Method for treating industrial waste and fermentation production of microbial oil by microorganism as well as special strain thereof

A technology for microbial oil and industrial waste, applied in biological water/sewage treatment, biochemical equipment and methods, microorganisms, etc., can solve the problem of cost, which cannot be effectively solved, and the high cost of biodiesel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1, the acquisition of Rhodotorula viscosus Rh.g CGMCC No.2258 bacterial strain

[0036] A series of mutagenized strains of Rhodotorula glutinis were obtained through multiple mutagenesis methods such as UV, EMS, LiCl and microwave, and various mutagenesis techniques, among which the optimal strain was selected and named as Rhodotorula glutinis. g, the specific mutagenesis process includes the following methods and steps:

[0037] 1) UV mutagenesis: the seed liquid of Rhodotorula glutinis (Rhodotorula glutinis) CICC No.1725 (purchased from China Institute of Food and Fermentation Industry) was cultured for 24-30h and then diluted 10 5 After doubling, spread on the yeast solid plate medium (glucose: 20%, yeast extract: 0.4%, urea: 0.2%, agar: 2%, pH4.5), respectively in the power of 15W, the irradiation distance is 30cm After irradiating for 10-600s under the ultraviolet lamp, incubate in the dark at 28-30°C for 3-5 days, check the growth of the colonies, and ...

Embodiment 2

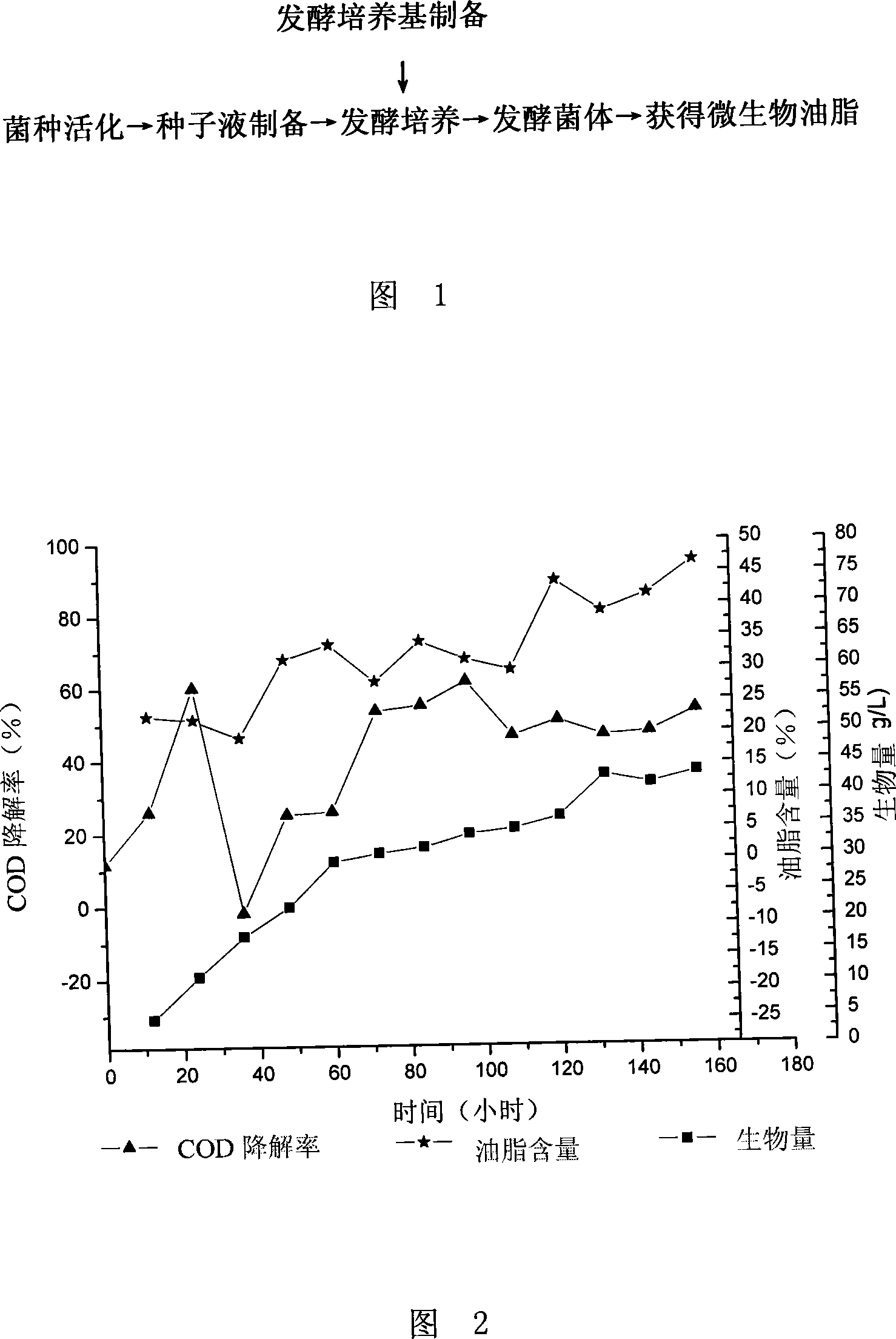

[0044] Embodiment 2, produce microbial oil under the condition of supplementing glucose mother liquor with the mixed solution of sauce residue and papermaking wastewater

[0045] Seed liquid medium formula: glucose 4g, (NH 4 ) 2 SO 4 0.2g, KH 2 PO 4 0.7g, Na 2 SO 4 0.2g, MgSO 4 ·7H 2 O 0.15g, yeast powder 0.15g, dilute to 100mL with water, pH 5.5.

[0046] Preparation of fermentation medium: papermaking wastewater (papermaking wastewater contains a large amount of degradation products such as lignin and hemicellulose, pigments, pentoses, residual alkali and other leached substances, the quality of wastewater is: COD=106000~157000mg / L, BOD =34500~42500mg / L, SS=23500~27800mg / L, pH=11~13.) After centrifugal sedimentation to remove insoluble particles, add glucose mother liquor (glucose mother liquor is the waste liquid of glucose produced by starch factory, the main component is glucose, concentration 400~500g / l) to 2% (g / dL) of glucose content, and then added to 2% (...

Embodiment 3

[0053] Embodiment 3, use monosodium glutamate waste water to produce microbial oil under the condition of adding glucose mother liquor

[0054] Seed solution medium formula: glucose 3g, (NH 4 ) 2 SO 4 0.1g, KH 2 PO 4 0.5g, Na 2 SO 4 0.1g, MgSO 4 ·7H 2 O 0.1g, yeast powder 0.1g, dilute to 100mL with water, pH 6.

[0055] Preparation of fermentation medium: monosodium glutamate waste water (monosodium glutamate waste water mother liquor is a kind of low-acid high-concentration organic waste water, waste water water quality is: COD=50000~70000mg / L, BOD5=25000~35000mg / L, N-NH 3 =8000~10000mg / L, containing about 1.5% glutamic acid, pH=2~3. ) after centrifugal sedimentation to remove insoluble particles, add glucose mother liquor to a glucose concentration of 4%, adjust the pH value to 5-6 with KOH, and sterilize for use.

[0056] Fermentative production microbial oil with the method of the present invention, concrete method comprises the following steps:

[0057] 1) S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com