Laser cladding method of composite coating containing spherical tungsten carbide

A technology of laser cladding and composite coating, which is applied in the direction of coating, metal material coating process, etc., can solve the problems such as porosity and cracks in the cladding layer, which affect the quality and application of the cladding layer, and achieve good toughness, Stable chemical properties and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

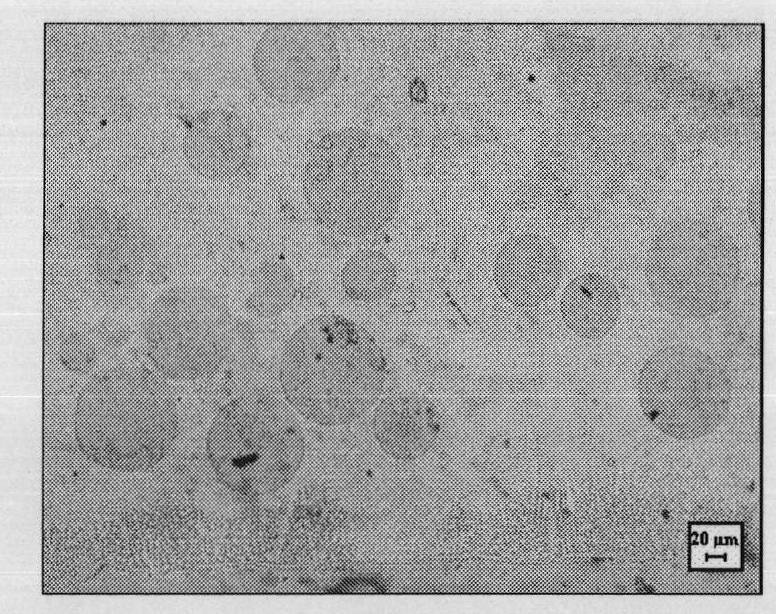

Embodiment 1

[0022] 5.0g spherical tungsten carbide powder and 45.0g Fe55 iron-based self-fluxing alloy powder.

[0023] CO2 laser power is 3300W, laser beam width is 3.0mm, laser cladding speed is 600mm / min, lap rate is 25%

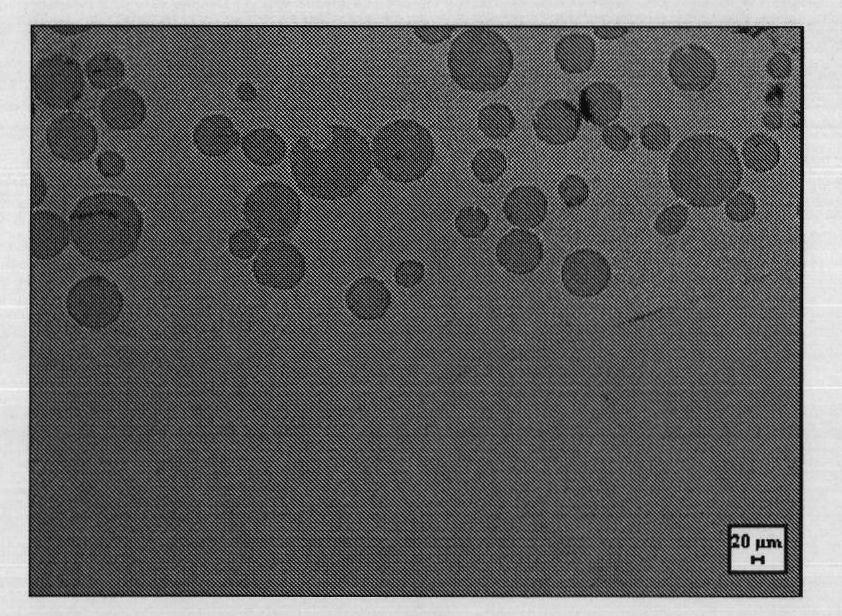

Embodiment 2

[0025] 12.5g spherical tungsten carbide powder and 37.5g Fe55 iron-based self-fluxing alloy powder.

[0026] The CO2 laser power is 4800W, the laser beam width is 8.5mm, the laser cladding speed is 800mm / min, and the overlap rate is 30%.

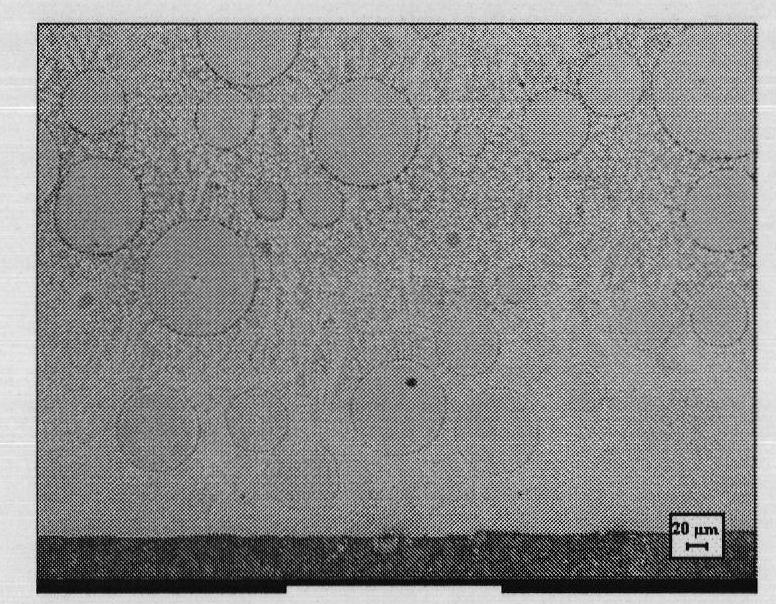

Embodiment 3

[0028] 15.0g spherical tungsten carbide powder and 35.0g Ni35 nickel-based self-fluxing alloy powder.

[0029] CO 2 The laser power is 5000W, the laser beam width is 8.5mm, the laser cladding speed is 400mm / min, and the overlap rate is 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com