Patents

Literature

35results about "Rare earth metal oxyhalides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano-scale metal halide scintillation materials and methods for making same

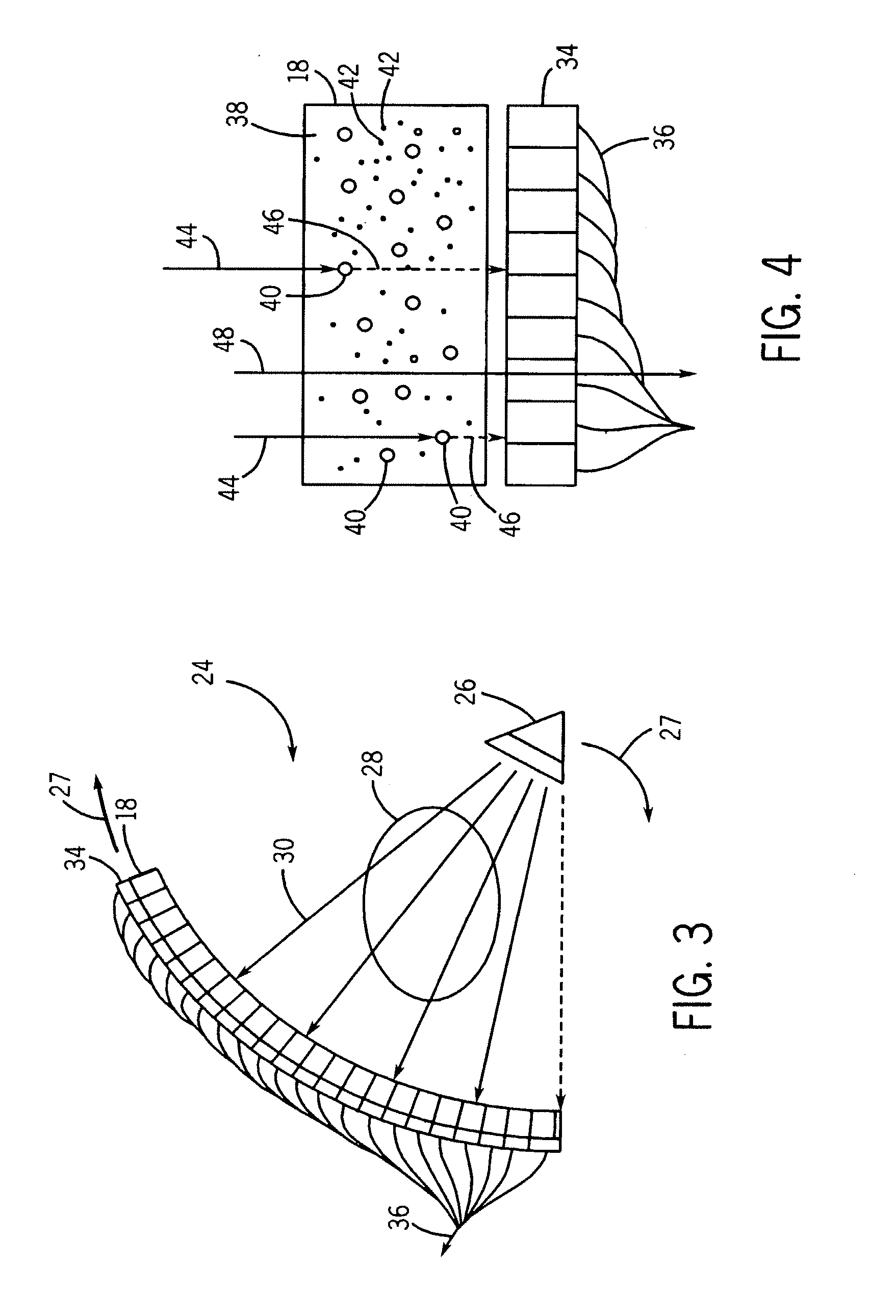

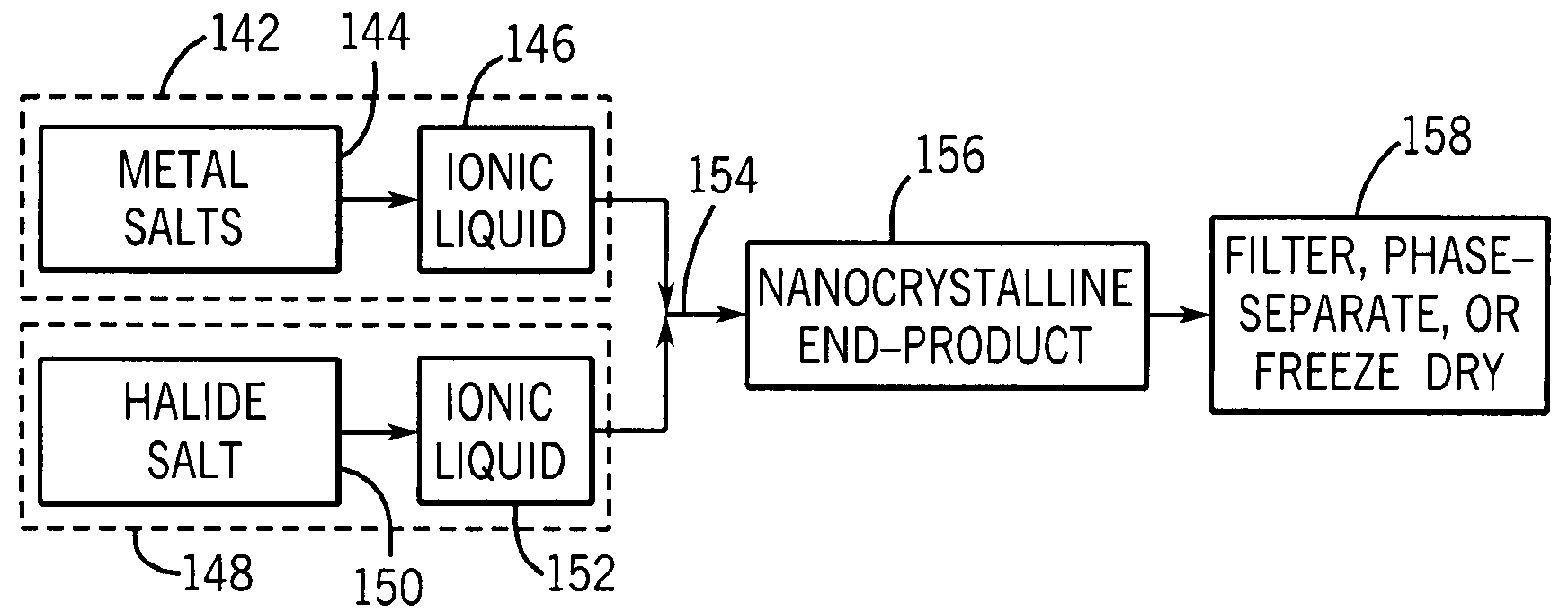

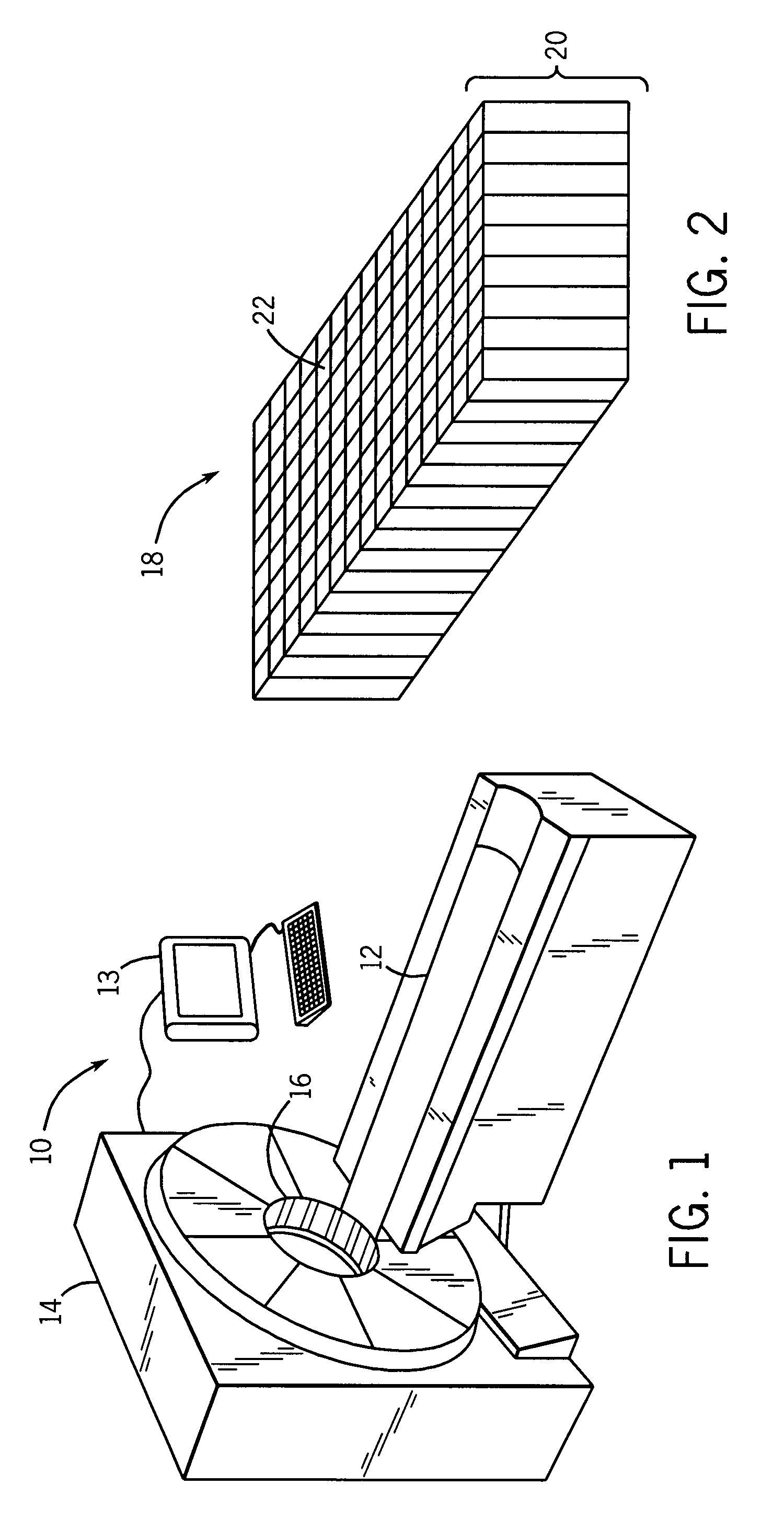

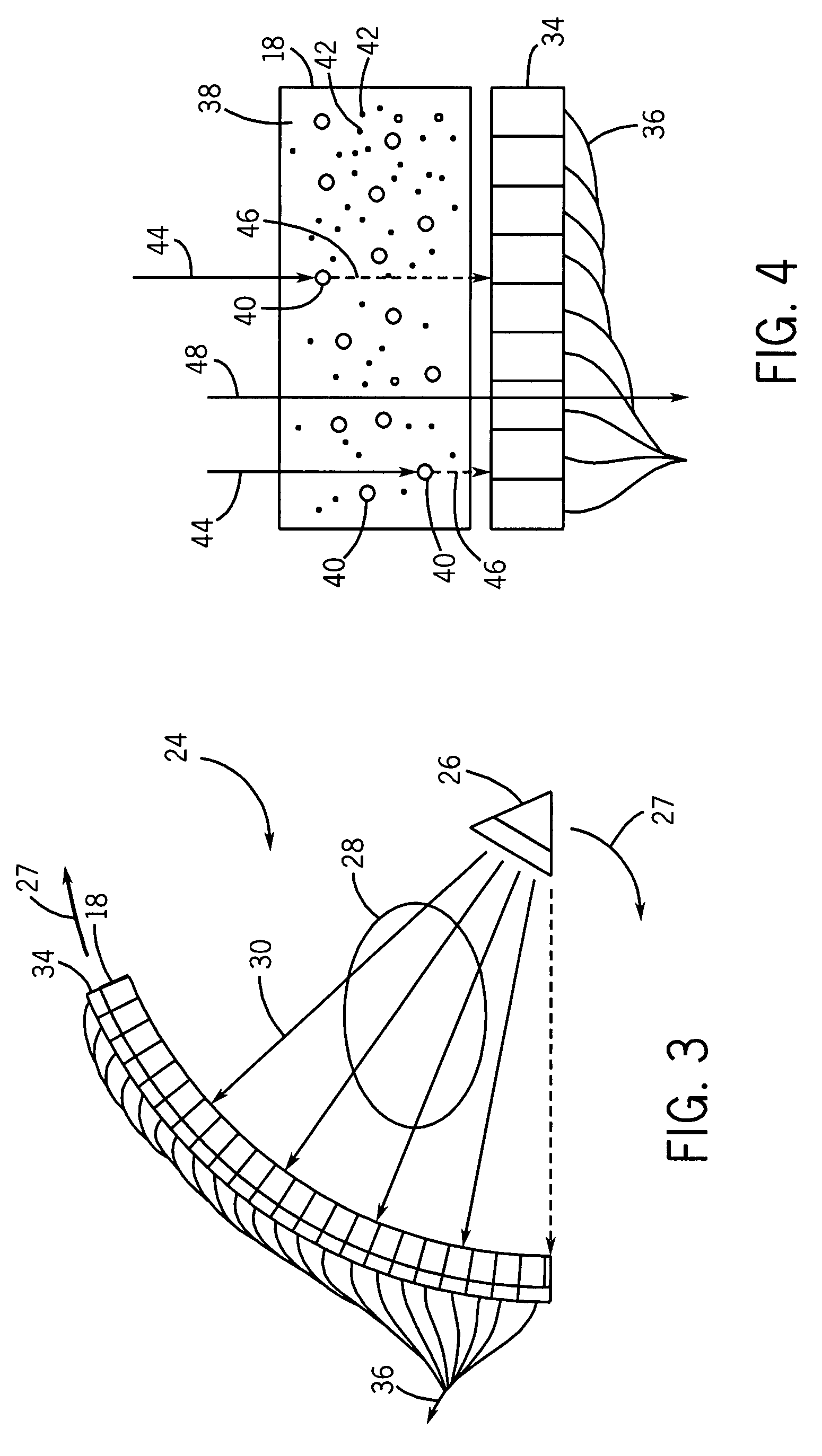

