Method and system for producing biogas through two-stage anaerobic processing of high-concentration waste

A treatment method and waste technology, which are applied in the field of high-concentration waste treatment methods and treatment systems, can solve the problems of high cost, poor treatment effect, and high energy consumption, and achieve the effects of improving productivity and reducing operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Pig farms are the most common and larger livestock and poultry farms. Pig manure and urine are representative of livestock and poultry wastewater, and the components of various livestock and poultry wastewater are roughly the same, so the present invention is also applicable to the treatment of other livestock and poultry wastewater. Therefore, in this embodiment, livestock and poultry wastewater is selected from pig farm wastewater.

[0028] Among them, livestock excrement includes livestock manure and urine; livestock wastewater includes livestock urine, part of excrement and flushing water.

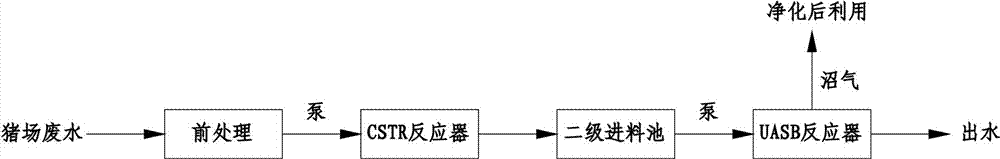

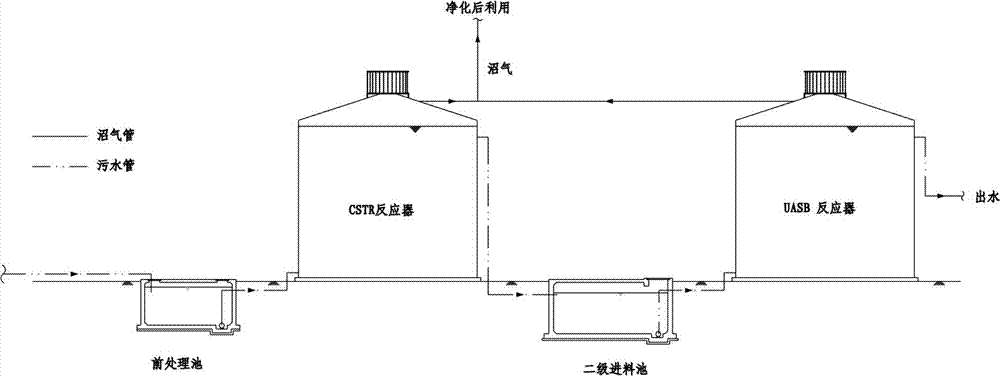

[0029] figure 1 is the process roadmap of the present invention, figure 2 It is a schematic diagram of the process flow of the present invention. combine figure 1 and figure 2 It can be seen that the specific processing steps include:

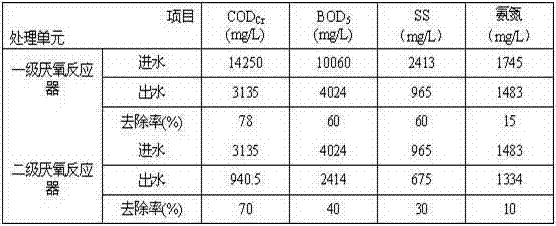

[0030] 1) The main parameters of livestock wastewater after pretreatment by hydraulic screen and hydrolysis acidification tank are: COD 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com