Patents

Literature

34 results about "Suspension plasma spray" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

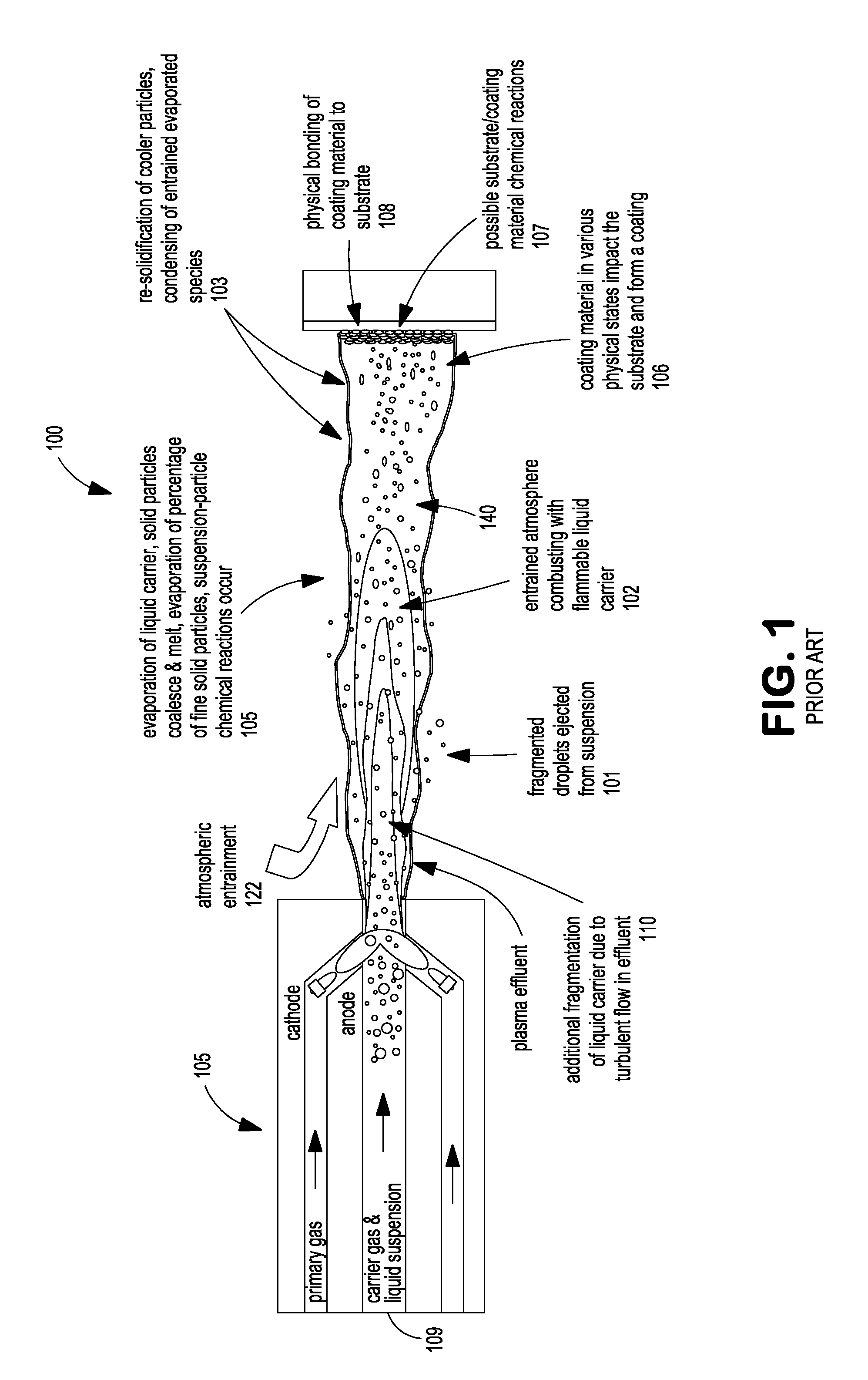

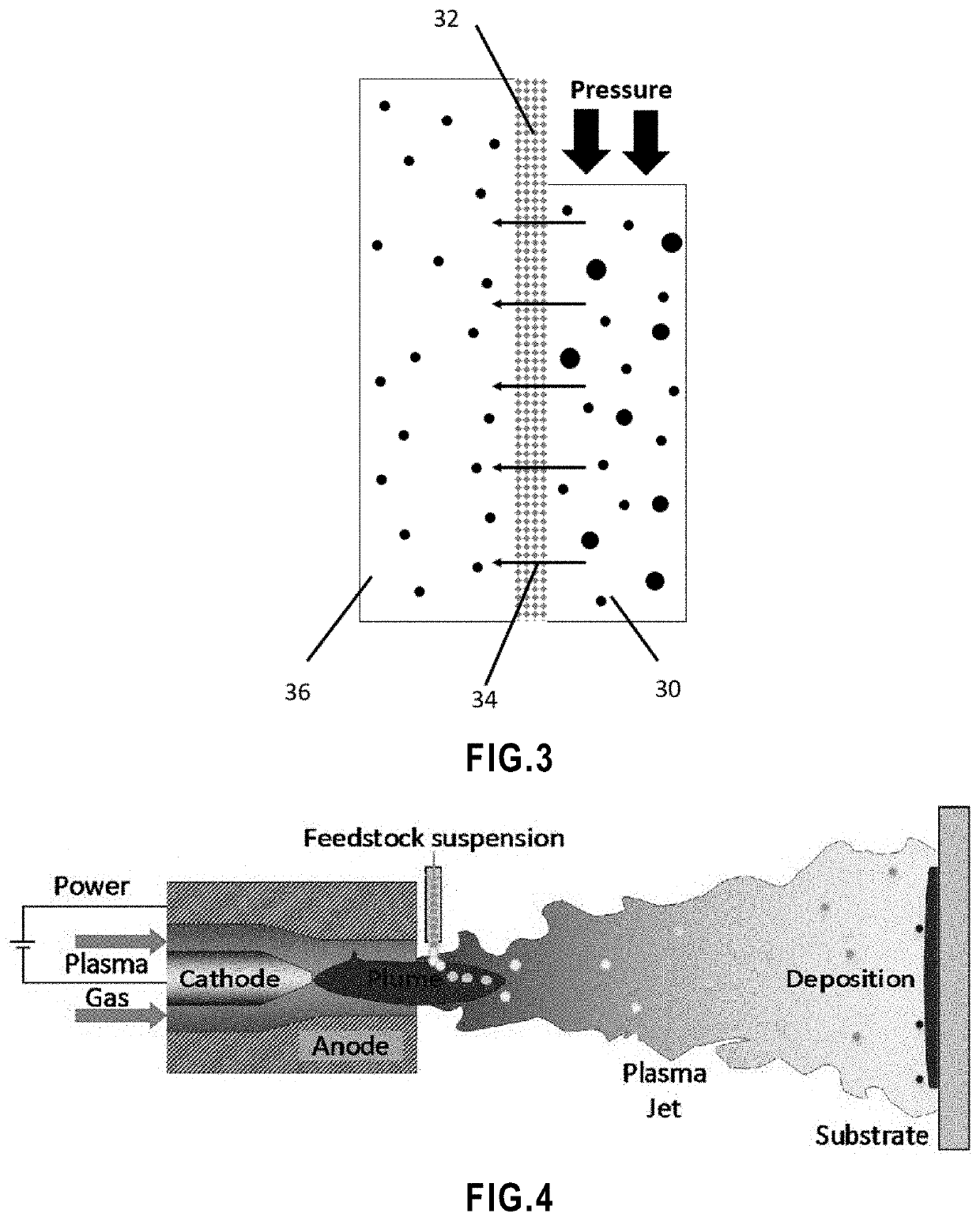

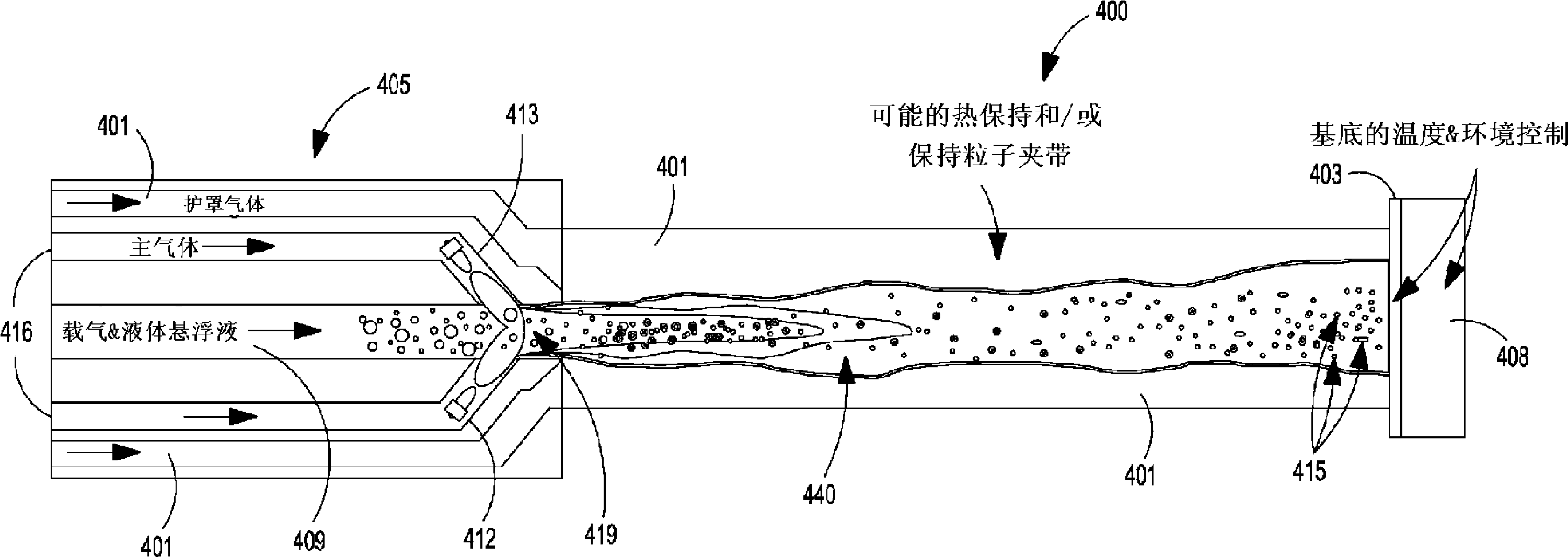

In materials engineering, suspension plasma spray (SPS) is a form of plasma spraying where the ceramic feedstock is dispersed in a liquid suspension before being injected into the plasma jet. By suspending powder in a fluid, normal feeding problems are circumvented, allowing the deposition of finer microstructures through the use of finer powders.

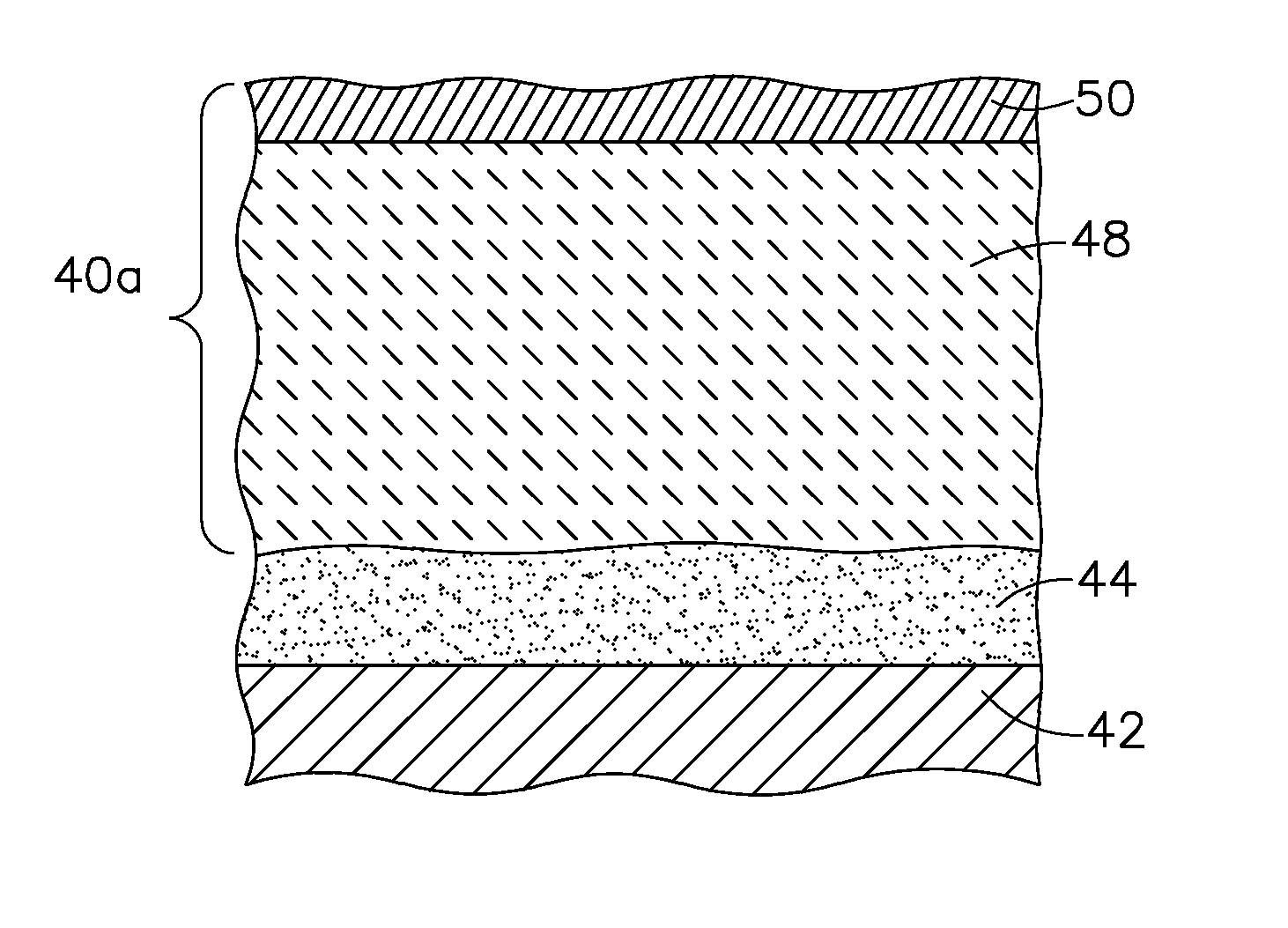

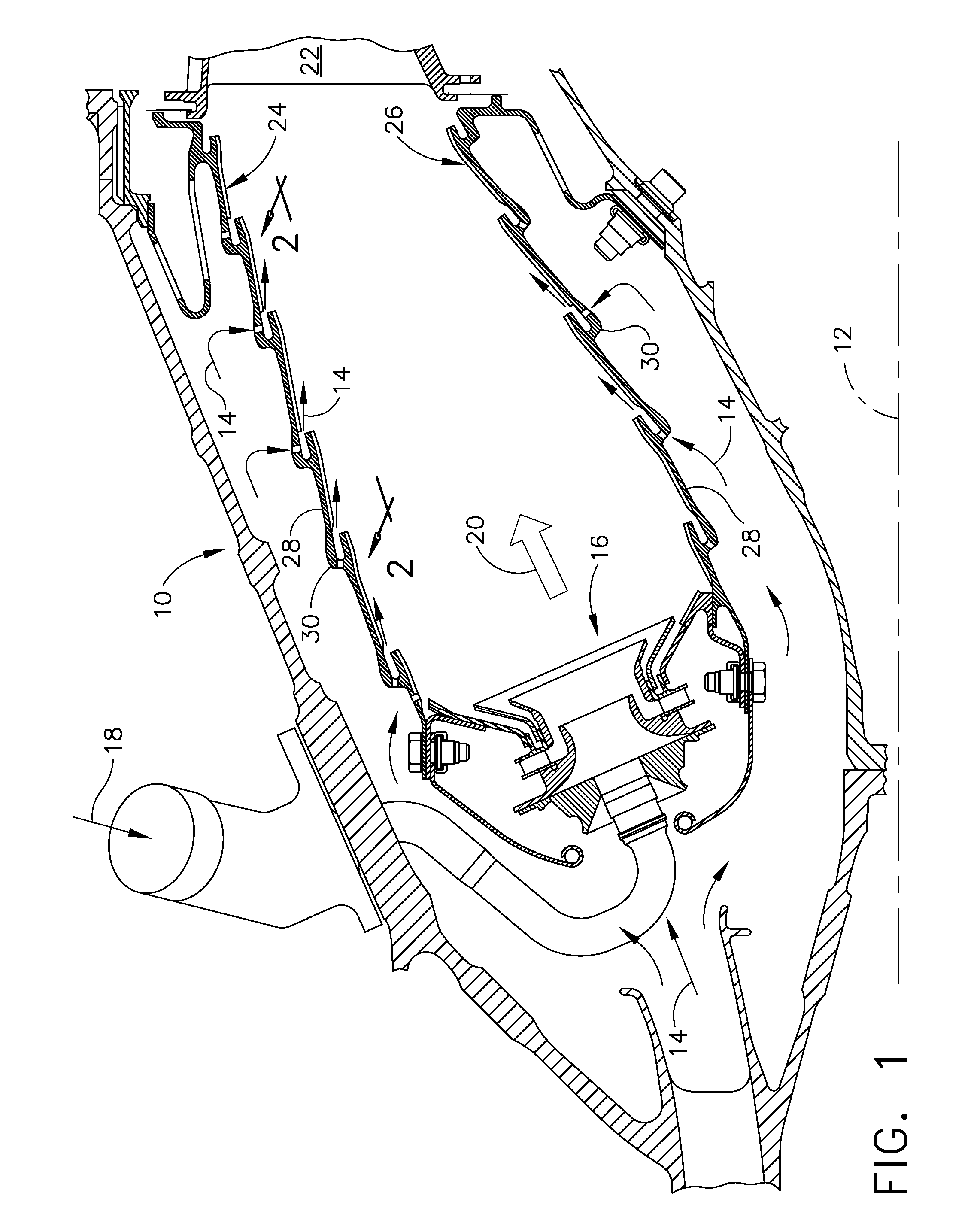

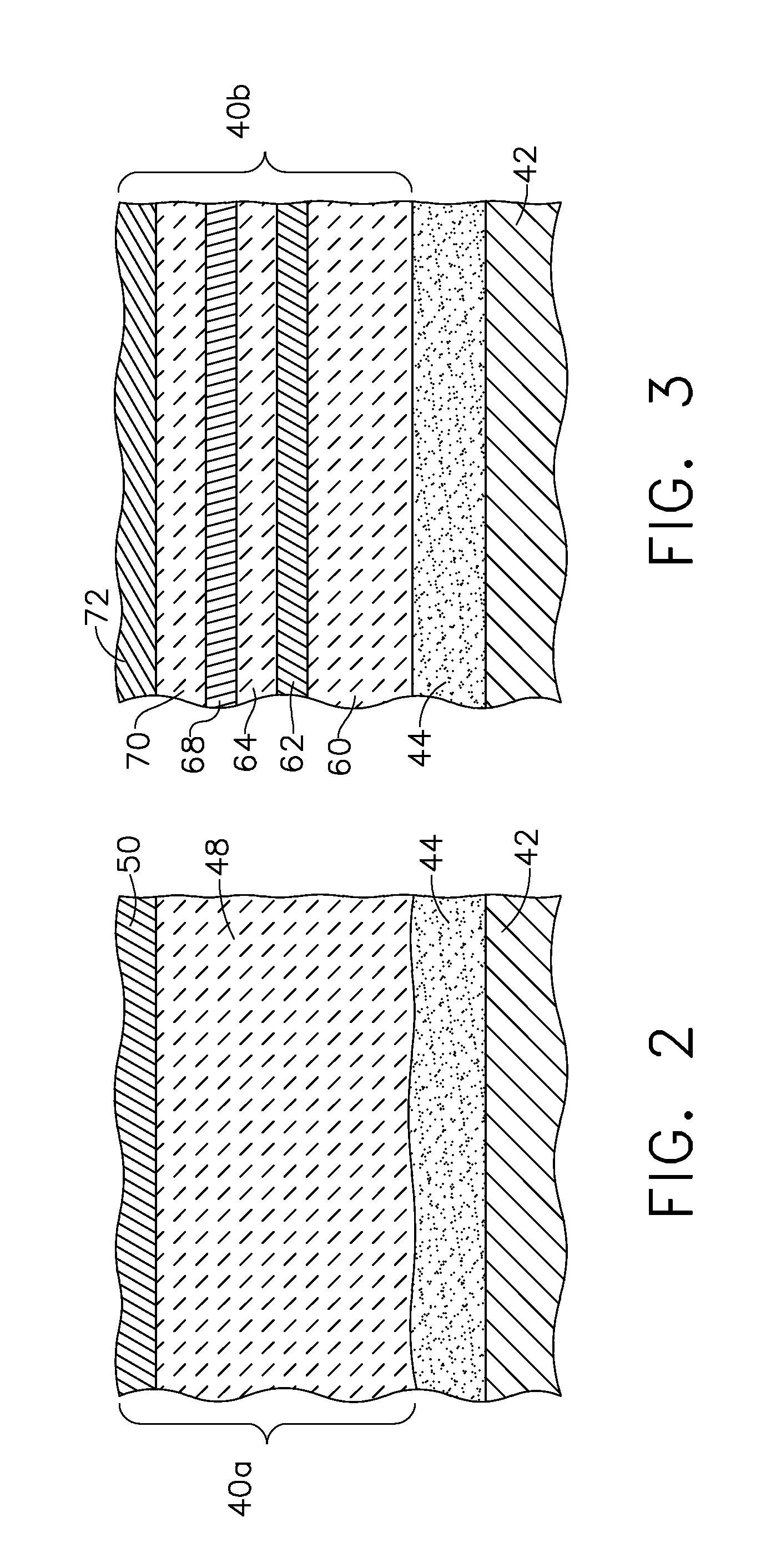

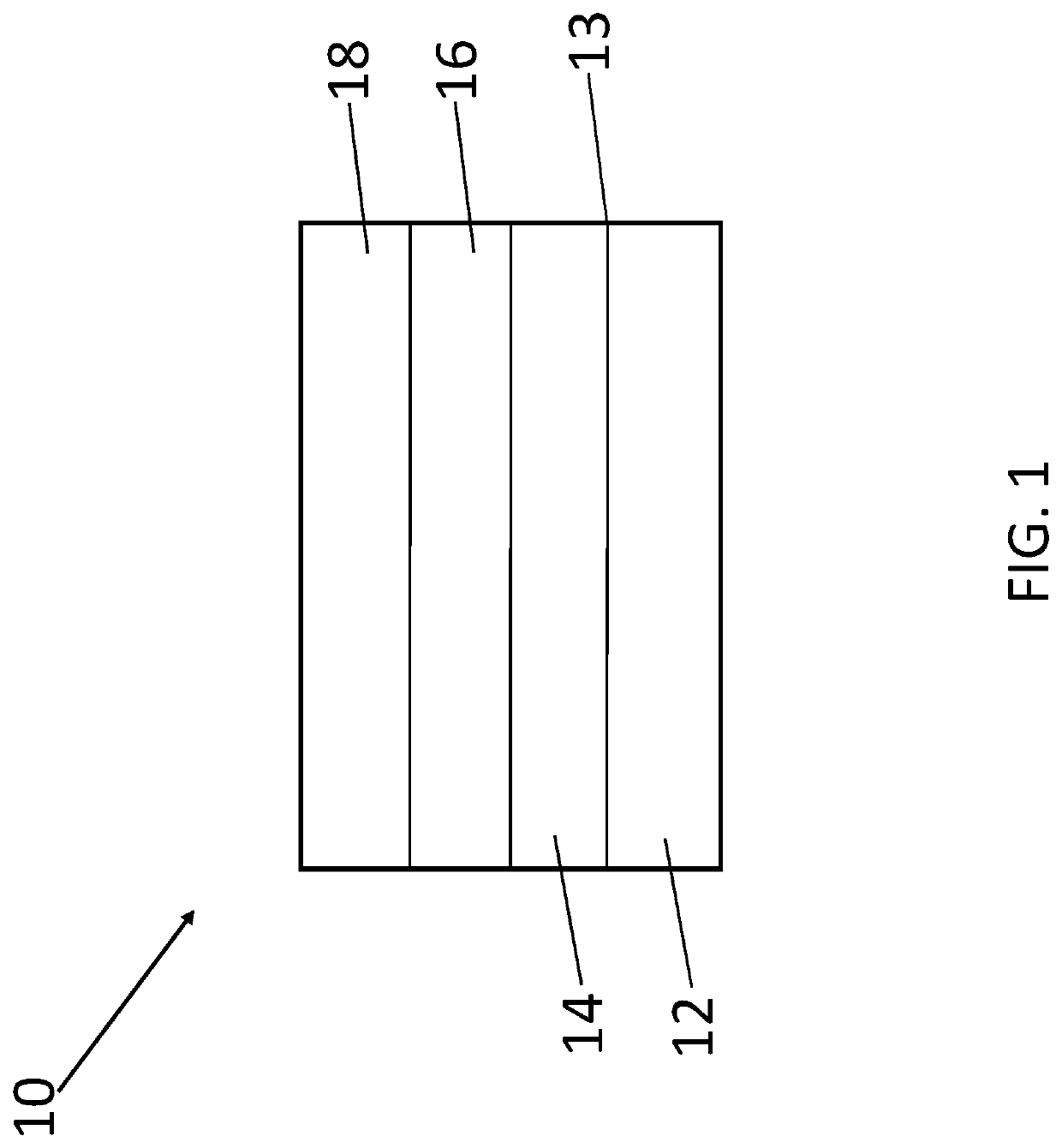

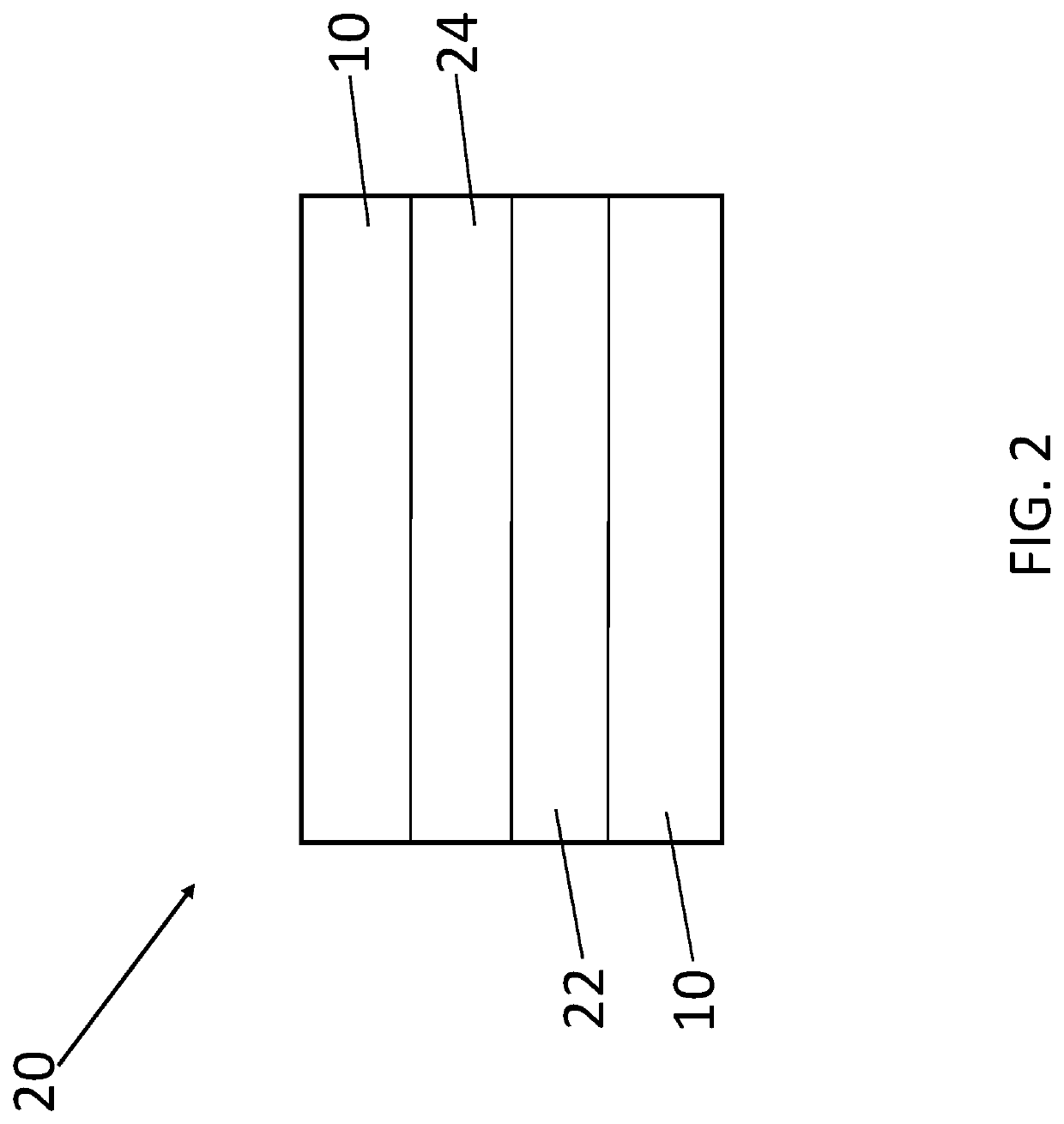

Coating Systems for Protection of Substrates Exposed to Hot and Harsh Environments and Coated Articles

InactiveUS20110151219A1Reduce the effectUsed in environmentContinuous combustion chamberMolten spray coatingCoating systemOxygen