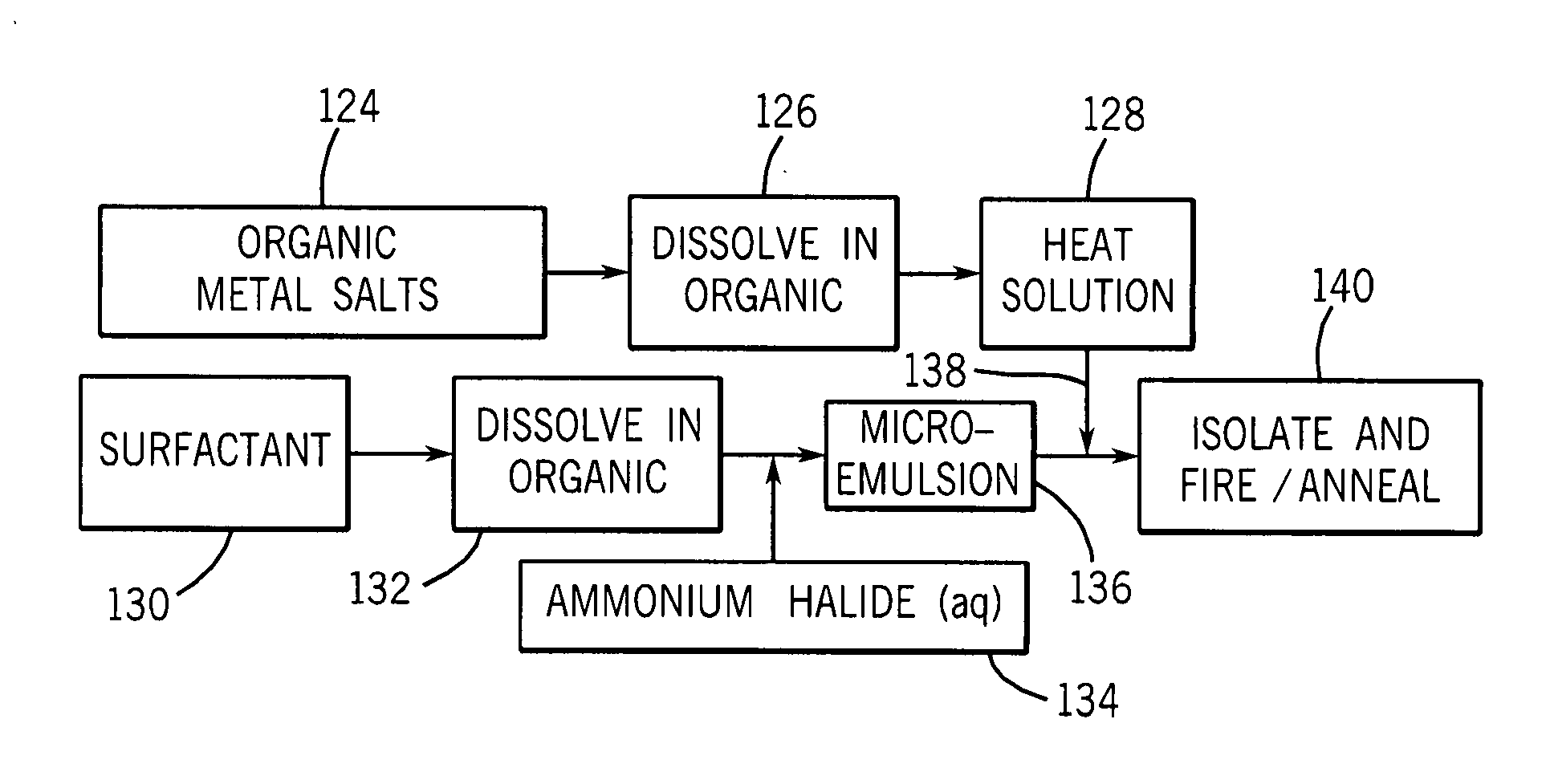

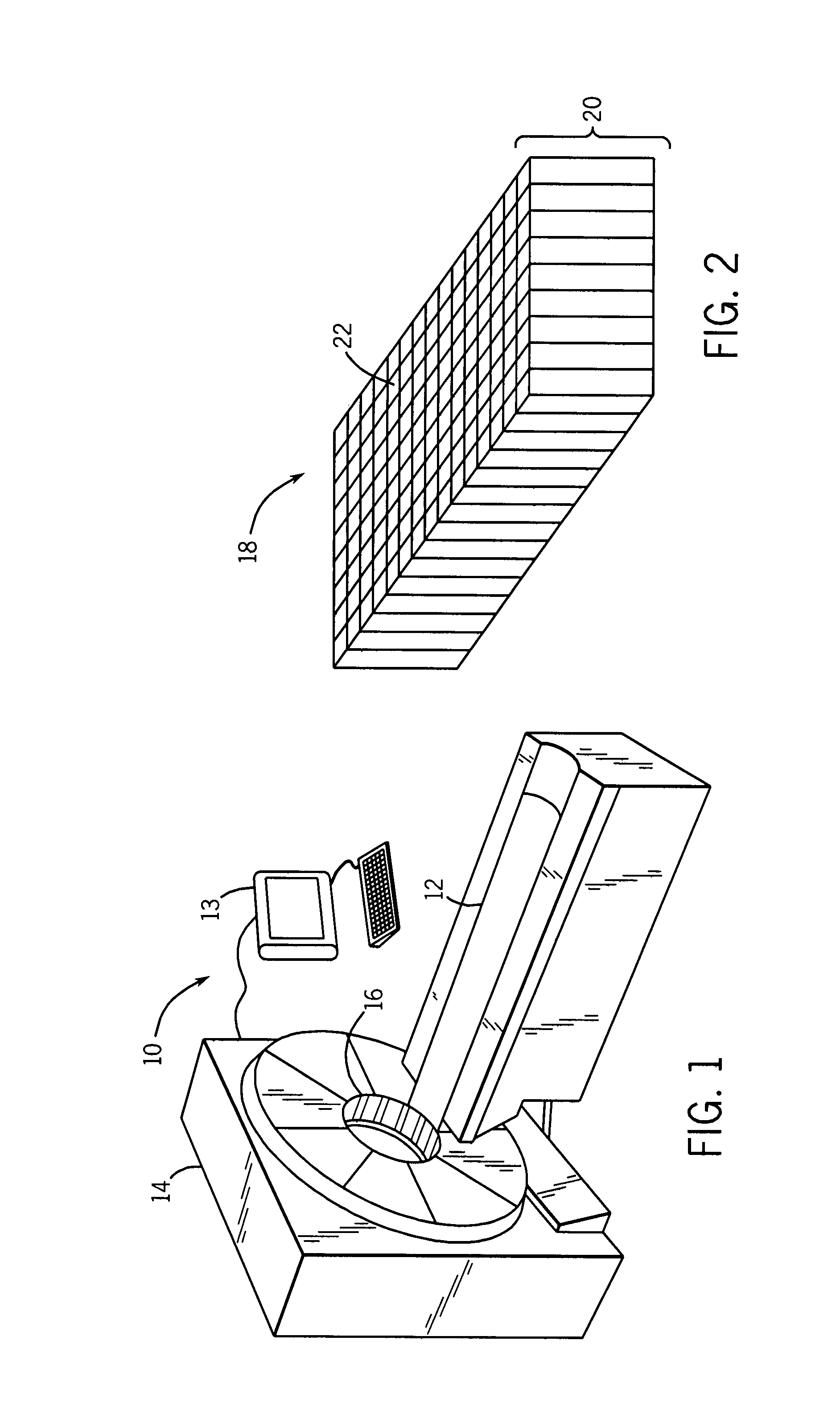

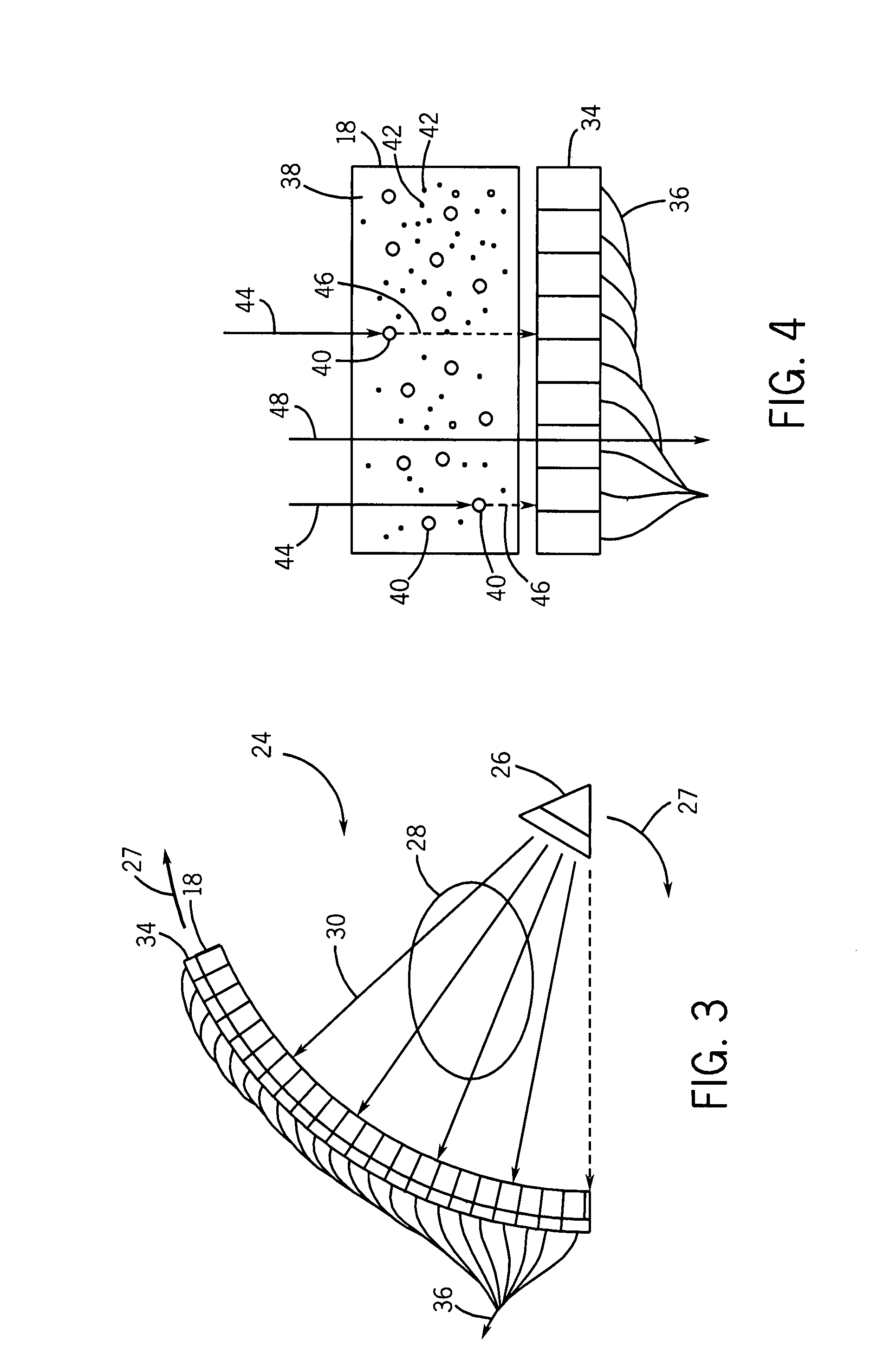

Crystalline scintillator materials comprising nano-scale particles of metal halides are provided. The nano-scale particles are less than 100 nm in size. Methods are provided for preparing the particles. In these methods, ionic liquids are used in place of water to allow precipitation of the final product. In one method, the metal precursors and halide salts are dissolved in separate ionic liquids to form solutions, which are then combined to form the nano-crystalline end product. In the other methods, micro-emulsions are formed using ionic liquids to control particle size.

