Method for preparing spherical carbon material

A spherical and carbonized technology, applied in the field of preparation of spherical porous carbon, can solve the problem of losing spherical appearance, and achieve the effect of simple particle size control method, uniform particle size and good sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

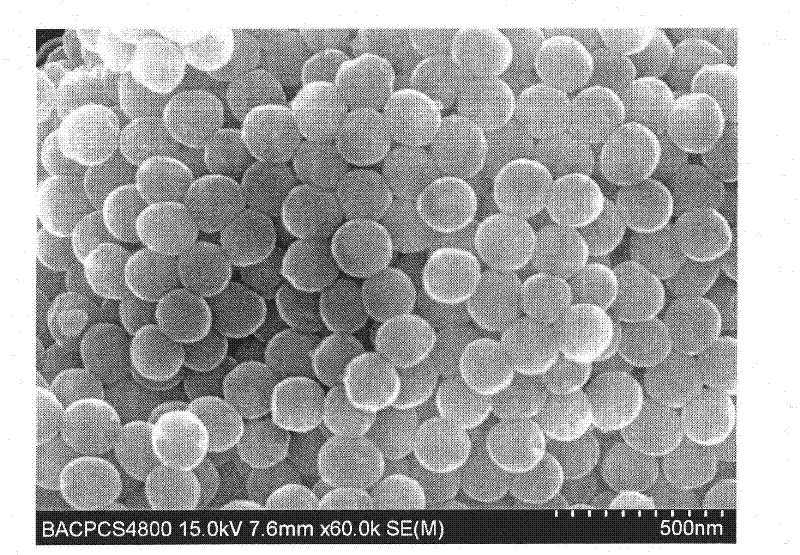

Embodiment 1

[0032] Weigh 5g of commercially available PVDF white powder (particle size: 500nm) and 35g of flaky KOH solid, mix them, grind them into a uniform fine powder, put them in an oven at 120°C for 10 hours, take them out, and wash them with dilute hydrochloric acid and deionized water in sequence until Neutral, the product dries and turns brown. The product was placed in a tube furnace, and under the protection of 200mL / min high-purity nitrogen, the temperature was raised to 150°C at 10°C / min, then to 700°C at 5°C / min, and the temperature was kept constant for 2h. After the furnace temperature was cooled to room temperature, it was taken out to obtain a black powder. SEM ( figure 1 ) observed as a spherical carbon material with a particle size of about 500nm and a specific surface area of 550m 2 / g.

