Laser cladding method for strengthening surface of piercing point

A technology of laser cladding and perforated plugs, which is applied in the coating process and coating of metal materials, can solve the problems of unsatisfactory preparation cost and performance, insufficient bonding strength, and low cost, and achieve excellent high-temperature oxidation resistance. Good wettability and hardness improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for strengthening the surface of a perforated plug by laser cladding. The process includes the following steps:

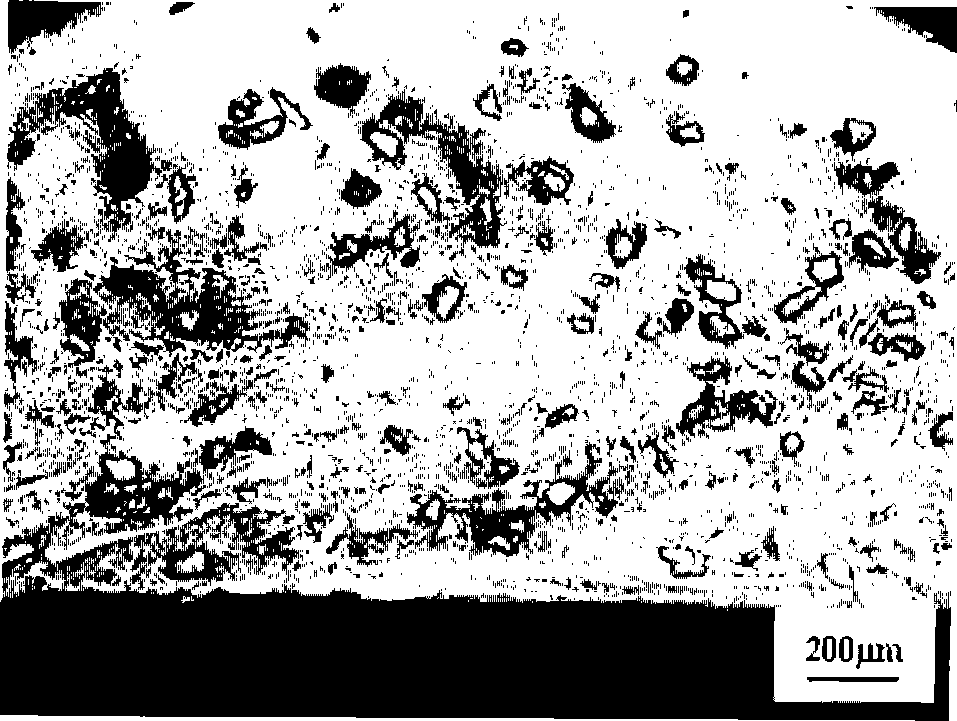

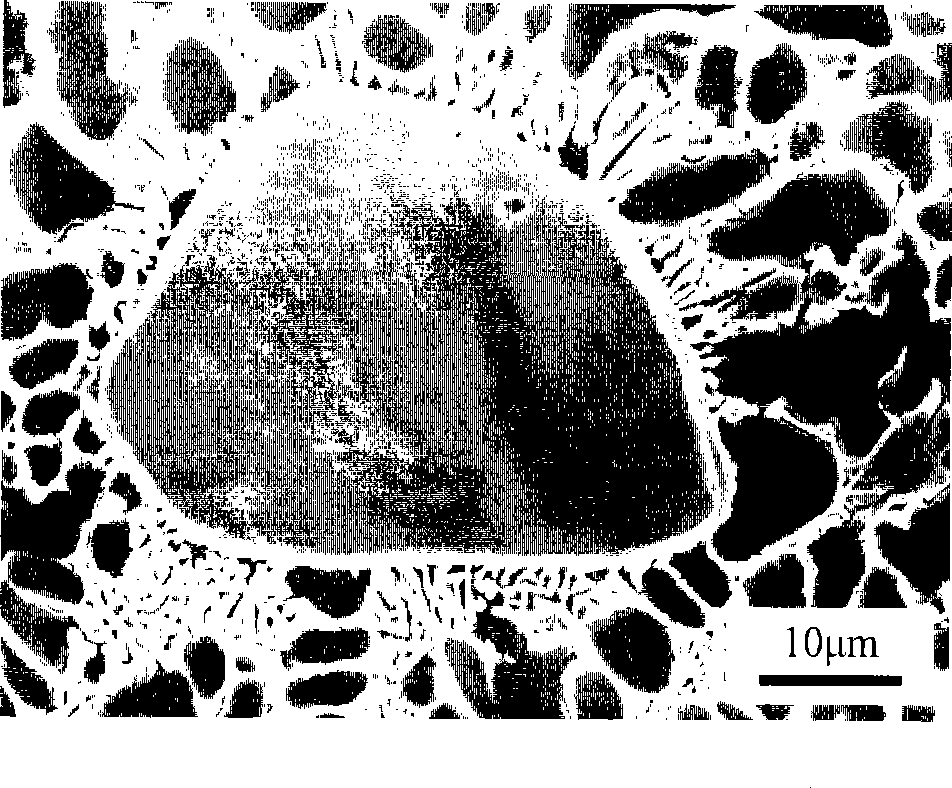

[0028] (1) Sample pretreatment: remove the working surface of the plug head, blacken it, and then preheat the plug at 500°C for 3.5 hours; (2) Prefabrication of the cladding powder: the base Co50 and Ni are coated with the WC ceramic reinforcing phase according to the mass ratio The two powders are mixed with 15wt.% WC and dried in a grinding dish after being fully ground; (3) Laser cladding process: the laser power is adjusted to 2.4kW, the laser scanning speed is 220mm / min, and the laser spot The diameter is 5mm, and the overlap rate of laser scanning passes is 40%. At the same time, under the action of the laser, the prefabricated composite alloy powder is cladding on the working surface of the head using a reverse synchronous powder feeding method; (4) Follow-up treatment: The perforated plug after laser cladding is placed in a heat treatment furnac...

Embodiment 2

[0030] A method for strengthening the surface of a perforated plug by laser cladding. The process includes the following steps:

