Slurry for suspension plasma spraying, method for forming rare earth acid fluoride sprayed film, and spraying member

A rare earth oxide and plasma technology, which is applied in the direction of rare earth metal fluoride, rare earth metal oxyhalide, rare earth metal oxide/hydroxide, etc., can solve the problems of unstable etching process and changes in fluorine gas concentration, etc. Achieves the effect of less particle generation and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7、 comparative example 1、2

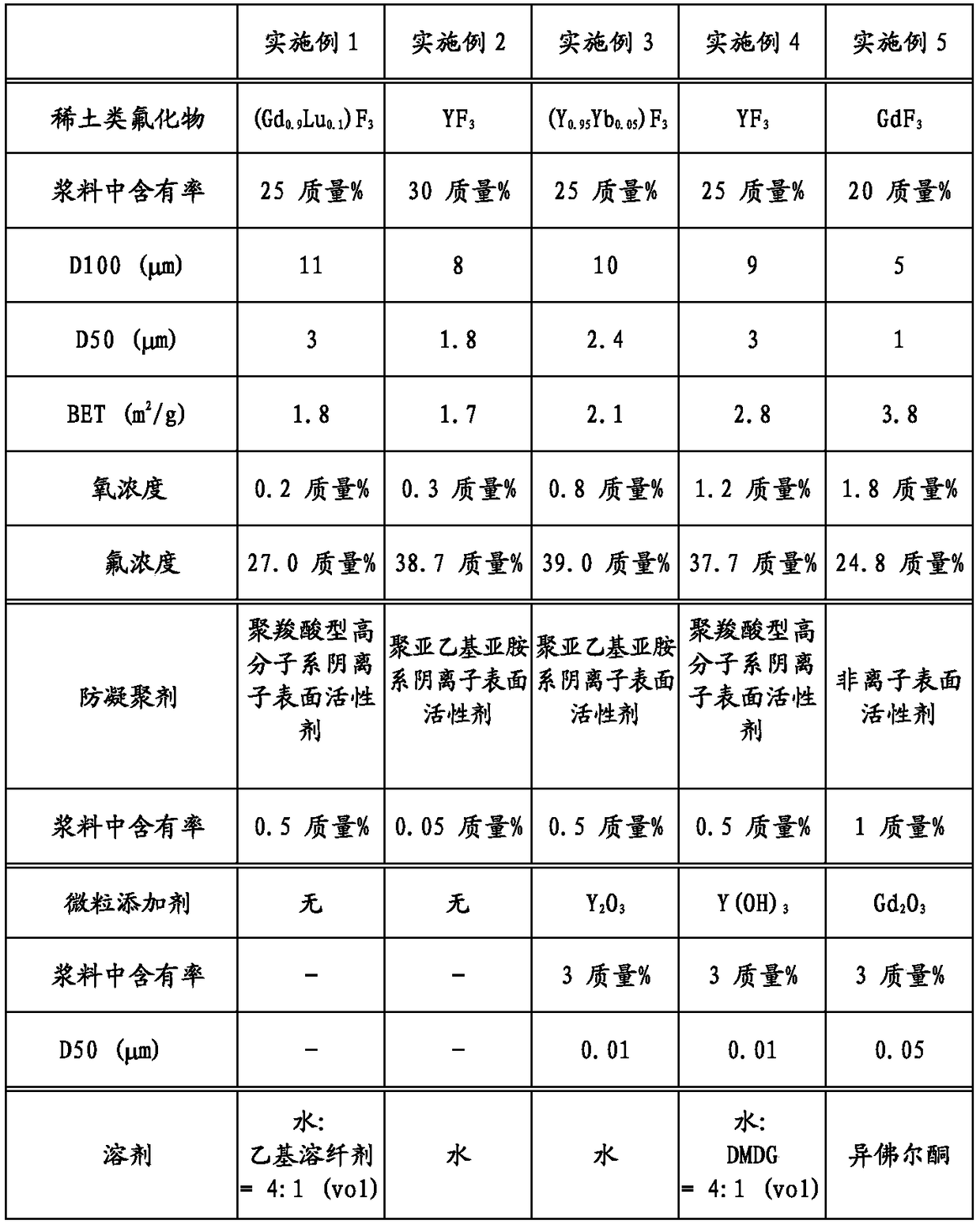