Owner:GENERAL ELECTRIC CO

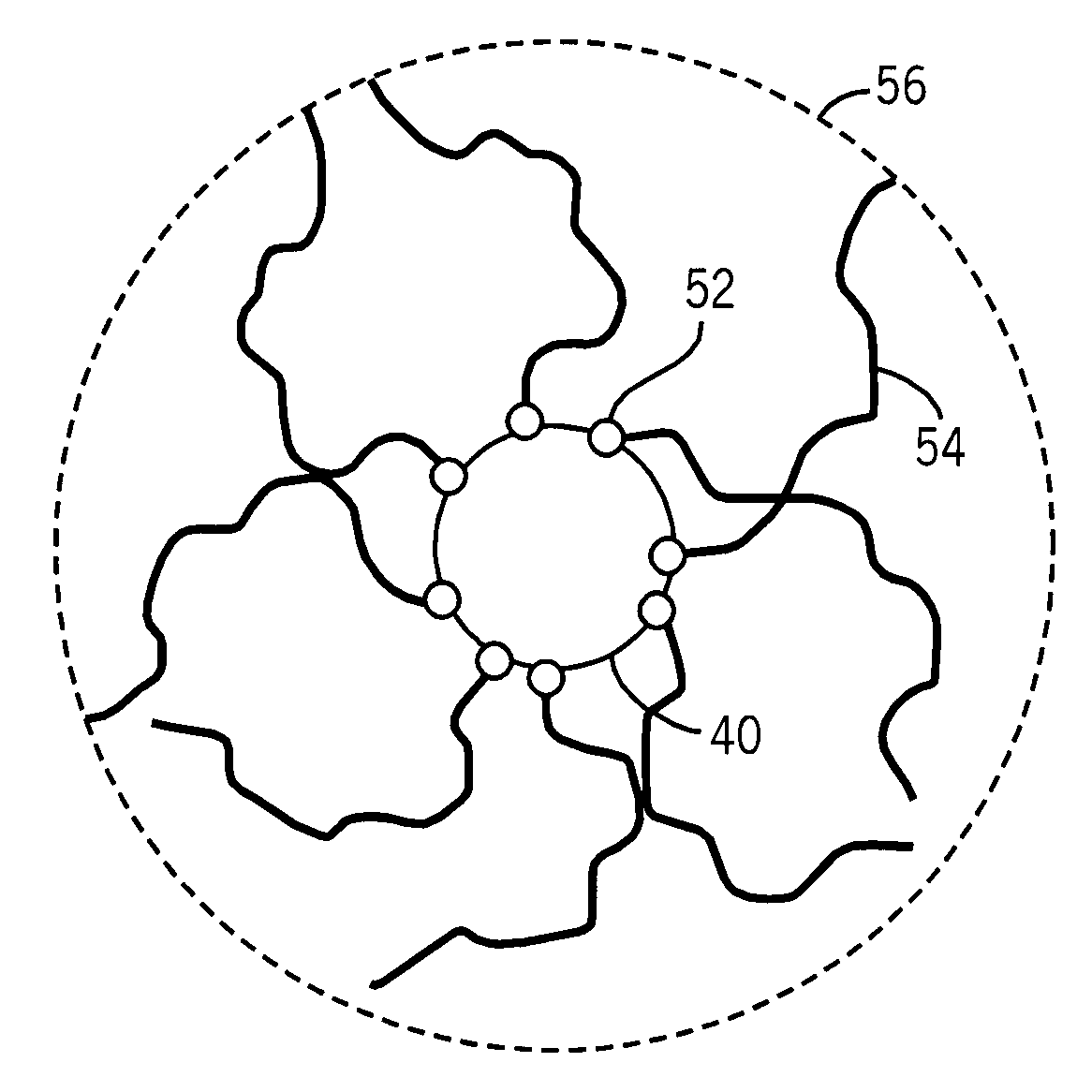

