A kind of preparation method of mems atomic vapor chamber and atomic vapor chamber

A vapor cavity and atomic technology, applied in the field of micro-electromechanical systems, to achieve the effect of reducing light loss, improving light transmittance, and being easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] A specific implementation steps of a MEMS atomic vapor single-chamber preparation method:

[0104] (1) Sample Selection

[0105] Select Pyrex glass-silicon-Pyrex glass material matching, wherein Pyrex glass sheet 18 and Pyrex glass sheet 20 are double-sided polished, and silicon wafer 1 is an N-type silicon wafer with a thickness of 500 μm polished on both sides.

[0106] (2) Sample cleaning

[0107] Cleaning with sulfuric acid-hydrogen peroxide solution and hydrofluoric acid immersion method: first soak silicon wafer 1, Pyrex glass wafer 18 and Pyrex glass wafer 20 in sulfuric acid-hydrogen peroxide solution with a temperature of 120°C and a ratio of 10:1 for 10 minutes; then At room temperature, soak with hydrofluoric acid aqueous solution at a ratio of 1:100 for 1 minute; finally, wash with deionized water and dehydrate with absolute ethanol.

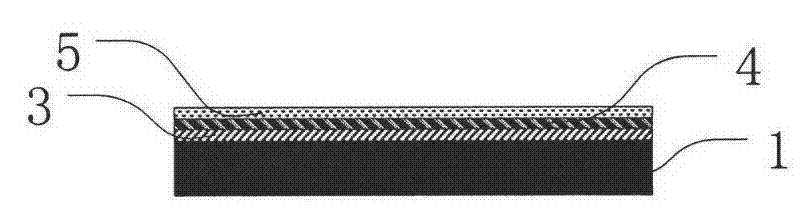

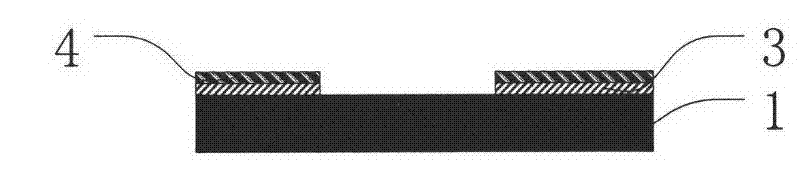

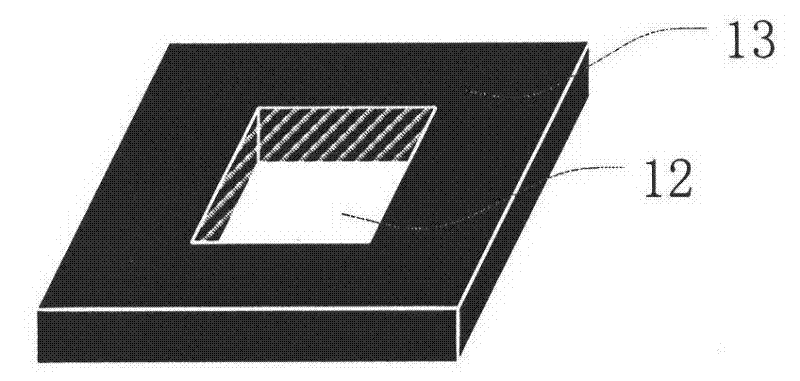

[0108] (3) Make a single-chamber space, such as figure 1 , figure 2 , image 3 shown;

[0109] The silicon wafer 1 w...

Embodiment 2

[0131] A specific implementation steps of a MEMS atomic vapor dual-chamber preparation method:

[0132] (1) Sample Selection

[0133] Pyrex glass-silicon-Pyrex glass material matching is selected, wherein Pyrex glass sheet 19 and Pyrex glass sheet 21 are double-sided polished, and silicon wafer 2 is an N-type silicon wafer with a thickness of 500 μm polished on both sides.

[0134] (2) Sample cleaning

[0135] Cleaning with sulfuric acid-hydrogen peroxide solution and hydrofluoric acid immersion method: first soak the silicon chip 2, the Pyrex glass chip 19 and the Pyrex glass chip 21 in a sulfuric acid-hydrogen peroxide solution with a temperature of 120°C and a ratio of 10:1 for 10 minutes; then At room temperature, soak with hydrofluoric acid aqueous solution at a ratio of 1:100 for 1 minute; finally, wash with deionized water and dehydrate with absolute ethanol.

[0136] (3) Make a double-chamber space, such as Figure 8 , Figure 9 , Figure 10 , Figure 12 , Figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com