Method for coating a surface of a solid substrate with a layer comprising a ceramic compound, and coated substrate thus obtained

A solid substrate and compound technology, applied in the plating, coating, blade support elements of superimposed layers, etc., can solve different problems and achieve the effect of increasing chemical resistance and increasing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

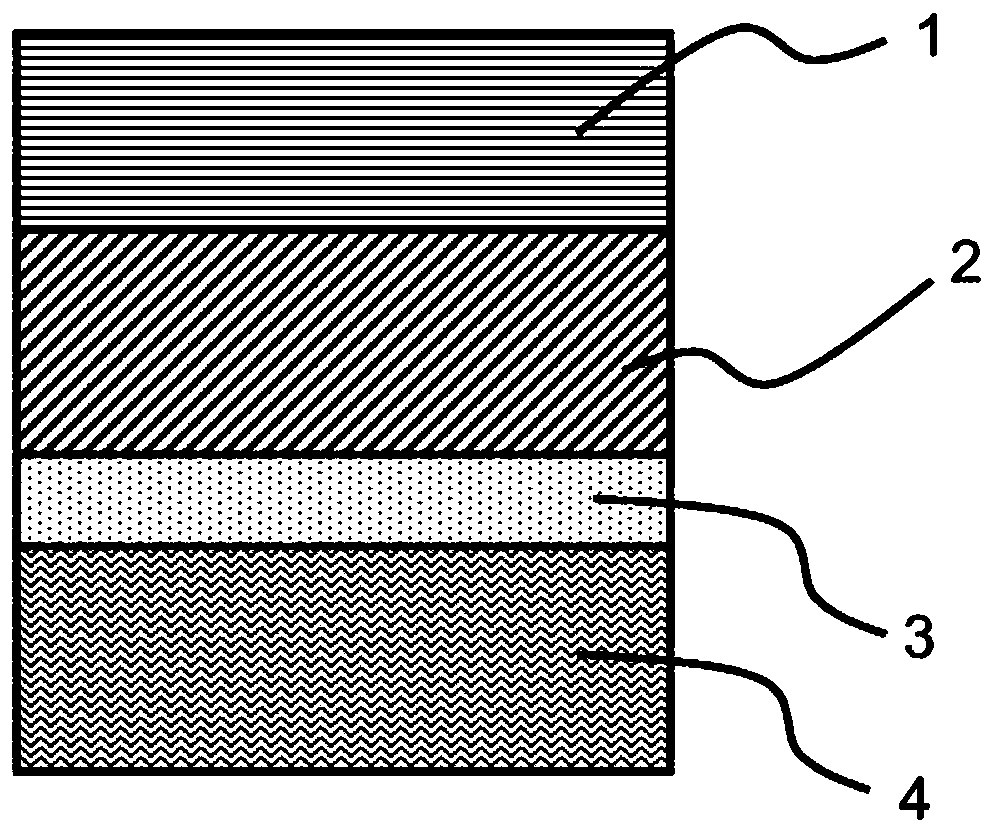

[0155] According to a first embodiment, a layer 1 according to the invention can be applied to a layer 2 obtained by SPS with a porous columnar microstructure ( image 3 Layer 6) in the middle.

[0156] According to a second embodiment, a layer 1 according to the invention can be applied to a layer 2 obtained by SPS with a porous dense columnar microstructure ( Figure 4 Layer 7) in the middle.

[0157] According to a third embodiment, a layer 1 according to the invention can be applied to a layer 2 with a columnar microstructure obtained by EB-PVD ( Figure 5 on layer 8) in

[0158] Advantageously, layer 2 can have a thermal and / or environmental insulation function. This layer can also (but is not limited to) guarantee good properties in terms of service life, thermal insulation or protection against oxidation and moisture corrosion.

[0159] Advantageously, layer 3 acts as an adhesive layer.

[0160] Layer 3 may be selected from metals; metal alloys such as β-NiAl metal a...

