Landfill leachate wastewater treatment system and process thereof

A wastewater treatment system and landfill leachate technology, which is applied in animal processing wastewater treatment, filtration treatment, contaminated groundwater/leachate treatment, etc., can solve the problems of secondary pollution, difficult promotion, high treatment cost, etc., and achieve biochemical The effects of improved performance, protection of follow-up equipment, and flexible operation mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

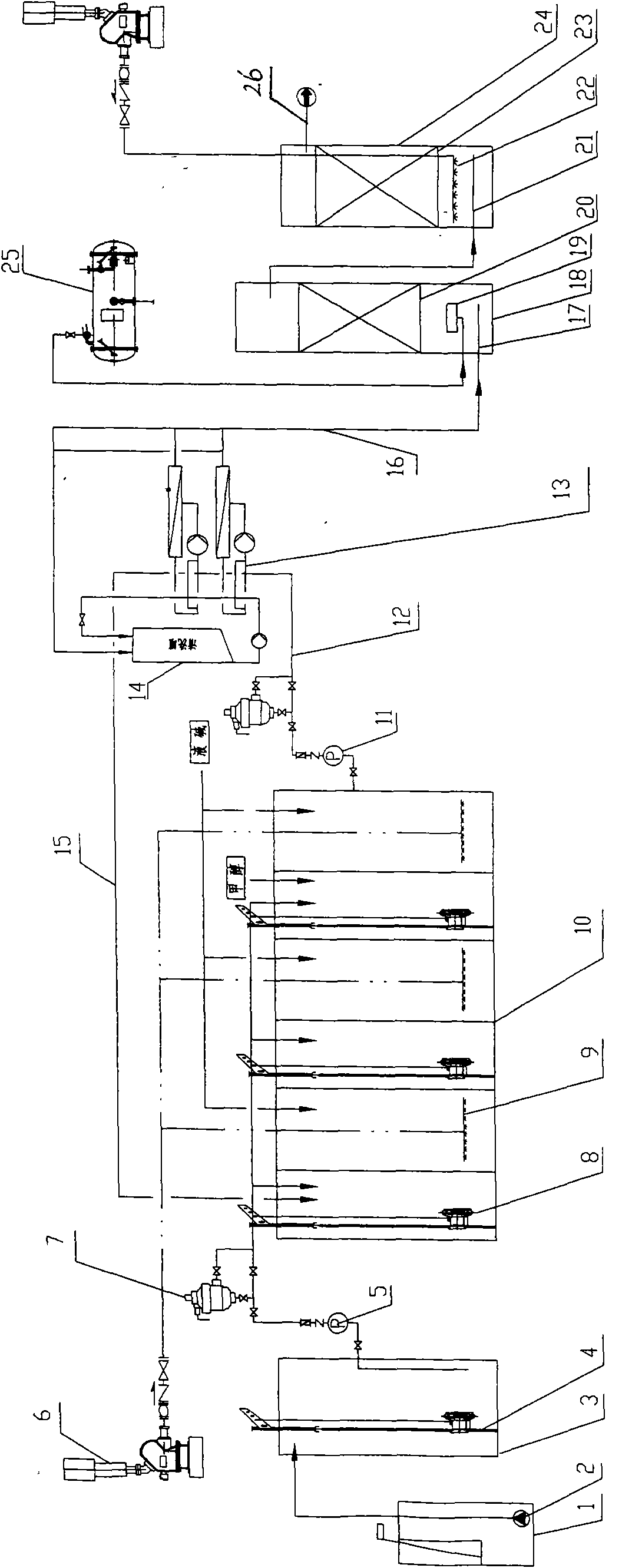

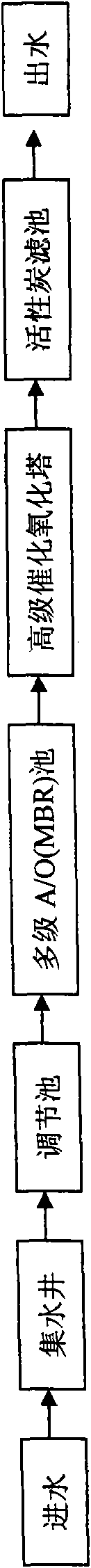

[0017] Such as figure 1 As shown, a kind of landfill leachate wastewater treatment system provided by the present invention includes a water collection well 1, and the water collection well 1 is connected to the water inlet of the regulating tank 3 through a pipeline and a lift pump 2 arranged therein, and the outlet of the regulating pond 3 The water port is connected to the inlet of the filter 7 through the pipeline and the water pump 5, and the outlet of the filter 7 is connected to the inlet of the multi-stage anoxic / aerobic tank and the comprehensive treatment system of the membrane bioreactor through the pipeline, and the multi-stage anoxic / aerobic tank And the outlet of membrane bioreactor comprehensive treatment system is connected with the water inlet of catalytic oxidation tower 18 by pipeline, and the outlet of catalytic oxidation tower 18 is connected with the inlet of biochar filter 24 by pipeline, and the outlet of biochar filter 24 is connected with standard Dis...

example 1

[0031] Example 1: A landfill leachate wastewater treatment project

[0032] Landfill leachate has a high concentration of organic matter (COD cr Up to 15000mg / L, BOD 5 Up to 5000mg / L), high concentration of ammonia nitrogen (up to 20000mg / L), high concentration of SS (up to 3000mg / L), imbalanced nutrient ratio and large changes in water quality and quantity.

[0033] By adopting the present invention, a set of first-level pretreatment + second-level biochemical treatment + third-level advanced treatment treatment system is established, which not only runs stably, but also has low cost. 2008) water discharge requirements.

Embodiment 2

[0034] Embodiment 2, the wastewater treatment project of a leather factory

[0035] Wastewater has the characteristics of high concentration of organic pollution, high ammonia nitrogen, and contains many refractory substances. The original wastewater treatment process, the effluent has not been able to meet the standard. If the present invention is adopted, the original system is transformed, and a set of first-level pretreatment + second-level biochemical treatment + third-level advanced treatment treatment system is built. Not only is the system running stably, but the cost is low, and the system after treatment can reach "Leather Products The effluent requirements of Industrial Pollutant Discharge Standards.

[0036] It can be seen that the present invention can achieve excellent results in the engineering application of landfill leachate wastewater, and can also achieve good results in the treatment of other high-ammonia-nitrogen organic wastewater, and the effluent can m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com