Multi-element rare earth boride Sm1-2xEuxBaxB6 polycrystal as well as preparation method and application thereof

A technology of rare earth borides and polycrystals, applied in the direction of boron/borides, metal borides, etc., can solve the problems of limited product size, complex preparation process, high pressing pressure, etc., and achieve simple preparation process, excellent emission performance, and compaction less stressful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

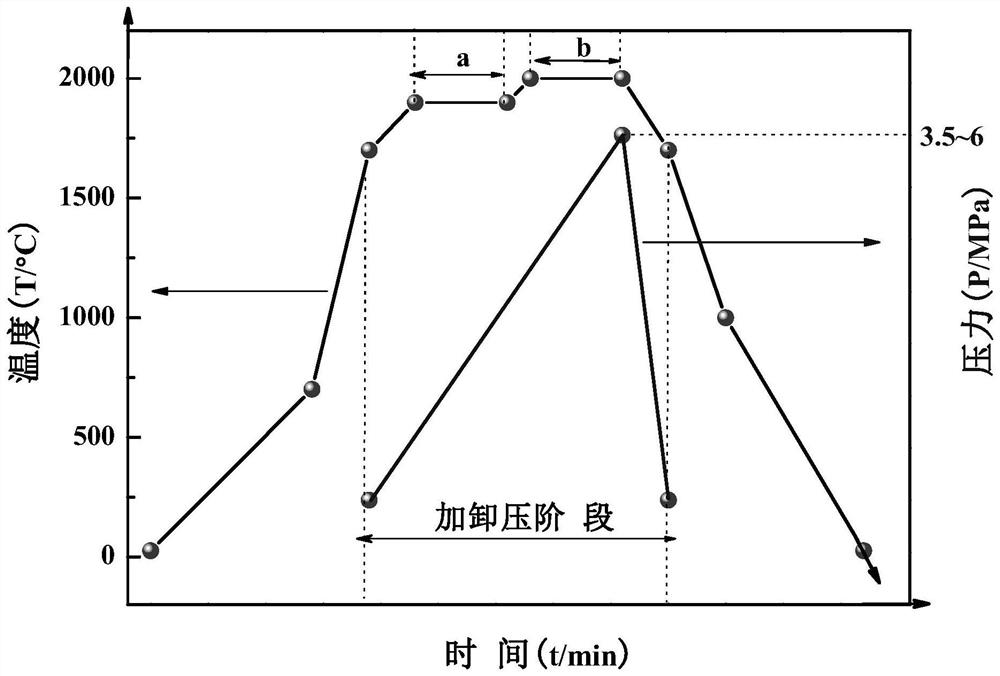

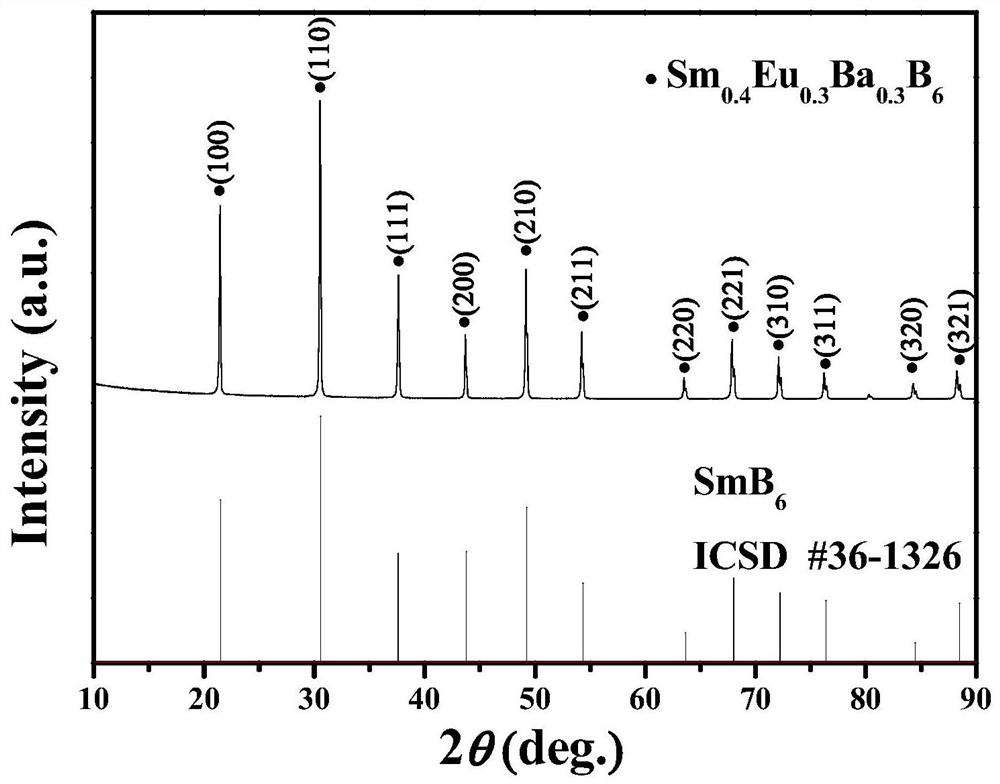

[0038] The invention adopts boron / carbothermal reduction method-hot pressing sintering integrated process to prepare Sm with different sizes and high performance 0.4 Eu 0.3 Ba 0.3 B 6 polycrystalline, including the following steps:

