Magnetic titanium dioxide hollow ball and preparation method thereof

A titanium dioxide and hollow sphere technology is applied in the magnetic titanium dioxide hollow sphere and its preparation. Controllable thickness and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

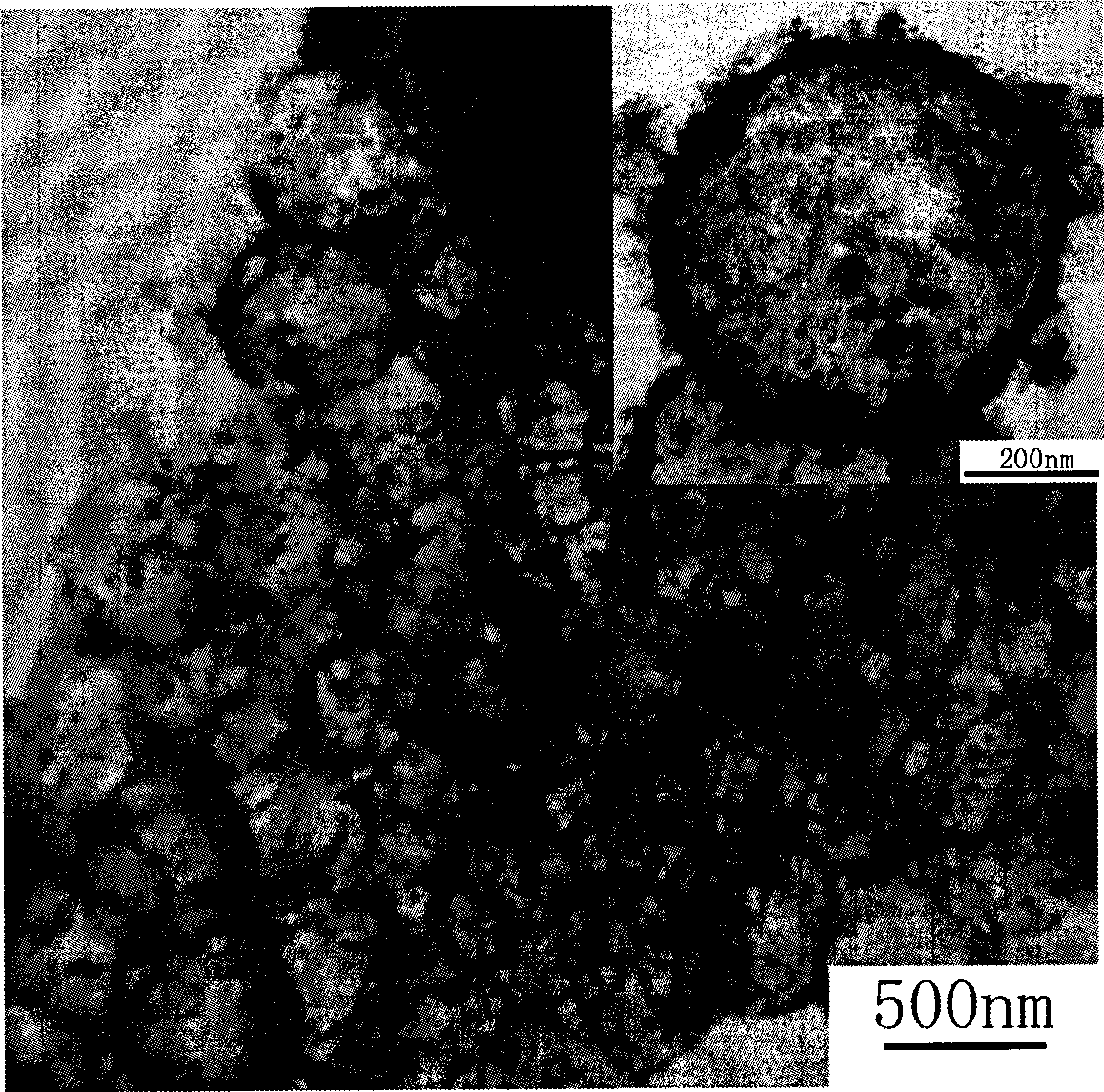

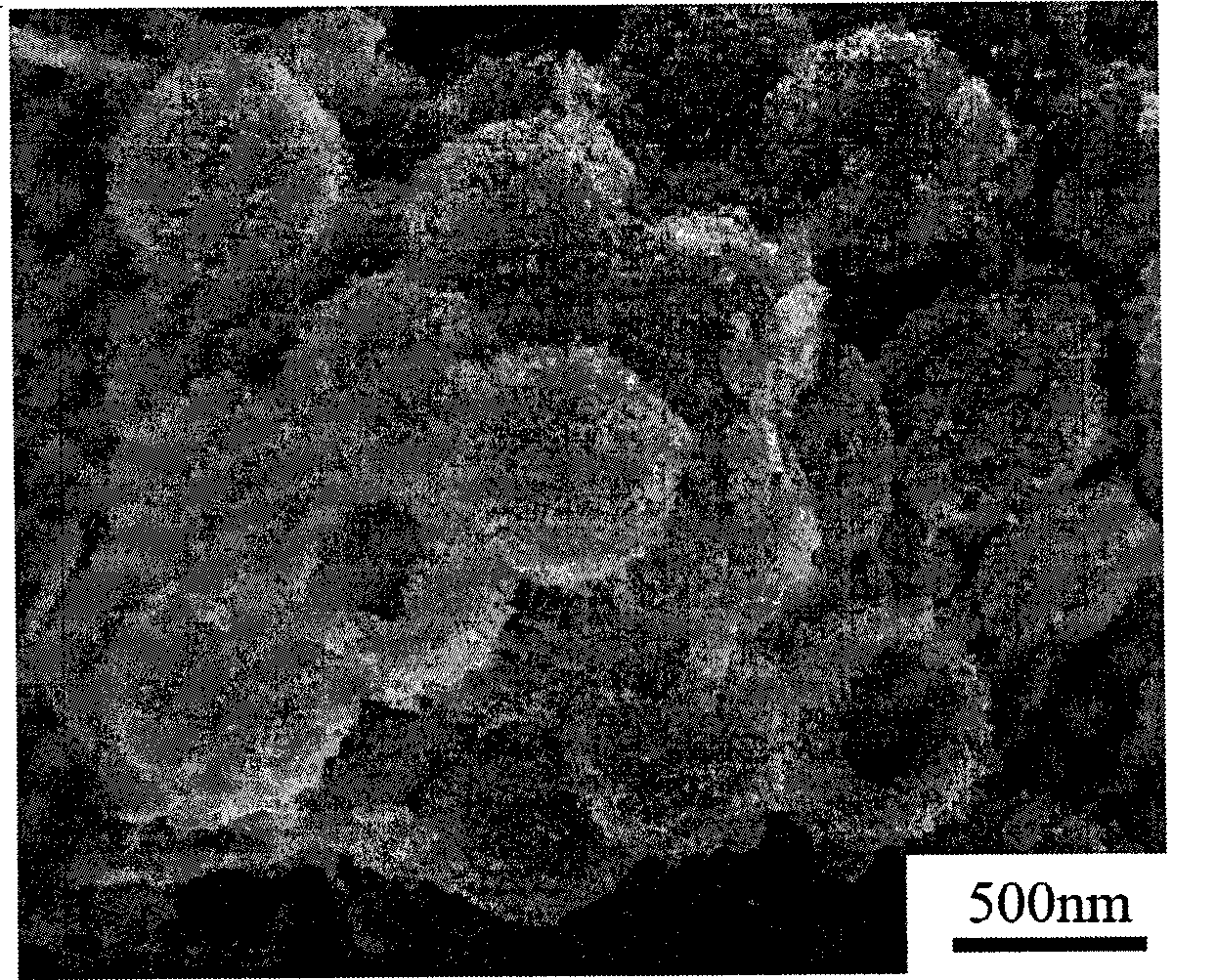

Image

Examples

Embodiment 1

[0030] (1) Preparation of polystyrene template spheres with a size of 560 nm

[0031] At room temperature, 220 mL of deionized water and 26 mL of styrene were added to a three-neck flask protected by nitrogen, and stirred at 300 rpm for 30 minutes, then the temperature was raised to 70°C in a water bath at a rate of 1°C / min. Then, 20 mL of an aqueous potassium persulfate solution with a concentration of 30 g / L was dropped into the three-necked flask, and reacted at 70° C. for 20 hours. After the reaction solution was cooled to room temperature, it was centrifuged and washed twice with deionized water and ethanol to obtain polystyrene template spheres.

[0032] (2) Preparation of polystyrene spheres coated with cobalt ferrite precursor

[0033] At room temperature, ultrasonically disperse 80 mg template polystyrene spheres in 50 mL of a mixed salt solution of cobalt nitrate and ferric chloride for 20 minutes, wherein the molar concentration of divalent cobalt ions is 0.025 mol...

Embodiment 2

[0039] (1) Preparation of polystyrene template spheres with a size of 560 nm

[0040] At room temperature, 220 mL of deionized water and 26 mL of styrene were added to a three-neck flask protected by nitrogen, and stirred at 300 rpm for 30 minutes, then the temperature was raised to 70°C in a water bath at a rate of 1°C / min. Then, 20 mL of an aqueous