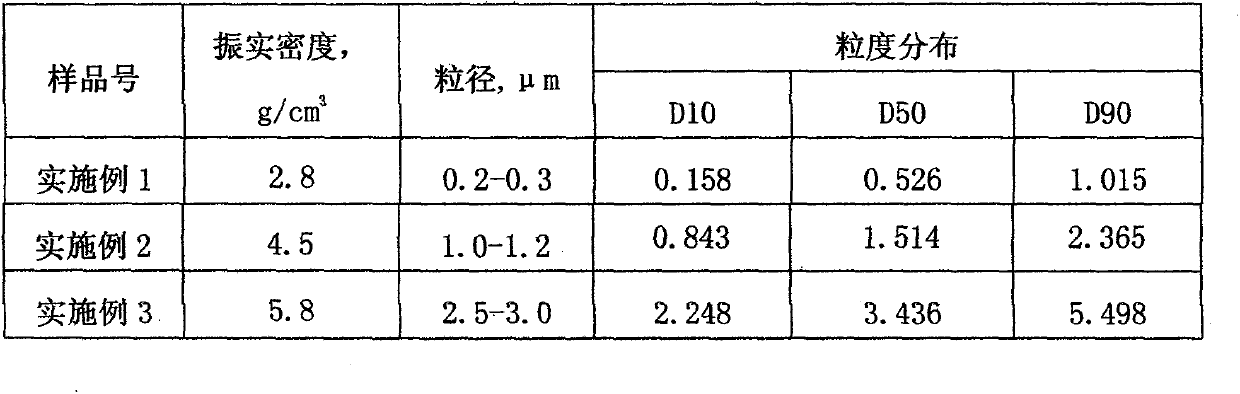

Embodiment 1

[0026] Silver solution preparation: dissolve 17KgAgNO3 and 1Kg Tween 60 in 100L deionized water, stir to dissolve, and keep the temperature at 40°C; preparation of reducing solution: dissolve 6L (50%) hydrazine hydrate and 50g sodium hydroxide in 100L deionized water Water, constant temperature at 40°C; pump the silver solution and reducing solution into the reaction at a flow rate of 200L / H, pump the suspension into the solid-liquid separation equipment for filtration after the reaction, and wash the silver powder after solid-liquid separation with deionized water until the conductivity is less than 200μs / cm, the filter cake was dried at 30°C, crushed and sieved to obtain silver powder, see figure 1 .

Embodiment 2

[0028] Preparation of silver solution: Dissolve 17KgAgNO3, 20L ammonia water, and 3KgPVA in deionized water, stir to dissolve, prepare a 200L solution, and keep the temperature at 40°C. Preparation of reducing solution: Dissolve 10KG of hydrazine hydrate in deionized water and adjust the preparation to 100L. The temperature is kept at 40°C; the silver solution and the reducing solution are pumped into the reactor at a flow rate of 200L / H and 100L / H respectively, and the silver powder suspension is separated from the solid and liquid after the reaction. Wash with deionized water until the conductivity is less than 200μs / cm, dry the filter cake at 50°C, crush and sieve to obtain silver powder, see figure 1 .

Embodiment 3

[0030] Preparation of silver solution: dissolve 17KgAgNO3 and 1KgPVP in 300L deionized water, stir to dissolve, and keep the temperature at 30°C; preparation of reducing solution: dissolve 17KG ascorbic acid in 100L of deionized water, keep the temperature at 30°C; The flow rate of 600L / H and 200L / H is pumped into the pipeline reactor, the silver powder after solid-liquid separation is washed with deionized water until the conductivity is less than 200μs / cm, the filter cake is dried at 60°C, crushed and sieved to obtain silver powder, powder For detection performance, see figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com