Nanometer ZSM-5 molecular sieve catalyst with high silica-alumina ratio and preparation method thereof

A ZSM-5 technology with a high silicon-aluminum ratio is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. It can solve the problem that the acidity and alkalinity of the synthetic liquid are not easy to control, and achieve good catalytic activity and wide application prospects. The effect of improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

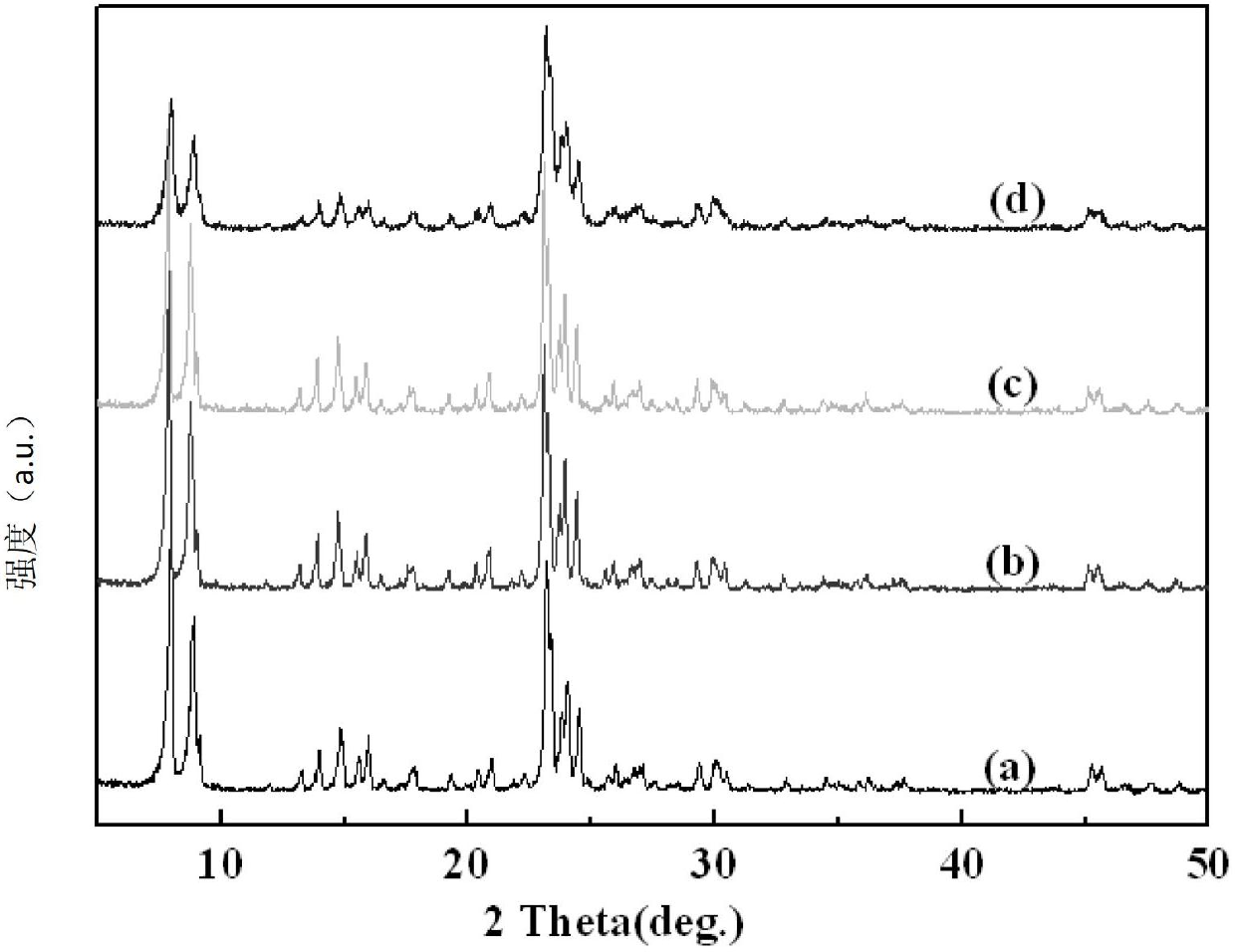

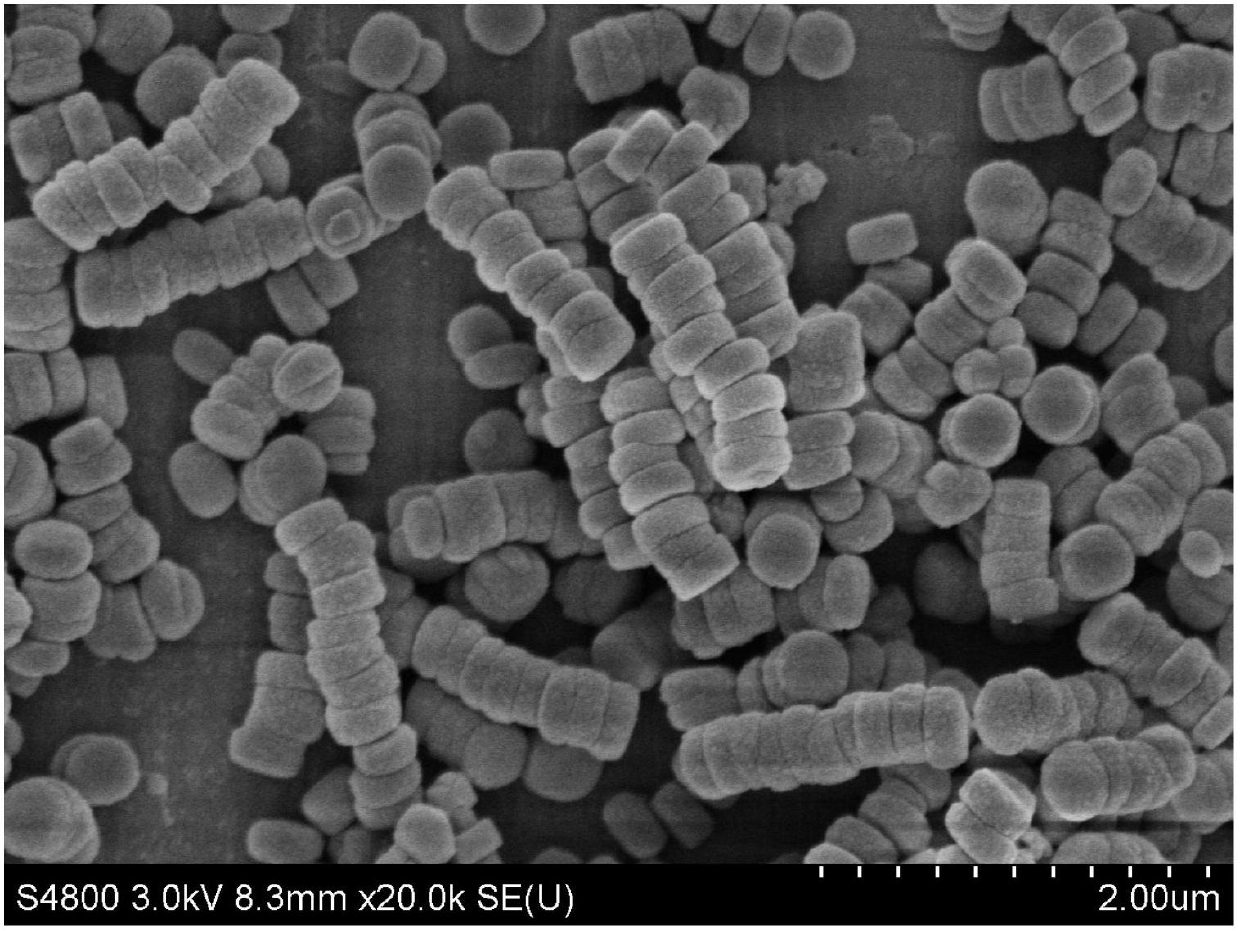

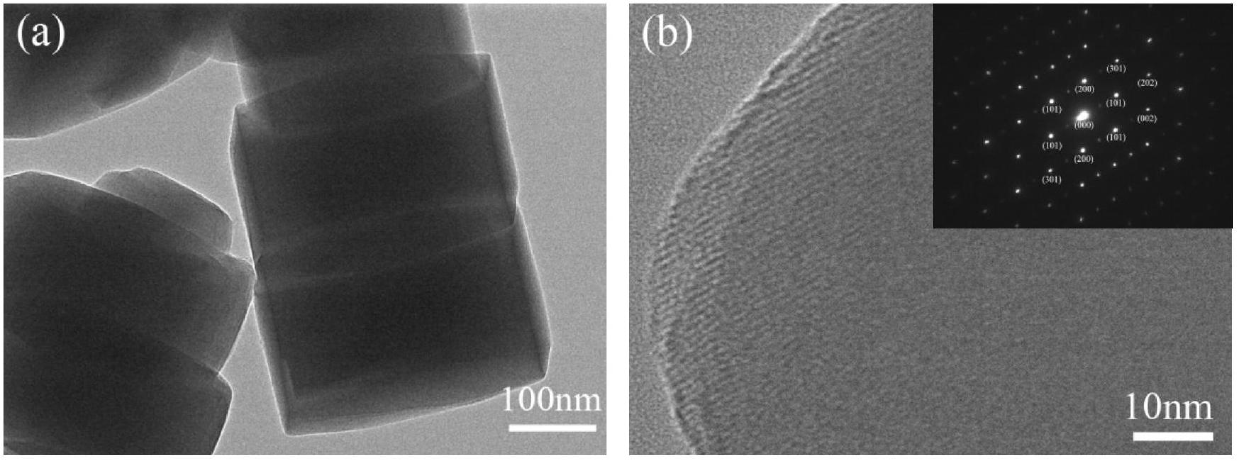

[0032] 13.5ml (0.06mol) of ethyl orthosilicate, 0.49g of aluminum isopropoxide (2.4×10 -3 mol), 10ml (0.01mol) of 25% tetrapropylammonium hydroxide and 30ml (1.67mol) of water were mixed evenly and added to the three-necked flask, refluxed and stirred at 60°C for 20h, and 0.48g (0.002mol) N,N- Diethylaminopropyltrimethoxysilane was added to the original molecular sieve solution, then condensed and refluxed and stirred for 6 hours to form a uniform gel;

