Plasma spray apparatus integrating water cleaning

a technology of spray apparatus and spraying water, which is applied in the direction of plasma technique, cleaning using liquids, coatings, etc., can solve the problems of dust particles on the substrate surface, poor adhesion of the applied coating, and additional maintenance, and equipment capital expenditur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

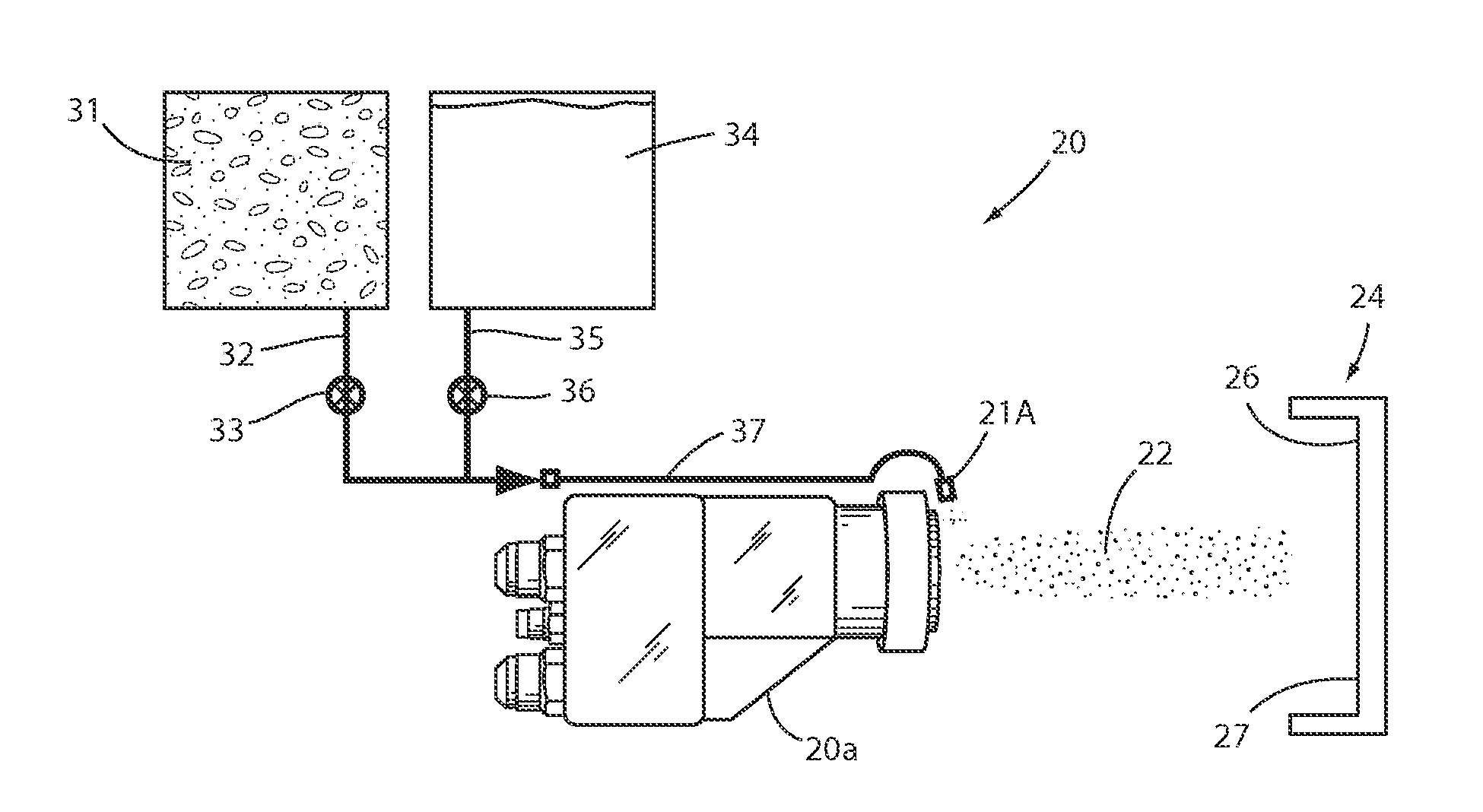

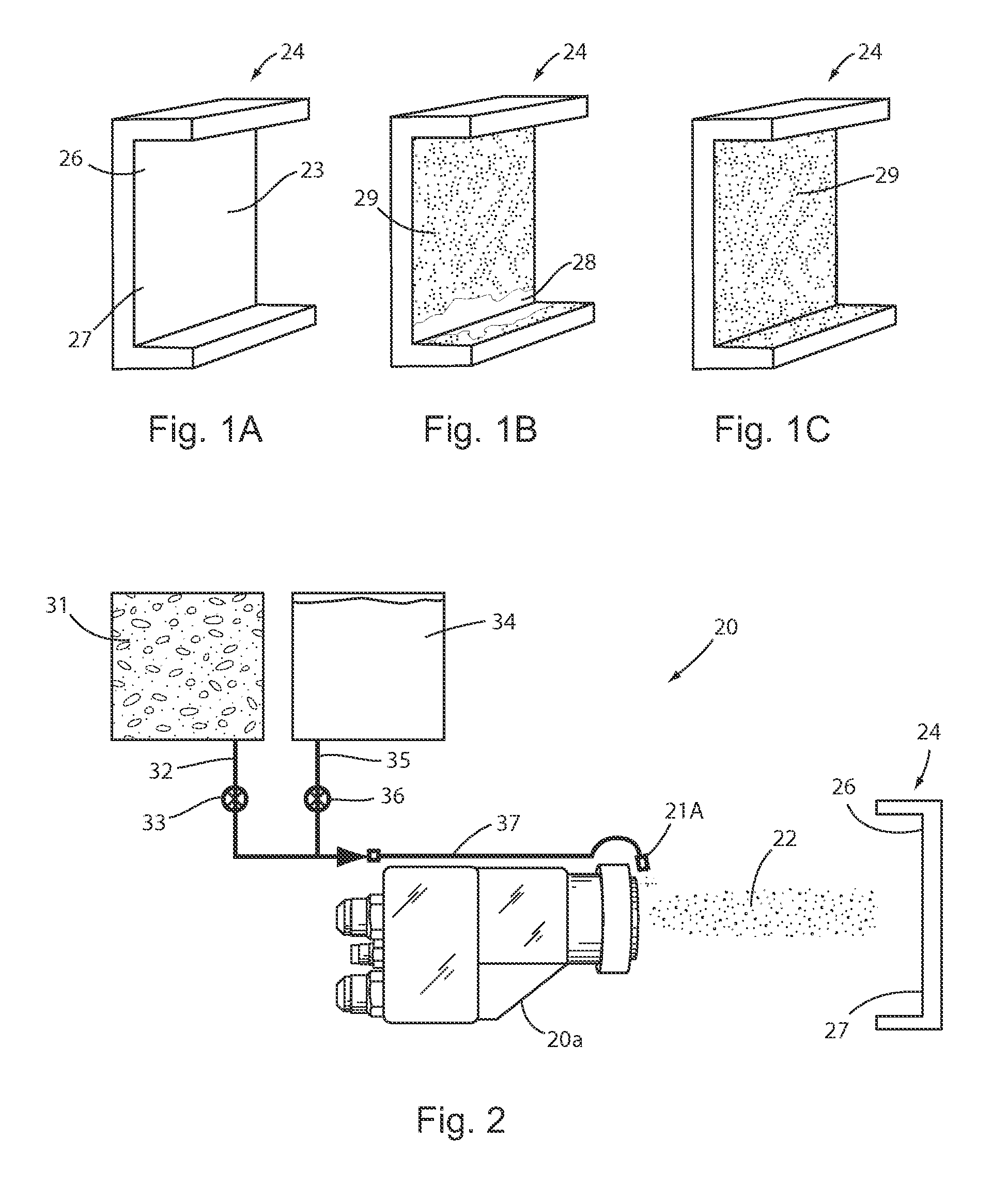

[0016]The present apparatus 20 and method incorporating the present innovative technology of a liquid (e.g. water) injected into the plume 22 of a thermal treatment process have been tested to effectively and efficiently clean debris 28 and loose undesired material from a surface 23 of a part 24, thus improving treatment of the surface 23 on a part 24. The cleaning is particularly useful in a suspension plasma spray (SPS) process for treating non-planar surfaces, such as where a plasma torch 20a applies surface treating plasma to a part 24 having a part geometry similar to that in FIG. 1A and FIG. 2. However, it is believed that a scope of the present innovation is broader than just suspension plasma spray processes. Specifically, while treating a surface 23 on the upper portion 26 of the illustrated part 24, such as when applying a coating 29, a dust-like overspray material 28 can be produced that lands on the adjacent lower portion 27 (and / or the upper portion 26) of part surfaces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com