Method for preparing polysiloxane-acrylate/styrene copolymers with large particle sizes and core-shell structures

A technology of styrene copolymers and polyacrylates, which is applied in the field of preparation of polysiloxane-acrylic ester/styrene copolymers with large particle size core-shell structure, can solve the problem of polysiloxane-acrylic acid Ester copolymer and other issues, to achieve obvious low-temperature toughening effect, good stability, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

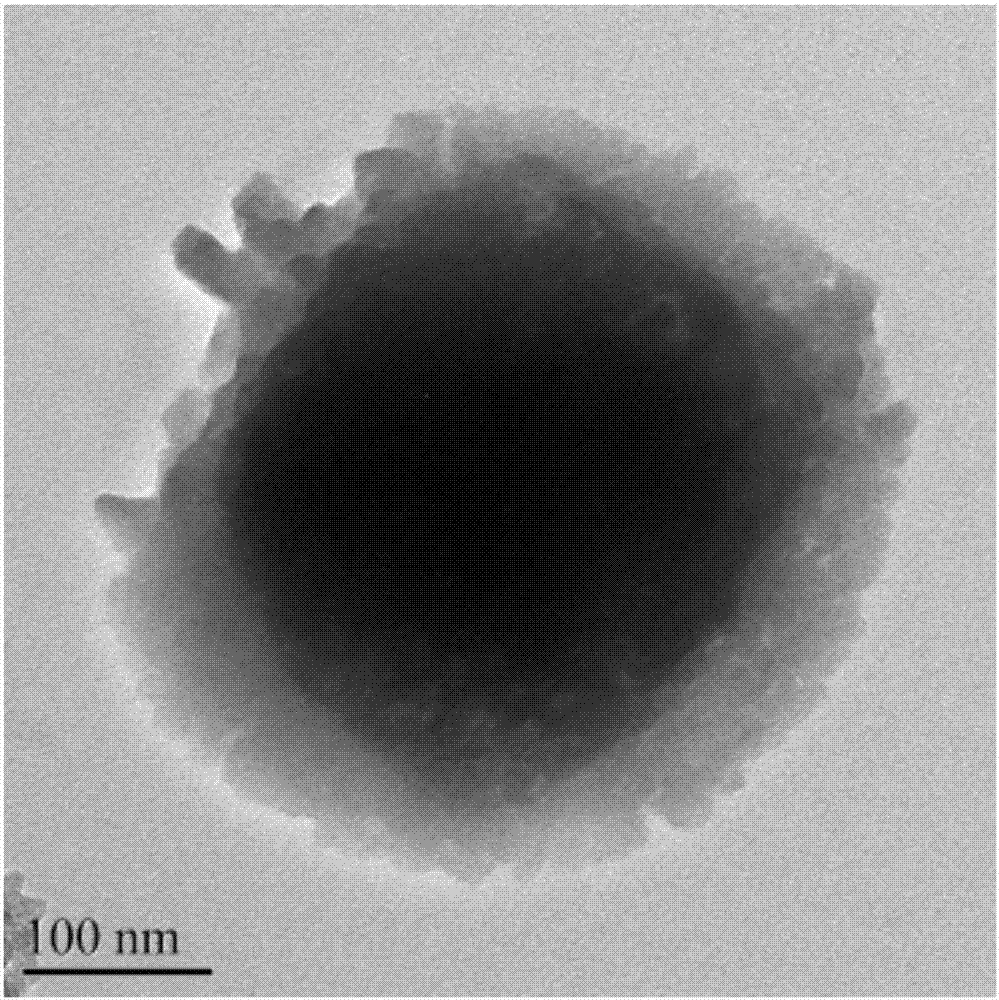

Image

Examples

Embodiment 1

[0035] Preparation of polysiloxane-butyl acrylate emulsion: add 0.3g of dodecylbenzenesulfonic acid, 0.3g of sodium dodecylsulfate and 50g of deionized water into a 250ml reaction bottle, stir well, and heat to 60°C , then add 9.0g of octamethylcyclotetrasiloxane and 1.0g of γ-methacryloxypropyl trimethoxysilane, and keep the reaction at 60°C for 3 hours; mix 20g of deionized water, 0.1g of dodecylbenzene Sulfonic acid, 0.1g sodium lauryl sulfate, 27g octamethylcyclotetrasiloxane, 3.0g γ-methacryloxypropyl trimethoxysilane and 0.04g hexamethyldisiloxane were passed through homogeneous Stir at high speed with the mixer until there is no obvious stratification. Within 2 hours, drop the pre-emulsified mixture into the above-mentioned reaction flask, and react at 60° C. for 5 hours to obtain a polysiloxane emulsion with a solid content of 33.8%.

[0036] Take 8.9g of the above polysiloxane emulsion, add 80g of deionized water, 0.6g of alkylphenol polyoxyethylene ether and 0.6g of ...

Embodiment 2