[0033] Add the above reaction mixture into the synthesis reaction kettle, crystallize at 150°C for 48h, and make it crystallize under static conditions; after the crystallization is complete, the product is centrifuged and washed with deionized water until the pH is 9-10. °C, and roasted at 500 °C for 3h to remove tetrapropylammonium hydroxide and organosilane, so as to obtain an average grain size of 300nm, SiO 2 / Al 2 o 3 ZSM-5 molecular sieve A of 50, and has micropores of 0.8~1.7nm.

[0034] Organosilane N,N-diethylami...

Embodiment 2

[0036] 22.5ml (0.10mol) of ethyl orthosilicate, 0.41g of aluminum isopropoxide (2.0×10 -3 mol), 10ml (0.01mol) of 25% tetrapropylammonium hydroxide and 30ml (1.67mol) of water were mixed evenly into the three-necked flask, refluxed and stirred at 80°C for 20h, and 0.48g (0.002mol) of 3-ammonium Propyltrimethoxysilane was added to the original molecular sieve solution, then condensed and refluxed and stirred for 6 hours to form a uniform gel;

[0037] Add the above reaction mixture into the synthesis reaction kettle, crystallize at 160°C for 60 hours, and make it crystallize under static conditions; after the crystallization is complete, the product is centrifuged and washed with deionized water to pH 9-10, °C, and roasted at 550 °C for 4h to remove tetrapropylammonium hydroxide and organosilane, so as to obtain an average grain size of 200nm, SiO 2 / Al 2 o 3 It is ZSM-5 molecular sieve B of 100, and has micropores of 0.8-1.5nm.

Embodiment 3

[0039] 31.5ml (0.14mol) of ethyl orthosilicate, 0.29g of aluminum isopropoxide (1.4×10 -3 mol), 2.66g (0.01mol) of tetrapropylammonium bromide and 30ml (1.67mol) of water were mixed evenly and added to the three-necked flask, refluxed and stirred at 90°C for 20h, and 0.96g (0.004mol) of 3-aminopropyl Trimethoxysilane was added to the original molecular sieve solution, then condensed and refluxed and stirred for 6 hours to form a uniform gel;

[0040] Put the reaction mixture into the synthesis reaction kettle, crystallize at 170°C for 72h, and make it crystallize under static conditions; after the crystallization is complete, the product is centrifuged, washed with deionized water until the pH is 9-10, and dried at 110°C , and roasted at 700°C for 5h to remove tetrapropylammonium bromide and organosilane, so as to obtain an average grain size of 200nm, SiO 2 / Al 2 o 3 The ZSM-5 molecular sieve is 200, and has micropores of 1.1-1.7nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| micropore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com