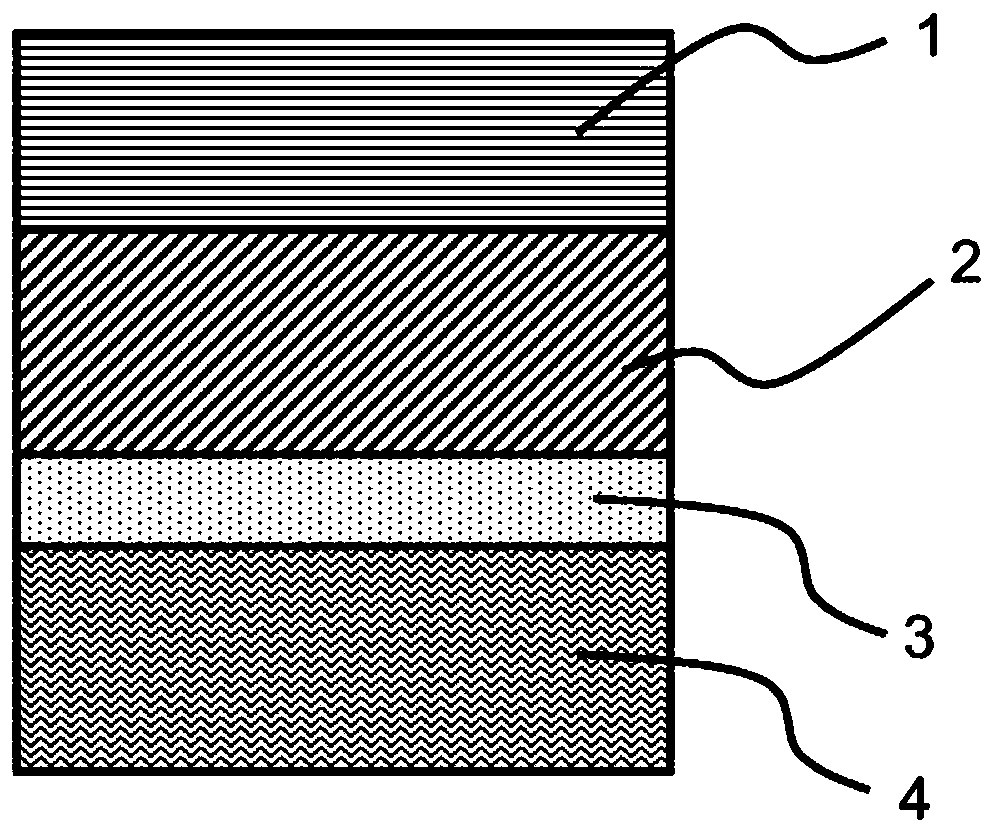

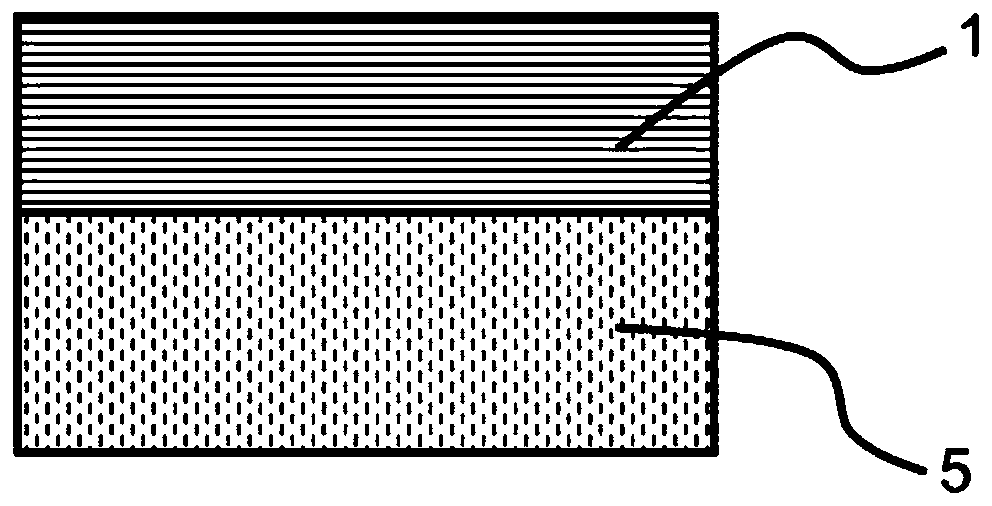

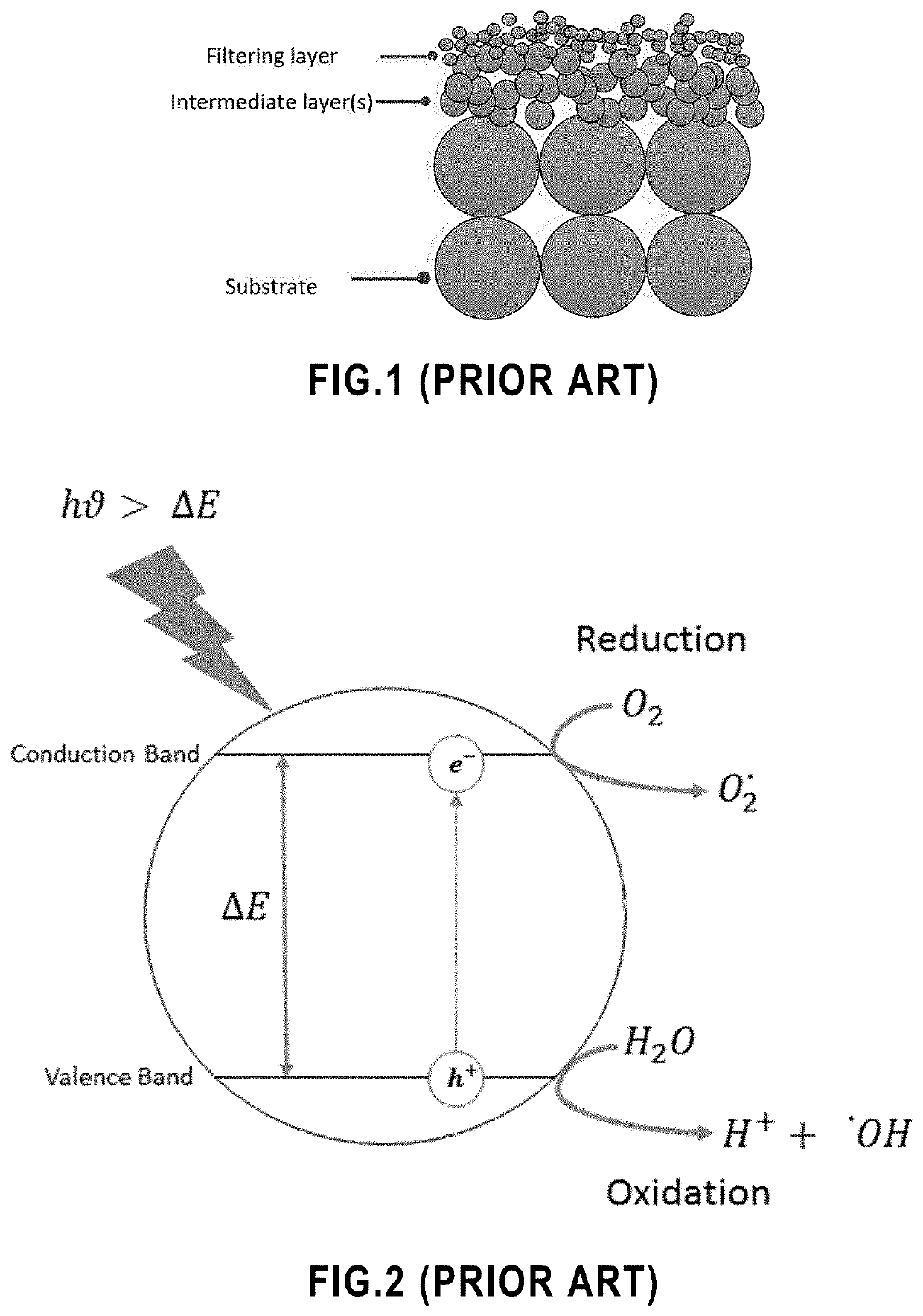

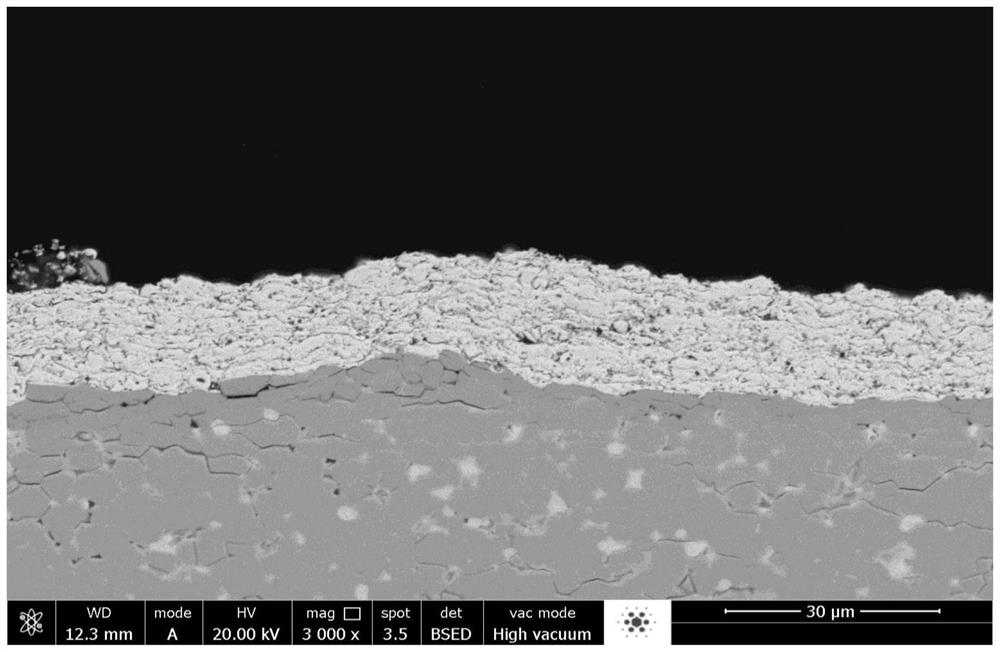

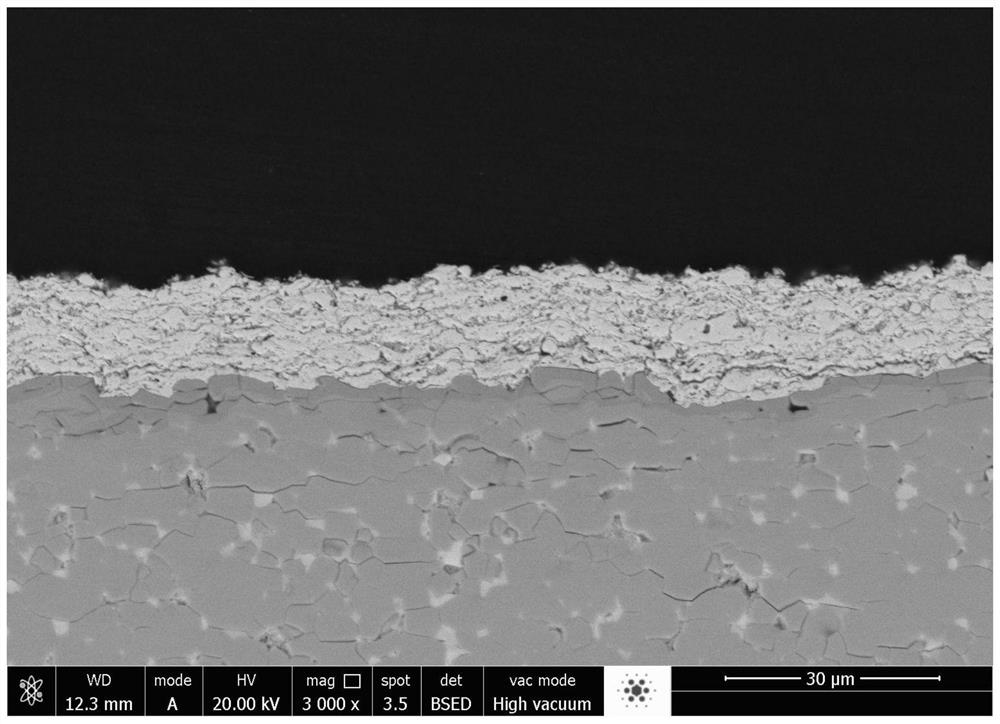

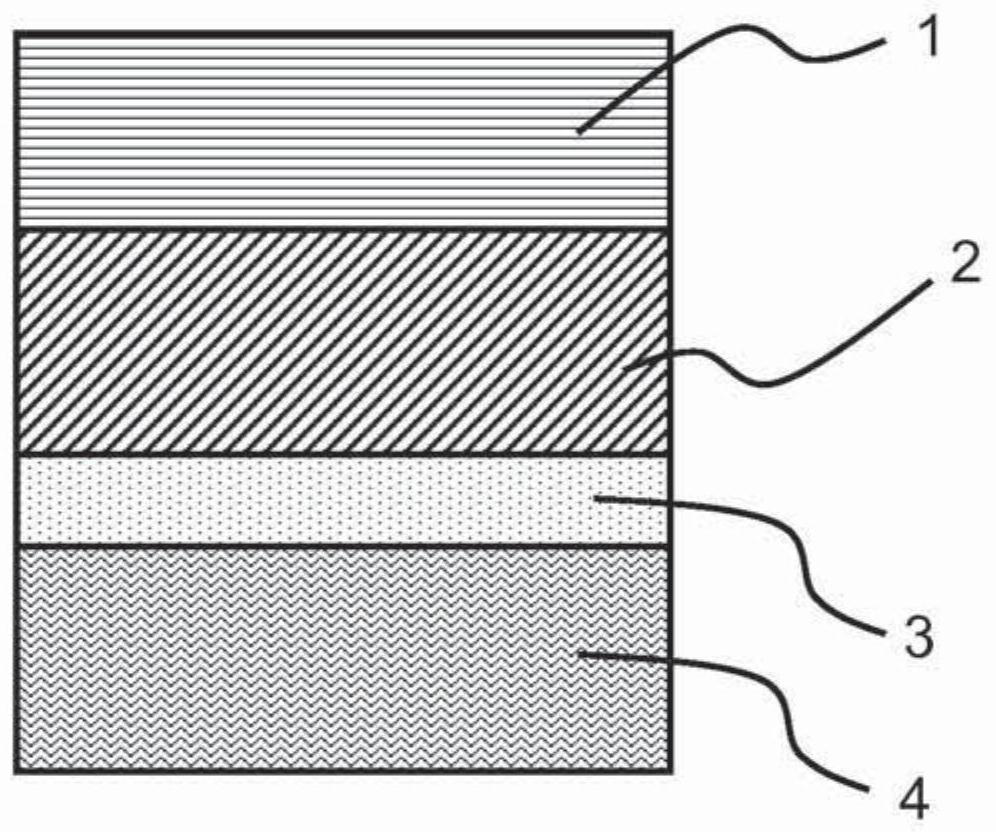

Coating system for reducing CMAS infiltration of substrates includes at least an inner ceramic layer and an outer alumina-containing layer. The outer layer includes up to 50 percent by weight titania. Additional ceramic layers and alumina-containing layers may be provided. The coating may be used for gas turbine engine components. Deposition techniques for the coating layers may depend on the end use of the component. Coated articles include a substrate, an optional bond coat on the substrate and a coating over the bond coat or on at least a portion of the substrate in the absence of a bond coat. The inner ceramic layer(s) exhibit a microstructure indicative of a deposition technique selected from thermal spray, physical vapor deposition, and suspension plasma spray, whereas the outer alumina-containing layer exhibits a microstructure indicative of suspension plasma spray, solution plasma spray, and a high velocity oxygen fuel spray.

Owner:GENERAL ELECTRIC CO

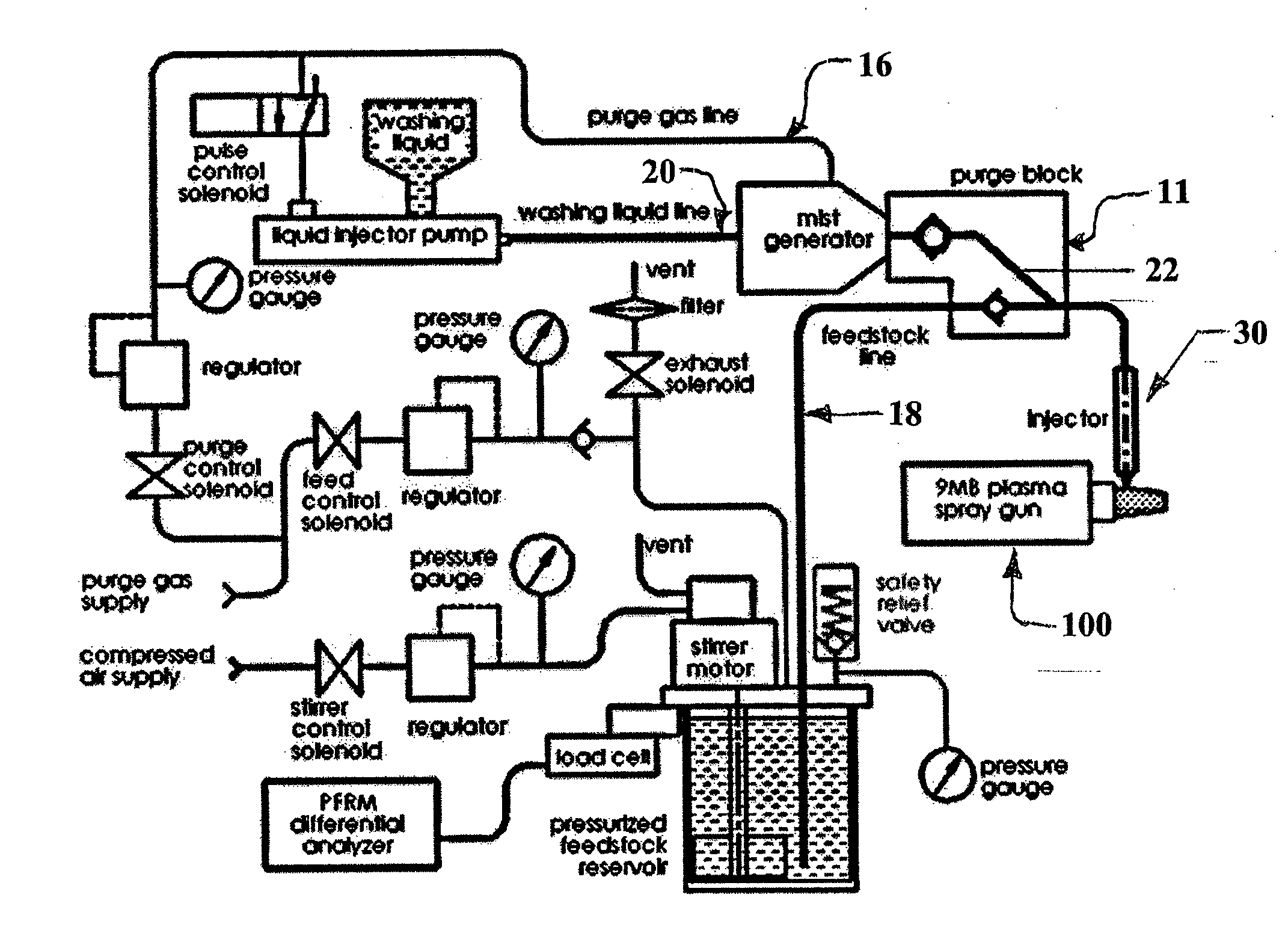

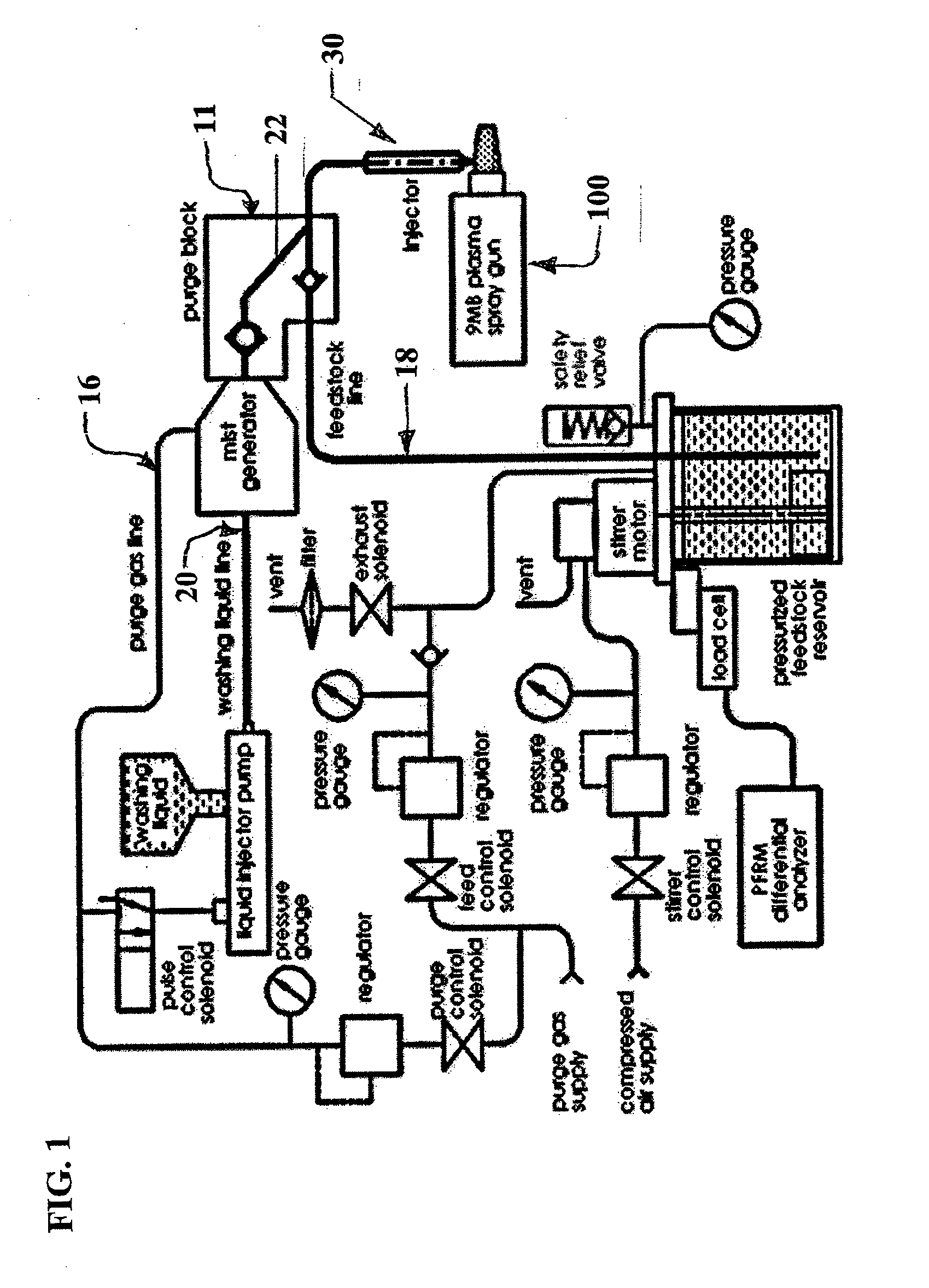

Pressure based liquid feed system for suspension plasma spray coatings

ActiveUS20130270355A1Avoid accumulationReduce cooling effectLiquid surface applicatorsMolten spray coatingLiquid jetLiquid medium