[0041] Preparation of polysiloxane-butyl acrylate emulsion: Add 0.4g of dodecylbenzenesulfonic acid, 0.4g of sodium dodecylsulfate and 60g of deionized water into a 250ml reaction bottle, stir well and heat to 70°C , then add 9.5g of octamethylcyclotetrasiloxane and 0.5g of γ-methacryloxypropyltrimethoxysilane, keep the reaction at 70°C for 3 hours; mix 30g of deionized water, 0.2g of dodecylbenzene The mixture of sulfonic acid, 0.2g sodium lauryl sulfate, 28.5g octamethylcyclotetrasiloxane, 1.5g vinyltrimethoxysilane and 0.08g hexamethyldisiloxane was stirred at a high speed by a homogeneous mixer to There is no obvious separation, within 2 hours, the pre-emulsified mixture is added dropwise to the reaction flask, and reacted at 70°C for 3 hours to obtain a polysiloxane emulsion with a solid content of 28.6%;

[0042] Take 25g of the above polysiloxane emulsion, add 100g of deionized water, 0.4g of alkylphenol polyoxyethylene ether and 0.2g of sodium lauryl sulfate into anoth...

Embodiment 3

[0047] Preparation of polysiloxane-butyl acrylate emulsion: add 0.4g of tetradecylbenzenesulfonic acid, 0.4g of cetyl sodium sulfate and 60g of deionized water into a 250ml reaction bottle, stir well, and heat to 80°C , then add 9.5g of octamethylcyclotetrasiloxane and 0.5g of γ-methacryloxypropyltrimethoxysilane, and keep it at 80°C for 2 hours; mix 20g of deionized water, 0.4g of tetradecylbenzene The mixture of sulfonic acid, 0.4g sodium cetyl sulfate, 28.5g octamethylcyclotetrasiloxane, 1.5g vinyltrimethoxysilane and 0.08g hexamethyldisiloxane was stirred at a high speed by a homogeneous mixer to There is no obvious separation, within 2 hours, the pre-emulsified mixture is added dropwise to the reaction flask, and reacted at 80°C for 3 hours to obtain a polysiloxane emulsion with a solid content of 31.4%;

[0048] Take 29g of the above polysiloxane emulsion, add 100g of deionized water, 0.8g of alkylphenol polyoxyethylene ether and 0.8g of sodium lauryl sulfate into anothe...