[0039] Step 1: Raw material Sm 2 o 3 、Eu 2 o 3 、BaCO 3 , B 4 C, B powder are weighed according to the stoichiometric ratio of 0.4:0.3:0.6:3:1 (molar ratio), wherein Sm 2 o 3 、Eu 2 o 3 、BaCO 3 Both are multiplied by an excess coefficient of 1 to 1.5, and the raw materials are mixed evenly and placed in a graphite crucible;

[0040] Step 2: Place the graphite crucible in a vacuum carbon tube furnace, and start heating when the vacuum degree is lower than 0.01Pa. The process parameters are: heating rate 10°C / min, holding temperature 1800°C, holding time 1-2h, Take it out with the furnace cooling to room temperature;

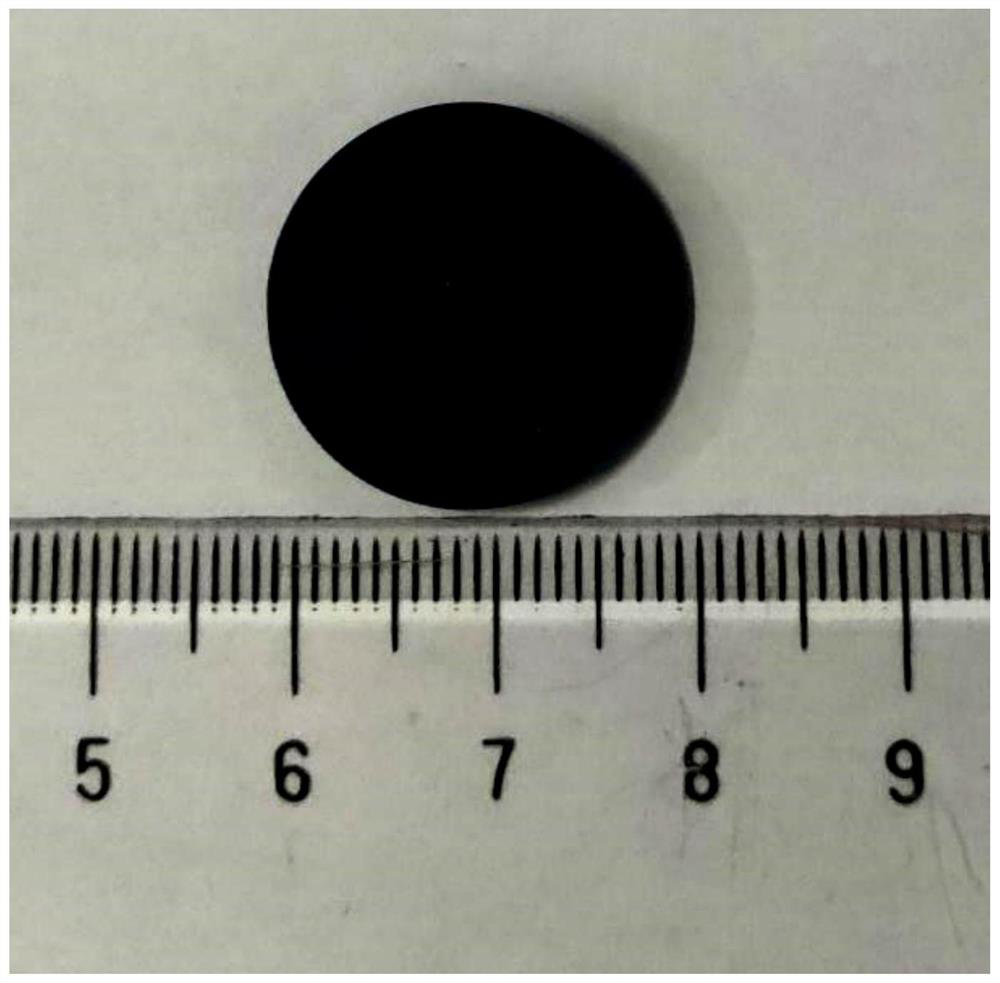

[0041] Step 3: Grinding the synthetic product in step 2, pickling (0.5mol / L dilute hydrochloric acid), washing with wat...

Embodiment 2

[0045] The difference between this example and Example 1 is that the stoichiometric ratio of the five raw materials in Step 1 is 0.6:0.2:0.4:3:1, and the others are the same as Example 1.

[0046] Prepared Sm 0.6 Eu 0.2 Ba 0.2 B 6 The color of the polycrystalline block is blue, and the XRD pattern is as follows Figure 4 As shown, it can be seen from the figure that the sample has a single-phase structure; through EDS energy spectrum analysis, the chemical purity of the polycrystal reaches 99.25%, the relative density is 95.2%, and the resistivity is ~258μΩ.cm.

Embodiment 3

[0048] The difference between this example and Example 1 is that the stoichiometric ratio of the five raw materials in Step 1 is 0.8:0.1:0.2:3:1, and the others are the same as Example 1.

[0049] Prepared Sm 0.8 Eu 0.1 Ba 0.1 B 6The color of the polycrystalline block is blue, and the XRD pattern is as follows Figure 5 As shown, it can be seen from the figure that the sample has a single-phase structure; by EDS energy spectrum analysis, the chemical purity of the polycrystal reaches 99.24%, the relative density is 96.1%, and the resistivity is ~270μΩ.cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com