Method for manufacturing nickel base brazing filler metal laser braze welding diamond abrasive grain

A technology of nickel-based brazing material and manufacturing method, which is applied in the direction of manufacturing tools, welding media, welding equipment, etc., and can solve the problems of limited size of brazing tools and long brazing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

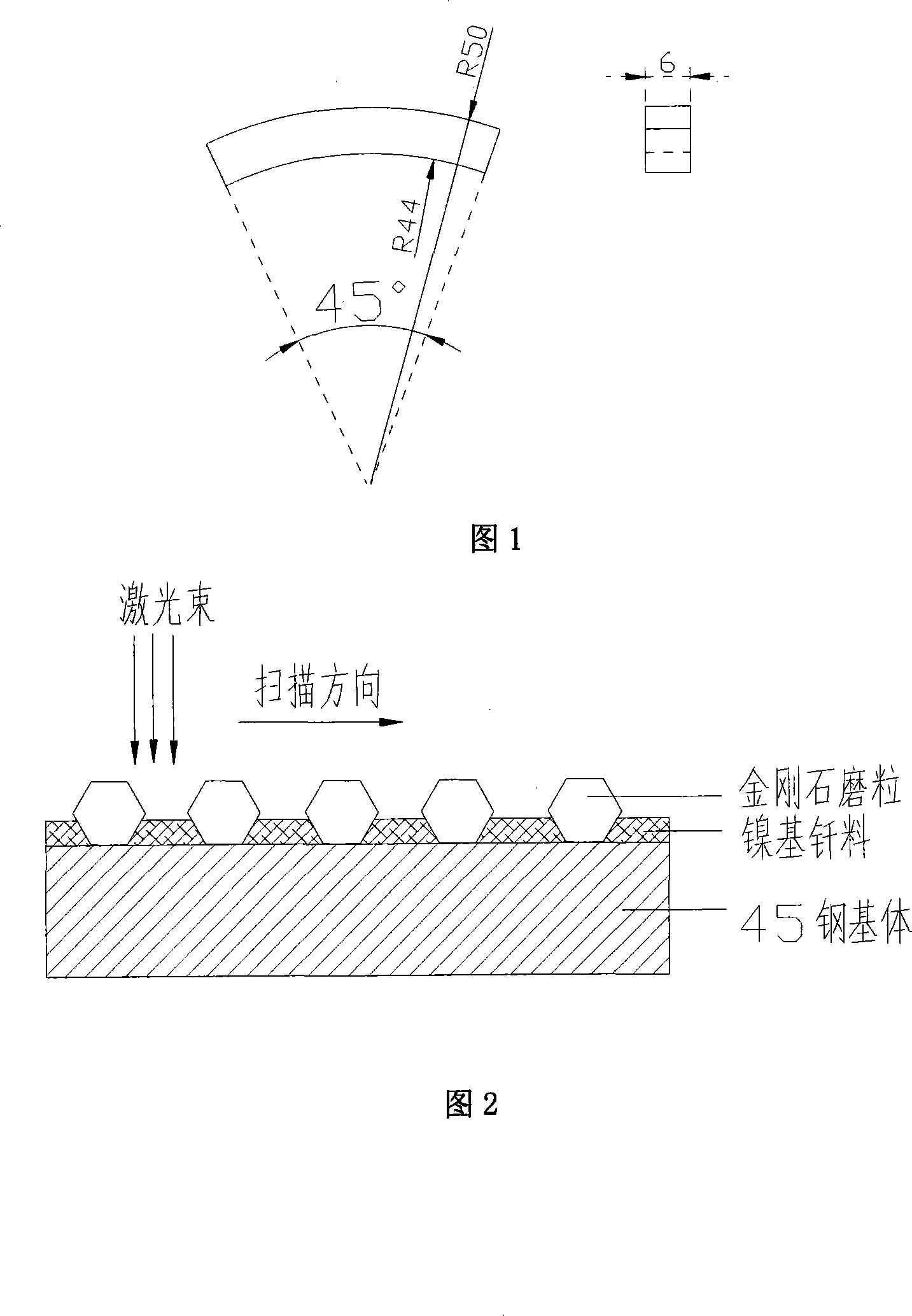

[0011] Embodiment: 45 steel substrates are processed into a nodular sample as shown in Figure 1; its brazing surface is properly polished with 100# metallographic sandpaper, and for eliminating the influence of various unclean factors, diamond abrasive grains and 45 The steel substrates were respectively placed in organic solvents for ultrasonic cleaning. Before brazing, pre-coat 40 / 50 mesh uncoated diamond and nickel-based brazing filler metals on The surface of 45 steel is laser brazed after drying, as shown in Figure 2.

[0012] Laser brazing process parameters: laser wavelength 10.6μm, multimode rectangular spot, area 18mm2, laser power 780W, scanning speed 30mm / min. After chemical analysis, it was found that the solder layer spread evenly after laser brazing, and the nickel-based solder exhibited good wettability to diamond abrasive grains. After brazing, the crystal shape of diamond abrasive grains was complete, with sharp edges and corners, and no cracks.

[0013] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com