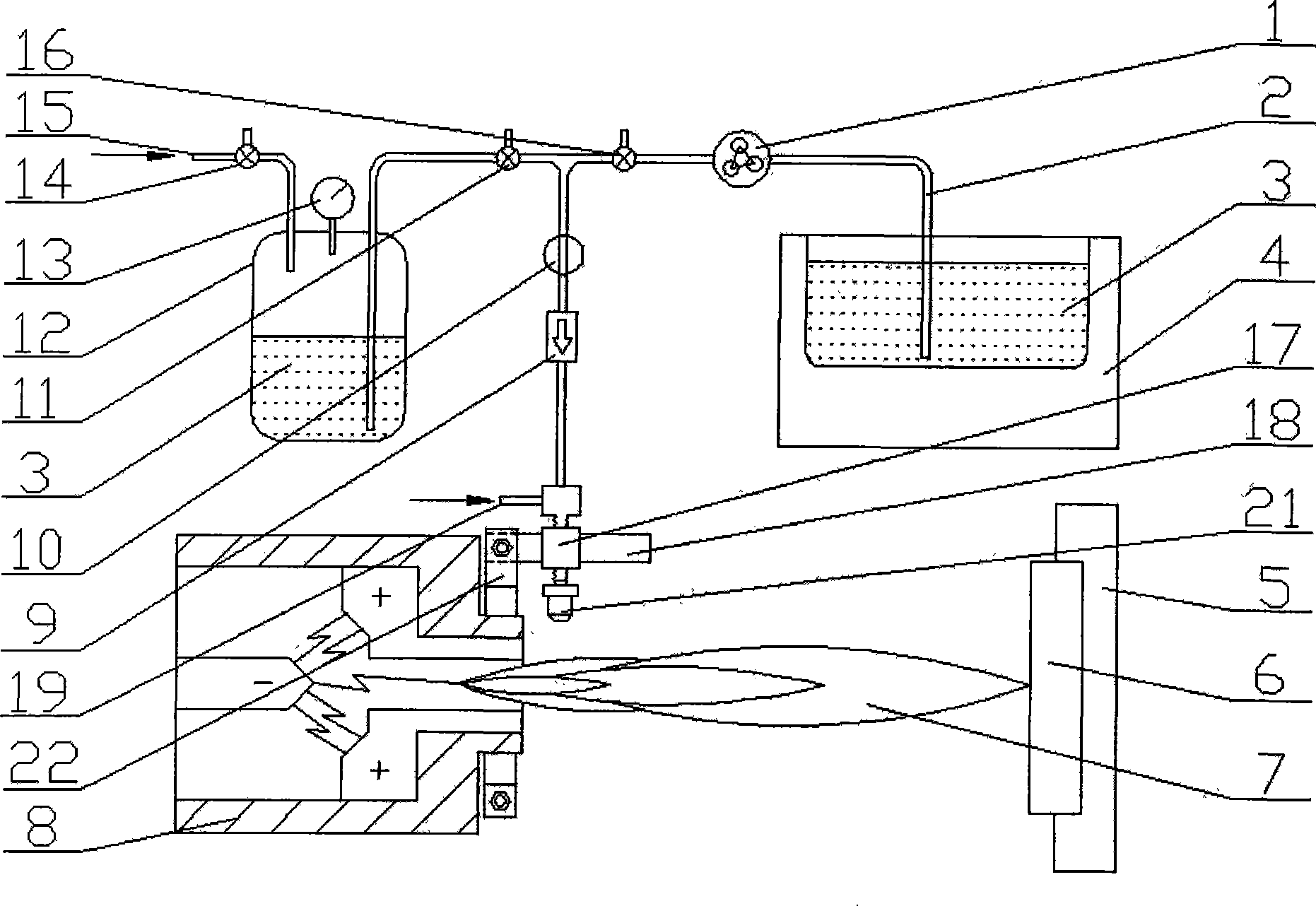

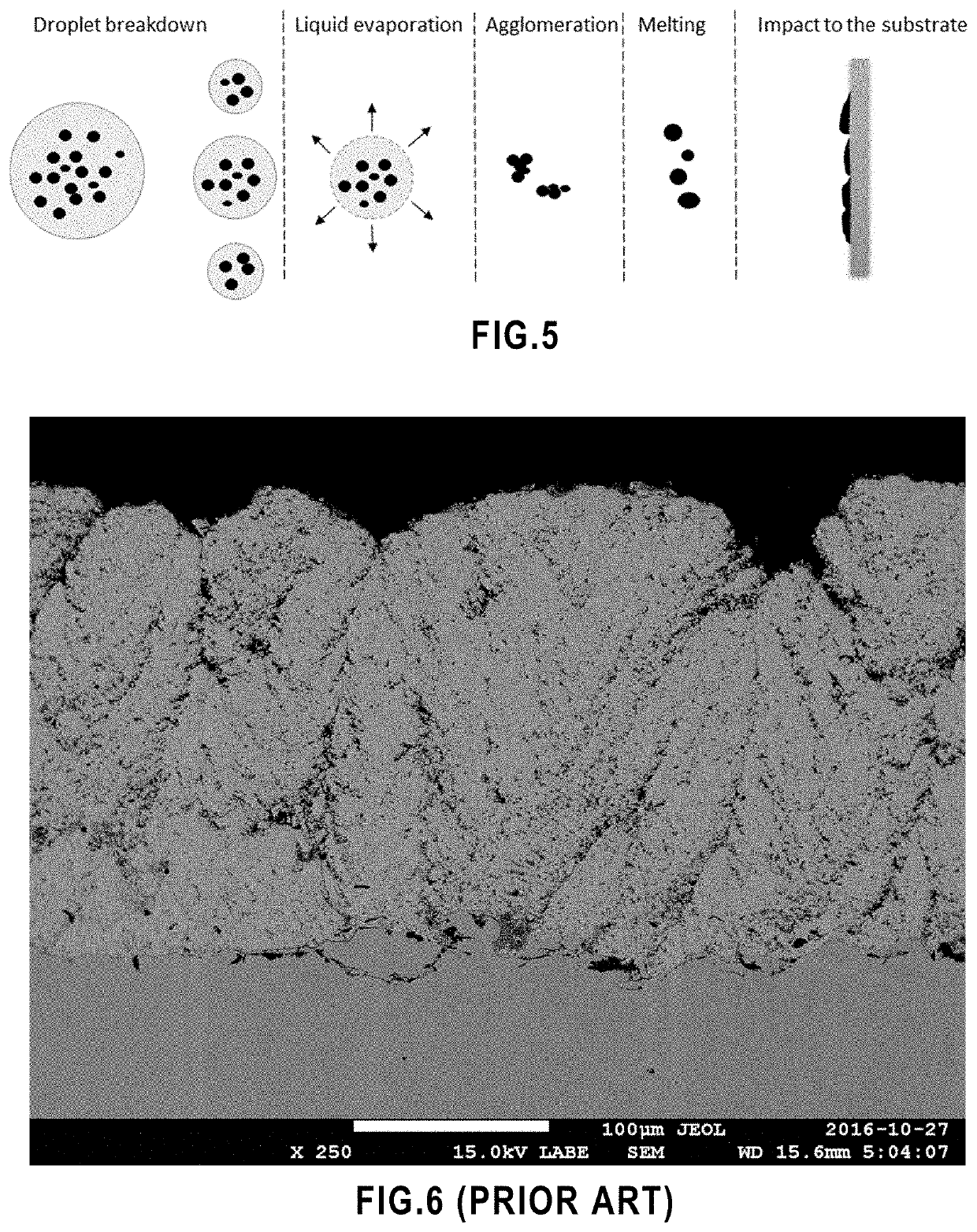

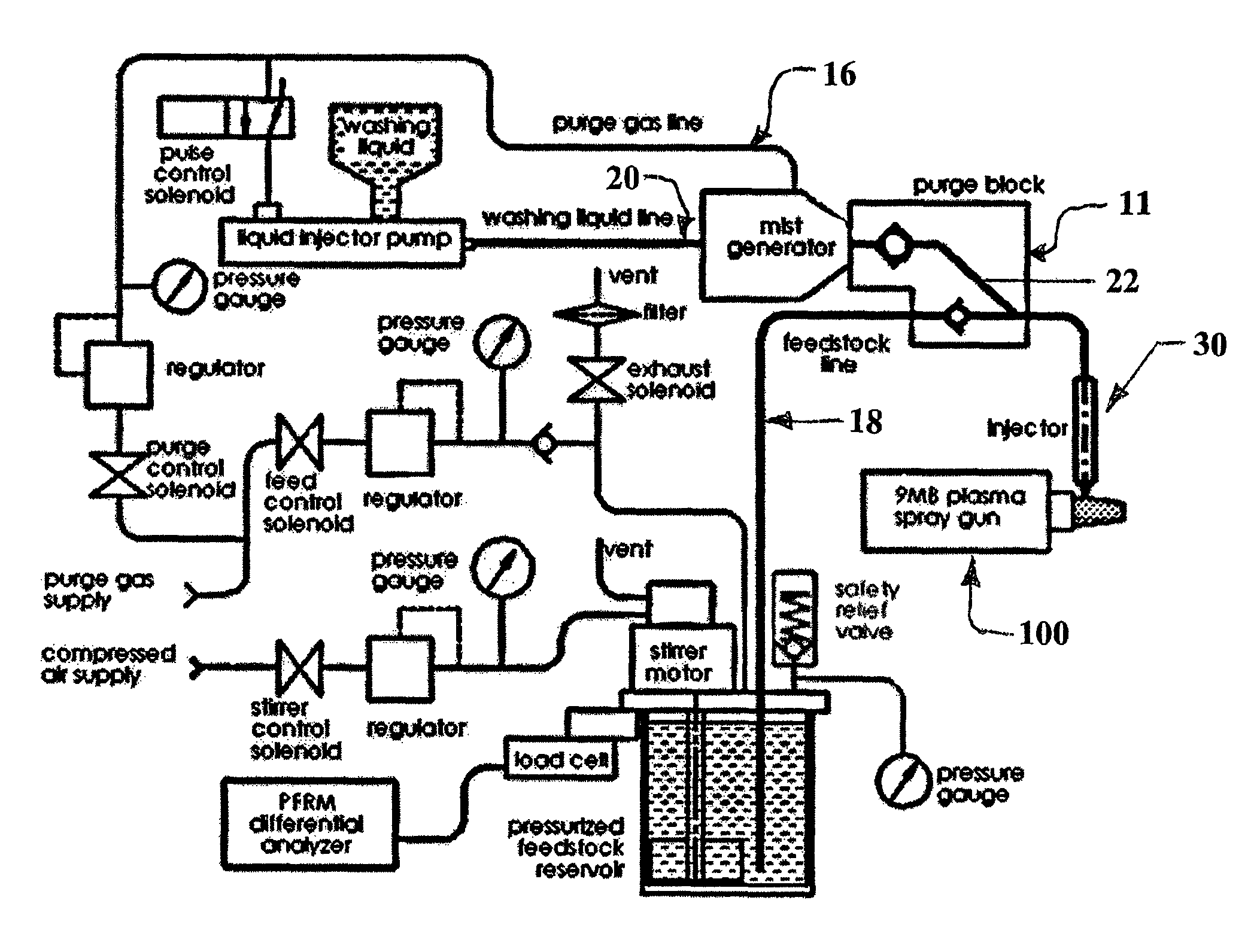

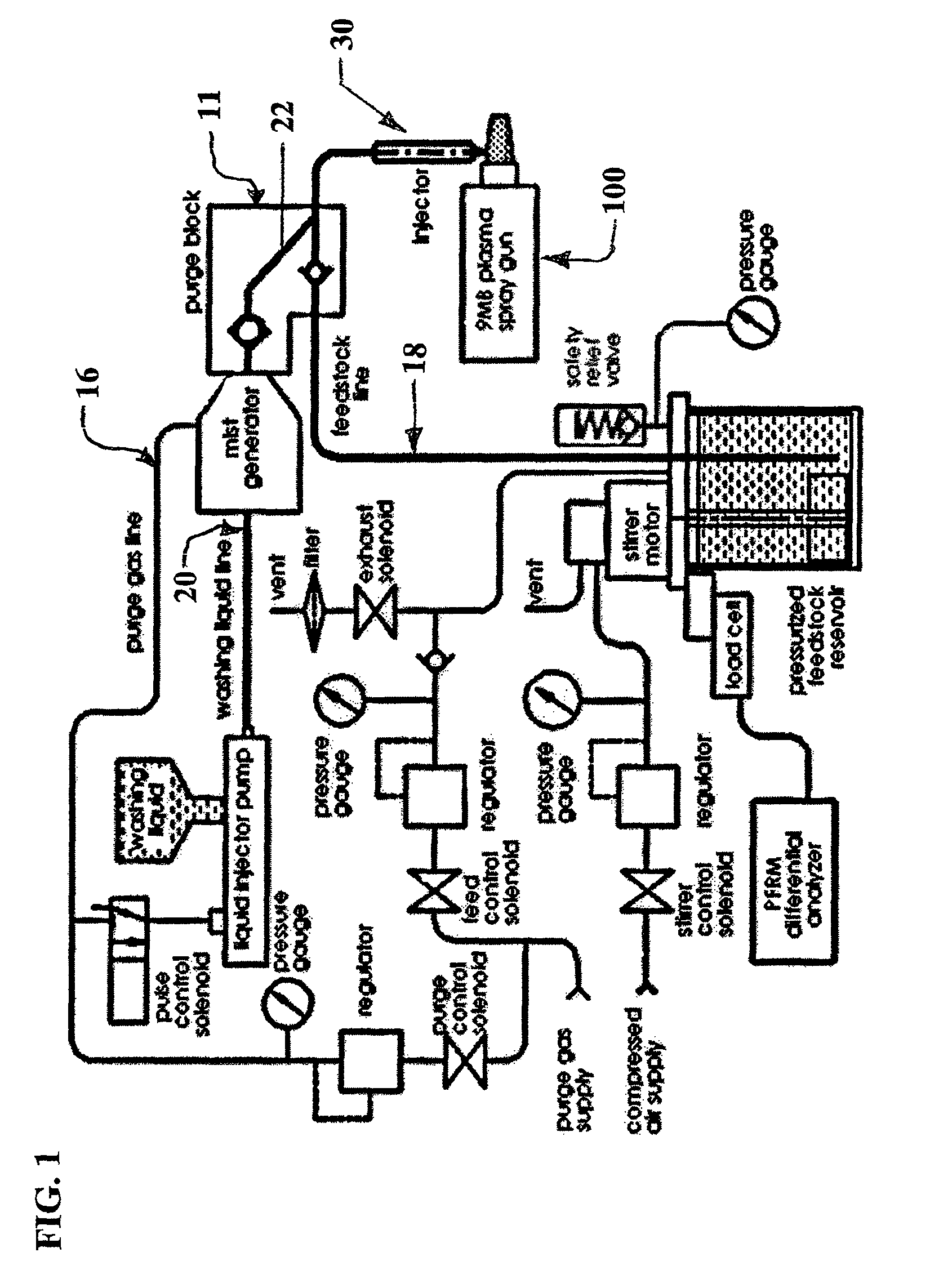

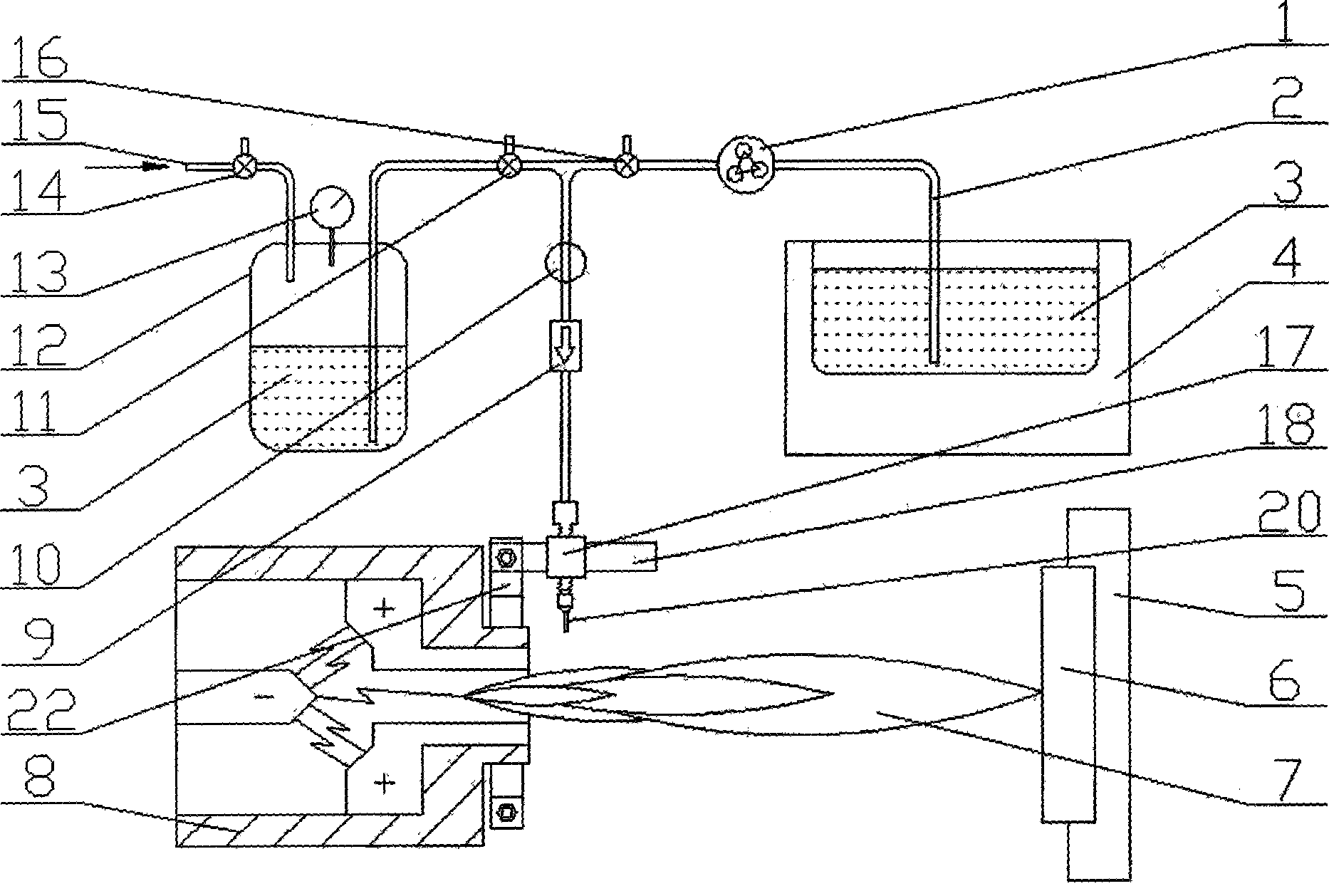

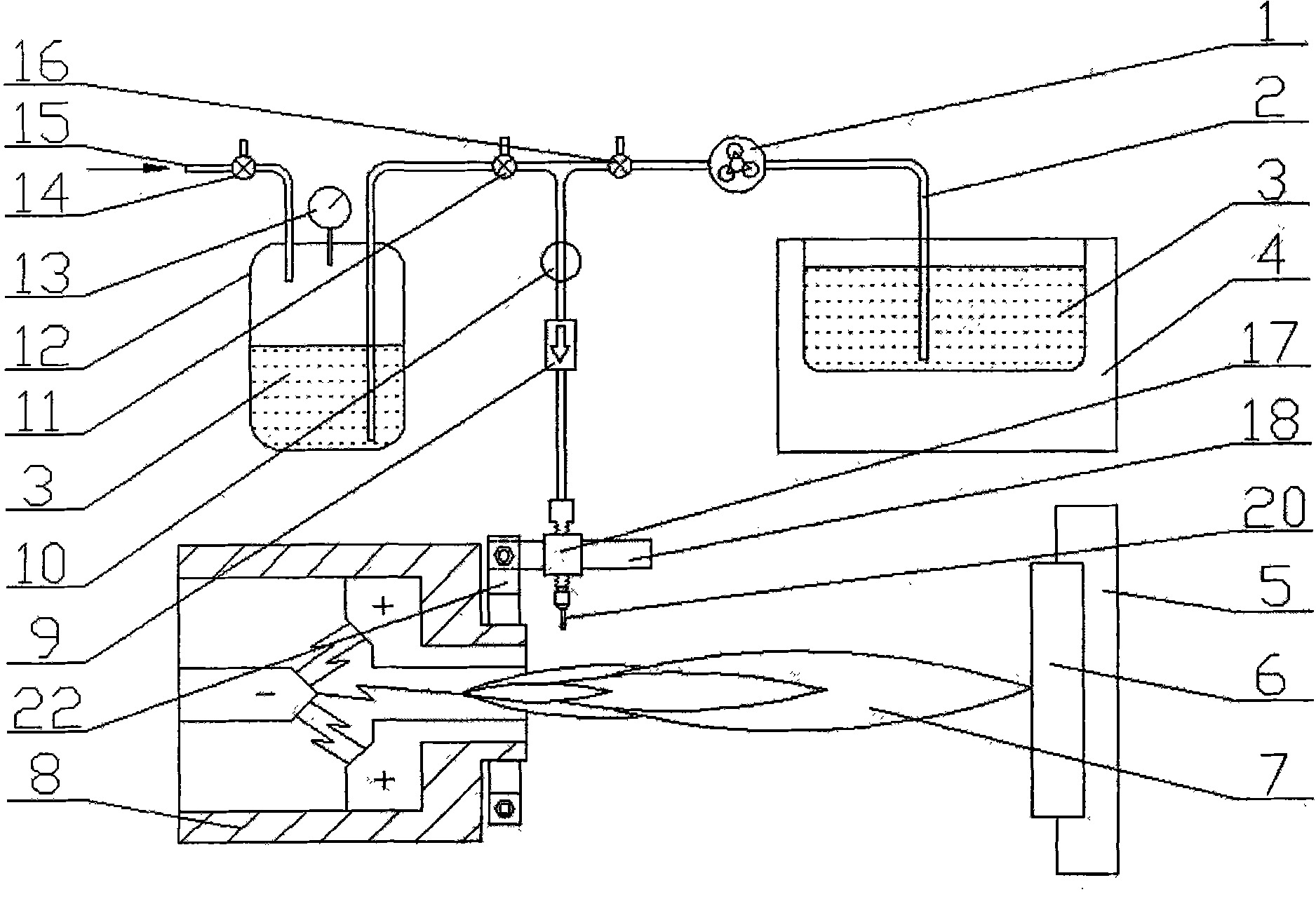

Apparatus (1) for injecting a liquid in an area of a thermal spray gun (100). The apparatus (1) includes an injector cleaning device (10) having an inlet connectable (19) to at least one feedstock supply line (18), an inlet connectable (17) to at least one gas supply line (16), and an inlet connectable (21) to at least one liquid medium supply line (20). An injector (30) orifice is coupled to the injector cleaning device (10) and is adapted to at least one of inject a liquid jet into a hot stream created in the area of the thermal spray gun (100) and receive feedstock, gas and liquid passing into the inlets.

Owner:SULZER METCO (US) INC

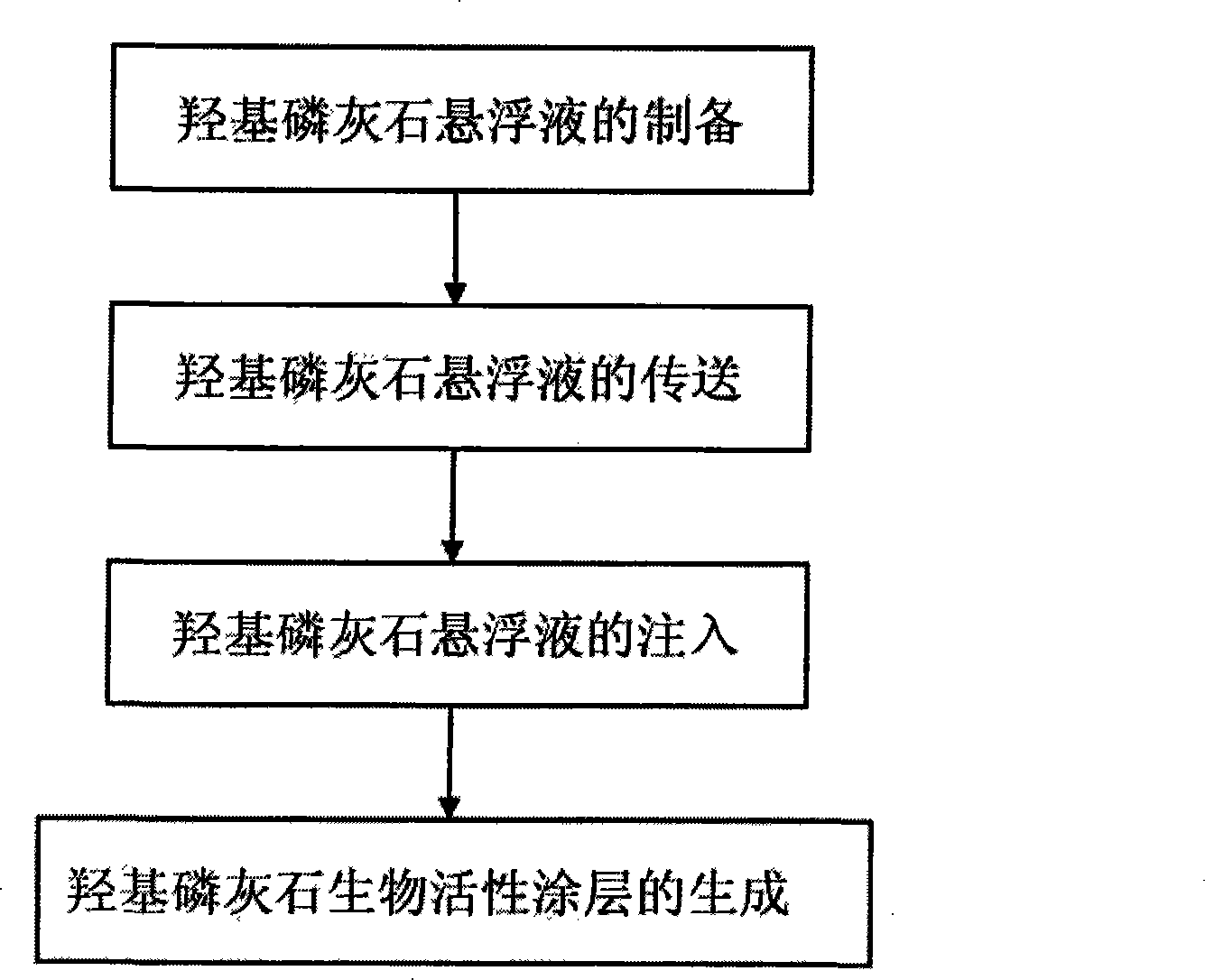

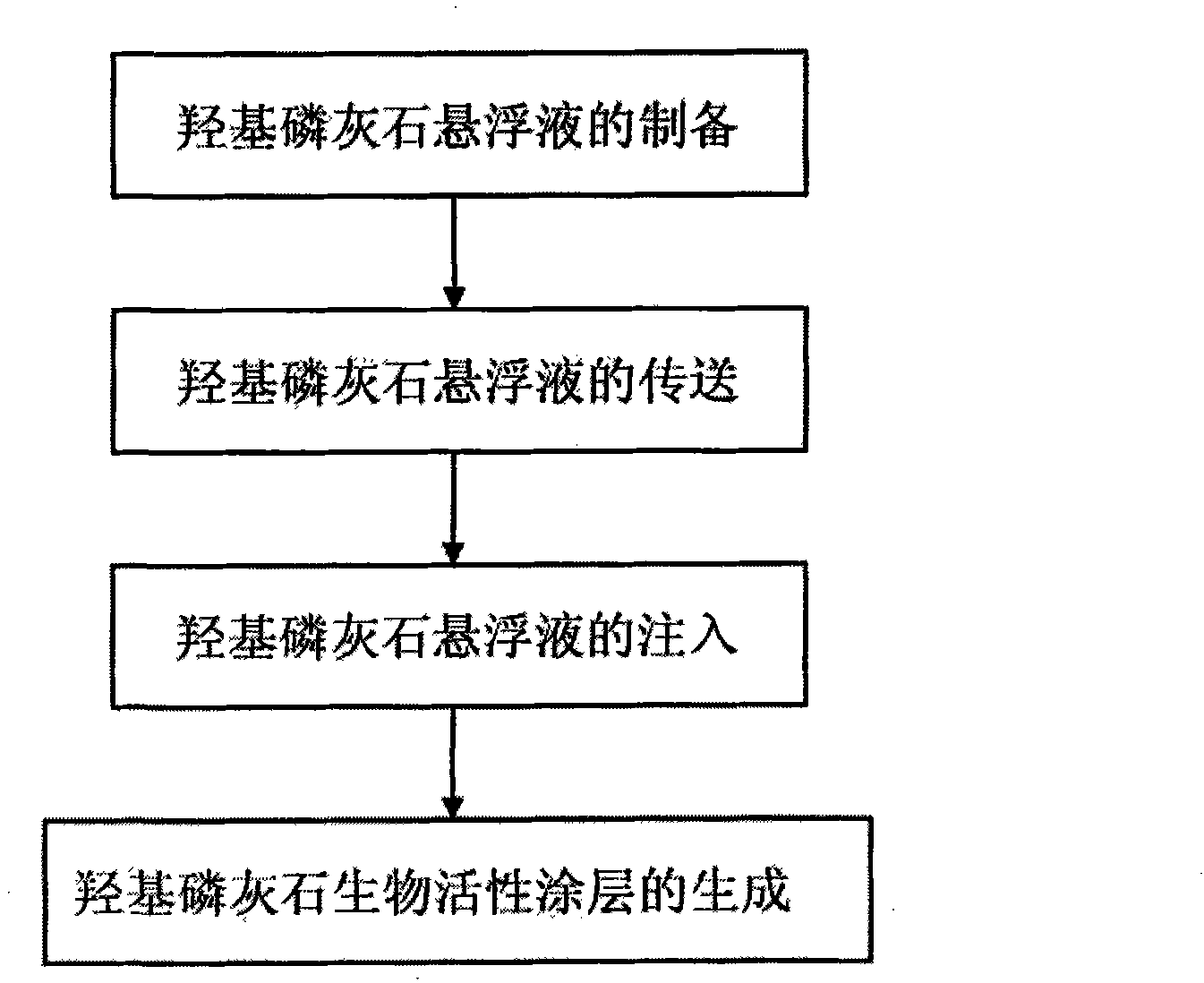

Method for suspending liquid plasma spraying preparation of hydroxyapatite bioactivity coatings

InactiveCN101250681AIncrease productivityReduce manufacturing costMolten spray coatingProsthesisPeristaltic pumpApatite

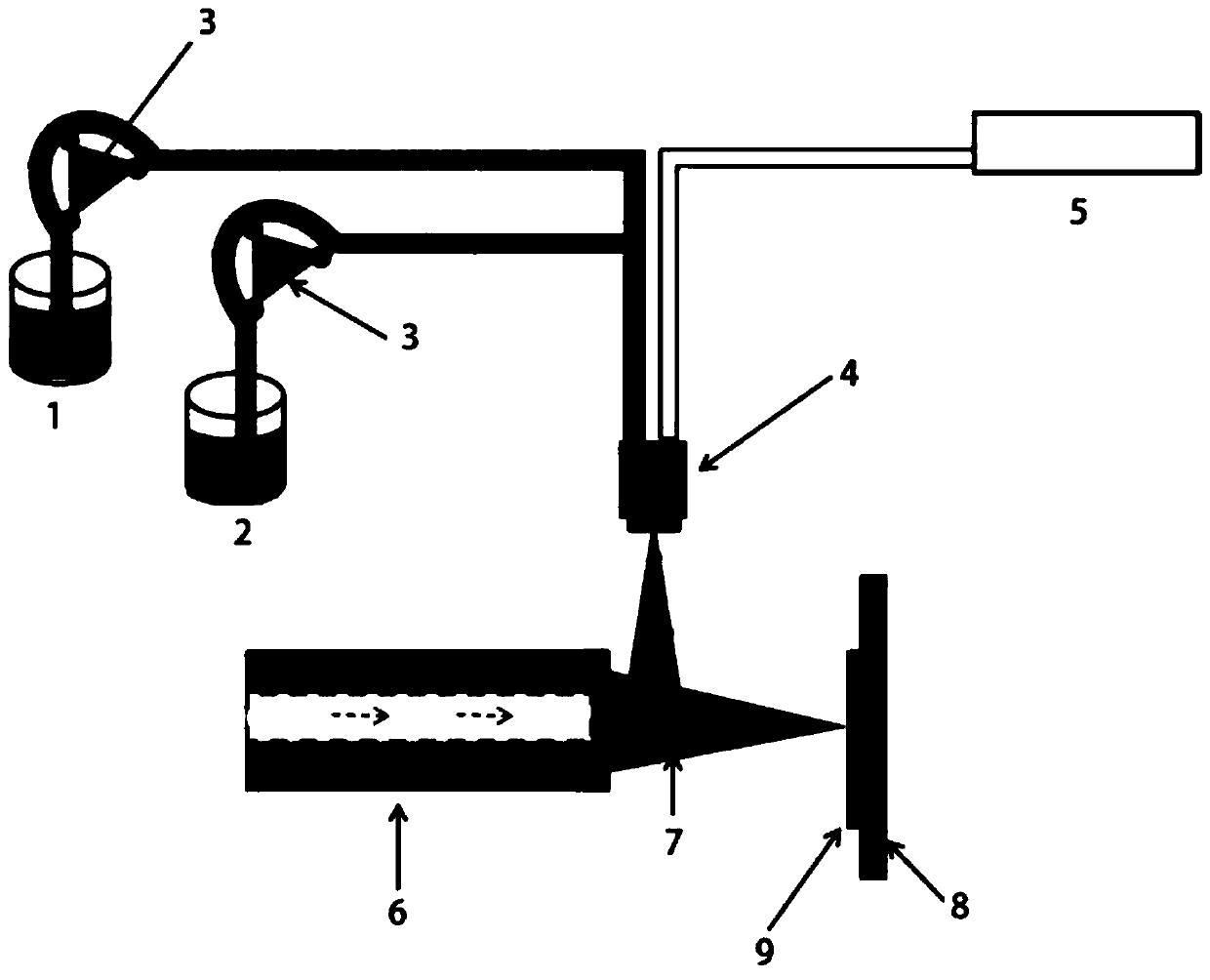

The invention relates to a method for spraying suspending liquid plasma to prepare hydroxyapatite bioactive coating, which comprises following steps: adopting hydroxyapatite suspending liquid as plasma spraying raw materials, adopting a pressure tank or an electronic peristaltic pump as a power transmitting device to transmit the hydroxyapatite suspending liquid, adopting an atomizing nozzle with a small angle to inject the hydroxyapatite suspending liquid into a central region of plasma flame directly and radially or adopting a duct with small diameter to inject the hydroxyapatite suspending liquid into the central region of the plasma flame directly and radially in a linear type jet-flow mode, exchanging heat between the suspending liquid and high temperature plasma flame through transmitting and injecting the suspending liquid, and directly generating the hydroxyapatite bioactive coating on the surface of a biological medical metal base through vaporizing liquid in the suspending liquid, crushing particles, smelting and depositing. The method simplifies a tedious technological link for preparing the spraying raw materials in a method for spraying powder plasma, the spraying raw materials and energy are saved, and the structural homogeneity of the hydroxyapatite bioactive coating which is prepared is good.