[0031] (1) Sample pretreatment: remove the working surface of the plug head, blacken it, and then preheat the plug head at 400°C for 5 hours; (2) Prefabrication of the cladding powder: the base Co50 and Ni are coated with the WC ceramic reinforcing phase according to the mass ratio The two powders are mixed with 10wt.% WC and dried in a grinding dish after being fully ground; (3) Laser cladding process: the laser power is adjusted to 1.8kW, the laser scanning speed is 300mm / min, and the laser spot The diameter is 5mm, and the overlap rate of laser scanning passes is 50%. At the same time, under the action of the laser, the prefabricated composite alloy powder is cladding on the working surface of the head using reverse synchronous powder feeding; (4) Follow-up treatment: The perforated plug after laser cladding is placed in a heat treatment furnace for ...

Embodiment 3

[0033] A method for strengthening the surface of a perforated plug by laser cladding. The process includes the following steps:

[0034] (1) Sample pretreatment: remove the working surface of the plug head, blacken it, and then preheat the plug at 600°C for 3 hours; (2) Prefabrication of the cladding powder: the base Co50 and Ni are coated with WC ceramic reinforcement according to the mass ratio The two powders are mixed with 20wt.% WC and dried in a grinding dish after being fully ground; (3) Laser cladding process: the laser power is adjusted to 3.0kW, the laser scanning speed is 150mm / min, and the laser spot The diameter is 4mm, and the overlap rate of laser scanning passes is 30%. At the same time, under the action of the laser, the prefabricated composite alloy powder is cladding on the working surface of the head by reverse synchronous powder feeding; (4) Follow-up treatment: The perforated plug after laser cladding is placed in a heat treatment furnace for stress relief an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com