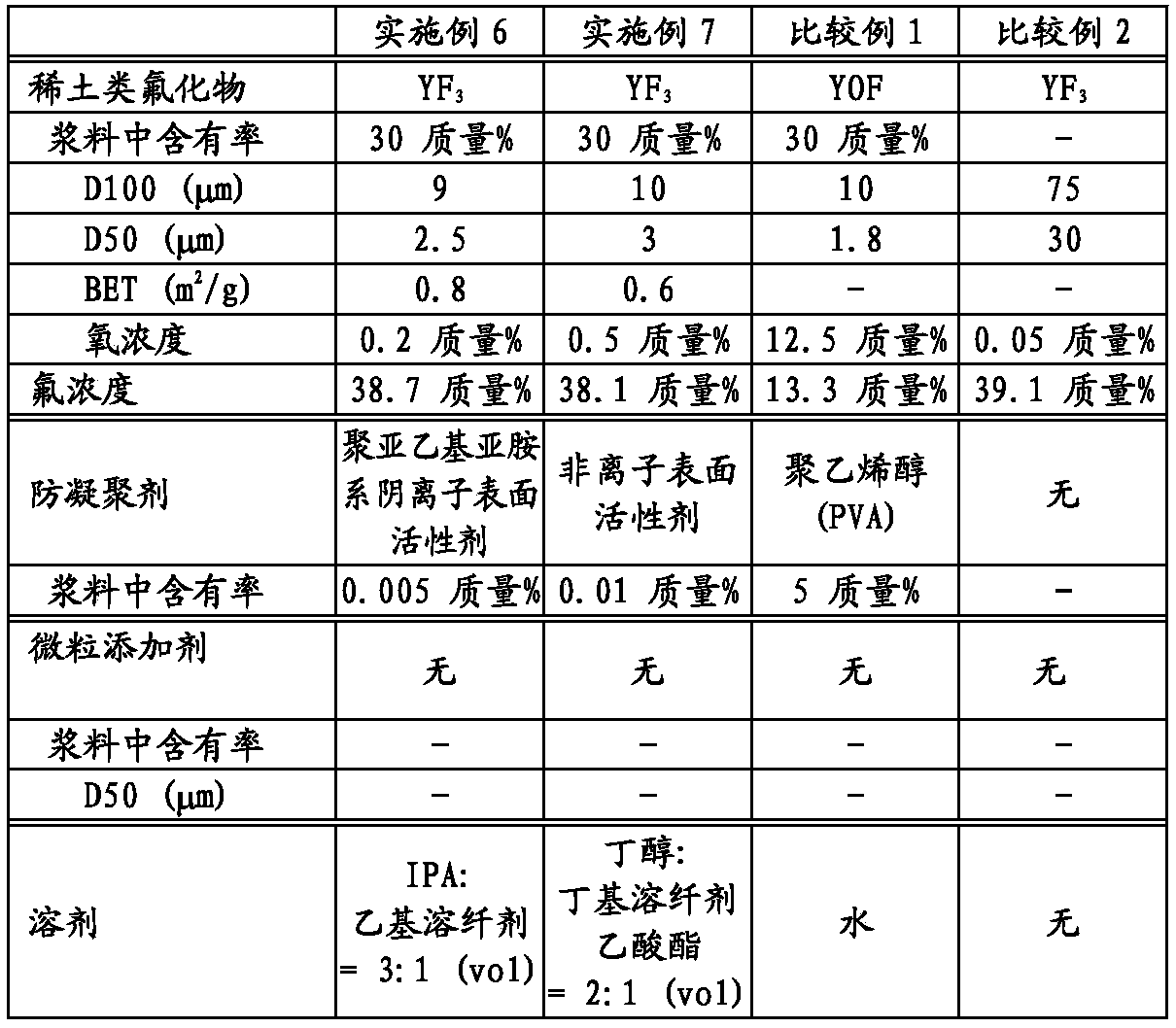

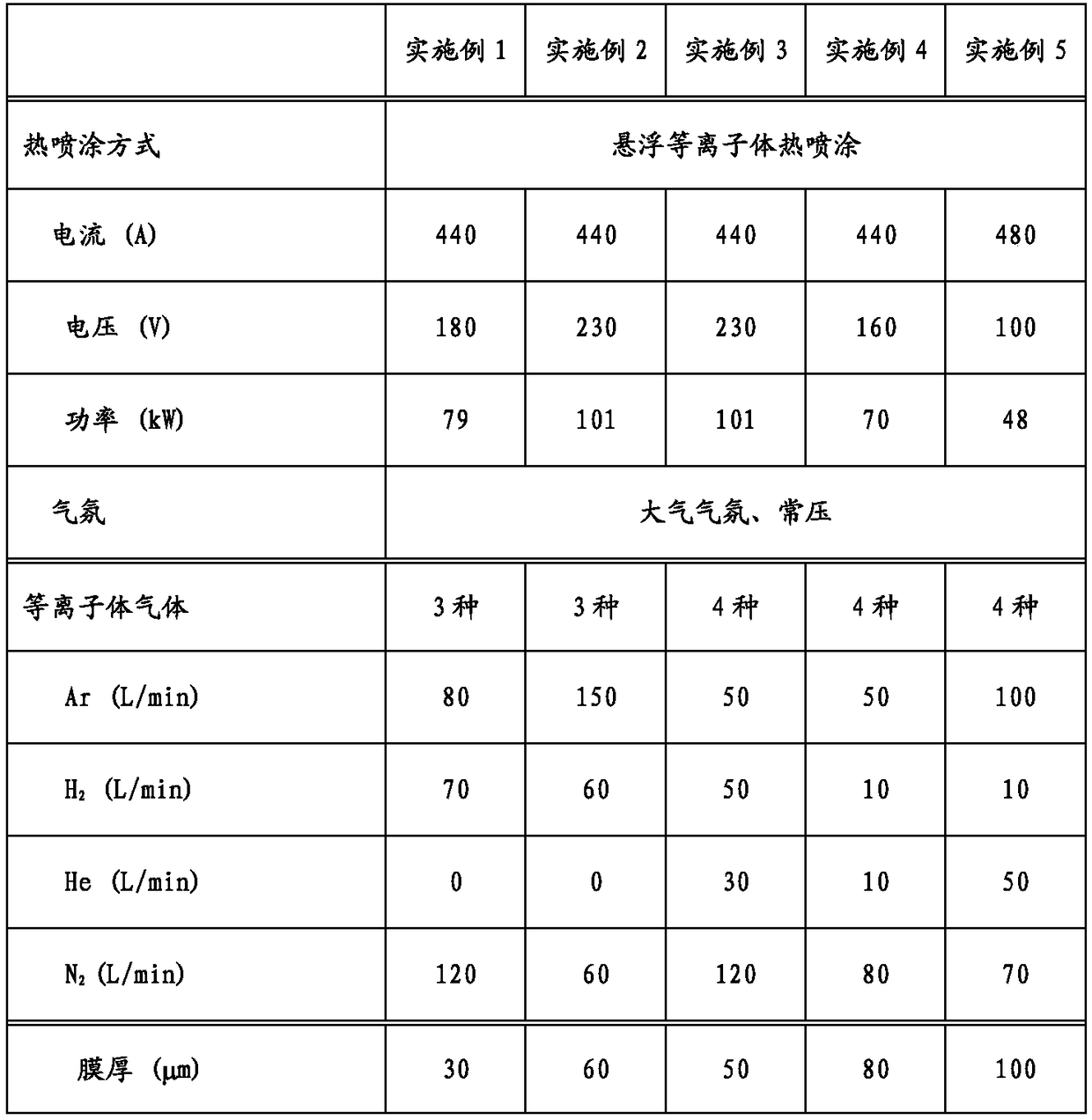

[0066] [Manufacture of Rare Earth Fluoride Particles and Slurry in Examples 1 to 7]

[0067] Adjust the composition ratio of the rare earth elements of the rare earth fluorides shown in Table 1 or Table 2, and mix 1.2 kg of acidic ammonium fluoride powder with respect to 1 kg of rare earth oxides, and bake 2 kg in a nitrogen atmosphere at 650 ° C. hours, the rare earth fluorides were obtained. The obtained rare earth fluoride was pulverized by a jet mill and subjected to air classification to prepare rare earth fluoride particles having the maximum particle diameter (D100) shown in Table 1 or Table 2. Table 1 or Table 2 shows the particle size distribution (D100, D50) and BET specific surface area of the obtained rare earth fluoride particles. The particle size distribution was measured by a laser diffraction method, and the BET specific surface area was measured by a fully automatic specific surface area measuring device Macsorb HM model-1280 manufactured by Mountec Co., L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com