Method for producing acetic acid by fermenting kitchen waste

A technology of food waste and acetic acid, which is applied in the field of bioengineering to achieve the effects of reducing pollution, reducing costs and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

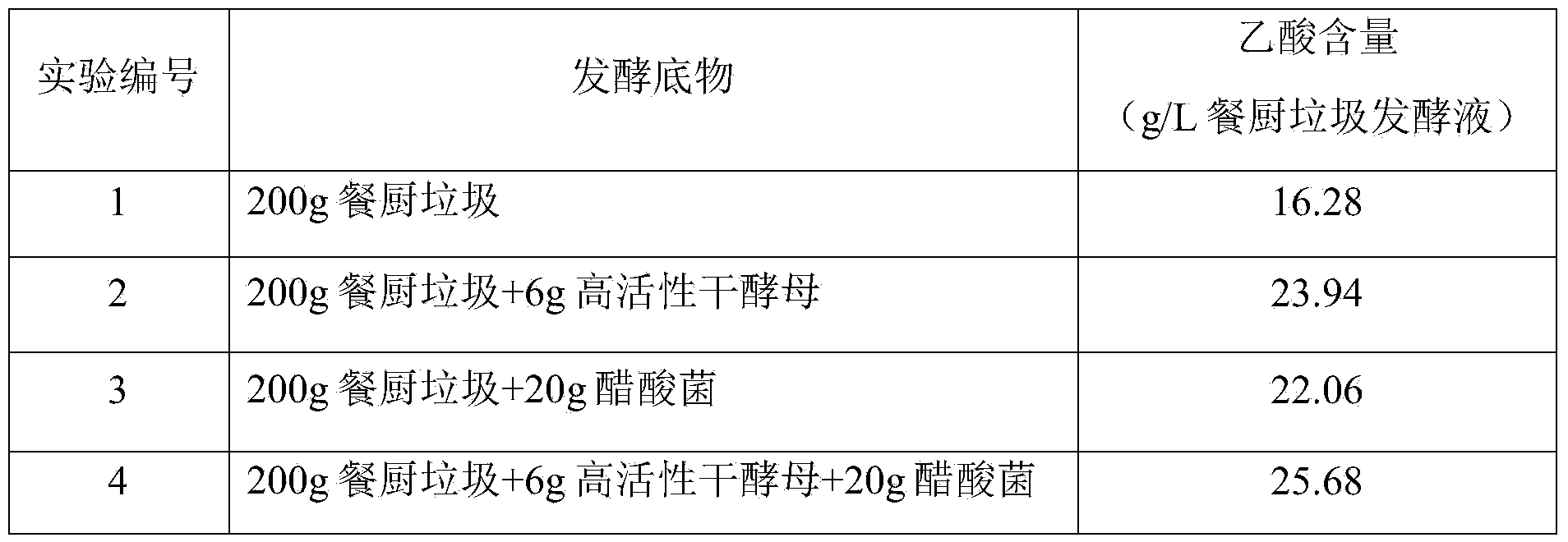

[0018] According to Table 1, the experiment of producing acetic acid by fermentation of food waste: measure 200g of food waste, 6g of Angel high-activity dry yeast produced by Hubei Angel Yeast Co., Ltd., the main component of which is Saccharomyces cerevisiae, stir well, Put it into a 500ml serum bottle, fill it with nitrogen to maintain the anaerobic environment, and perform anaerobic fermentation at 25°C for 72 hours. Measure the 10% mass percentage of acetic acid bacteria in the weight of food waste. The acetic acid bacteria is Hu Niang No. 1.01 produced by Shanghai Jiamin Brewing Food Co., Ltd. Brew No. 1. Inoculate the acetic acid bacteria into the food waste in the 500ml serum bottle, 30 Aerobic fermentation at ℃ for 72 hours. The acetic acid content in the product was determined. The results are shown in Table 1. The per liter of food waste fermentation liquid of the present invention can convert 25.68g of acetic acid, which is 0.58 times higher than the acetic acid ...

Embodiment 2

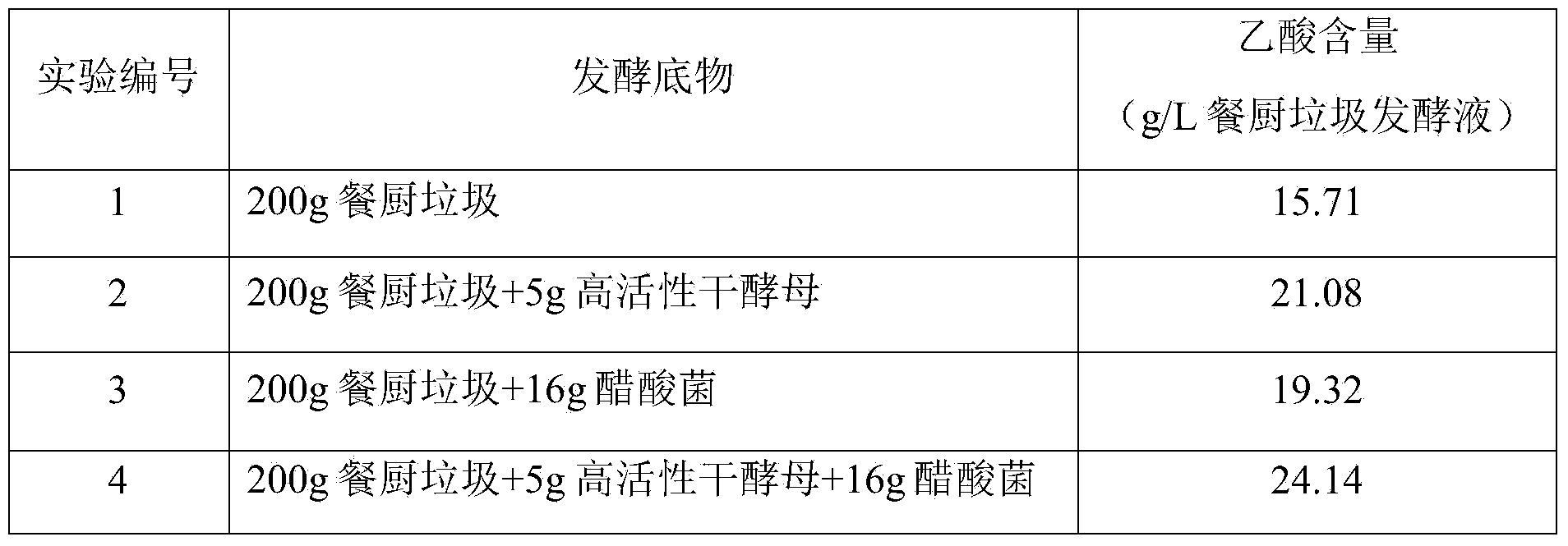

[0022] According to Table 2, the experiment of acetic acid production by fermentation of kitchen waste was carried out: 200g of kitchen waste was added with 5g of high-activity dry yeast, packed into a 500ml serum bottle, filled with nitrogen to maintain anaerobic environment, and anaerobically fermented at 25°C for 72 hours. Measure 8% by mass of acetic acid bacteria in the weight of the food waste, inoculate it into the food waste in a 500ml serum bottle, and ferment aerobically at 30°C for 72 hours. The acetic acid content in the product was determined. The results are shown in Table 2. 24.14g of acetic acid can be converted per liter of food waste fermentation liquid, which is 0.58 times higher than that of the fermentation without adding high active dry yeast and acetic acid bacteria. After testing, there are few types of miscellaneous acids in the food waste fermentation liquid, and acetic acid accounts for 84-93% of the total mass of organic acids in the food waste fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com