Method and device for strengthening surface modification by combination of laser cladding and laser peening

A technology of laser peening and laser cladding, which is applied in coating, metal material coating technology, etc., and can solve problems that have not yet been retrieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

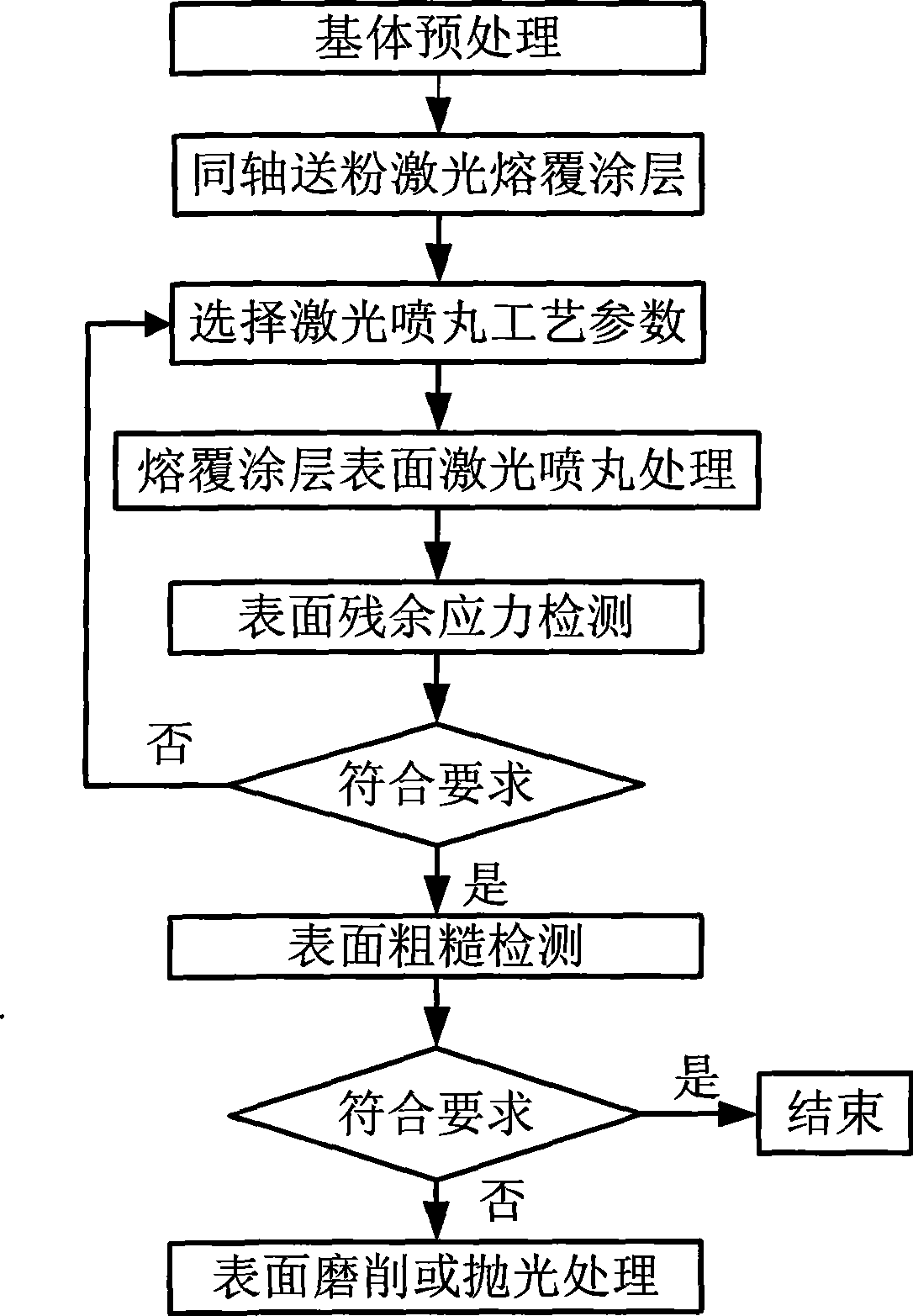

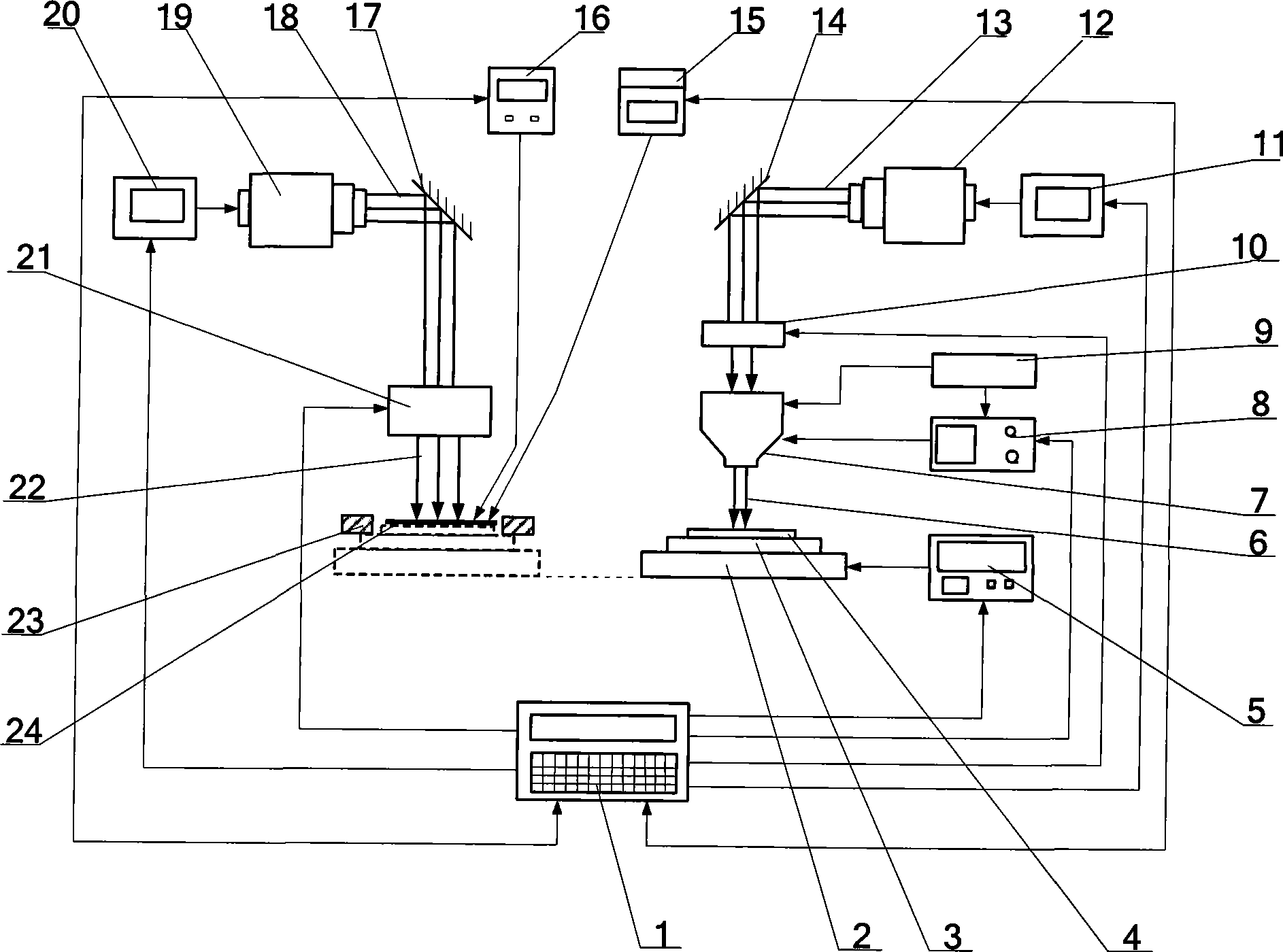

[0028] The device of the present invention is as figure 2 , including coaxial powder feeding laser cladding unit, laser shot peening strengthening unit, measurement feedback system, numerical control working system and central control and processing system. The coaxial powder feeding laser cladding unit includes a carbon dioxide laser 12, a light guide pipe 13, a full reflection mirror 14, a spot adjustment device 10, an argon protection device 9, a powder feeder 8 and a coaxial powder feeding nozzle 7. device, the power of carbon dioxide laser 12 reaches 2.5kw, and there are two working modes: (1) gate pulse work, pulse frequency 0-2000HZ, width 10μs; (2) enhanced pulse work, pulse frequency 0-2000Hz, width 10μs, peak power It is 2-3 times that of continuous wave; laser shot peening strengthening unit includes neodymium glass laser 19, light pipe 18, total reflection mirror 17, beam conversion and adjustment device 21, pulse laser: Nd:YAG, maximum pulse energy 50J, maximum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com