Owner:SICHUAN UNIV

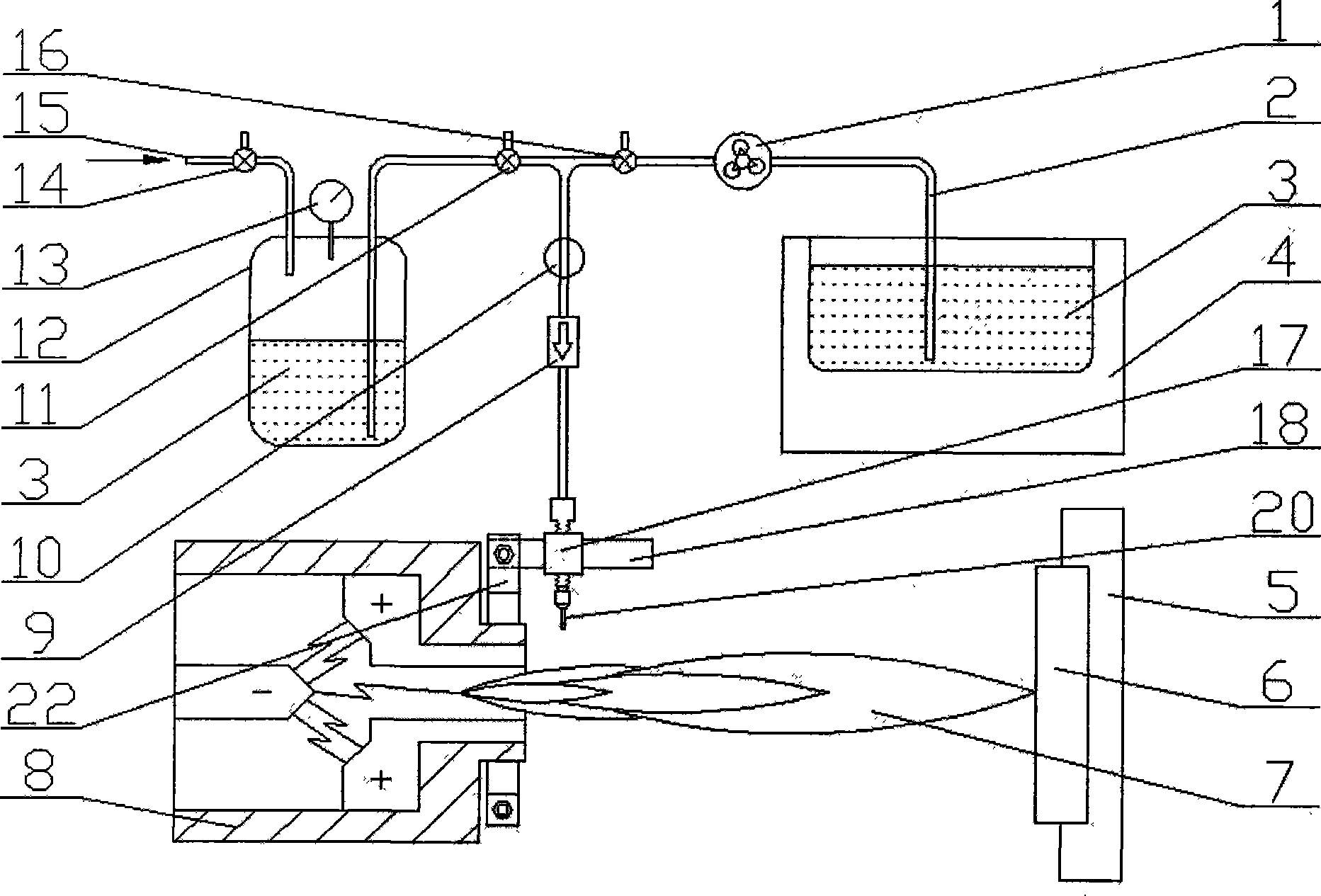

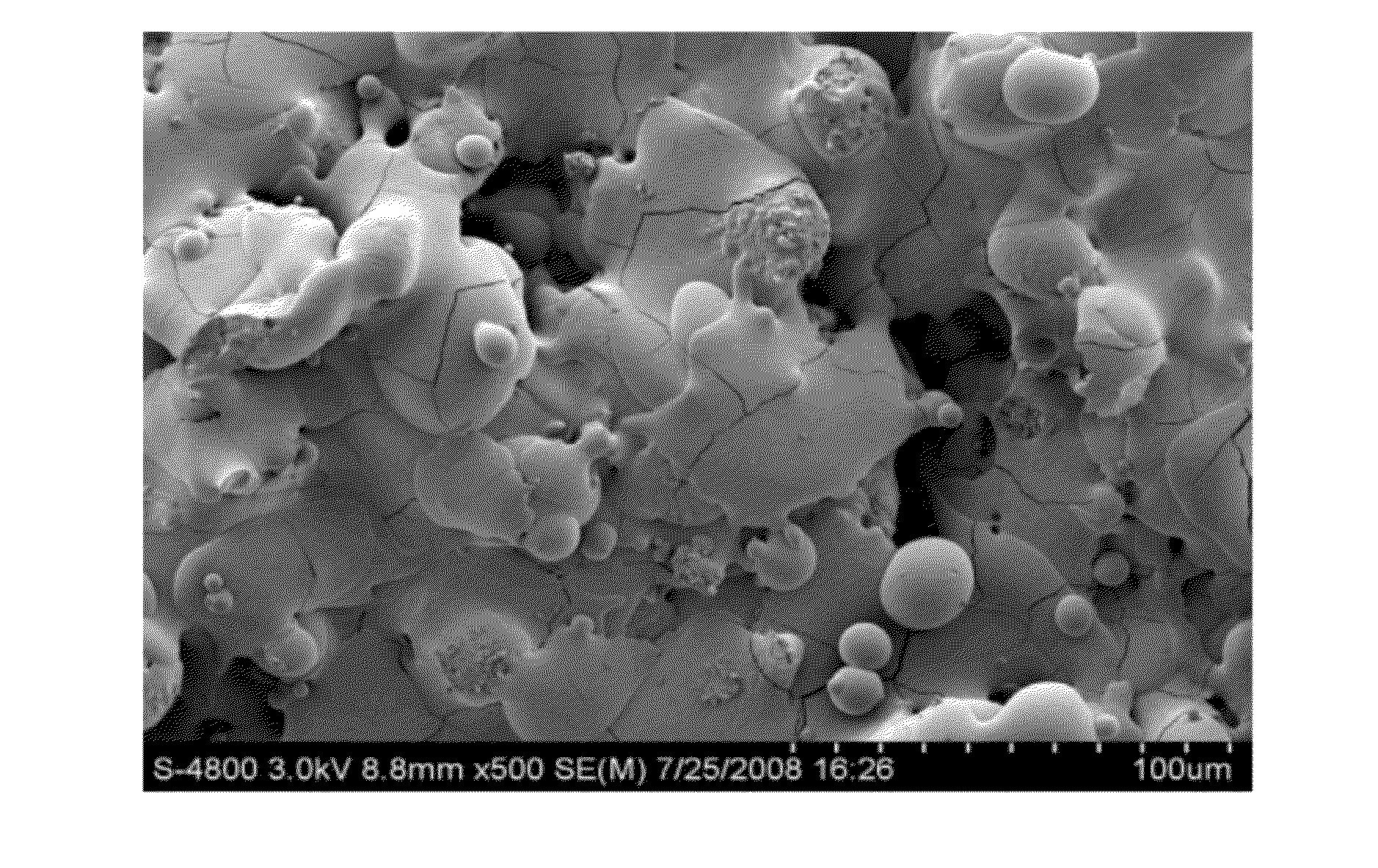

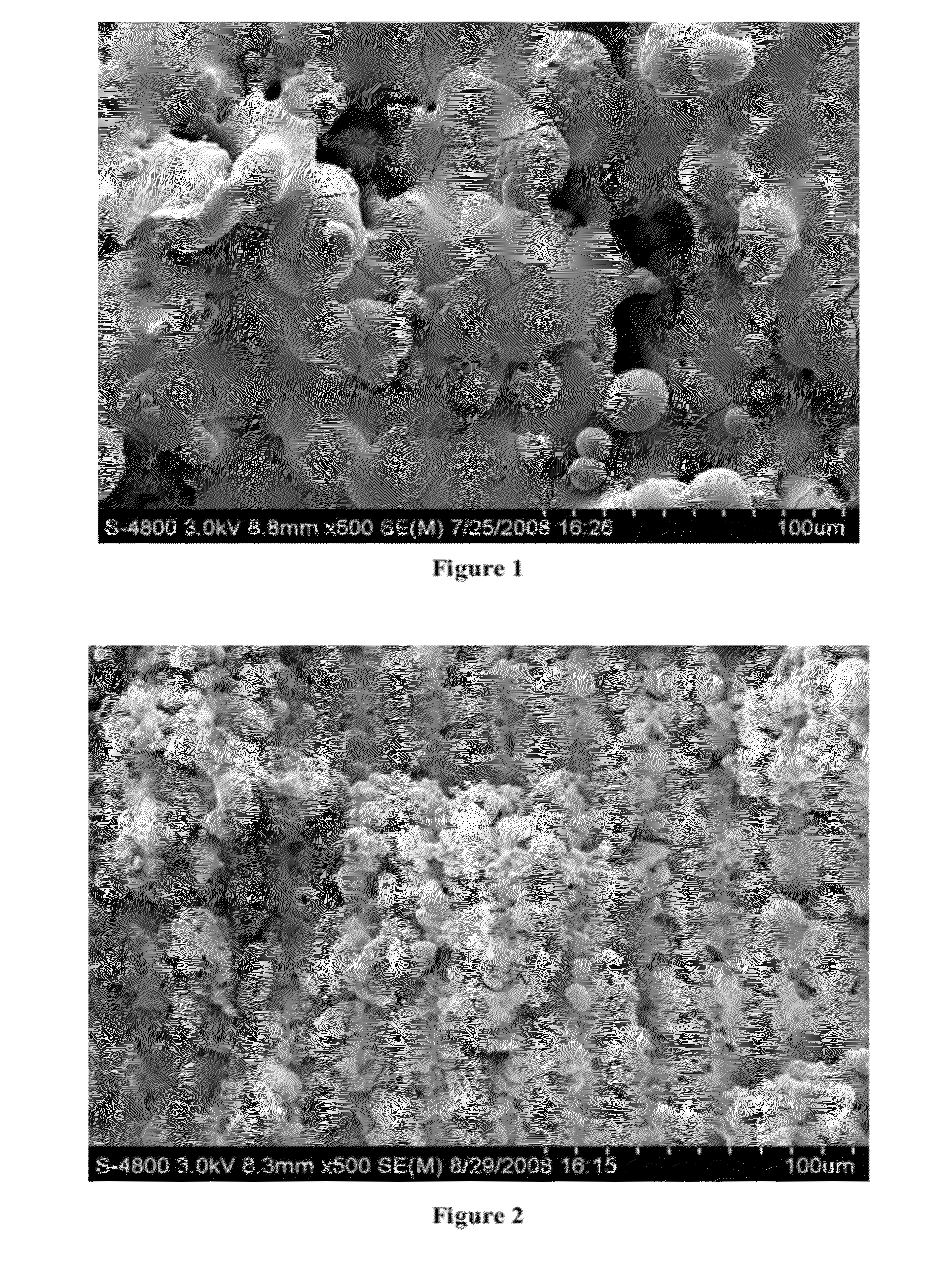

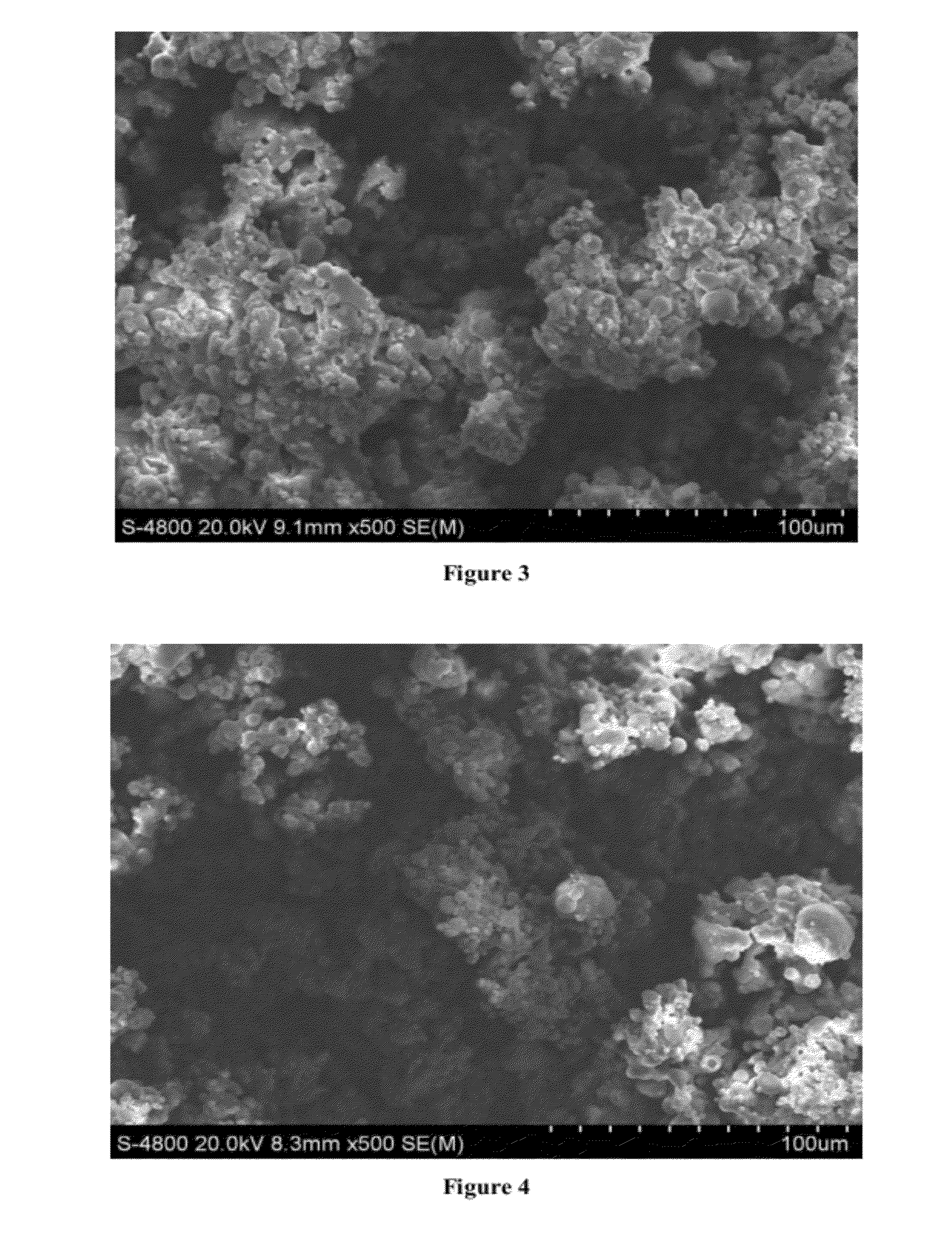

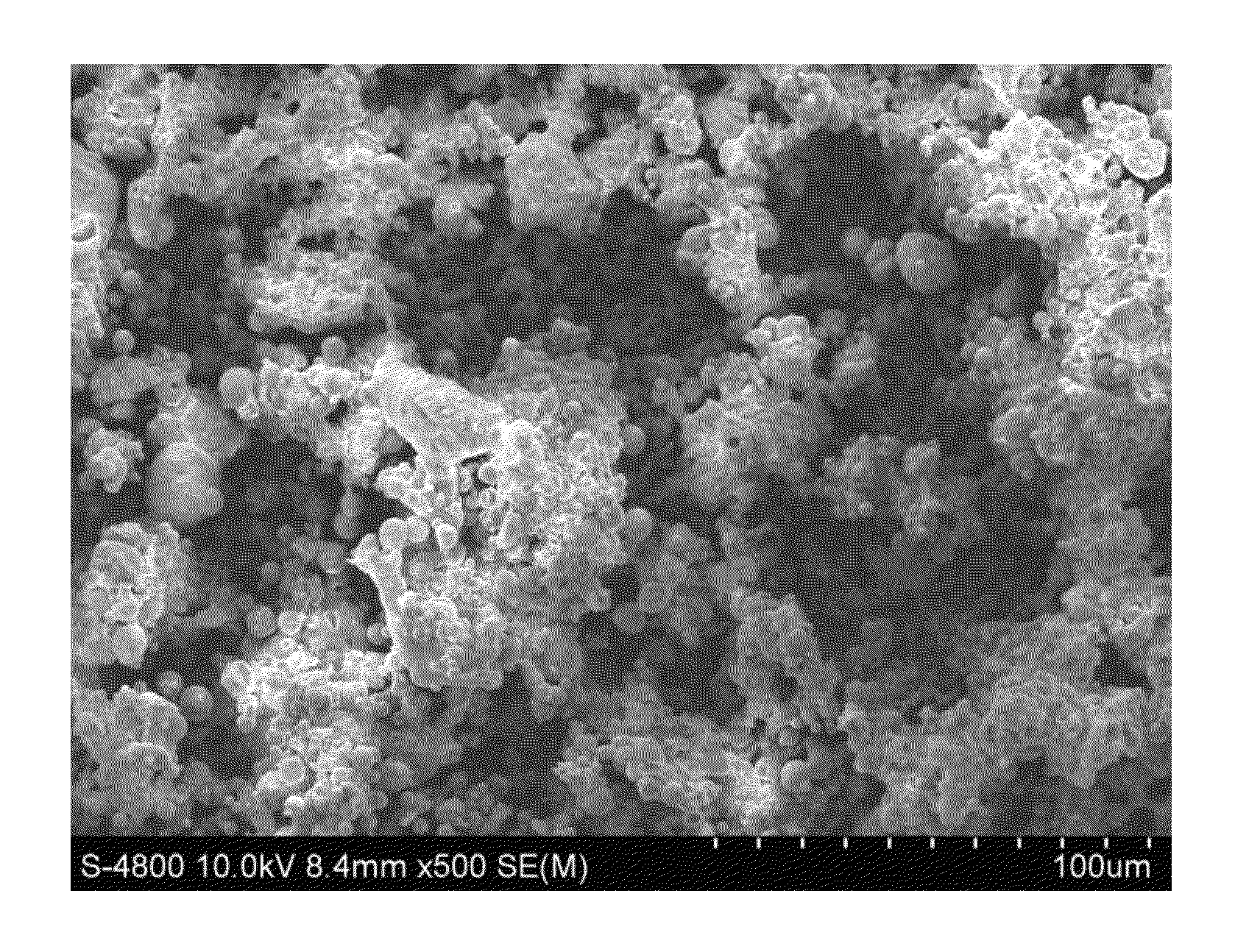

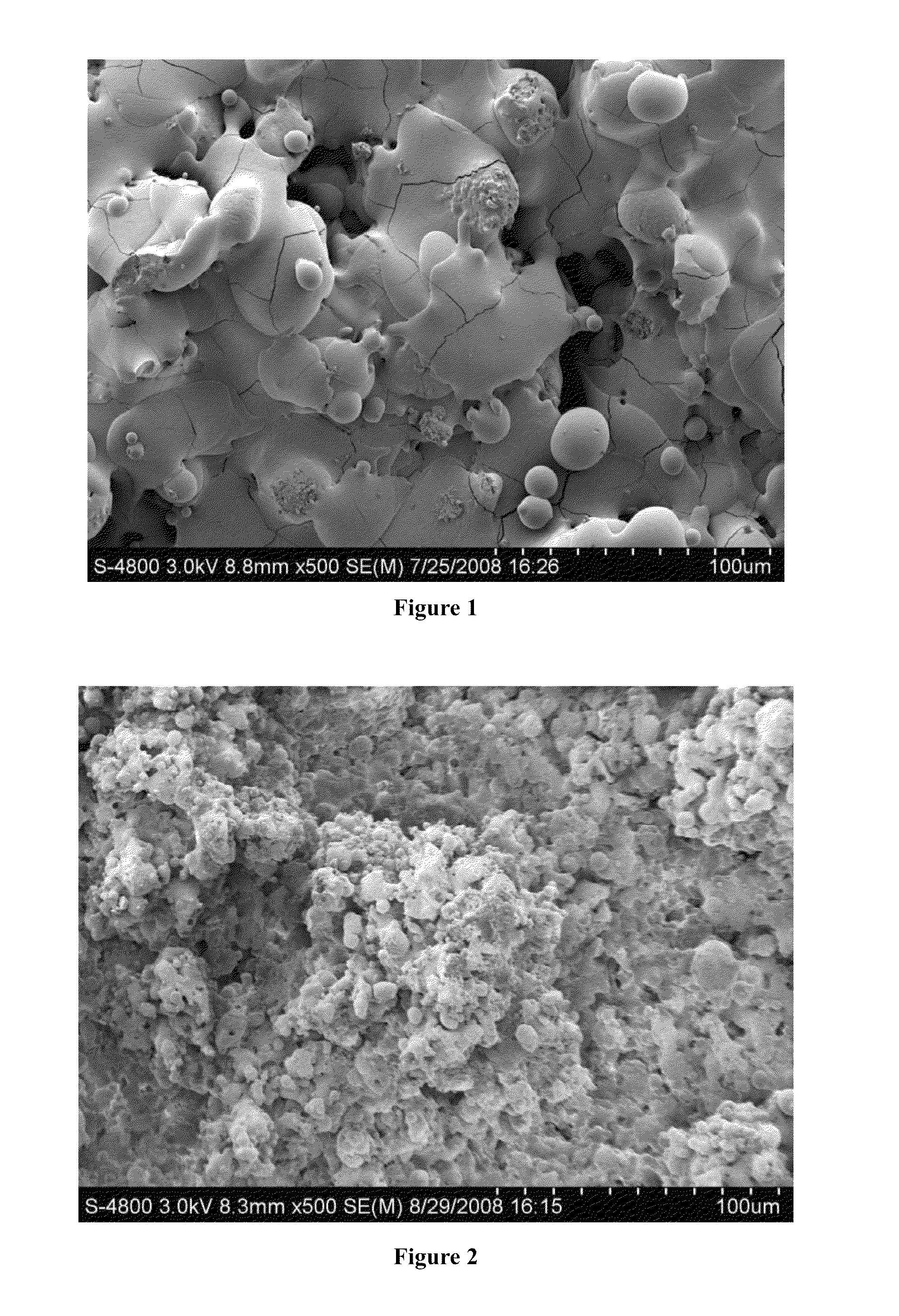

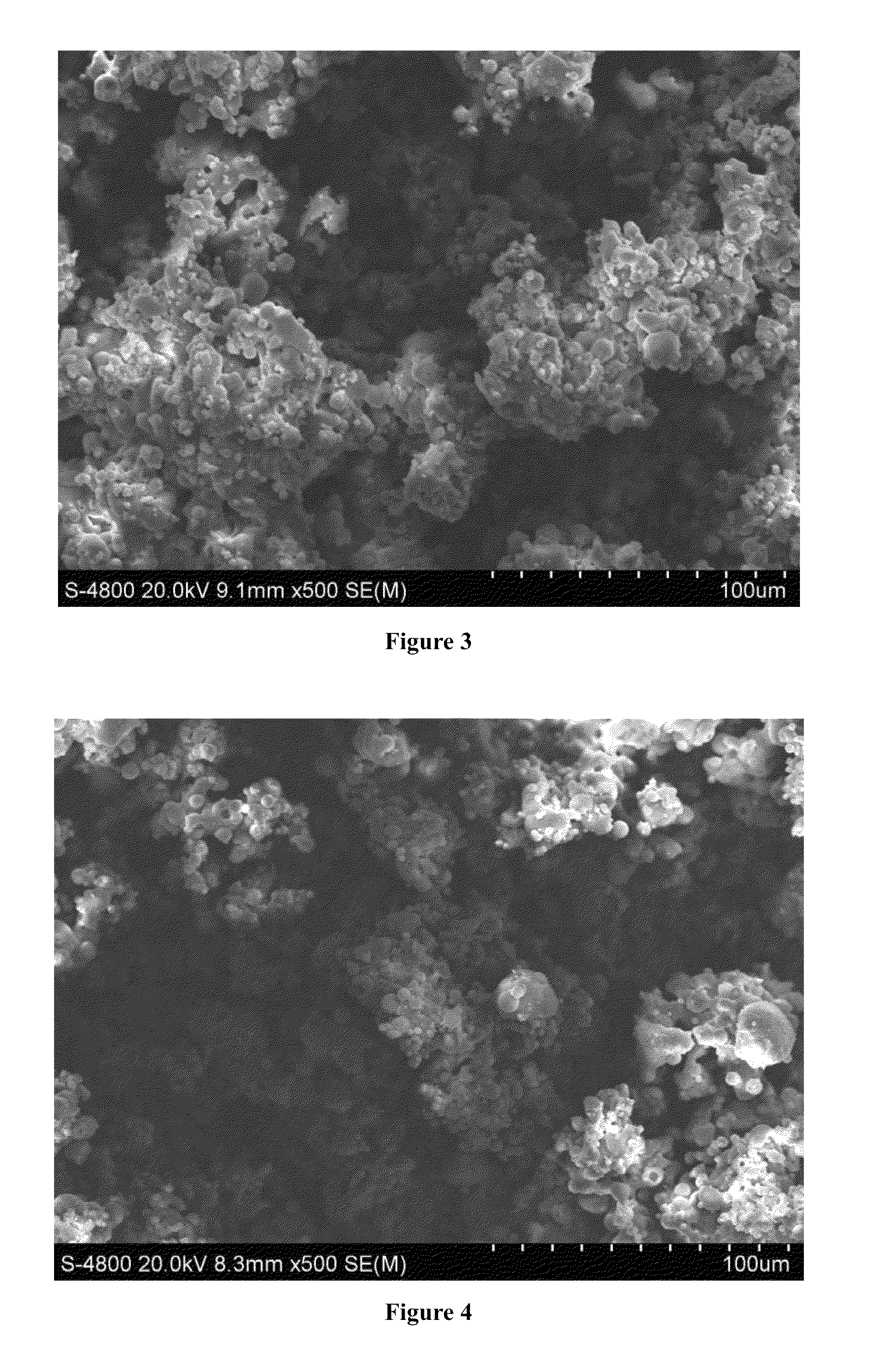

Method for preparing porous hydroxyapatite coatings by suspension plasma spraying

InactiveUS20120052183A1Good biological propertiesSimple methodMolten spray coatingPharmaceutical containersDecompositionApatite

The present invention relates to a preparation method for porous hydroxyapatite coatings. In particular, it is a method of using suspension plasma spraying to prepare porous hydroxyapatite coatings, which belongs to the technical field of biomedical material preparations. The present invention added a pore-forming agent into the hydroxyapatite suspension with a solid content of 16%-45%. After full stirring, the feedstock materials for plasma spraying were transferred into the injection system, and injected into the high temperature area of the central plasma flame. Then, the feedstock materials made the heat exchange with the high plasma flame of plasma spraying gun. Then the sprayed raw materials were subjected to breakup and refinement of the droplets, solvent evaporation, the decomposition and gasification of the pore-forming agent and melting of feedstock materials. Finally, the porous hydroxyapatite coatings are directly deposited onto the substrate surfaces of the biomedical materials.

