Spherical carriers for olefin polymerization catalyst and preparation method

A spherical carrier and olefin polymerization technology, applied in the field of magnesium-containing spherical carrier and its preparation, can solve the problems of complex preparation process, low cooling forming temperature, high melting temperature and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

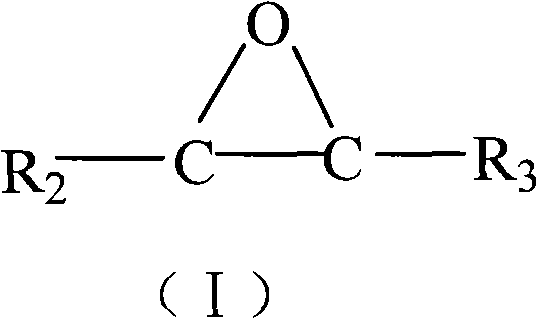

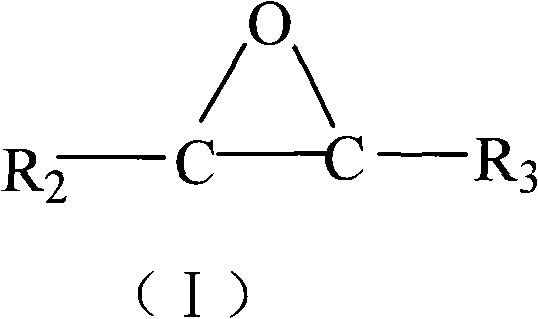

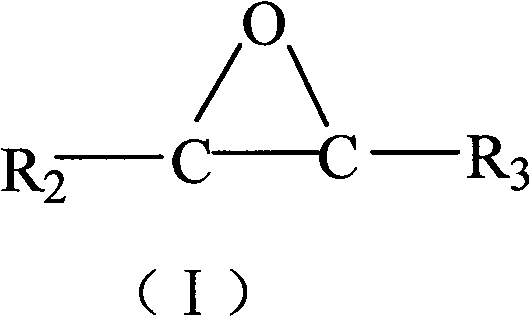

Method used

Image

Examples

Embodiment 1

[0035] A. Preparation of spherical carrier

[0036] In a 500mL reactor, add 7.2g of magnesium chloride, 180ml of white oil, and 82ml of ethanol in sequence, and heat up to 90°C while stirring. After constant temperature reaction for 1 hour, 24 ml of epichlorohydrin was added, the temperature was maintained for 0.5 hour, the liquid was filtered off, the solid was washed 5 times with hexane, and dried in vacuum to obtain a spherical magnesium-containing compound.

[0037] B. Preparation of spherical catalyst

[0038] Into a 300mL glass reaction bottle, add 100ml of titanium tetrachloride, cool to -20°C, add 8g of the above-mentioned spherical magnesium-containing composition, and heat up to 110°C. Add 1.5ml of diisobutyl phthalate during the heating process, filter off the liquid, wash twice with titanium tetrachloride, wash three times with hexane, and obtain a spherical catalyst after vacuum drying.

[0039] C. Propylene polymerization

[0040] In a 5L stainless steel autoc...

Embodiment 2

[0042] Preparation of the spherical carrier: the same as in Example 1 except that the reaction temperature is 100°C.

[0043] The preparation of the spherical catalyst and the polymerization of propylene are the same as in Example 1.

Embodiment 3

[0045] In a 500mL reaction kettle, add 10.5g of magnesium chloride, 180ml of white oil, and 120ml of ethanol in sequence, and raise the temperature to 85°C while stirring. After constant temperature reaction for 1 hour, 35 ml of epichlorohydrin was added, the temperature was maintained for 0.5 hour, the liquid was filtered off, the solid was washed 5 times with hexane, and vacuum-dried to obtain a spherical magnesium-containing compound.

[0046] The preparation of the spherical catalyst and the polymerization of propylene are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com