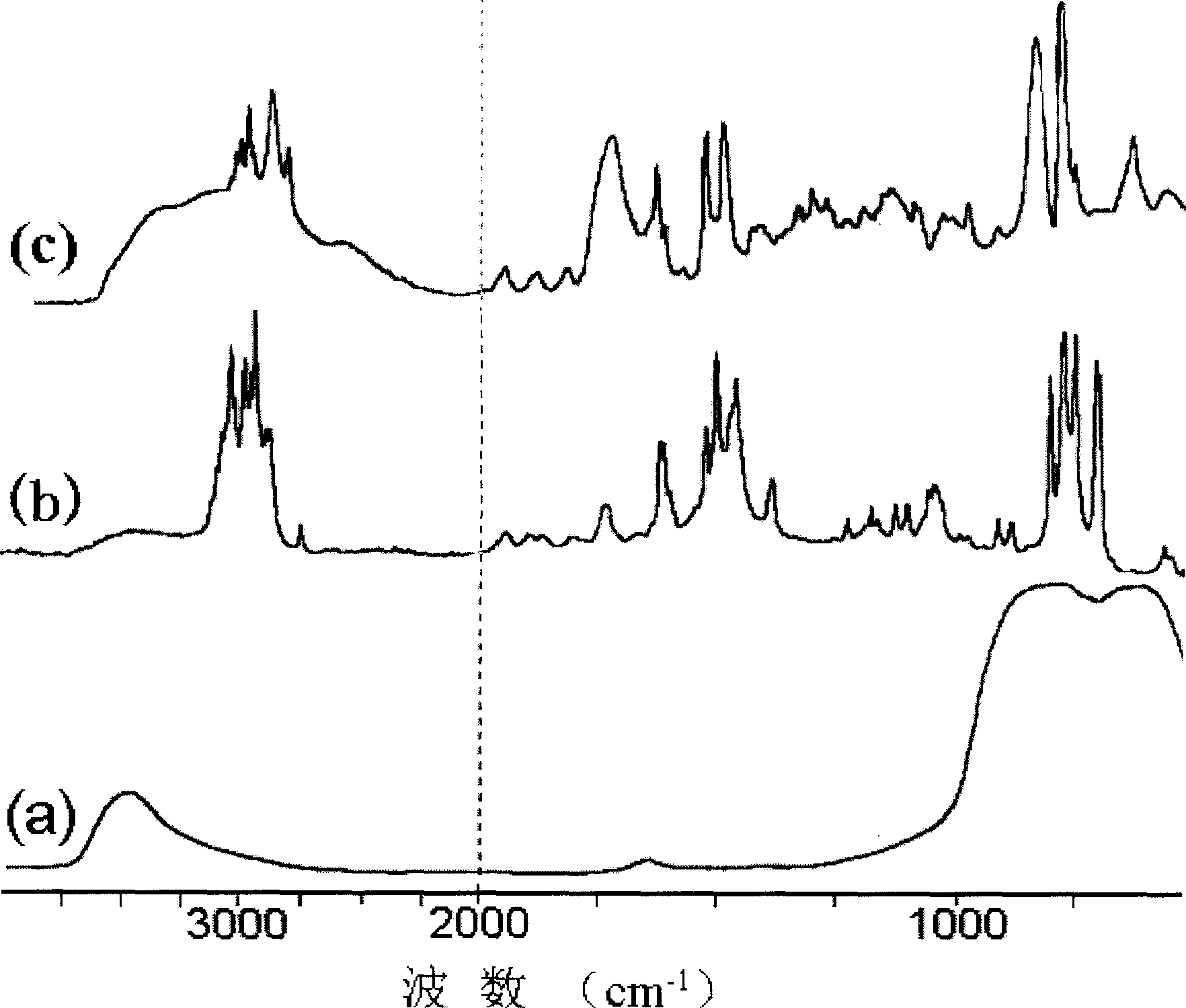

Process for preparing reaction functional macromolecule/Al2O3 nano composite particles

A technology of nanocomposite particles and polymers, which is applied in the field of preparation of reactive functional polymers/Al2O3 nanocomposite particles, which can solve the problem of low grafting rate and grafting efficiency, non-spherical particles are difficult to coat, and the coating layer is easy to fall off and other issues to achieve the effects of improved compatibility, high universality, easy storage and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