Owner:SICHUAN UNIV

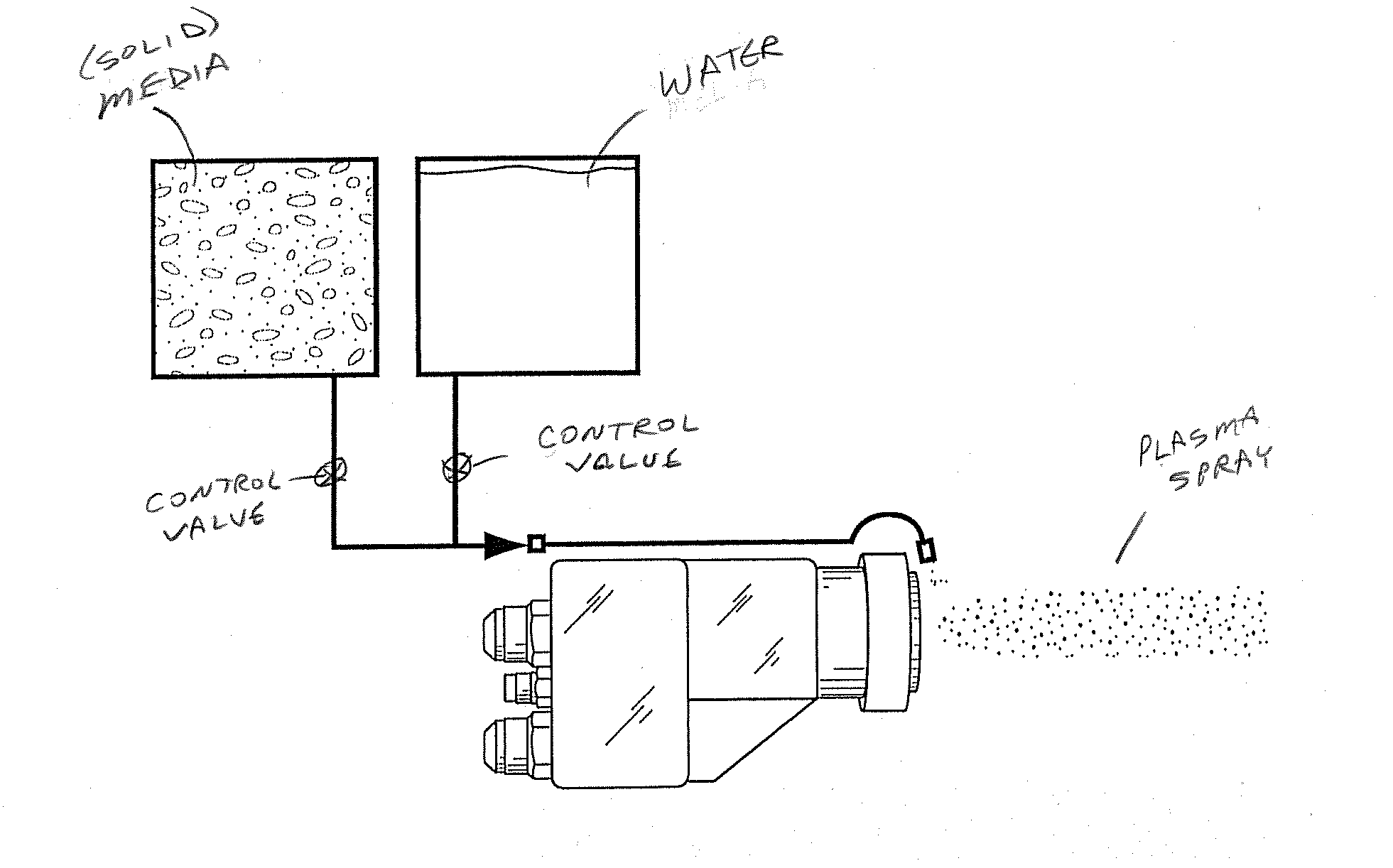

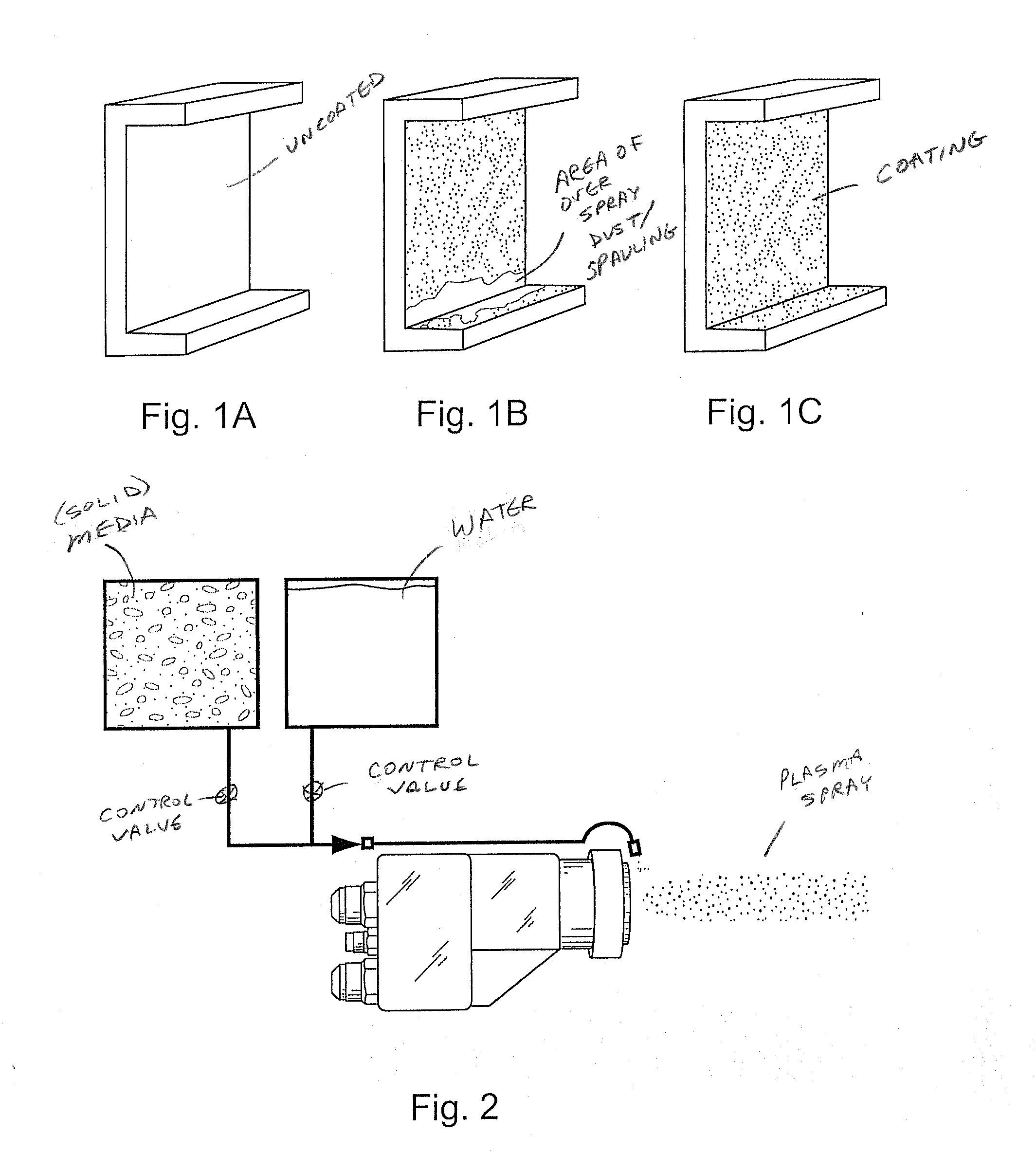

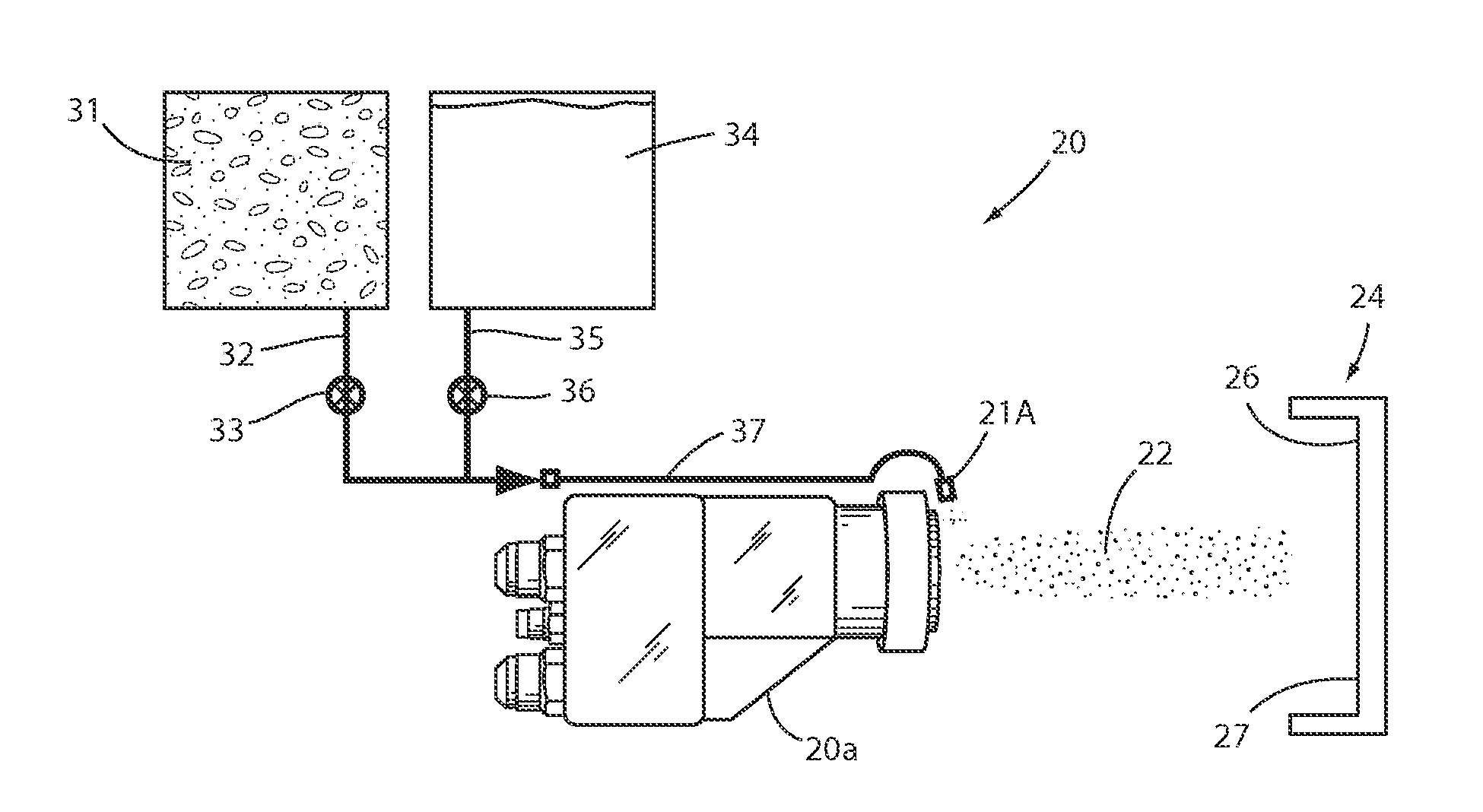

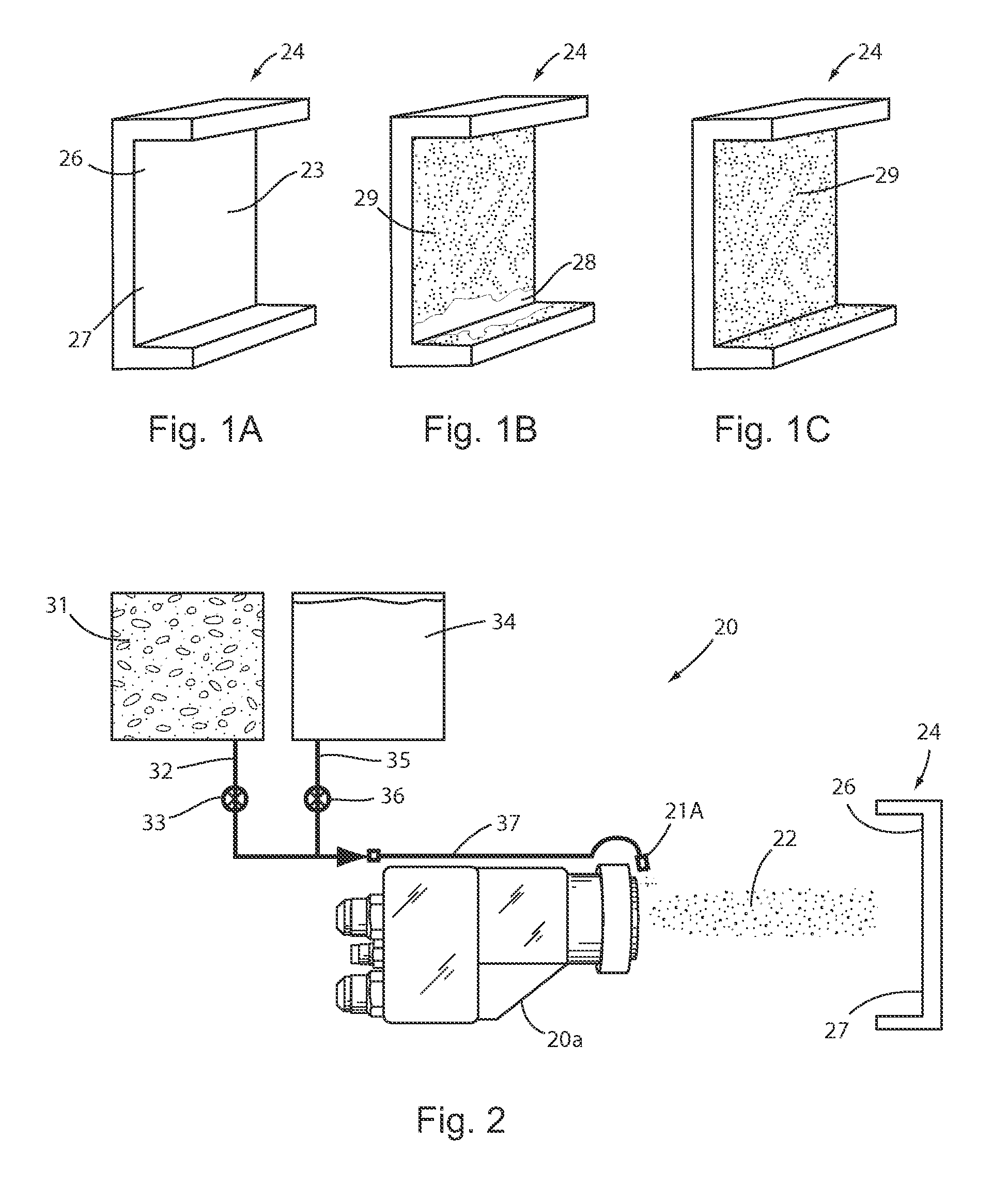

Plasma spray apparatus integrating water cleaning

An integrated apparatus and method comprises a plasma gun with a water supply, treatment fluid supply, and controls, the combination of which is adapted for directing a plume onto a surface of a three-dimensional part to treat the surface; and for controlling injection of water into the plume with the plume directed onto an adjacent surface to clean debris and undesired material from the adjacent surface; and for subsequently directing the plume (without water) onto the adjacent surface to treat the adjacent surface. The apparatus and method are particularly useful in suspension plasma spray systems, but are not believed to be limited to that.

Owner:PROGRESSIVE SURFACE

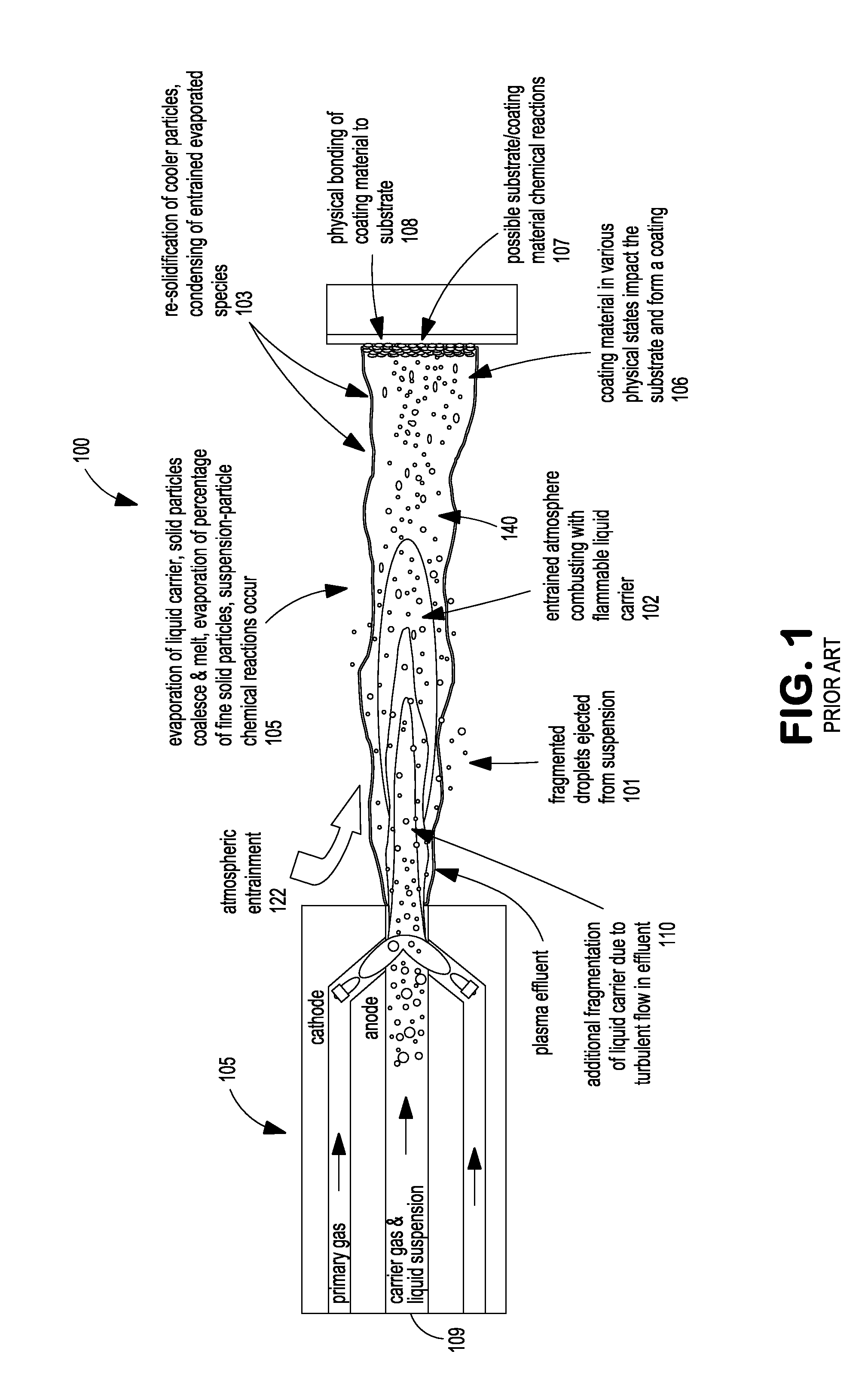

Reactive gas shroud or flame sheath for suspension plasma spray processes

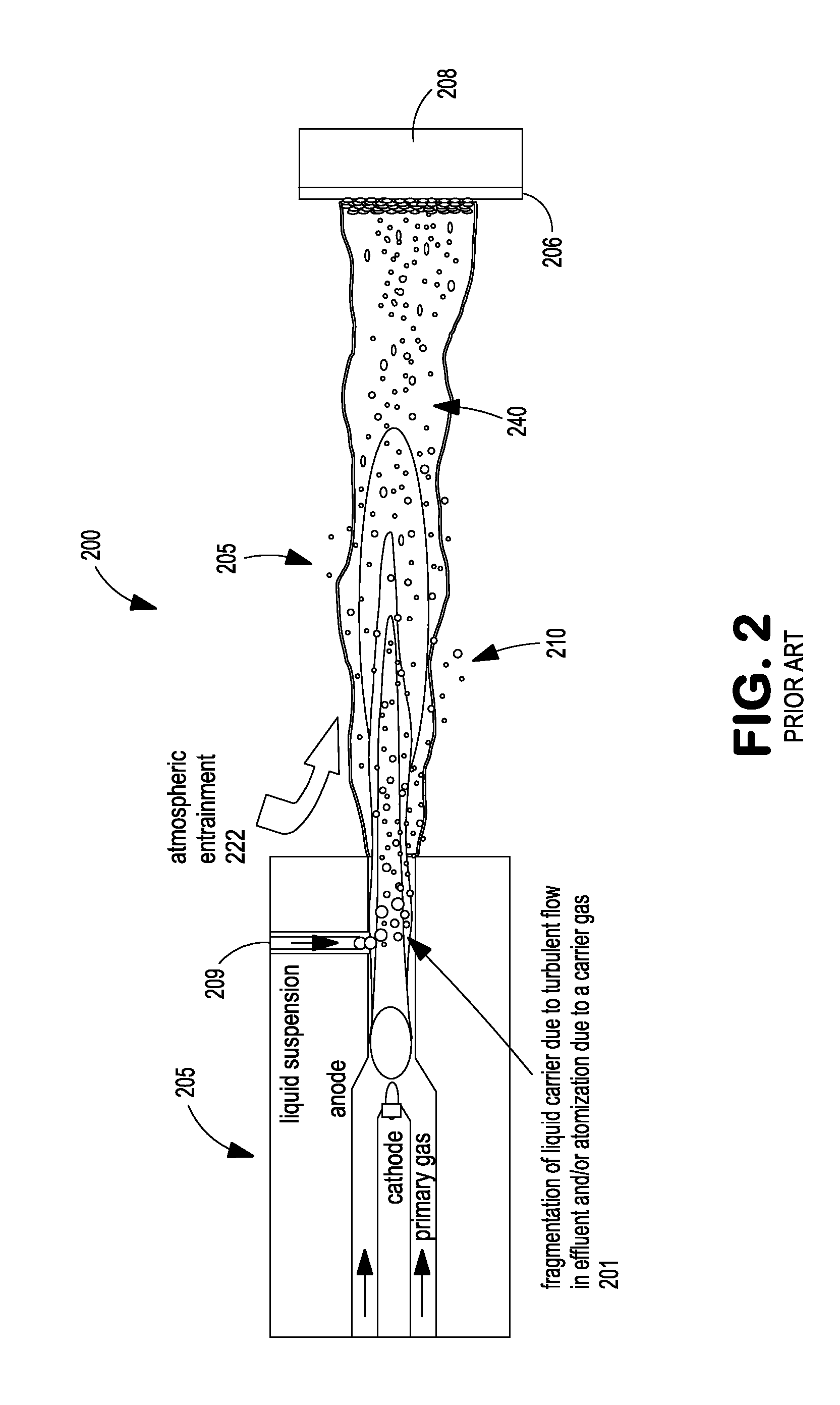

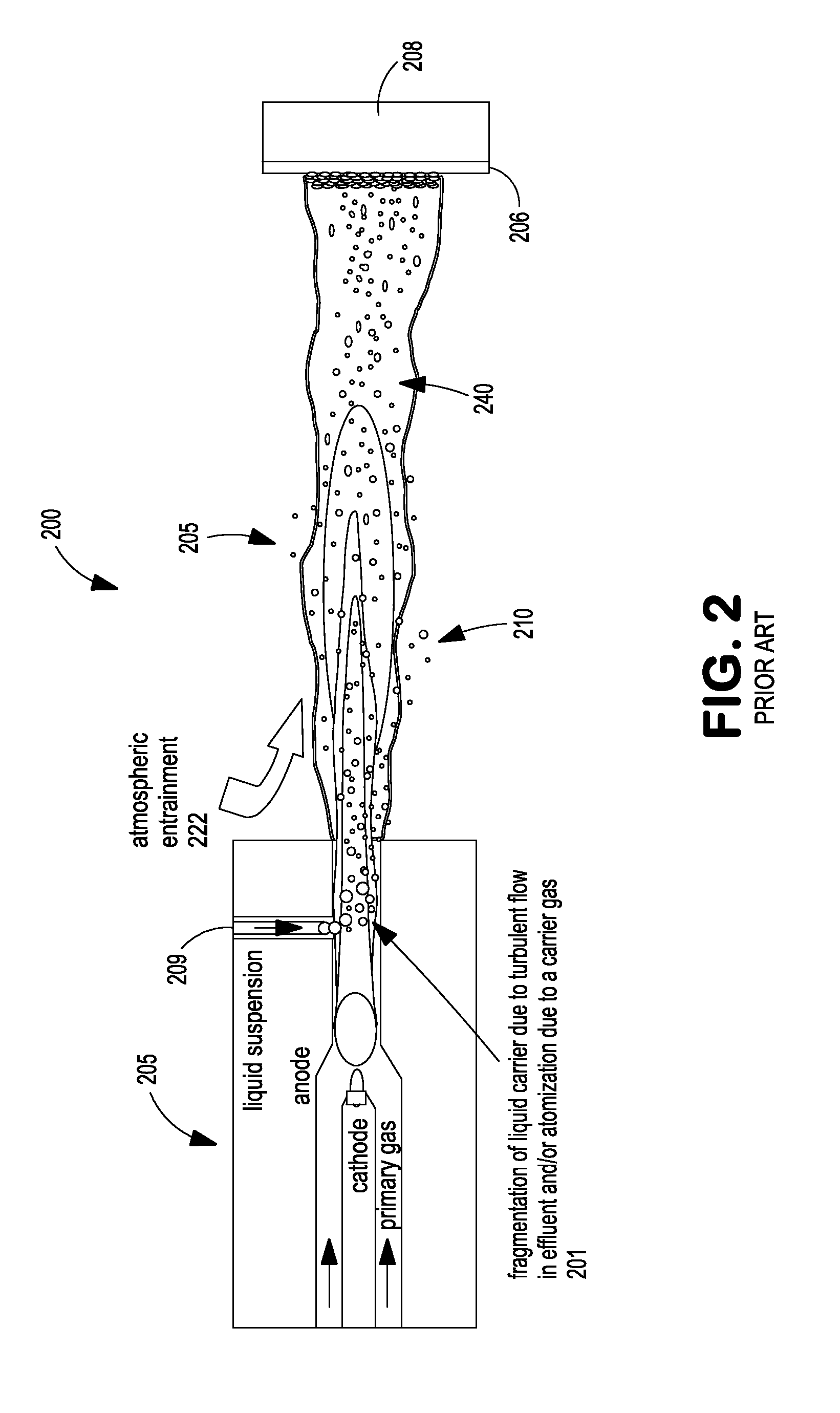

InactiveUS20130156968A1Improve abilitiesProvide controlLiquid surface applicatorsMolten spray coatingReactive gasTorch

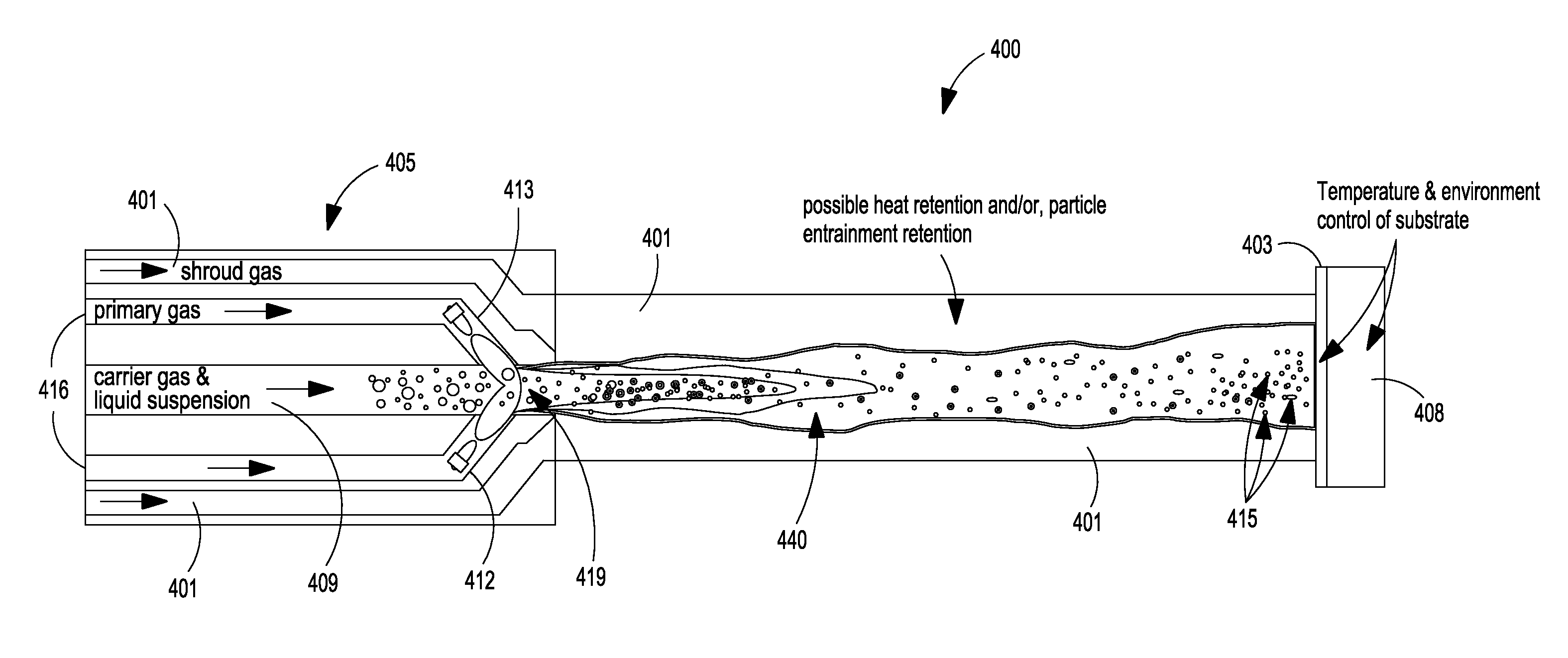

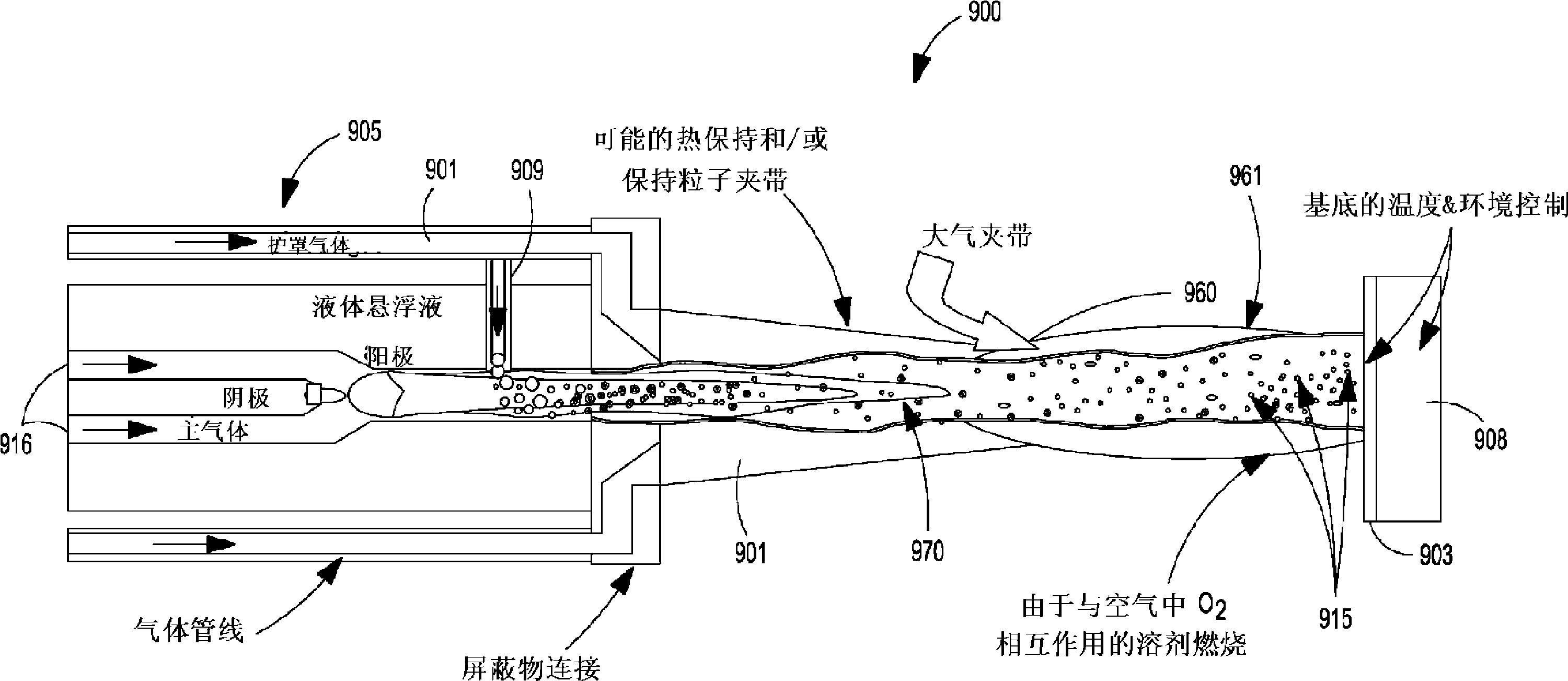

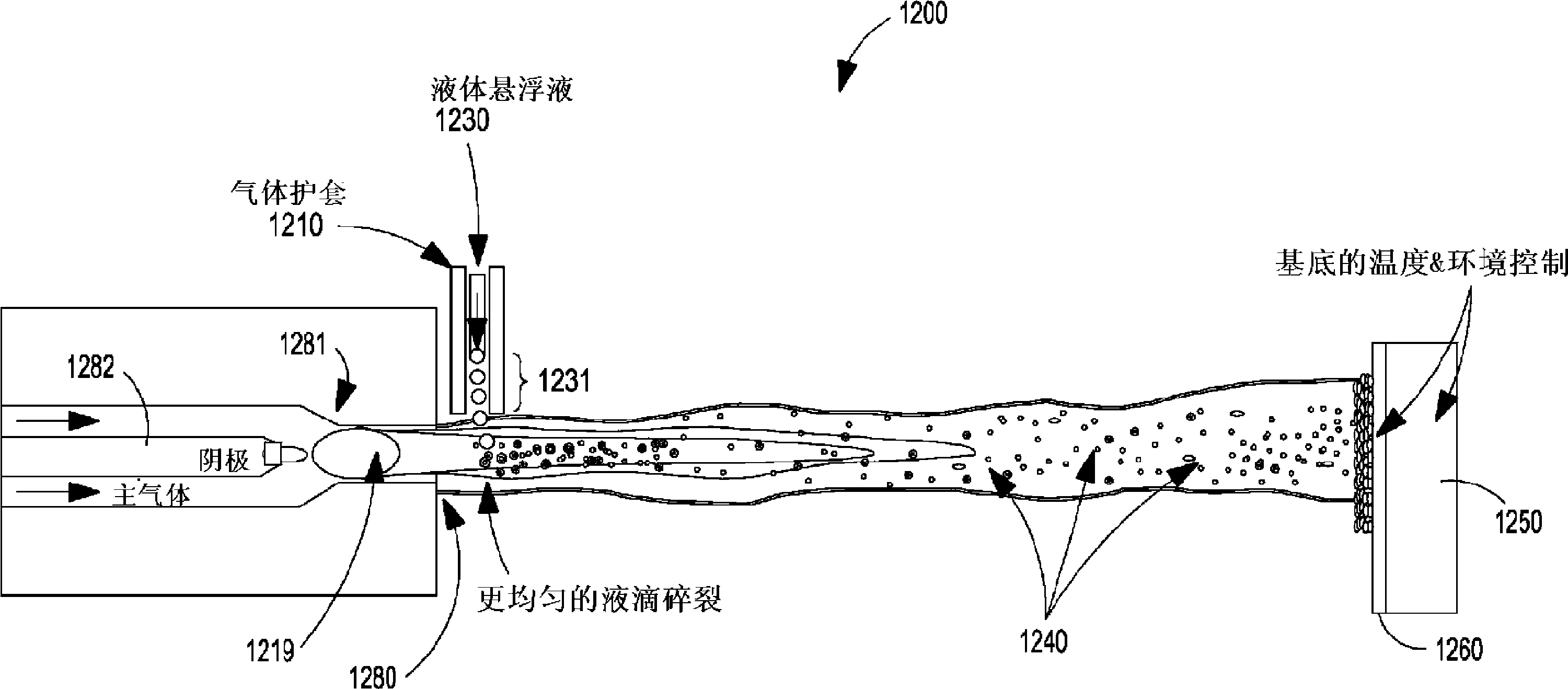

A system and method for producing thermal spray coatings on a substrate from a liquid suspension is disclosed. The disclosed system and method include a thermal spray torch for generating a plasma and a liquid suspension delivery subsystem for delivering a flow of liquid suspension with sub-micron particles to the plasma to produce a plasma effluent. The liquid suspension delivery subsystem comprises an injector or nozzle which can produce a reactive gas shroud surrounding the plasma effluent. A flame envelope can also be used to isolate injection of the liquid suspension. The shroud or flame envelope can retain the sub-micron particles entrained within the plasma effluent and substantially prevent entrainment of ambient gases into the plasma effluent. The liquid suspension delivery subsystem can be arranged as an axial injection system, a radial internal injection system or an external radial injection system.

