Slurry for suspension plasma spraying and method for forming sprayed coating

一种等离子、悬浮液的技术,应用在金属材料涂层工艺、涂层、熔融喷镀等方向,能够解决方法产率劣化等问题,达到高抗腐蚀性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 4 and comparative Embodiment 1 and 2

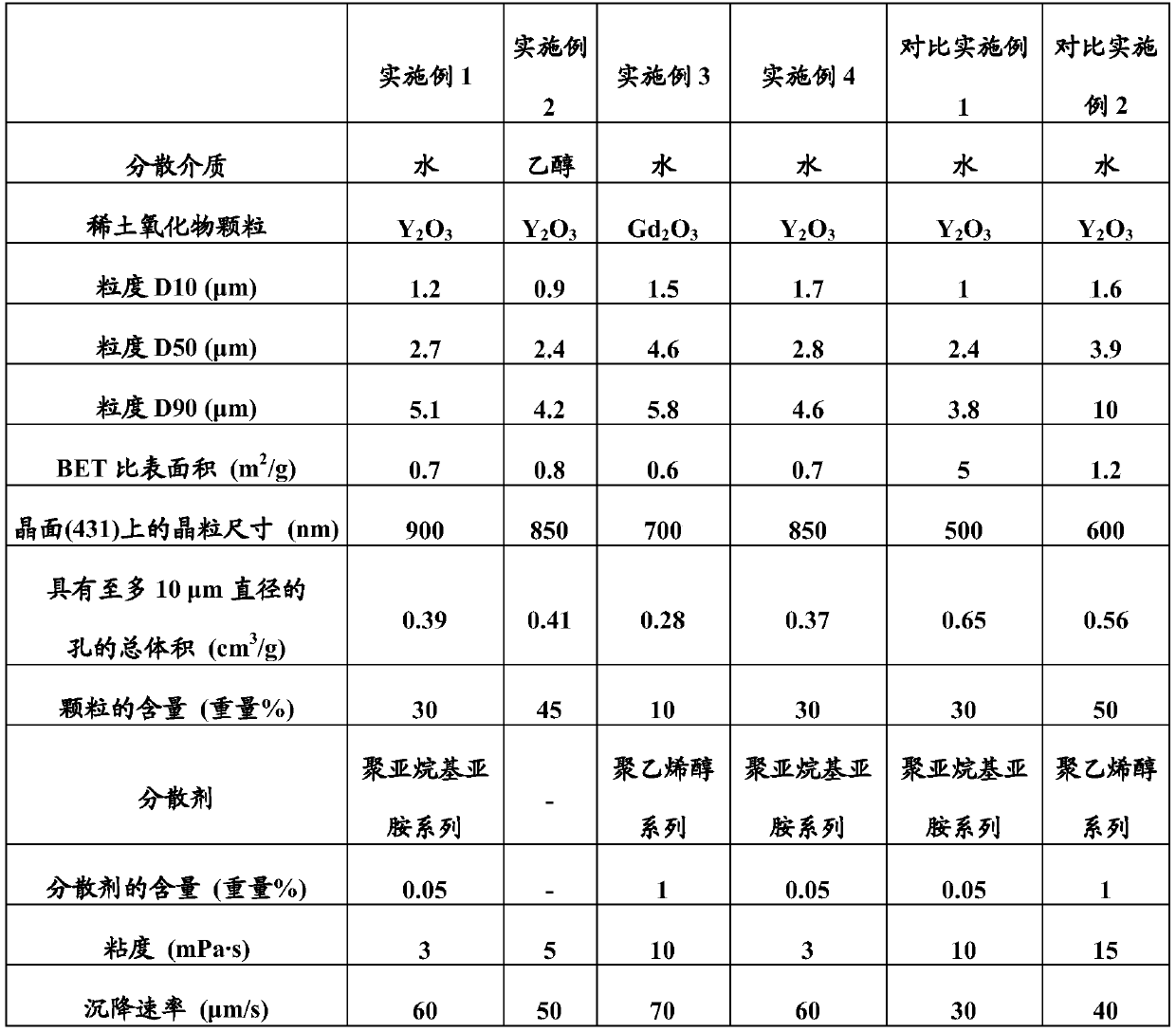

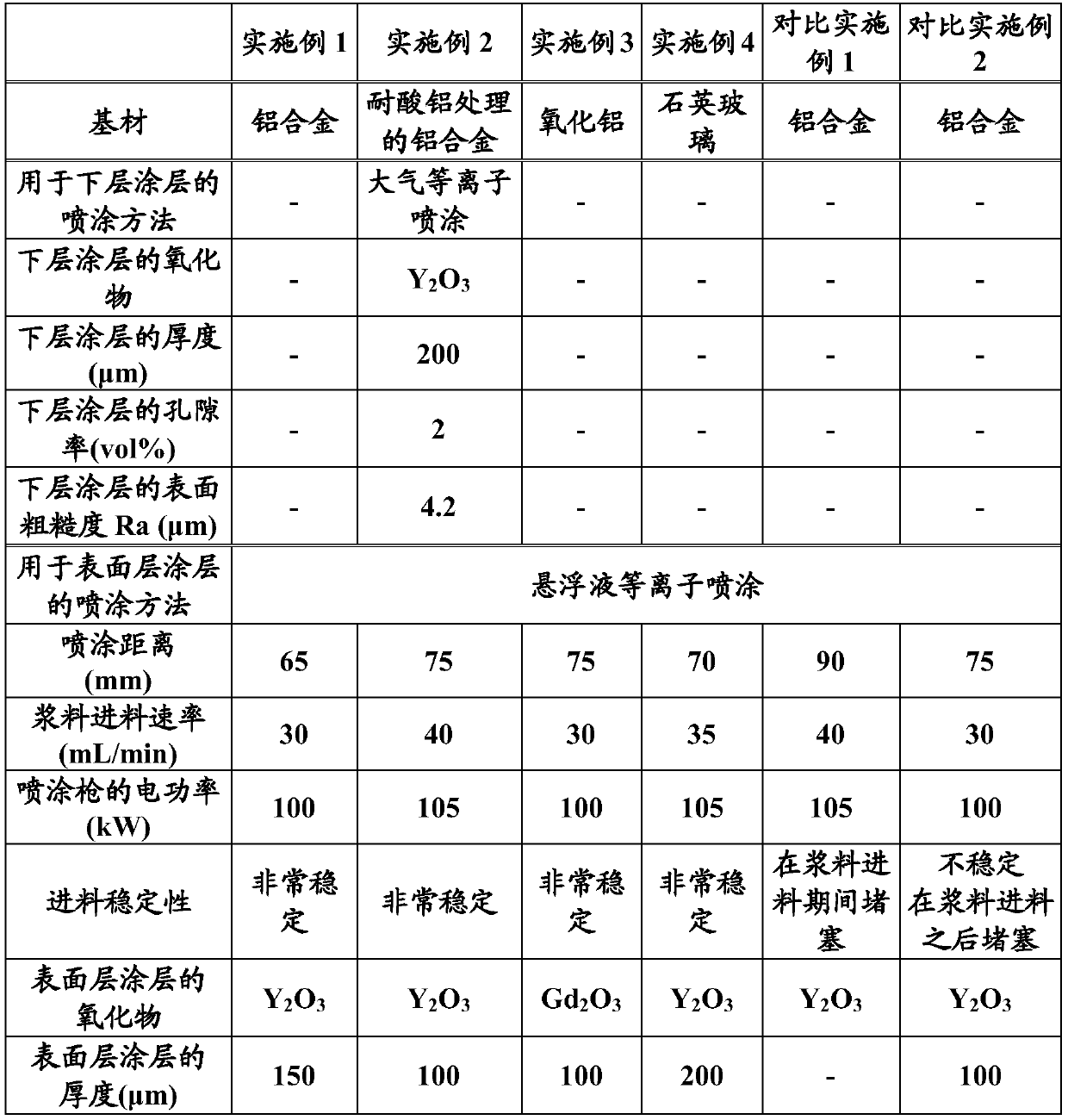

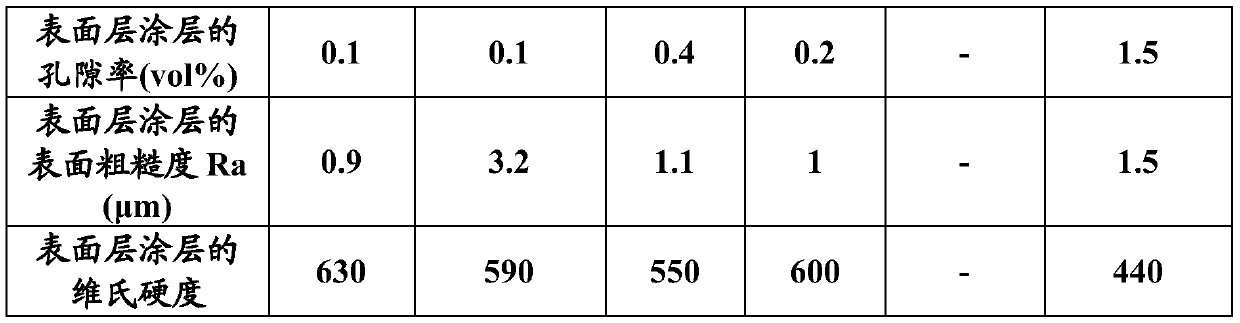

[0055] Slurries for thermal spraying shown in Table 1 including dispersion media and rare earth oxide particles were prepared. The content of the rare earth oxide particles was adjusted as shown in Table 1. The dispersants shown in Table 1 were added to the slurry in the amounts shown in Table 1, except for Example 2.

[0056] For the rare earth oxide particles, the particle sizes D10, D50, and D90, the BET specific surface area, the grain size on the crystal plane (431), and the total volume of pores having a diameter of up to 10 μm were measured by the following respective methods. In addition, for the slurry including the rare earth oxide particles, the viscosity and the sedimentation rate were measured by the following respective methods. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com