PUM

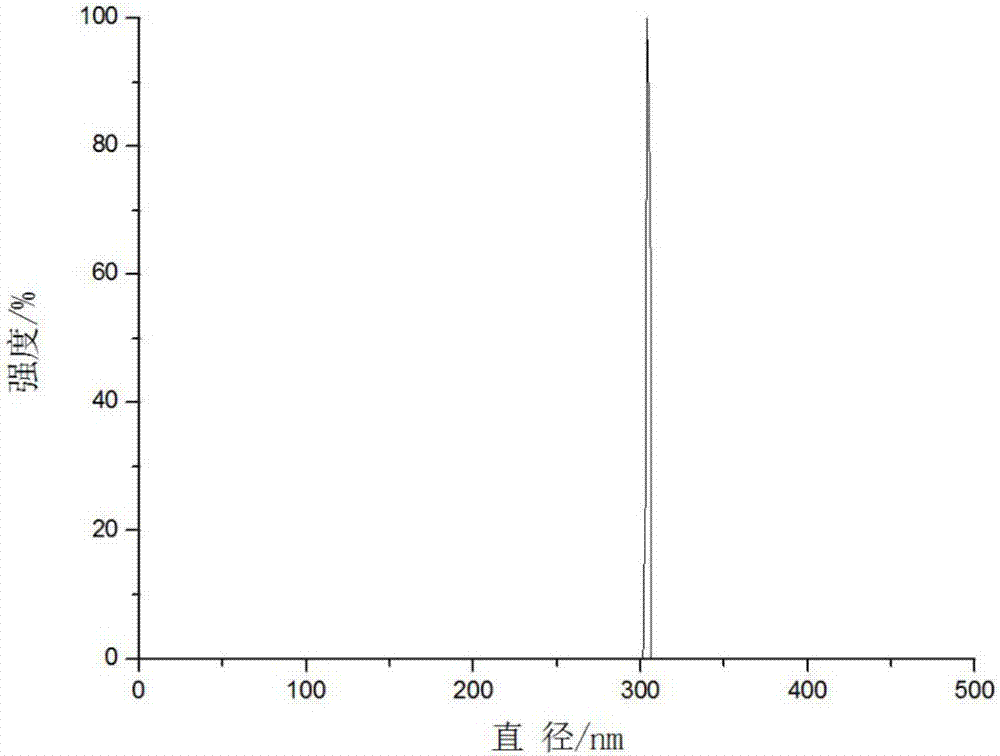

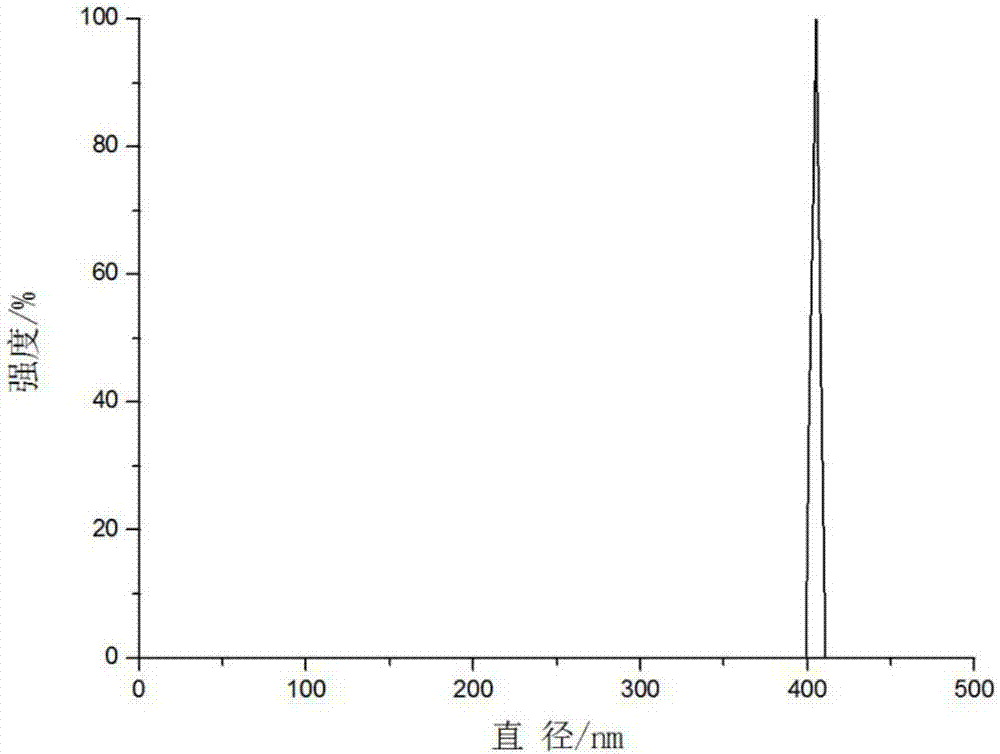

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com