Owner:PRAXAIR ST TECH INC

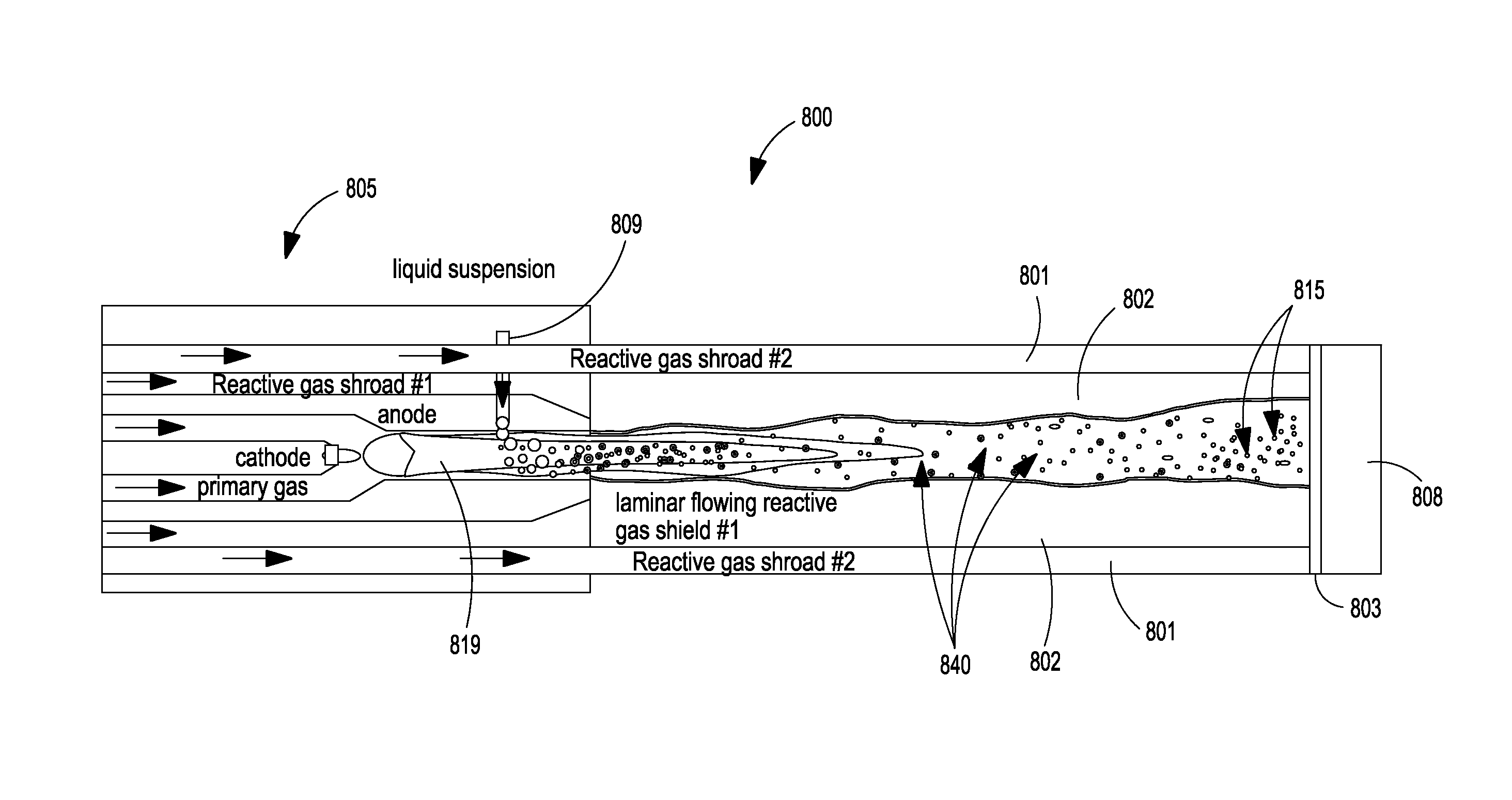

System and method for utilization of shrouded plasma spray or shrouded liquid suspension injection in suspension plasma spray processes

InactiveUS20130157040A1Improve current suspension plasma sprayImprove abilitiesLiquid surface applicatorsMolten spray coatingThermal sprayingReactive gas

A system and method for producing thermal spray coatings on a substrate from a liquid suspension is disclosed. The disclosed system and method include a thermal spray torch for generating a plasma and a liquid suspension delivery subsystem for delivering a flow of liquid suspension with sub-micron particles to the plasma to produce a plasma effluent. The liquid suspension delivery subsystem comprises an injector or nozzle which can produce an inert or reactive gas sheath partially or fully surrounding the plasma effluent. A sheath can also be used to isolate injection of the liquid suspension. A gas assist stream can also be employed at or near the suspension injection point. The shroud, sheath or gas assist technique can retain the sub-micron particles entrained within the plasma effluent and substantially prevent entrainment of ambient gases into the plasma effluent. The liquid suspension delivery subsystem can be arranged as an axial injection system, a radial internal injection system or an external radial injection system.

Owner:PRAXAIR ST TECH INC

Method for coating a surface of a solid substrate with a layer comprising a ceramic compound, and coated substrate thus obtained

ActiveCN109874330AImprove patienceUniform toleranceMolten spray coatingBlade accessoriesPlasma jetPolymer science

The invention relates to a method for coating at least one surface of a solid substrate with at least one layer comprising at least one ceramic compound by a suspension plasma spraying (SPS) technique, in which at least one suspension of solid particles of at least one ceramic compound is injected into a plasma jet, and then the thermal jet that contains the solid particle suspension is sprayed onto the surface of the substrate, by means of which the layer comprising at least one ceramic compound is formed on the surface of the substrate; method characterised in that, in the suspension, at least 90 vol% of the solid particles have a larger dimension (referred to as d90), such as a diameter, smaller than 15 mum, preferably smaller than 10 mum, and at least 50 vol% of the solid particles have a larger dimension, such as a diameter (referred to as d50), no smaller than 1 mum. The invention also relates to a substrate coated with at least one layer that can be obtained by said method. Theinvention also relates to a part comprising said coated substrate. The invention further relates to the use of said layer in order to protect a solid substrate against degradations caused by contaminants such as CMAS.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

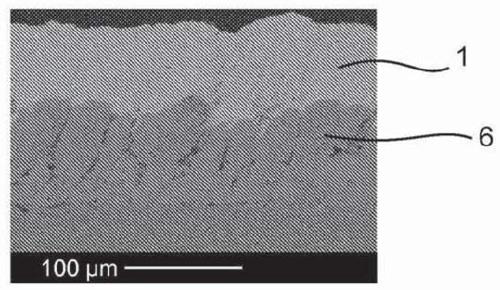

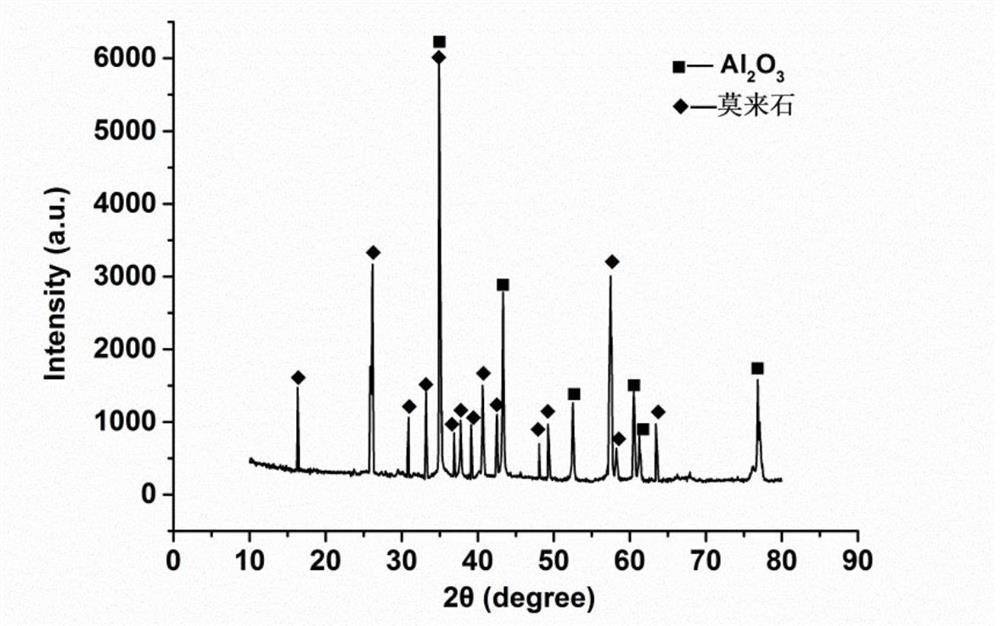

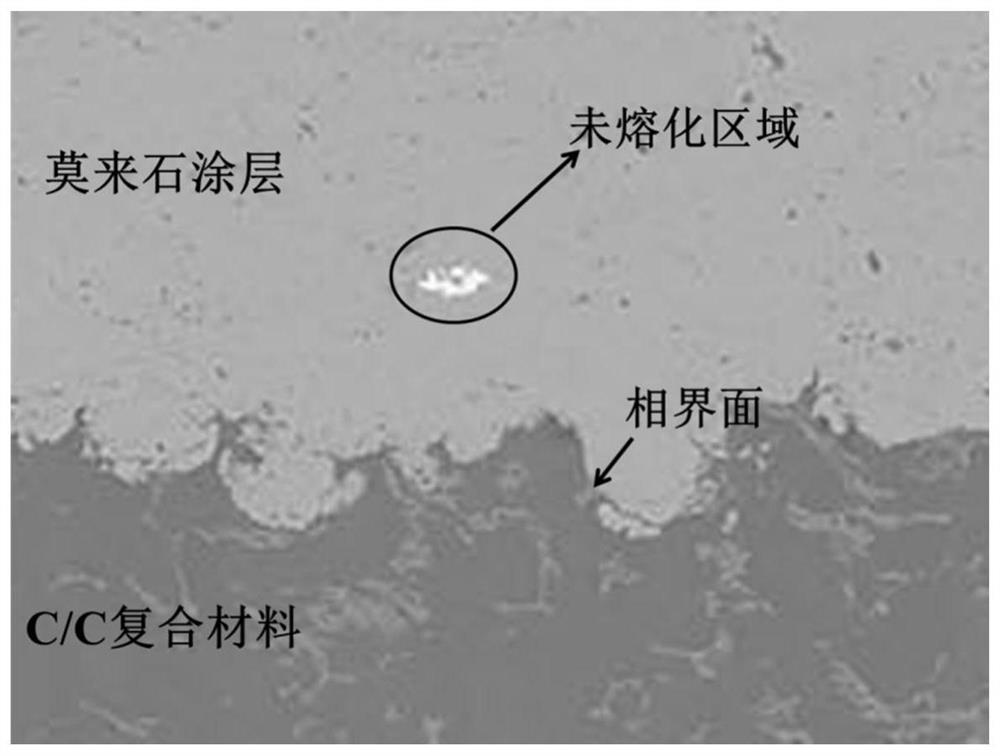

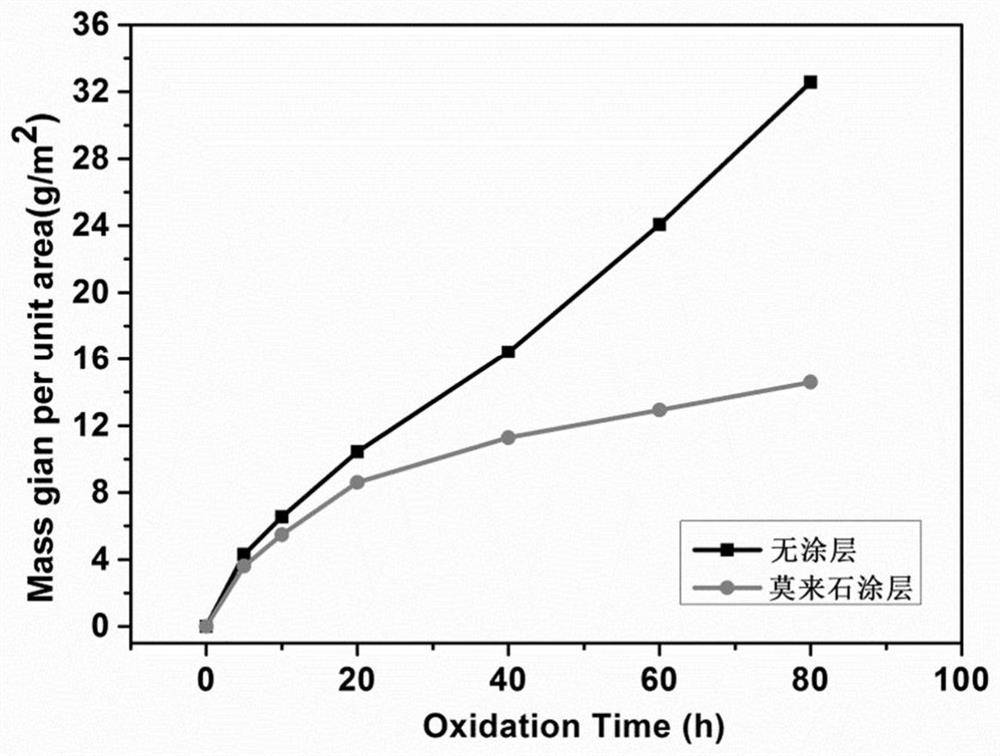

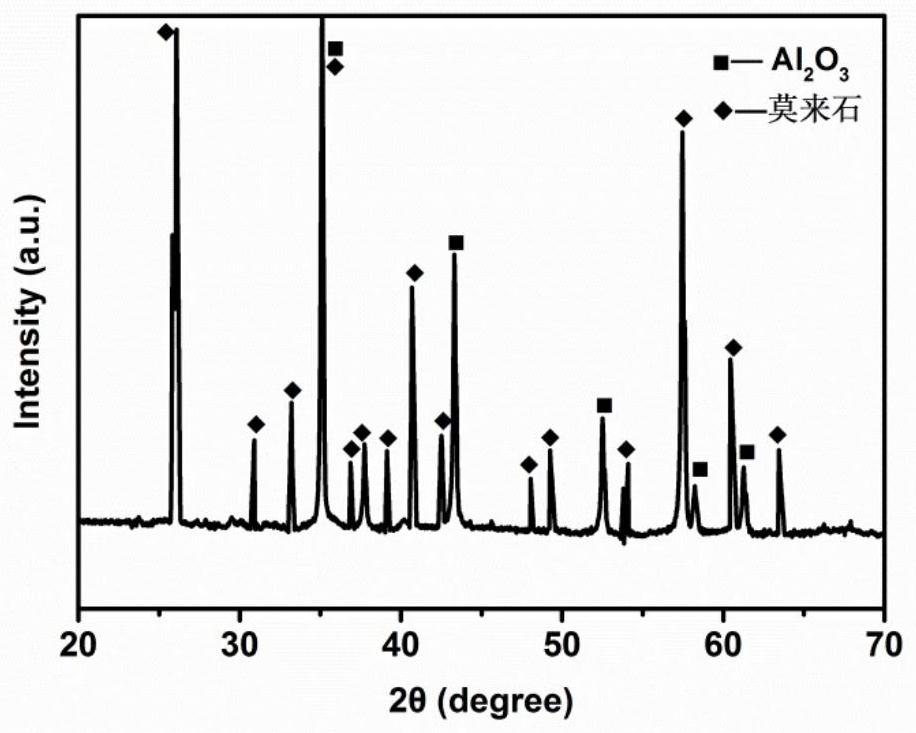

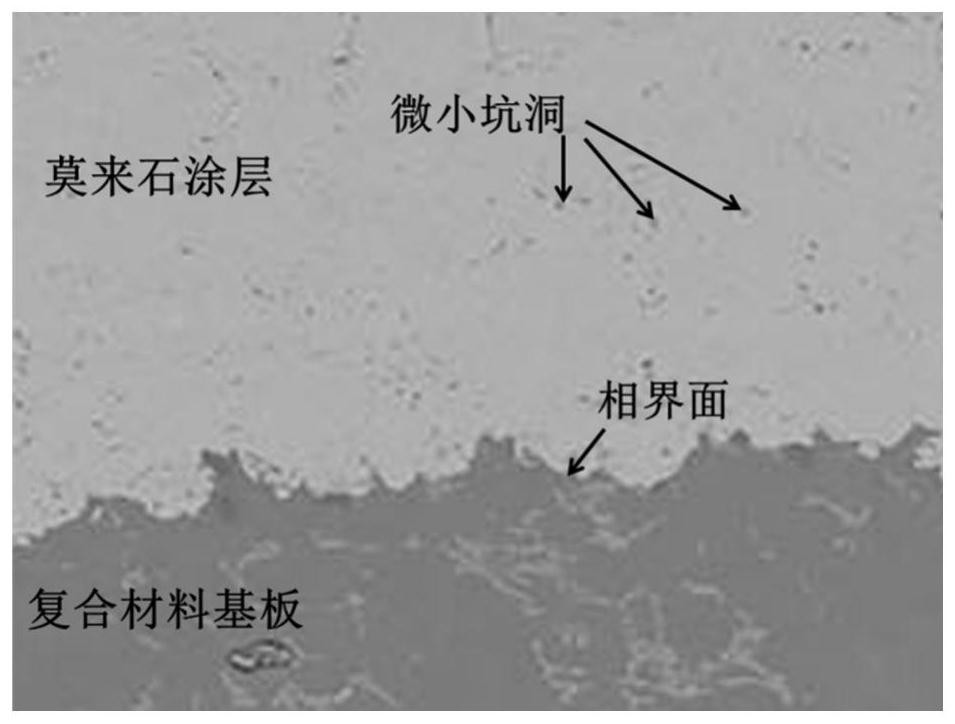

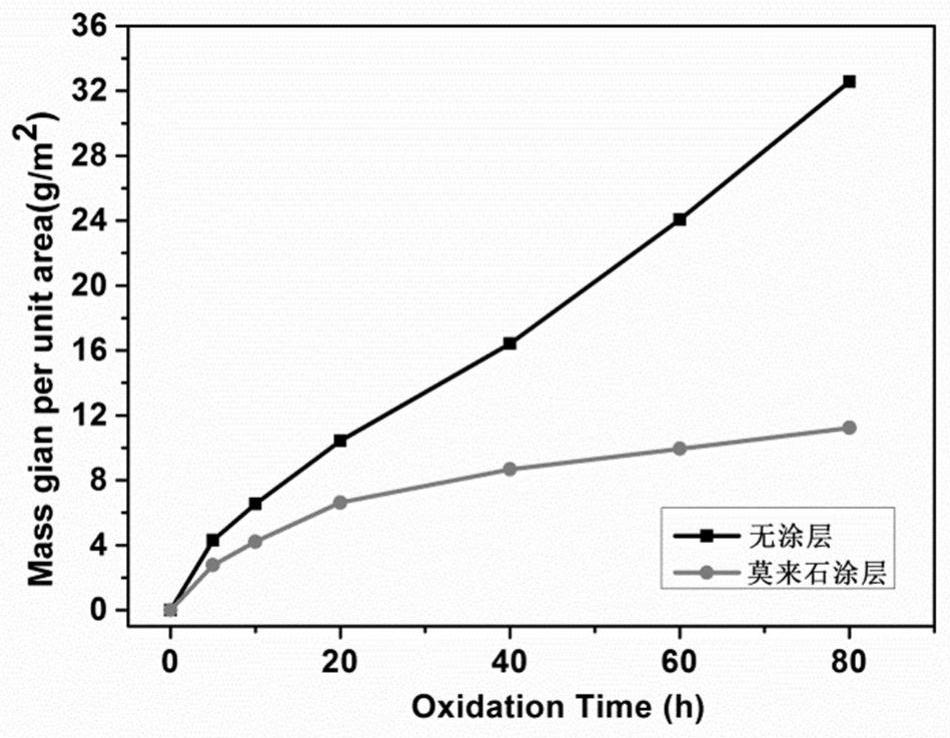

Mullite high-temperature anti-oxidation coating on surface of composite material and preparation method of mullite high-temperature anti-oxidation coating

The invention discloses a mullite high-temperature anti-oxidation coating on the surface of a composite material and a preparation method of the mullite high-temperature anti-oxidation coating. The preparation method comprises the following steps of: preparing an Al (NO3) 3.9 H2O solution with a set concentration; dropwise adding excessive ammonia water into the solution obtained in the previous step, and continuously stirring until white precipitate is generated; adding transparent silica sol into the white precipitate; placing the mixed suspension in the previous step on a roller type ball mill for ball milling; placing a C / C composite material plate and the mixed suspension on liquid-phase plasma spraying equipment, and preparing Al (OH) 3 and SiO2 coatings on the composite material plate by using suspension plasma spraying equipment; and carrying out vacuum heat treatment on the prepared coatings at high temperature to make the coatings react to generate a mullite coating. According to the invention, Al2O3 and SiO2 are compounded to generate a mullite phase with good high-temperature stability, so that the oxidation resistance of the composite material is improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

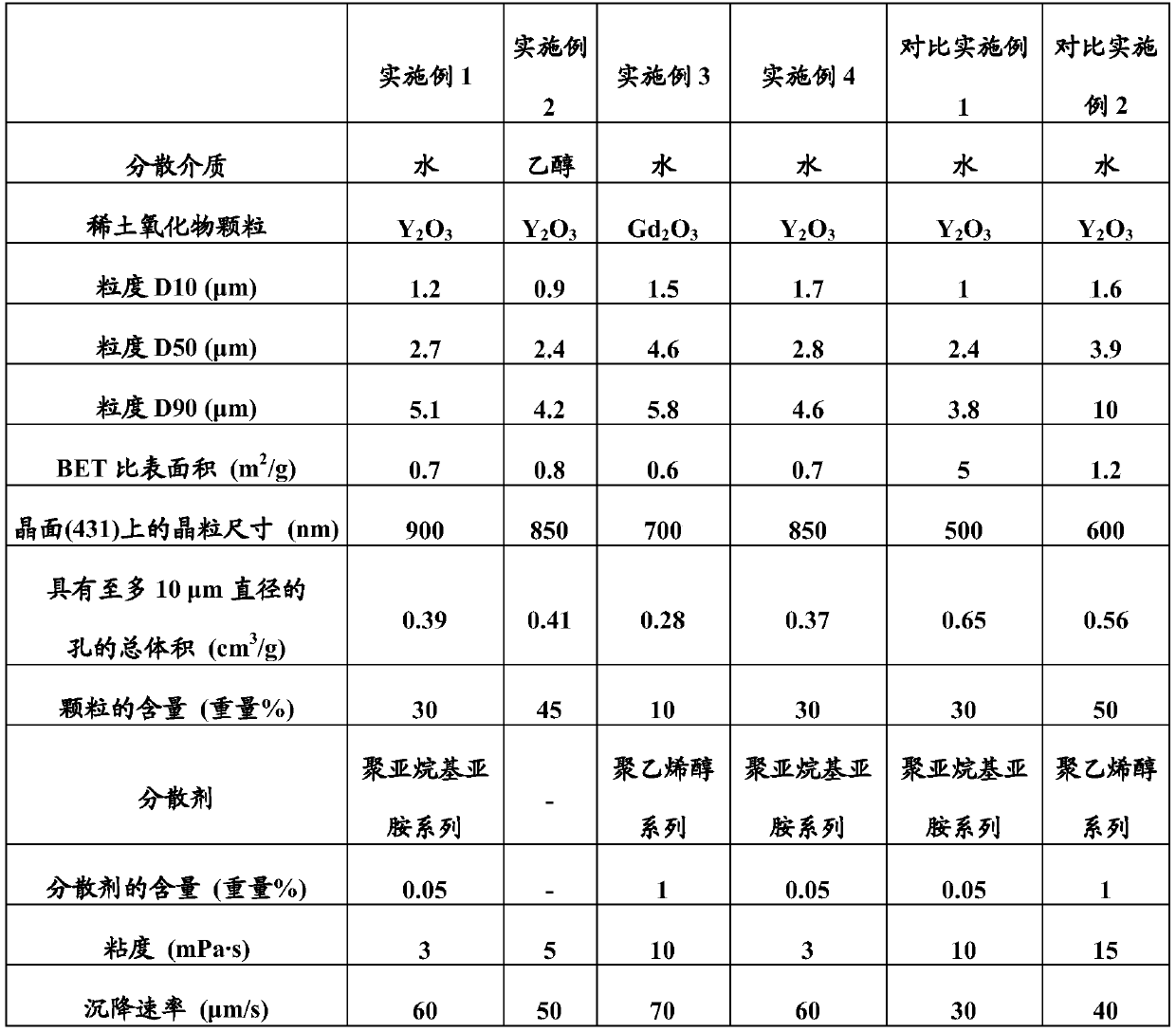

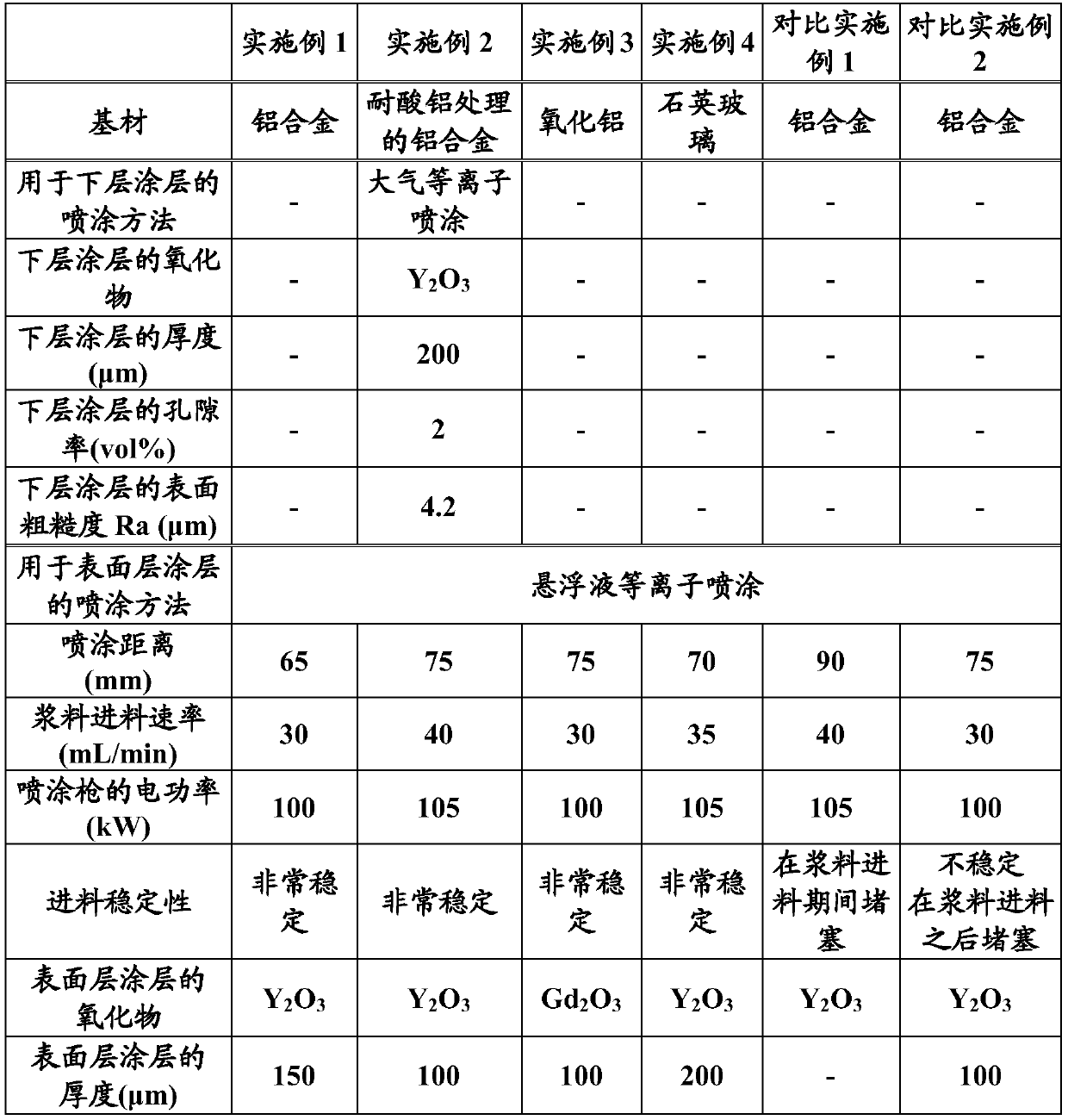

Slurry for suspension plasma spraying and method for forming sprayed coating

ActiveCN110819933AImprove corrosion resistanceMolten spray coatingYittrium oxides/hydroxidesMetallurgySlurry

The invention relates to a slurry for suspension plasma spraying and a method for forming sprayed coating. The invention provides a slurry for use in suspension plasma spraying including a dispersionmedium and rare earth oxide particles, the rare earth oxide particles having a particle size D50 of 1.5 to 5 [mu]m and a BET specific surface area of less than 1 m2 / g, and a content of the rare earthoxide particles in the slurry being 10 to 45 wt %.