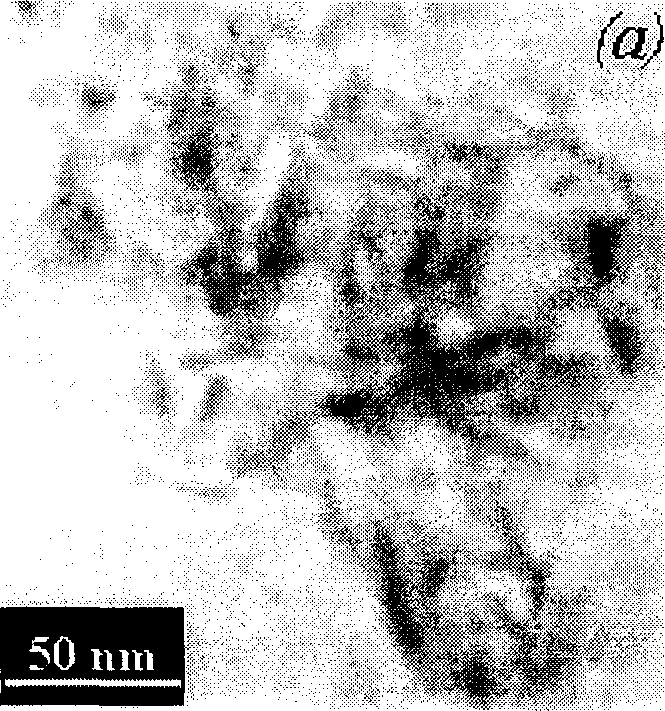

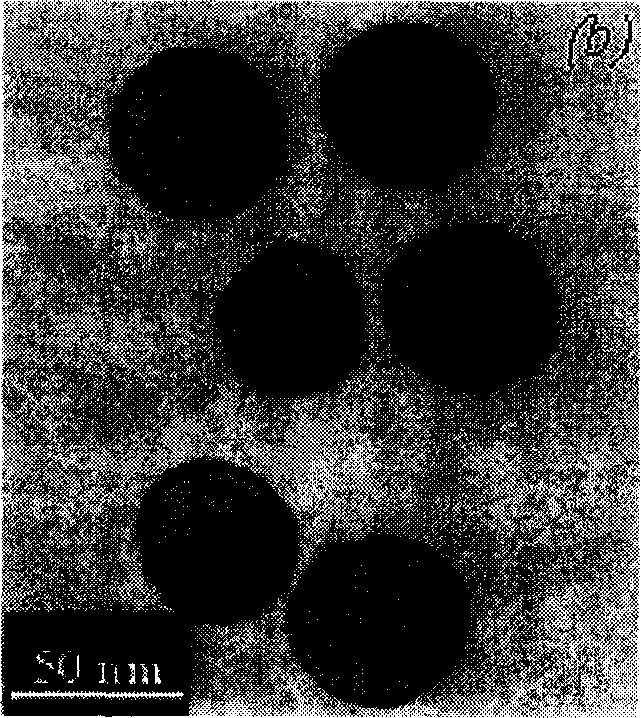

[0048] Example 1: The average particle size is 30 ± 5nm, the aspect ratio is 5, and the specific surface area is 180m 2 / g of acicular nano-Al 2 o 3 After dry treatment with 10wt% KH-570 silane coupling agent, weigh 4 parts and add to 100 parts of styrene monomer, stir and ultrasonically disperse evenly. Add 370 parts of deionized water, 50 parts of sodium dodecylsulfonate (SDS) and 6 parts of nonylphenol polyoxyethylene ether (10 parts) in a four-necked bottle equipped with mechanical stirring, reflux condenser, nitrogen protection and thermometer. ), heated to 40°C and stirred to dissolve, then added monomer and Al 2 o 3 mixture. Then, the temperature was raised to 60° C. and 20% of an aqueous initiator solution composed of 0.5 parts of ammonium persulfate (APS) and 75 parts of deionized water was added. After reacting for 8 hours, the remaining initiator solution was added, and the temperature was raised to 80° C. to continue the reaction for 1 hour. Then add 10 parts...

Embodiment 2

[0049] Embodiment 2: The emulsifier SDS among the embodiment 1 is changed into hexadecyltrimethylammonium bromide, and consumption increases to 65 parts, monomer and Al 2 o 3 The mixture was added to the system at 50°C, and all the other formulations were the same as in Example 1. The yield, grafting rate and grafting efficiency of the obtained product are 93.6%, 2321% and 91.3% respectively, and the particle size distribution is 40-50nm.

Embodiment 3

[0050] Embodiment 3: The emulsifier SDS is changed into octylphenol polyoxyethylene ether (20), the consumption is reduced to 45 parts, and the glycidyl methacrylate is increased to 20 parts. All the other formulas and steps are the same as in Example 1. The yield, grafting rate and grafting efficiency of the obtained product are 88.5%, 2218% and 90.7% respectively, and the particle size distribution is 60-70nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com