Embodiment 1

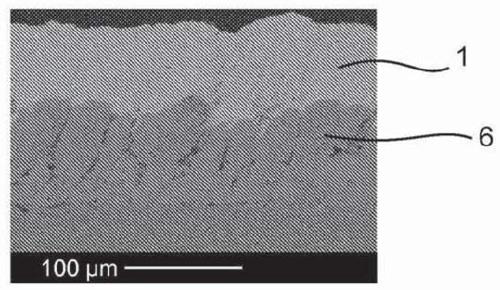

[0187] In this embodiment, the anti-CMAS layer according to the invention is prepared by the method according to the invention (see image 3 ).

[0188] by Gd 2 Zr 2 o 7 The compositional anti-CMAS layer 1 is prepared on the surface of the porous columnar YSZ layer 6 obtained by the SPS method. By the SPS method using d 90 Less than 10μm (ie d 90 is 7μm) and d 50 A suspension of primary particles greater than or equal to 1 μm (ie 3 μm) was used to prepare the anti-CMAS layer.

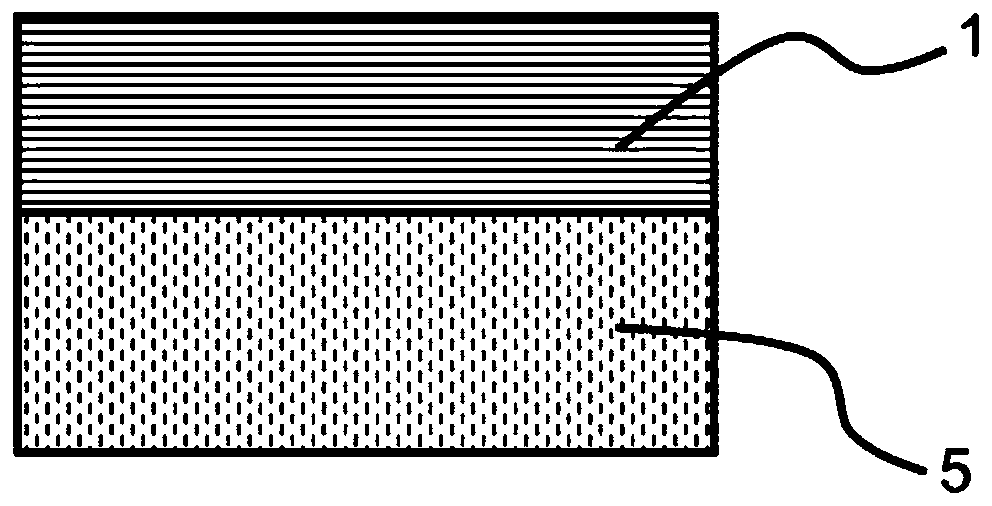

[0189] A sample thus prepared consisting of an anti-CMAS layer on a substrate fell into figure 1 and figure 2 within the range of the system shown.

[0190] image 3 A scanning electron microscope (SEM) micrograph using backscattered electrons using a polished portion of the sample prepared in this example is shown.

Embodiment 2

[0192] In this example, the anti-CMAS layer according to the invention was produced by the method according to the invention.

[0193] by Gd 2 Zr 2 o 7 The compositional anti-CMAS layer 1 was prepared on the surface of the columnar dense porous YSZ layer 7 obtained by the SPS method. By the SPS method using d 90 Less than 10μm (ie d 90 is 7μm) and d 50 A suspension of primary particles greater than or equal to 1 μm (ie 3 μm) was used to prepare the anti-CMAS layer.

[0194] A sample thus prepared consisting of an anti-CMAS layer on a substrate fell into figure 1 and figure 2 within the range of the system shown.

[0195] Figure 4 A scanning electron microscope (SEM) micrograph using backscattered electrons using a polished portion of the sample prepared in this example is shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com