Owner:SHIN ETSU CHEM CO LTD

Method for preparing continuous gradient biological coating by utilizing suspension plasma spraying

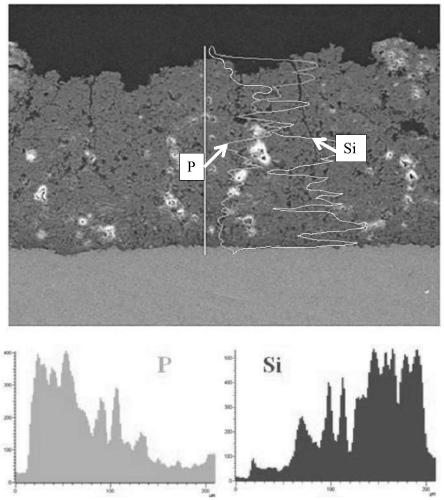

ActiveCN111286691AReduce internal stressReduce sensitivityMolten spray coatingCalcium silicateFluorohydroxyapatite

The invention discloses a method for preparing a continuous gradient biological coating by utilizing suspension plasma spraying. A calcium silicate / fluorohydroxyapatite continuous gradient biologicalcoating is prepared on the surface of a titanium or titanium alloy matrix by utilizing a suspension plasma spraying method. The high bonding strength between a calcium silicate coating and the titanium matrix and the low solubility of fluorohydroxyapatite are utilized, solid phase components of a mixed solution are gradually changed by adjusting the liquid feeding rates of two suspensions, the continuous gradient coating is prepared on the surface of the titanium or titanium alloy matrix by adopting a suspension plasma spraying technology, namely, the calcium silicate is arranged at the bottomof the coating, the fluorohydroxyapatite is arranged at the top of the coating, gradient component transition is achieved between the top and the bottom, the internal stress of the coating can be greatly reduced through gradient design, and the sensitivity at an interface is reduced. The binding force between the calcium silicate / fluorohydroxyapatite gradient coating and the titanium matrix is obviously improved, the dissolution rate is obviously reduced, and the coating shows good biological activity and antibacterial activity.

Owner:INNER MONGOLIA UNIV OF TECH

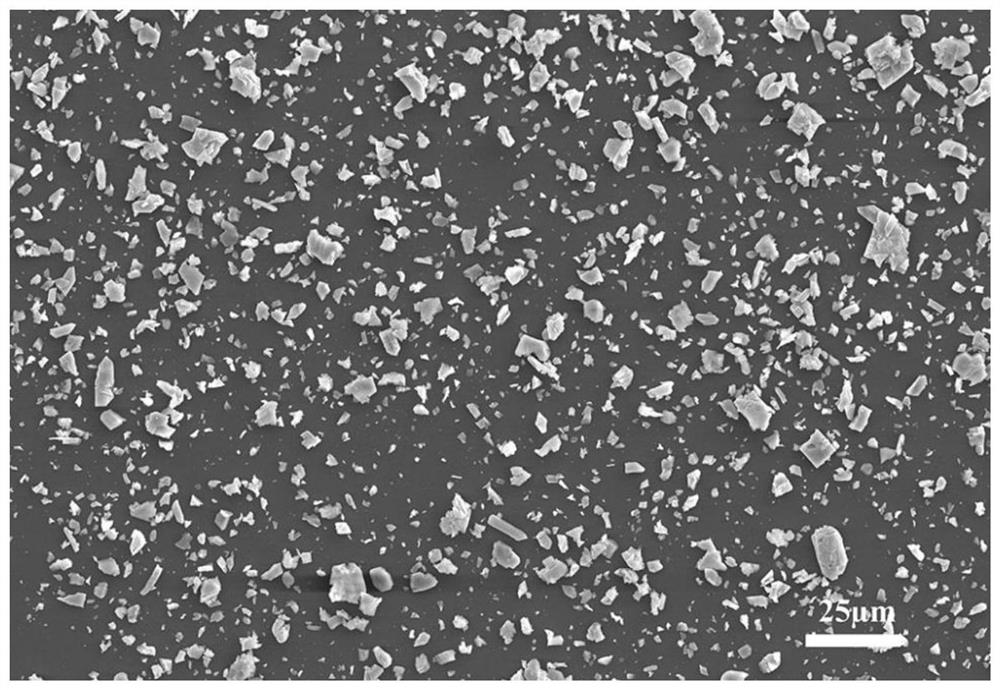

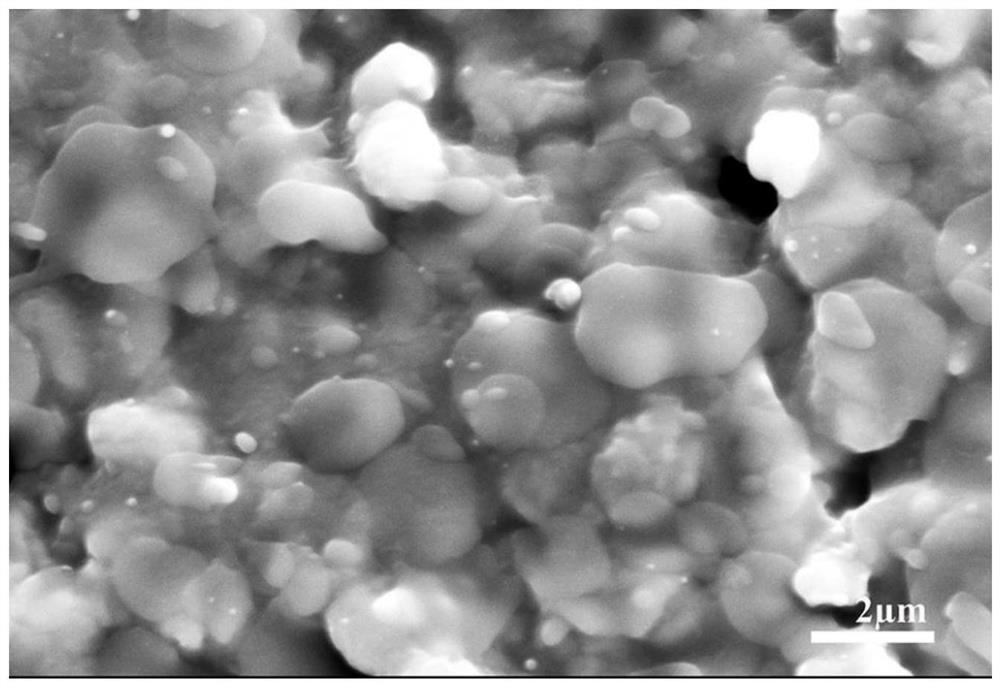

Filtration membrane and methods of use and manufacture thereof

ActiveUS20200353424A1High mechanical propertiesRemove pollutantsMembranesSemi-permeable membranesPolymer scienceFiltration membrane

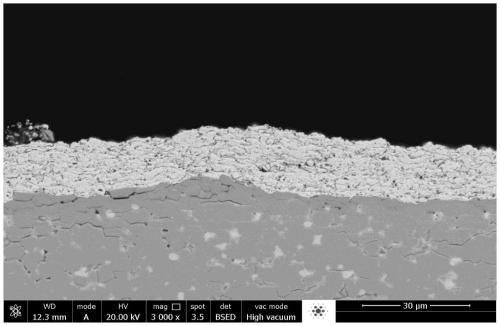

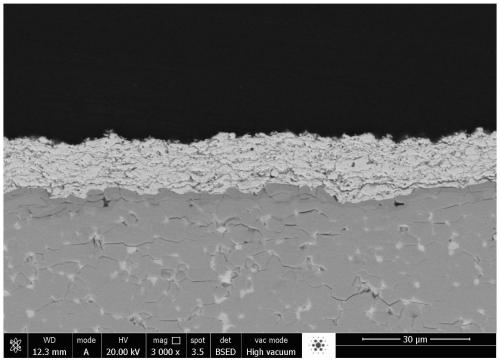

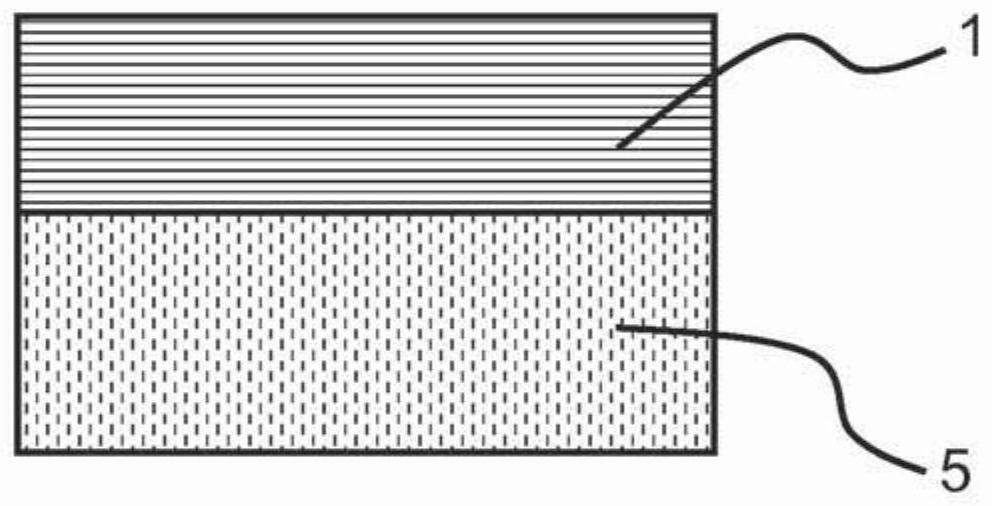

A filtration membrane is provided. It comprises a porous support substrate and a porous active layer on top of the support substrate, wherein the active layer is formed of a network of interconnected, randomly arranged ceramic splats with ceramic particles occupying interstices between the splats, and wherein free spaces between the particles define a network of interconnected pores extending through the thickness of the active layer. There are also provided a method of filtering a feed using the membrane and a method of manufacturing the membrane by suspension plasma spraying.

Owner:VALORBEC PARTNERSHIP

System and method for utilization of shrouded plasma spray or shrouded liquid suspension injection in suspension plasma spray processes

InactiveCN104114737AMolten spray coatingLiquid spraying apparatusSuspension plasma sprayLiquid suspension

A system and method for producing thermal spray coatings on a substrate from a liquid suspension is disclosed. The disclosed system and method include a thermal spray torch for generating a plasma and a liquid suspension delivery subsystem for delivering a flow of liquid suspension with sub-micron particles to the plasma to produce a plasma effluent. The liquid suspension delivery subsystem comprises an injector or nozzle which can produce an inert or reactive gas sheath partially or fully surrounding the plasma effluent. A sheath can also be used to isolate injection of the liquid suspension. A gas assist stream can also be employed at or near the suspension injection point. The shroud, sheath or gas assist technique can retain the sub-micron particles entrained within the plasma effluent and substantially prevent entrainment of ambient gases into the plasma effluent. The liquid suspension delivery subsystem can be arranged as an axial injection system, a radial internal injection system or an external radial injection system.

Owner:PRAXAIR ST TECH INC

Suspension plasma spraying high-purity Y2O3 erosion-resistant coating and preparation method and application thereof

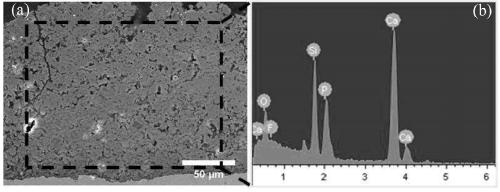

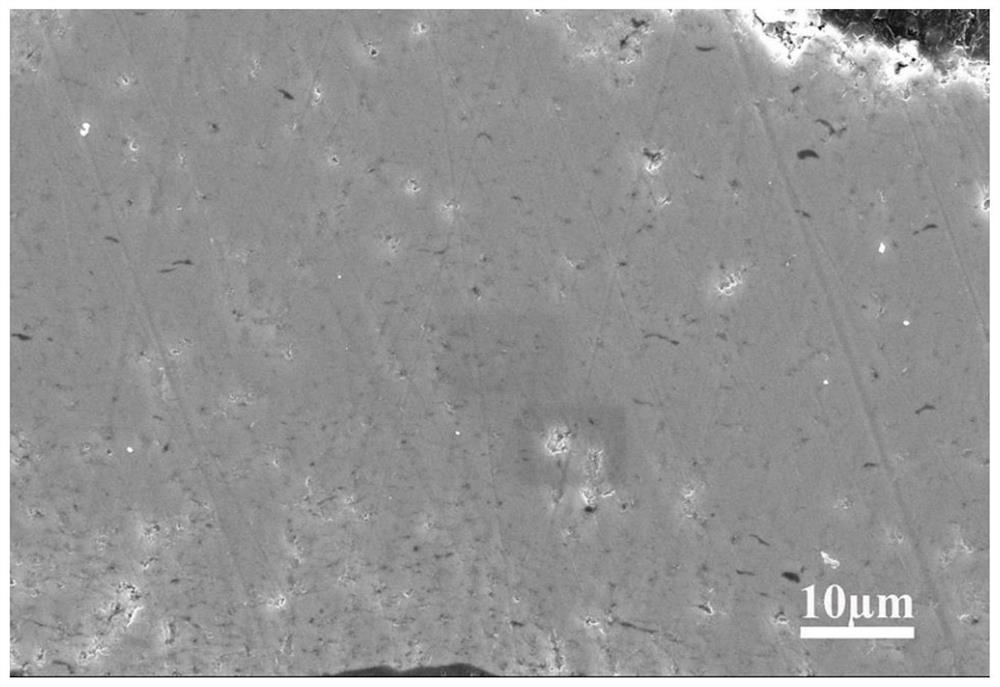

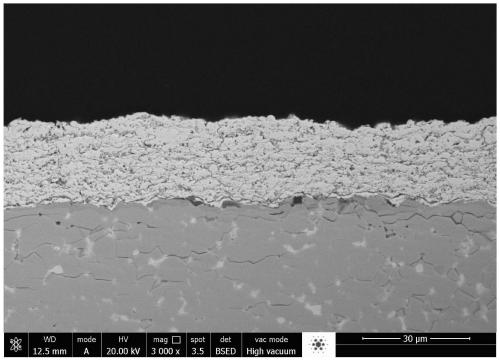

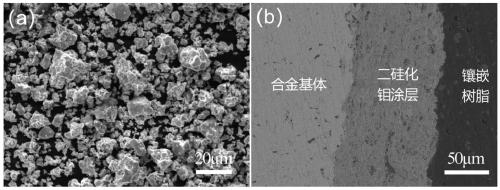

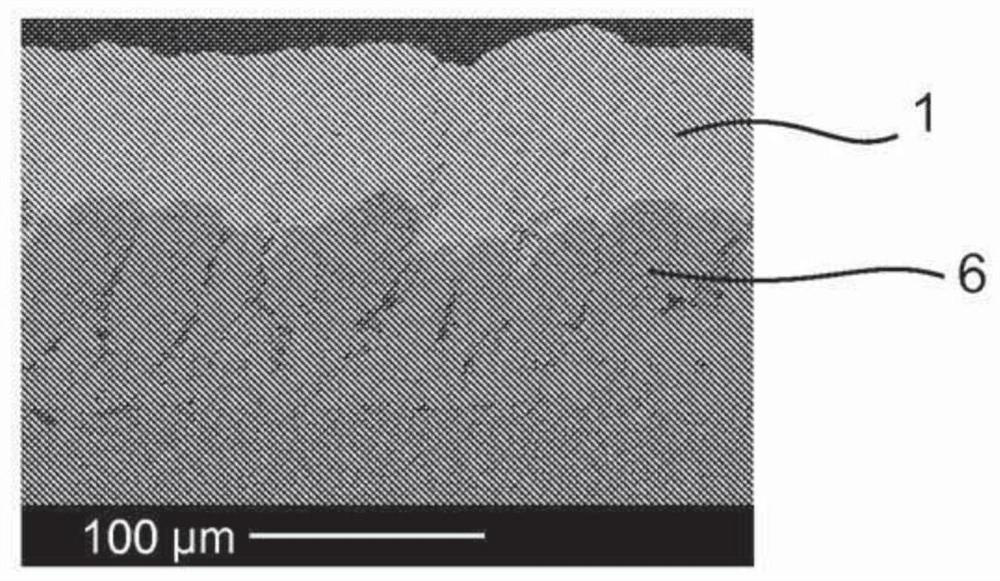

PendingCN112063956ALoose tissue defectUniform and dense coating sectionMolten spray coatingMicro nanoCrazing

The invention discloses a suspension plasma spraying (SPS) high-purity Y2O3 erosion-resistant coating and a preparation method and application thereof, and belongs to the field of suspension plasma spraying. Micro-nano superfine Y2O3 powder is sprayed on the surface of an aluminum alloy through a suspension plasma spraying process to prepare the Y2O3 coating. According to the preparation method, the problems that a traditional atmospheric plasma spraying (APS) method and a current SPS method are complex in powder preparation process, the porosity of the coating is high, the microstructure of the coating is not uniform, the number of structure defects is large, and the plasma erosion degradation rate is high are solved. The prepared SPS high-purity Y2O3 erosion-resistant coating is uniformand dense in cross section, free of vertical or transverse microscopic cracks and free of convex structures and loose and porous columnar-crystal-like structure defects, and the density is close to that of a sintered Y2O3 ceramic block; and the plasma erosion resistance of the coating can be greatly improved, the maintenance cost of a plasma etching machine is reduced, and the service life of an aluminum alloy cavity is prolonged.

Owner:JINAN UNIVERSITY

Slurry for suspension plasma spraying, and method for forming sprayed coating

ActiveUS20200048752A1Improve corrosion resistanceSuitable for useMolten spray coatingYittrium oxides/hydroxidesMetallurgySlurry

A slurry for use in suspension plasma spraying including a dispersion medium and rare earth oxide particles, the rare earth oxide particles having a particle size D50 of 1.5 to 5 μm and a BET specific surface area of less than 1 m2 / g, and a content of the rare earth oxide particles in the slurry being 10 to 45 wt %.

Owner:SHIN ETSU CHEM IND CO LTD

Plasma spray apparatus integrating water cleaning

InactiveUS20140349023A1Liquid surface applicatorsMolten spray coatingPlasma sprayedSuspension plasma spray

An integrated apparatus and method comprises a plasma gun with a water supply, treatment fluid supply, and controls, the combination of which is adapted for directing a plume onto a surface of a three-dimensional part to treat the surface; and for controlling injection of water into the plume with the plume directed onto an adjacent surface to clean debris and undesired material from the adjacent surface; and for subsequently directing the plume (without water) onto the adjacent surface to treat the adjacent surface. The apparatus and method are particularly useful in suspension plasma spray systems, but are not believed to be limited to that.

Owner:PROGRESSIVE SURFACE

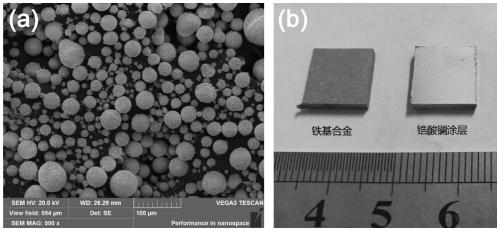

Preparation method of neodymium-iron-boron magnet surface suspension plasma spraying coating

ActiveCN111304577ASolve the difficult problem of transportationSimple processMolten spray coatingInductances/transformers/magnets manufactureRare-earth elementMetallurgy

The invention discloses a preparation method of a neodymium-iron-boron magnet surface suspension plasma spraying coating. The preparation method comprises the following steps that (1), a rare earth suspension is prepared; (2), spraying is carried out on double sides of a neodymium-iron-boron magnet by adopting a suspension plasma spraying technology to obtain the suspension plasma spraying coating; and (3), the sprayed magnet is treated through a grain boundary thermal diffusion method. According to the method, the plasma spraying technology is combined with the grain boundary thermal diffusion technology, the method has the characteristics of high production efficiency, environmental friendliness and the like, the diffusion depth of heavy rare earth elements in the magnet can be effectively increased, the improvement of the magnetic performance is promoted, and meanwhile, the industrialization process of the grain boundary diffusion technology is accelerated and promoted favorably.

Owner:INNER MONGOLIA UNIV OF TECH +1

Pressure based liquid feed system for suspension plasma spray coatings

ActiveUS9089862B2Reduce cooling effectHigh gas velocityLiquid surface applicatorsMolten spray coatingLiquid jetHeat flow

Apparatus (1) for injecting a liquid in an area of a thermal spray gun (100). The apparatus (1) includes an injector cleaning device (10) having an inlet connectable (19) to at least one feedstock supply line (18), an inlet connectable (17) to at least one gas supply line (16), and an inlet connectable (21) to at least one liquid medium supply line (20). An injector (30) orifice is coupled to the injector cleaning device (10) and is adapted to at least one of inject a liquid jet into a hot stream created in the area of the thermal spray gun (100) and receive feedstock, gas and liquid passing into the inlets.

Owner:SULZER METCO (US) INC

Method for preparing porous hydroxyapatite coatings by suspension plasma spraying

InactiveUS8877283B2Good biological propertiesMolten spray coatingPharmaceutical containersDecompositionPlasma flame

The present invention relates to a preparation method for porous hydroxyapatite coatings. In particular, it is a method of using suspension plasma spraying to prepare porous hydroxyapatite coatings, which belongs to the technical field of biomedical material preparations. The present invention added a pore-forming agent into the hydroxyapatite suspension with a solid content of 16%-45%. After full stirring, the feedstock materials for plasma spraying were transferred into the injection system, and injected into the high temperature area of the central plasma flame. Then, the feedstock materials made the heat exchange with the high plasma flame of plasma spraying gun. Then the sprayed raw materials were subjected to breakup and refinement of the droplets, solvent evaporation, the decomposition and gasification of the pore-forming agent and melting of feedstock materials. Finally, the porous hydroxyapatite coatings are directly deposited onto the substrate surfaces of the biomedical materials.

Owner:SICHUAN UNIV

Slurry for suspension plasma spraying, method for forming rare earth acid fluoride sprayed film, and spraying member