potassium persulfate solution with a concentration of 30 g / L was dropped into the three-necked flask, and reacted at 70° C. for 20 hours. After the reaction solution was cooled to room temperature, it was centrifuged and washed twice with deionized water and ethanol to obtain polystyrene template spheres.

[0041] (2) Preparation of polystyrene spheres coated with cobalt ferrite precursor

[0042] At room temperature, ultrasonically disperse 80 mg template polystyrene spheres in 50 mL of a mixed salt solution of cobalt nitrate and ferric chloride for 20 minutes, wherein the molar concentration of divalent cobalt ions is 0.025 mol...

Embodiment 3

[0048] (1) Preparation of polystyrene template spheres with a size of 560 nm

[0049] At room temperature, 220 mL of deionized water and 26 mL of styrene were added to a three-neck flask protected by nitrogen, and stirred at 300 rpm for 30 minutes, then the temperature was raised to 70°C in a water bath at a rate of 1°C / min. Then, 20 mL of an aqueous potassium persulfate solution with a concentration of 30 g / L was dropped into the three-necked flask, and reacted at 70° C. for 20 hours. After the reaction solution was cooled to room temperature, it was centrifuged and washed twice with deionized water and ethanol to obtain polystyrene template spheres.

[0050] (2) Preparation of magnetic cobalt ferrite hollow spheres

[0051] At room temperature, ultrasonically disperse 80 mg template polystyrene spheres in 50 mL of a mixed salt solution of cobalt nitrate and ferric chloride for 20 minutes, wherein the molar concentration of divalent cobalt ions is 0.025 mol / L, and the molar ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Shell thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com