Recycling treatment method of dye wastewater

A technology for dye wastewater and a treatment method, which is applied in the field of resource treatment of dye wastewater, can solve problems such as harming the environment, environmental pollution, secondary pollution, etc., and achieves the effects of high degree of automation, wide application range and high regeneration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

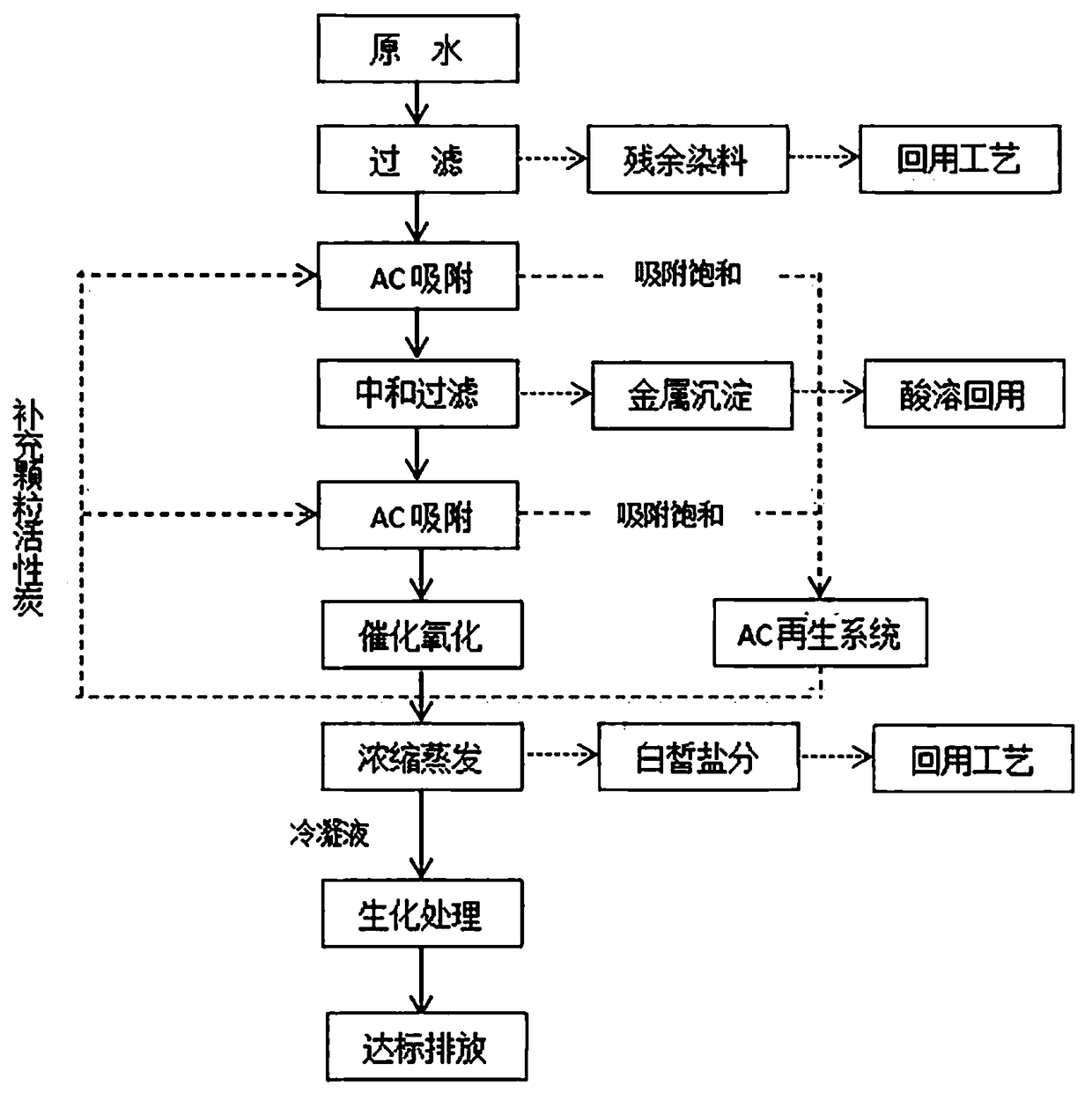

[0037] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

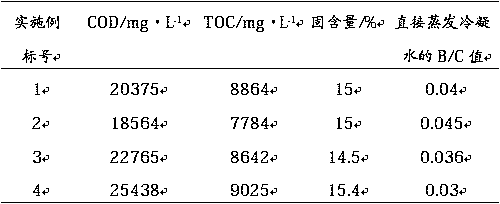

[0038] Embodiment 1~4 is the example of processing acid dye wastewater, and its processing method may further comprise the steps:

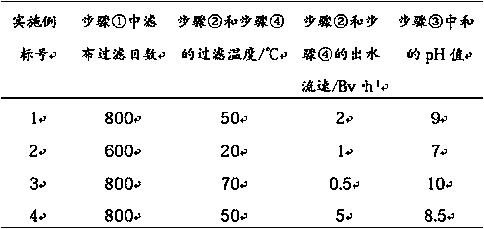

[0039] ① Filtration: filter the dye wastewater to obtain the filtrate and filter residue, the filtrate is processed in the next step, and the filter residue is reused;

[0040] ②Initial adsorption: Activated carbon is used to perform initial adsorption treatment on the filtrate obtained in step ①, and the effluent obtained by the initial adsorption enters the next step of treatment, and the saturated activated carbon is to be regenerated;

[0041] ③ Neutralization: neutralize the effluent obtained in step ② to obtain neutralized effluent and sediment;

[0042] ④Secondary adsorption: Activated carbon is used to perform secondary adsorption treatment on the neutralized effluent obtained in step ③, and the efflue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com