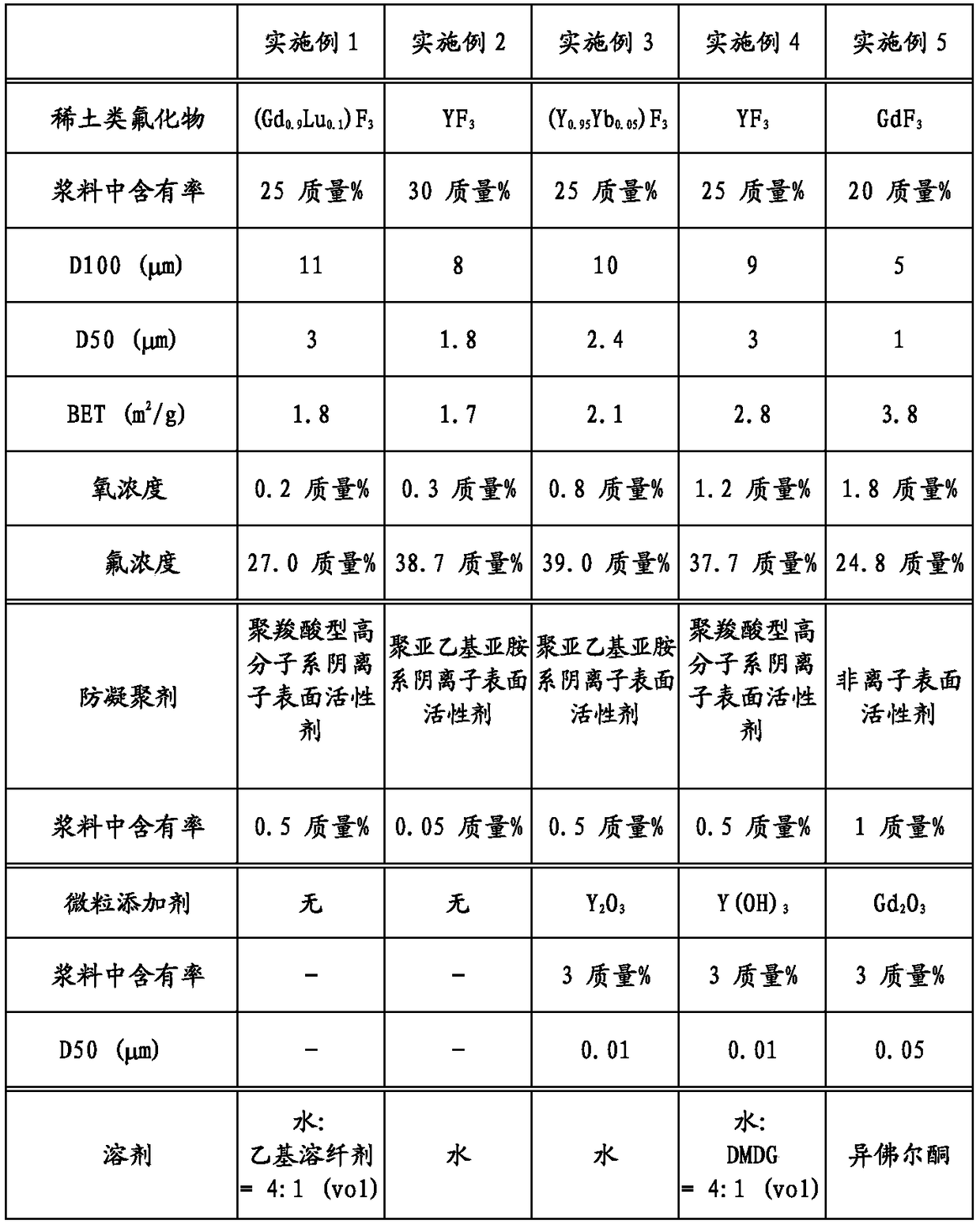

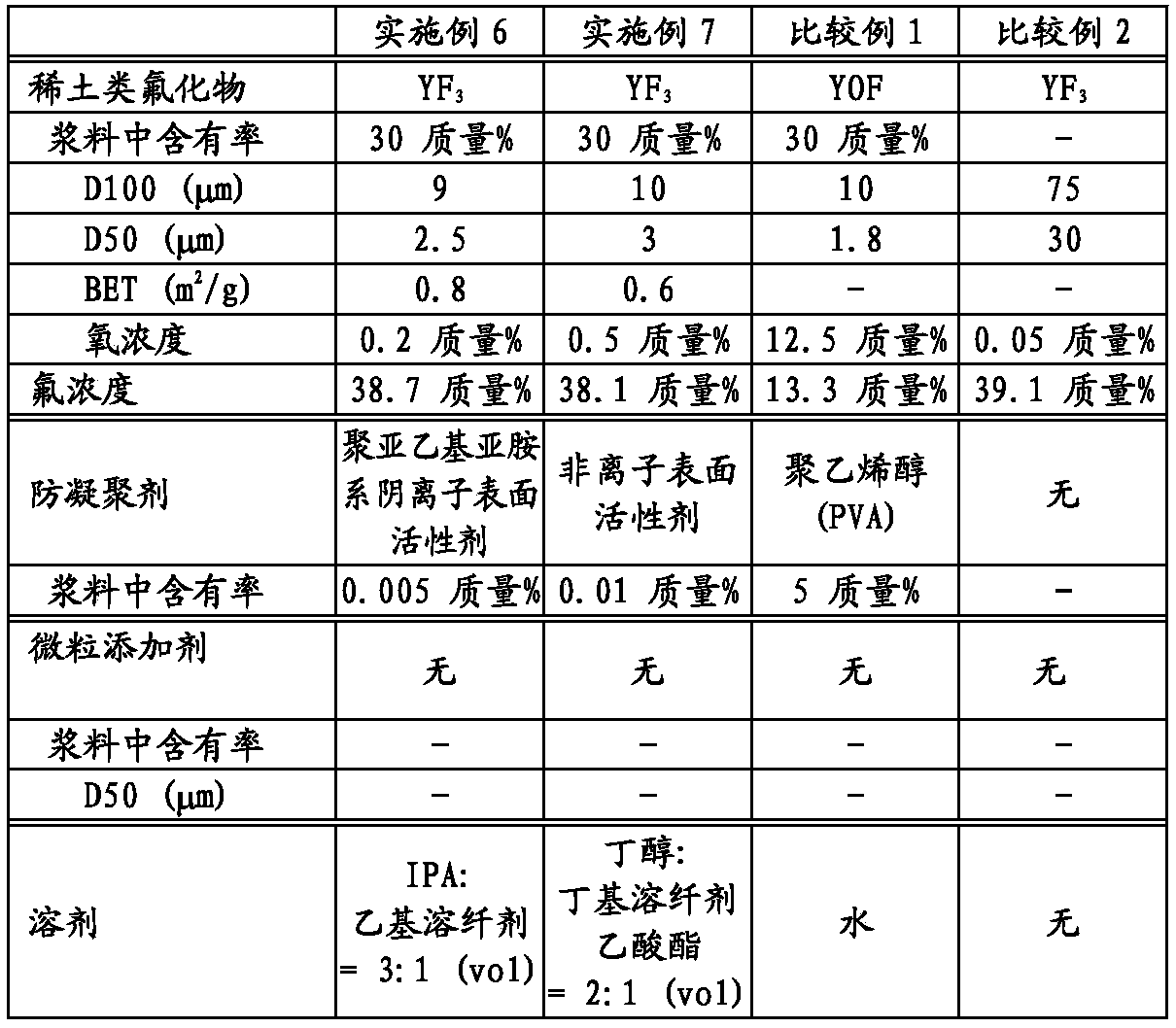

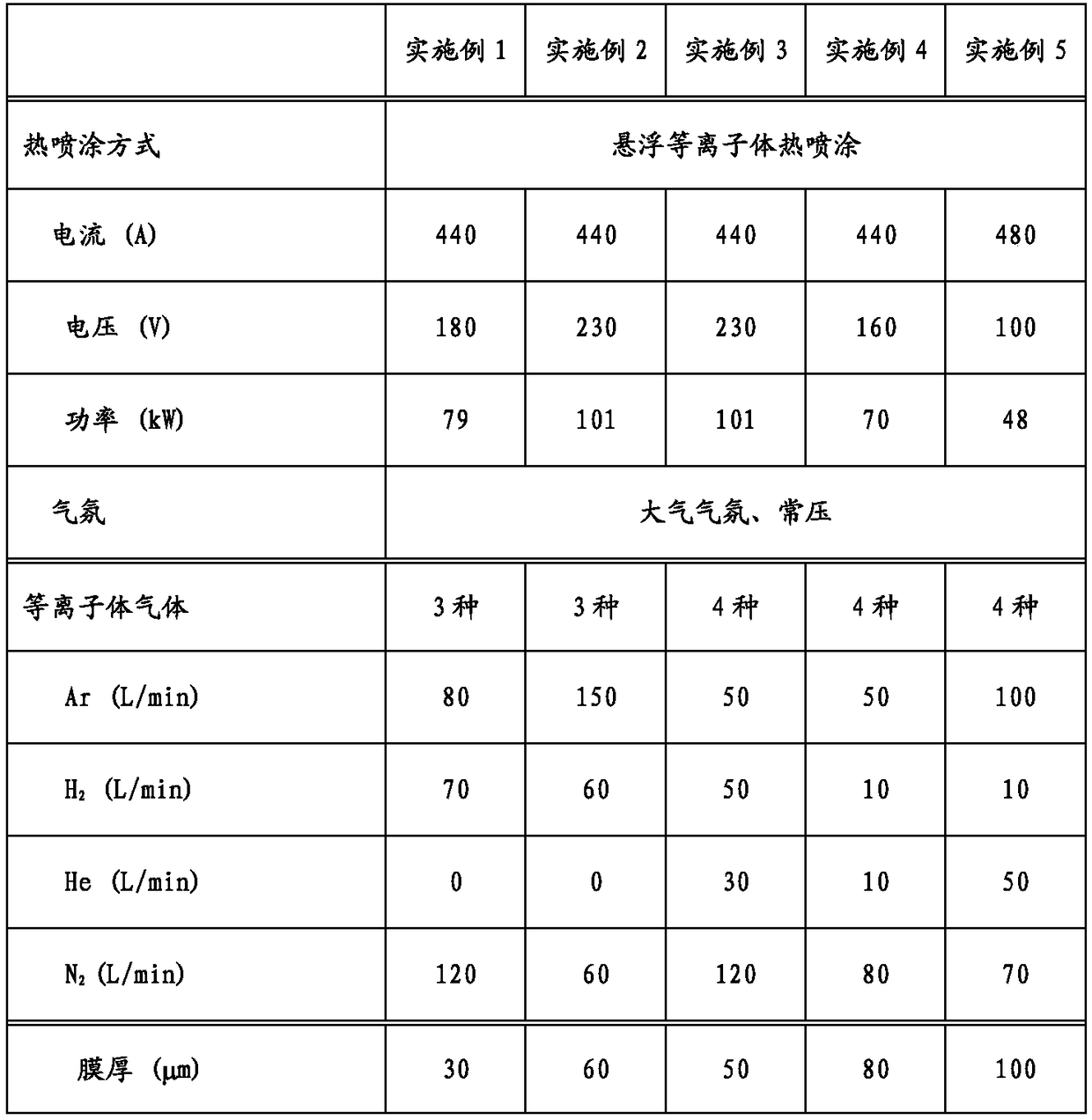

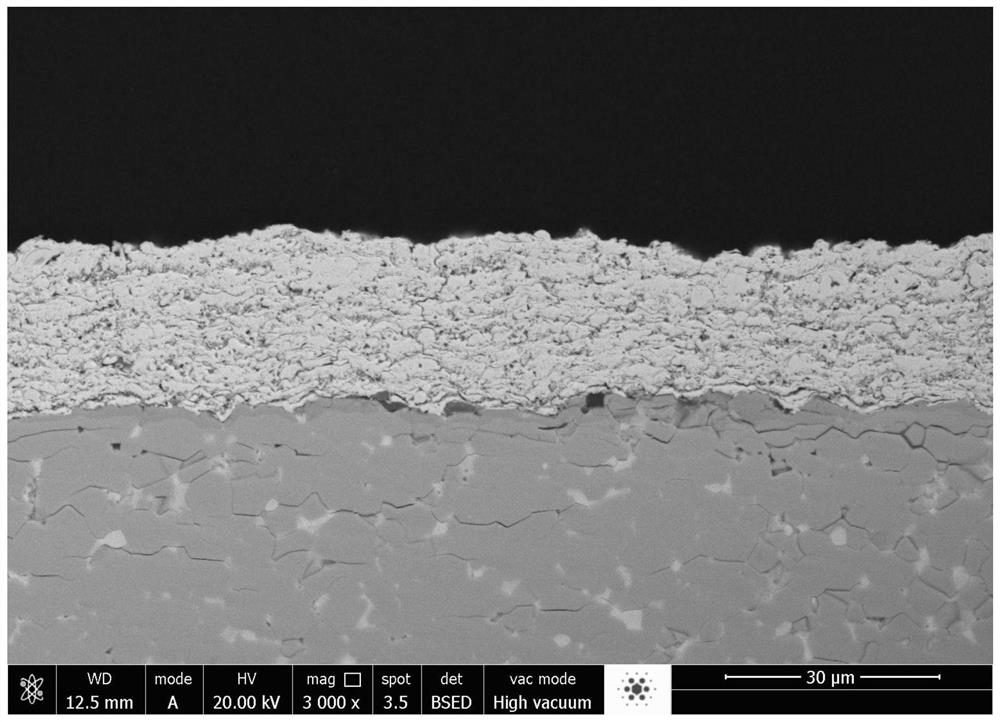

ActiveCN109477199AImprove corrosion resistanceSmall particlesMolten spray coatingYittrium oxides/hydroxidesThermal sprayingHalogen

Provided is a slurry for suspension plasma spraying, which is a spray material used for suspension plasma spraying in an atmosphere including an oxygen-containing gas, contains 5-40 mass% of rare earth fluoride particles having a maximum particle diameter (D100) of 12 mum or less, and contains one or more types of solvent selected from among water and organic solvents. A rare earth acid fluoride-containing sprayed film, in which process shift and particle generation hardly occur, can be stably formed on a base material by carrying out suspension plasma spraying in an atmosphere including an oxygen-containing gas. A spraying member provided with this sprayed film exhibits excellent corrosion resistance to halogen-based gas plasma.

Owner:SHIN ETSU CHEM CO LTD

A kind of preparation method of suspension liquid plasma spraying coating on the surface of NdFeB magnet

ActiveCN111304577BImprove magnetismSolve the difficult problem of transportationMolten spray coatingInductances/transformers/magnets manufactureRare-earth elementMetallurgy

The invention discloses a preparation method of a suspension plasma spray coating on the surface of a NdFeB magnet, comprising the following steps: (1) preparing a rare earth suspension; (2) using the suspension plasma spraying technology to spray the two sides of the NdFeB magnet , to obtain a suspension plasma spray coating; (3) The magnet after spraying is treated by grain boundary thermal diffusion method. Plasma spraying technology combined with grain boundary thermal diffusion technology has the characteristics of high production efficiency and environmental friendliness, which can effectively increase the diffusion depth of heavy rare earth elements in magnets, promote the improvement of magnetic properties, and also help accelerate the industry of grain boundary diffusion technology. process.

Owner:INNER MONGOLIA UNIV OF TECH +1

Method for suspending liquid plasma spraying preparation of hydroxyapatite bioactivity coatings

InactiveCN101250681BIncrease productivityReduce manufacturing costMolten spray coatingProsthesisPeristaltic pumpApatite

The invention relates to a method for spraying suspending liquid plasma to prepare hydroxyapatite bioactive coating, which comprises following steps: adopting hydroxyapatite suspending liquid as plasma spraying raw materials, adopting a pressure tank or an electronic peristaltic pump as a power transmitting device to transmit the hydroxyapatite suspending liquid, adopting an atomizing nozzle witha small angle to inject the hydroxyapatite suspending liquid into a central region of plasma flame directly and radially or adopting a duct with small diameter to inject the hydroxyapatite suspendingliquid into the central region of the plasma flame directly and radially in a linear type jet-flow mode, exchanging heat between the suspending liquid and high temperature plasma flame through transmitting and injecting the suspending liquid, and directly generating the hydroxyapatite bioactive coating on the surface of a biological medical metal base through vaporizing liquid in the suspending liquid, crushing particles, smelting and depositing. The method simplifies a tedious technological link for preparing the spraying raw materials in a method for spraying powder plasma, the spraying rawmaterials and energy are saved, and the structural homogeneity of the hydroxyapatite bioactive coating which is prepared is good.

Owner:SICHUAN UNIV

Mullite anti-oxidation coating for composite material and preparation method of mullite anti-oxidation coating

The invention relates to a mullite anti-oxidation coating for a composite material and a preparation method of the mullite anti-oxidation coating. The preparation method comprises the following steps of: preparing an Al (NO3) 3.9 H2O solution; putting the Al (NO3) 3.9 H2O solution into a hydrothermal pot, continuously stirring, and dropwise adding a proper amount of ammonia water to generate Al (OH) 3 transparent sol; adding transparent silica sol into the Al (OH) 3 transparent sol; placing the mixed sol in the previous step on a roller ball mill for ball milling; placing a pretreated C / C composite material substrate and the mixed sol on liquid-phase plasma spraying equipment, and spraying Al (OH) 3 and SiO2 coatings on the substrate by using suspension plasma spraying equipment; and carrying out vacuum heat treatment on the prepared coatings at high temperature to make the coatings react to generate a mullite coating. According to the invention, Al2O3 and SiO2 are compounded to generate a mullite phase with better high-temperature stability, so that the oxidation resistance of the composite material is improved, and the service life of the composite material is prolonged.

Owner:XIAN THERMAL POWER RES INST CO LTD

Method of making an electrochemical cell

Disclosed is a method of making an electrochemical cell, comprising: depositing an anode layer on a surface of a porous metal support layer; depositing an electrolyte layer on a surface of the anode layer, wherein the electrolyte layer is deposited via suspension plasma spray, wherein the electrolyte layer conducts protons; and depositing a cathode layer on a surface of the electrolyte layer. Also disclosed is a stack comprising two or more of the electrochemical cell.

Owner:HAMILTON SUNDSTRAND CORP

Slurry for suspension plasma spraying, and method for forming sprayed coating

ActiveUS11149339B2Improve corrosion resistanceSuitable for useMolten spray coatingYittrium oxides/hydroxidesMetallurgySlurry

A slurry for use in suspension plasma spraying including a dispersion medium and rare earth oxide particles, the rare earth oxide particles having a particle size D50 of 1.5 to 5 μm and a BET specific surface area of less than 1 m2 / g, and a content of the rare earth oxide particles in the slurry being 10 to 45 wt %.

Owner:SHIN ETSU CHEM CO LTD

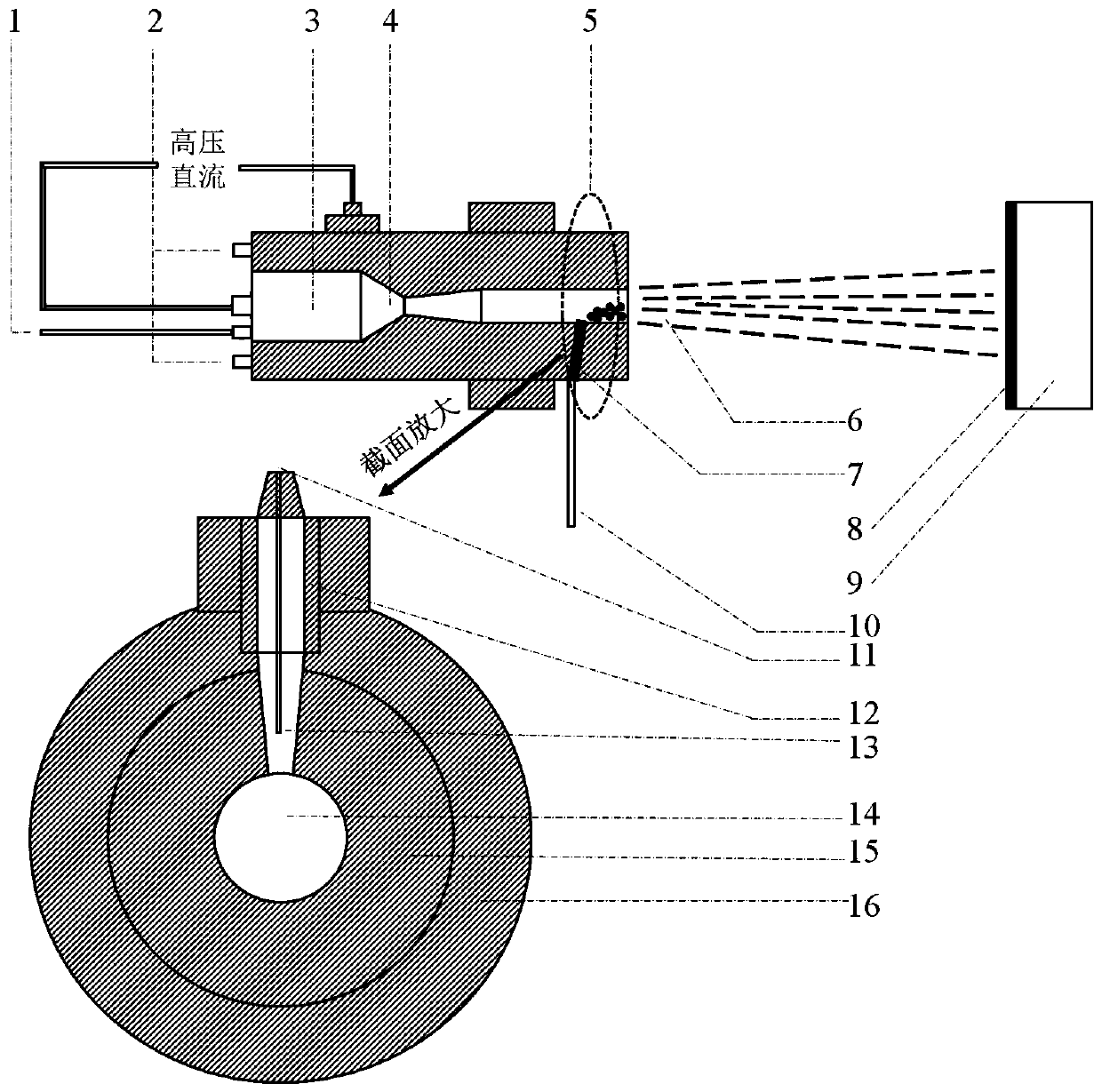

A micron-scale supersonic suspension plasma spraying device and spraying method

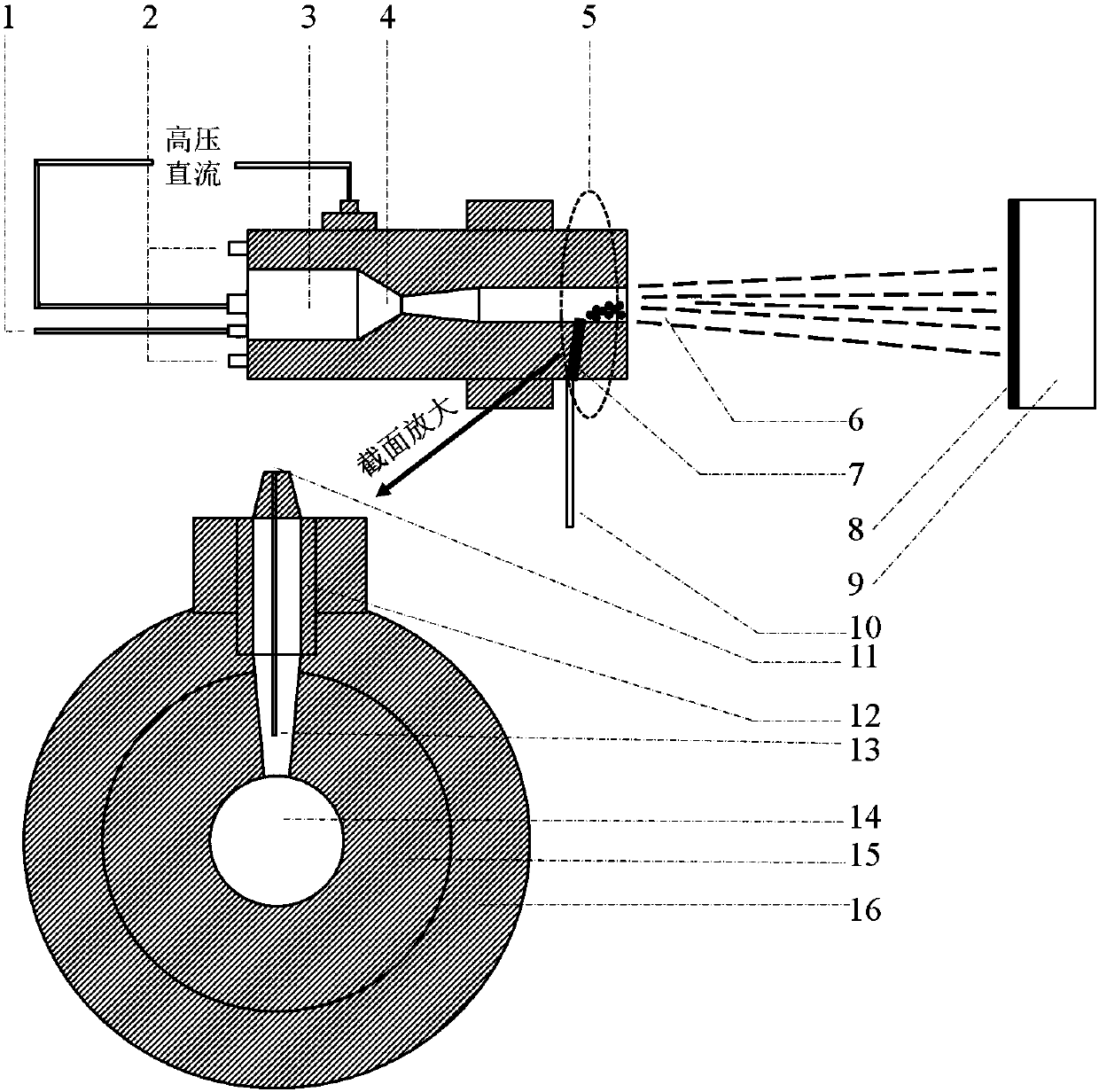

ActiveCN107916389BImprove production efficiencyIncrease meltingMolten spray coatingPeristaltic pumpPlasma jet

The invention relates to a micron-order supersonic speed suspension plasma spraying device and method. Pinhole type internal feeding powder feeding design is provided, a powder feeding mechanism commonly using a Laval type plasma spraying gun on engineering is transformed, sprayed powder (the grain size ranges from 500 nanometers-150 micrometers), absolute ethyl alcohol, an additive and deionizedwater are reasonably matched, and stable liquid slurry capable of achieving sufficient suspension is obtained; and a mechanical peristaltic pump is used for conveying the suspended liquid slurry to animproved pin type internal feeding opening of the supersonic speed Laval spraying gun, and after the suspension slurry and supersonic speed plasma jet flow generate sufficient heat exchange, the suspension slurry is deposited on a base plate through a supersonic spraying process to form a coating. The grain size of particles needing to be sprayed by the spraying device can reach 150 micrometers,the shape, the slurry viscosity and the fluidity of the sprayed powder are free of limitation, the deposition efficiency can reach 5-7 micrometers per pass, and the coating preparing efficiency can beimproved by nearly 7 times.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A kind of preparation method of thermal barrier coating with interlayer pore structure

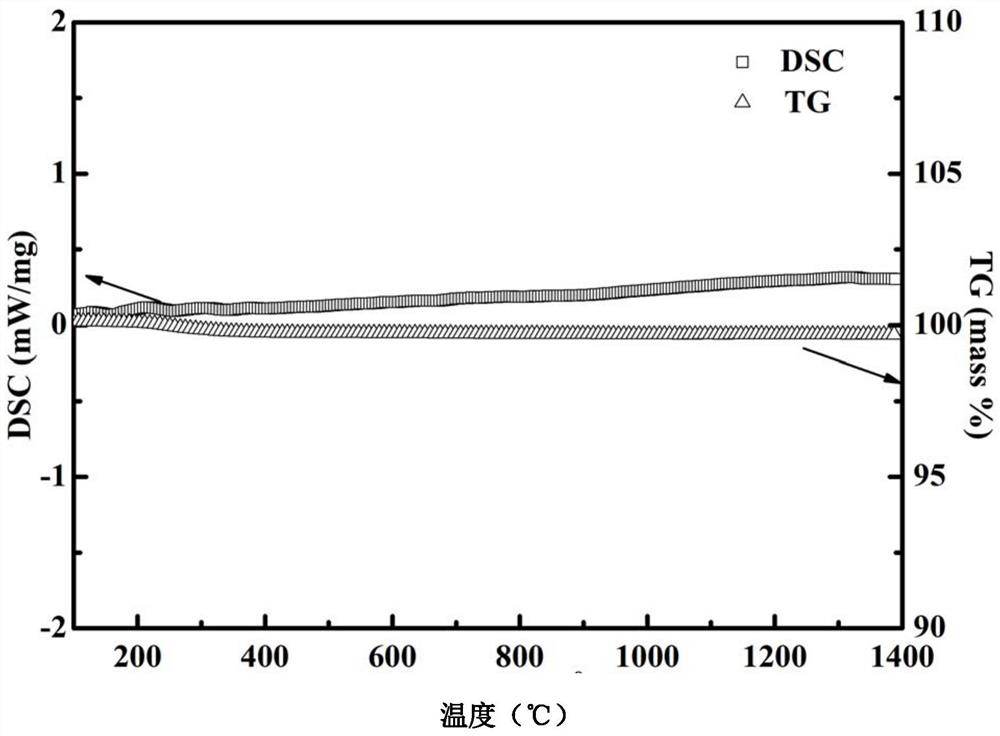

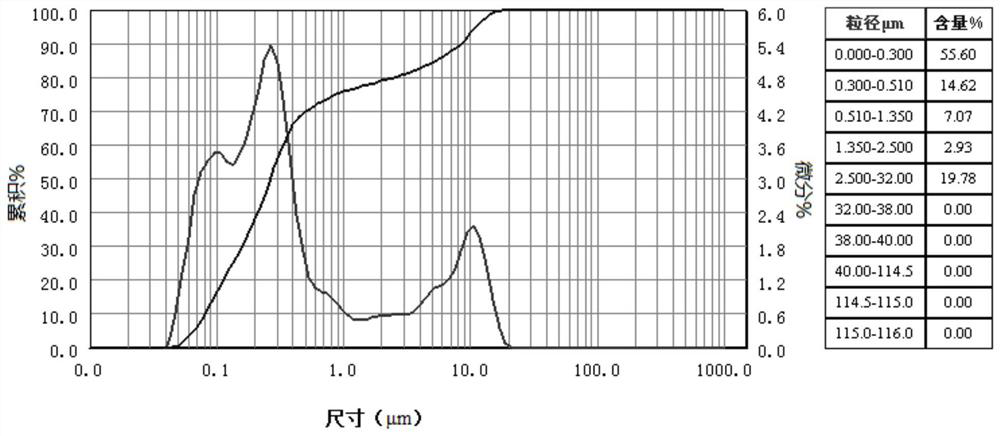

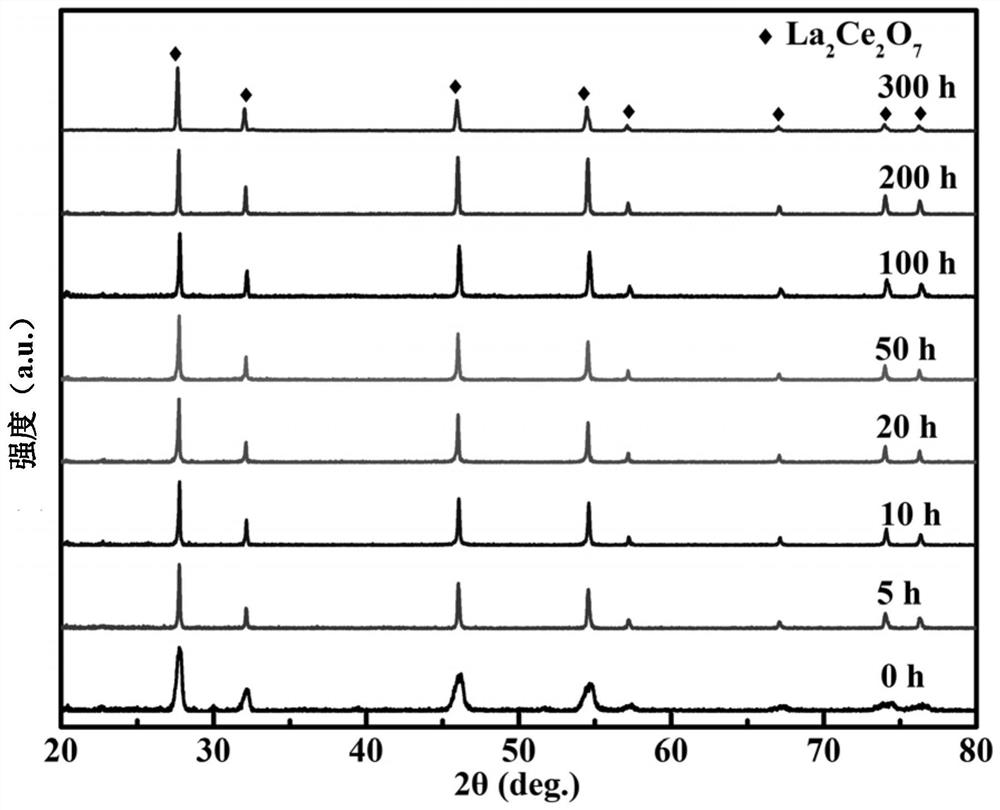

ActiveCN110106463BGood phase stability at high temperatureUniform interlayer pore structureMolten spray coatingPhysical chemistrySlurry

The invention relates to a preparation method of a thermal barrier coating with an interlayer pore structure, which comprises La 2 o 3 , CeO 2 , ZrO 2 The powder is heat-treated; the heat-treated powder is mixed with a dispersant in proportion, and deionized water is added for ball milling to obtain a slurry; La 2 o 3 , CeO 2 , ZrO 2 The molar ratio between the powders is 0.5:(1-x):x, wherein 0≤x≤0.8; the slurry after ball milling is dried and heat-treated to form a phase to obtain a phase-forming powder; the phase-forming powder is mixed with deionized water and dispersed The mixture is ball-milled to obtain a suspension; the suspension is used as a raw material, and the suspension plasma spraying method is used to spray on the base material. The present invention adopts the La prepared by the suspension plasma spraying method 2 (Ce 1‑x Zr x ) 2 o 7 The coating has excellent high-temperature phase stability, and the prepared coating has a uniform interlayer pore structure, which is conducive to reducing the thermal conductivity of the coating and improving the thermal cycle life of the coating.

Owner:INNER MONGOLIA UNIV OF TECH

Process for coating the surface of a solid substrate with a layer comprising a ceramic compound and the coated substrate obtained

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

Micron-order supersonic speed suspension plasma spraying device and method

ActiveCN107916389AImprove production efficiencyResolving particle sizes at the nanoscale (<500nm)Molten spray coatingPeristaltic pumpPlasma jet

The invention relates to a micron-order supersonic speed suspension plasma spraying device and method. Pinhole type internal feeding powder feeding design is provided, a powder feeding mechanism commonly using a Laval type plasma spraying gun on engineering is transformed, sprayed powder (the grain size ranges from 500 nanometers-150 micrometers), absolute ethyl alcohol, an additive and deionizedwater are reasonably matched, and stable liquid slurry capable of achieving sufficient suspension is obtained; and a mechanical peristaltic pump is used for conveying the suspended liquid slurry to animproved pin type internal feeding opening of the supersonic speed Laval spraying gun, and after the suspension slurry and supersonic speed plasma jet flow generate sufficient heat exchange, the suspension slurry is deposited on a base plate through a supersonic spraying process to form a coating. The grain size of particles needing to be sprayed by the spraying device can reach 150 micrometers,the shape, the slurry viscosity and the fluidity of the sprayed powder are free of limitation, the deposition efficiency can reach 5-7 micrometers per pass, and the coating preparing efficiency can beimproved by nearly 7 times.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method of making an electrochemical cell

Disclosed is a method of making an electrochemical cell, comprising: depositing an anode layer on a surface of a porous metal support layer; depositing an electrolyte layer on a surface of the anode layer, wherein the electrolyte layer is deposited via suspension plasma spray, wherein the electrolyte layer conducts protons; and depositing a cathode layer on a surface of the electrolyte layer. Also disclosed is a stack comprising two or more of the electrochemical cell.

Owner:HAMILTON SUNDSTRAND CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com