Deodorizing composite biological stuffing special for dyeing and finishing wastewater treatment and preparing method thereof

A technology of printing and dyeing sewage and biological fillers, which is applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of wasting resources and not being able to obtain resource utilization, etc., and achieve good effects, good adhesion space, and large specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

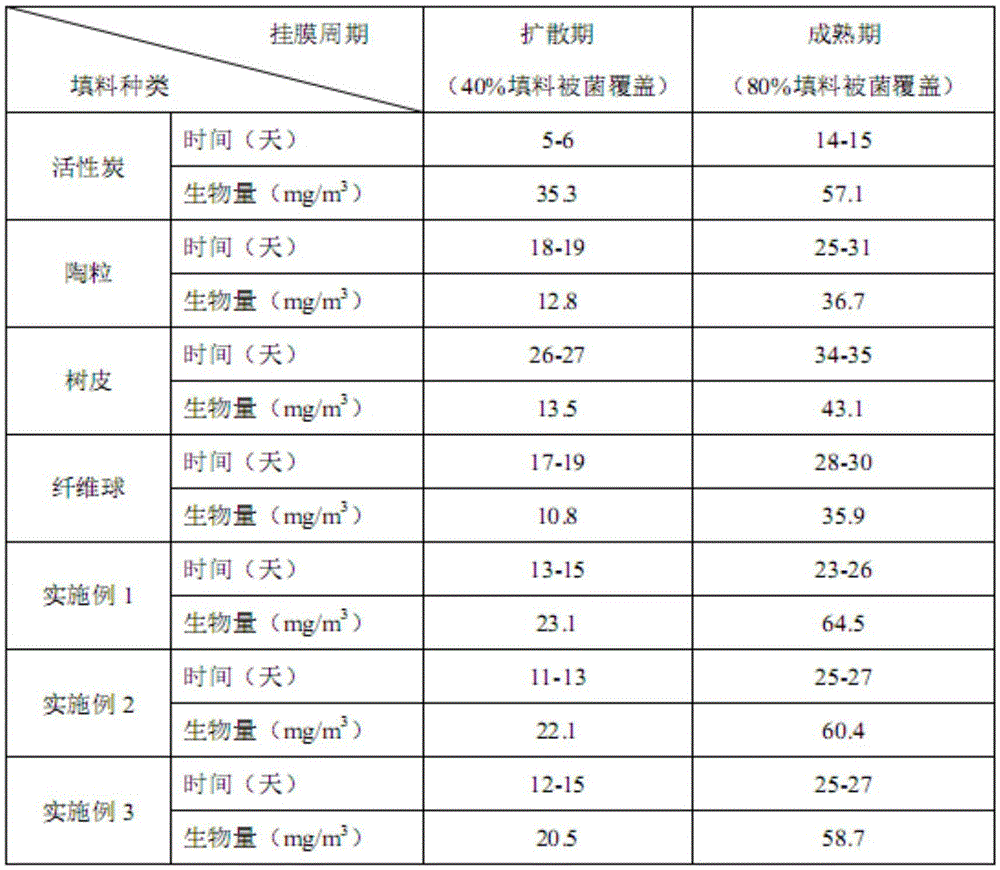

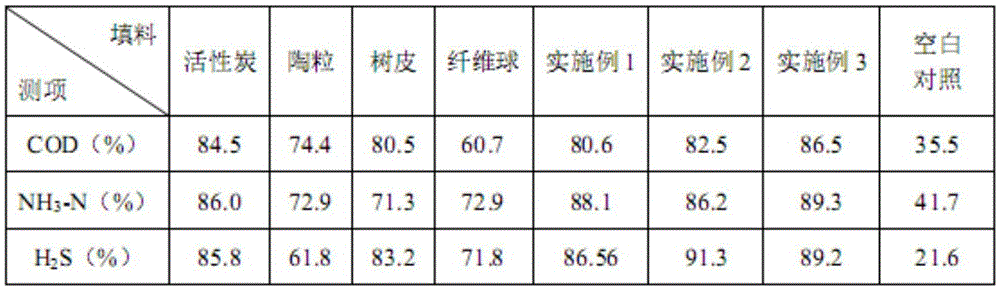

Embodiment 1

[0033] In the embodiment of the present invention, a method for preparing a special deodorizing composite biological filler for printing and dyeing sewage treatment is obtained by first preparing component A and then mixing it with component B; the specific steps are as follows:

[0034] Component A preparation method is as follows:

[0035] (1) Drying the residual printing and dyeing sludge after mechanical dehydration to obtain dried sludge;

[0036] (2) After pulverizing the dried sludge, converter slag and fly ash, mix them with clay according to the mass ratio of 5:5:2:5 and then mix them evenly, and the mixed materials pass through 100 mesh;

[0037] (3) The mixed material is put into a molding machine for compression molding, and made into raw balls with a particle diameter of 10mm;

[0038] (4) Raise the temperature of the formed raw balls to 450°C, keep them warm for 10 minutes, take them out and cool them down to 25°C.

[0039] (5) After cooling down, put it into a...

Embodiment 2

[0047] In the embodiment of the present invention, a method for preparing a special deodorizing composite biological filler for printing and dyeing sewage treatment is obtained by first preparing component A and then mixing it with component B; the specific steps are as follows:

[0048] Component A preparation method is as follows:

[0049] (1) drying the remaining printing and dyeing sludge after mechanical dehydration to obtain dried printing and dyeing sludge;

[0050] (2) After pulverizing the dried sludge, converter slag and fly ash, mix them with clay according to the mass ratio of 8:7:3:5 and then mix them evenly, and the mixed materials pass through 100 mesh;

[0051] (3) The mixed material is put into a molding machine for compression molding, and made into raw balls with a particle diameter of 10mm;

[0052] (4) Raise the temperature of the formed raw meal balls to 600°C, keep them warm for 10 minutes, take them out and cool them down to 28°C.

[0053] (5) After c...

Embodiment 3

[0061] In the embodiment of the present invention, a method for preparing a special deodorizing composite biological filler for printing and dyeing sewage treatment is obtained by first preparing component A and then mixing it with component B; the specific steps are as follows:

[0062] The preparation method of component A of special deodorizing composite biological filler for printing and dyeing sewage treatment is as follows:

[0063] (1) drying the remaining printing and dyeing sludge after mechanical dehydration to obtain dried printing and dyeing sludge;

[0064] (2) After the dried sludge, converter slag and fly ash are pulverized, they are mixed with clay according to the mass ratio of 6:6:3:4 and then mixed, and the mixed material passes through 100 mesh;

[0065] (3) The mixed material is put into a molding machine for compression molding, and made into raw balls with a particle diameter of 10mm;

[0066] (4) Raise the temperature of the formed raw balls to 550°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com