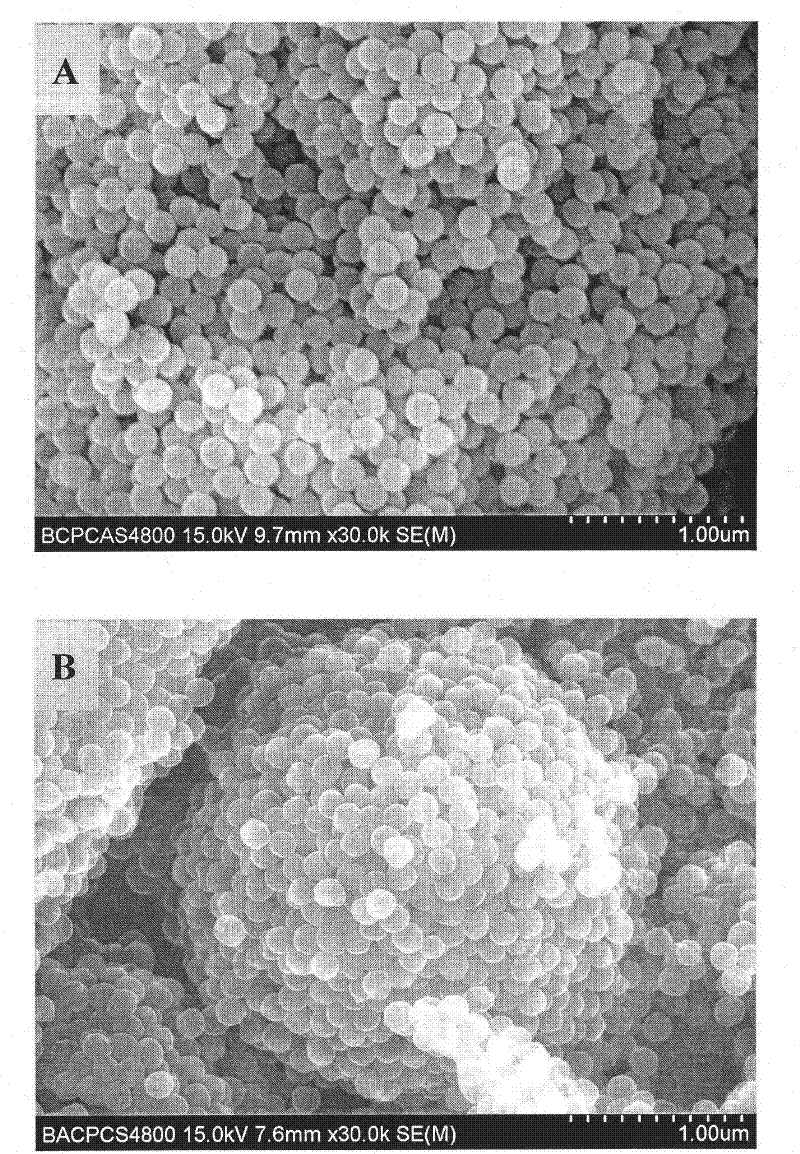

Embodiment 2

[0034]Dissolve 25g of KOH in 70mL of deionized water, add 5g of PVDF white powder (particle size 170nm), stir magnetically for 90min, then heat in an oven at 120°C for 20h, take it out and wash it with dilute hydrochloric acid and deionized water until neutral. The product dried and was dark brown. The product was placed in the center of a tube-type resistance furnace, and under the protection of high-purity argon, the temperature was raised to 600°C at a constant temperature for 2 hours, and then the temperature was raised to 850°C at 10°C / min, and 100mL / min CO was introduced. 2 Gas for 5 hours, after the furnace temperature is cooled to room temperature, take it out to obtain a black product, which is spherical in shape under the scanning electron microscope, with a particle size of about 170nm and a specific surface area of 1130m 2 / g. The scanning electron micrographs of PVDF white powder and obtained spherical carbon are shown in figure 2 (A) and (B).

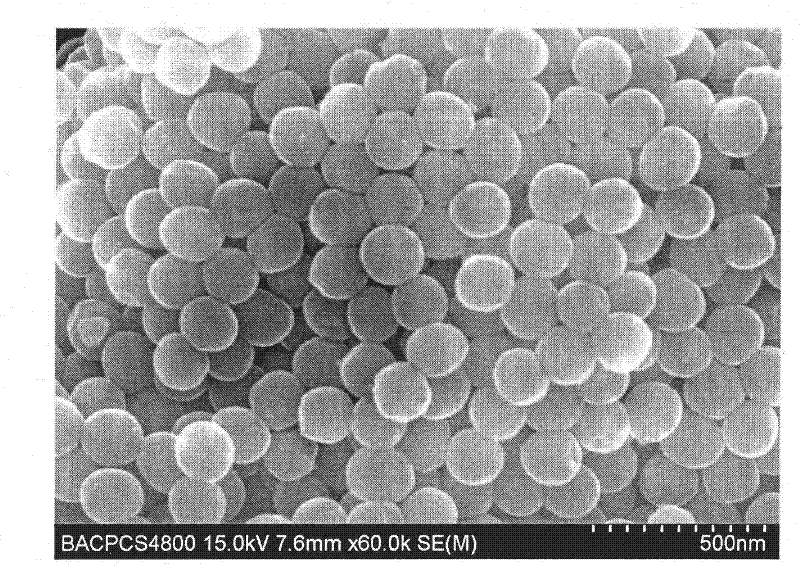

Embodiment 3

[0036] Measure 60 mL of absolute ethanol in a beaker, and measure 40 mL of N,N-dimethylformamide (DMF) into the absolute ethanol. Measure about 18mL of DBU into the above solution, stir well until the solution becomes clear and uniform, weigh 5g of PVDF white powder (particle size 170nm) and gradually add it to the above mixed solution, stir to dissolve it. Place in an oven at 70°C for 18h. Take it out, wash it with methanol until the filtrate is colorless, and dry it at 110°C to obtain a brown powder. Place it in the center of a tube furnace, under the protection of 200mL / min high-purity nitrogen, raise it to 700°C at 5°C / min, and carbonize at a constant temperature for 2h to obtain a black carbonized product. Mix the carbonized material and KOH at a mass ratio of 1:3, place it in the center of a tube furnace, and under the protection of 250mL / min high-purity nitrogen, raise it to 780°C at a rate of 5°C / min, activate it at a constant temperature for 5 hours, and wait for the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com