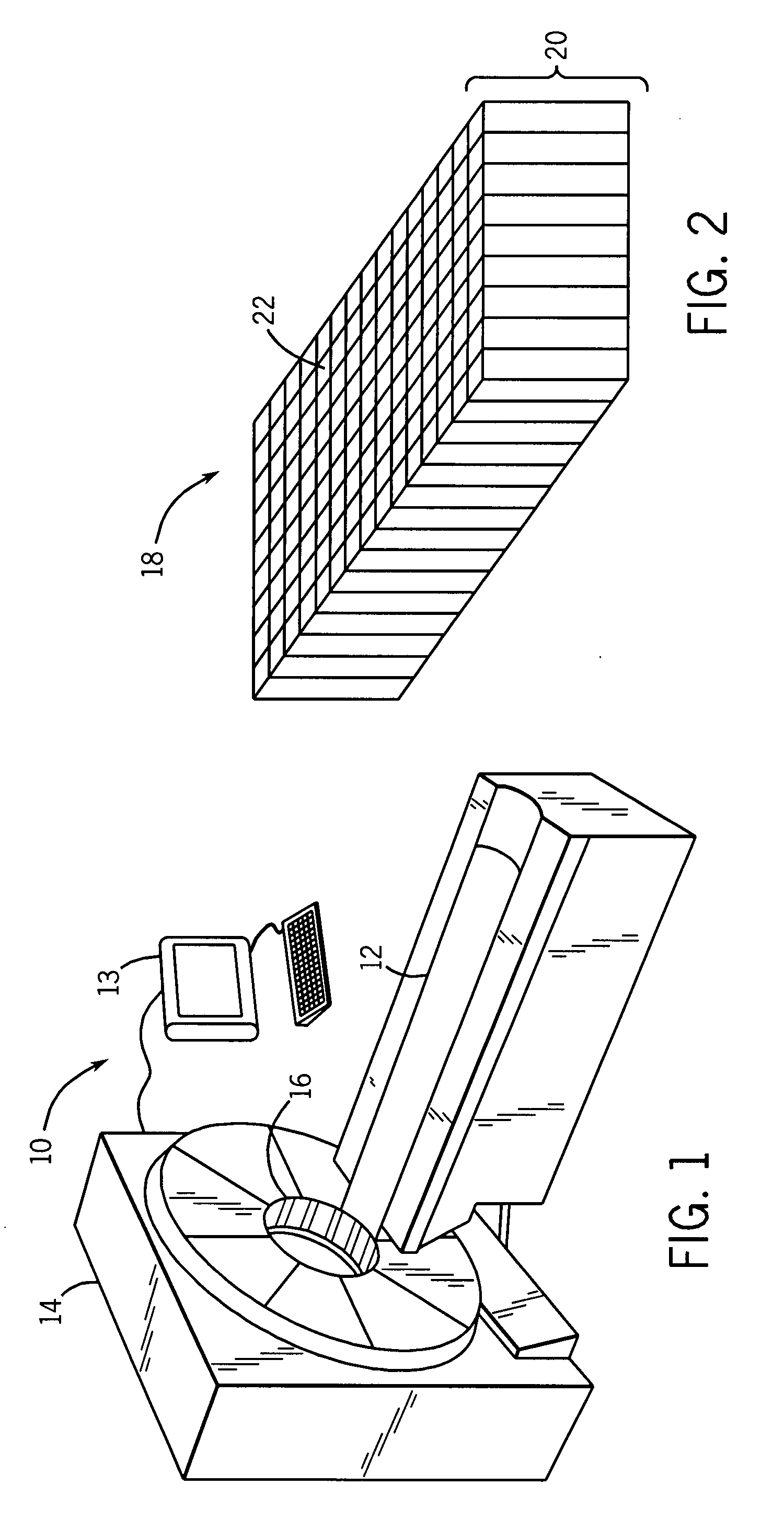

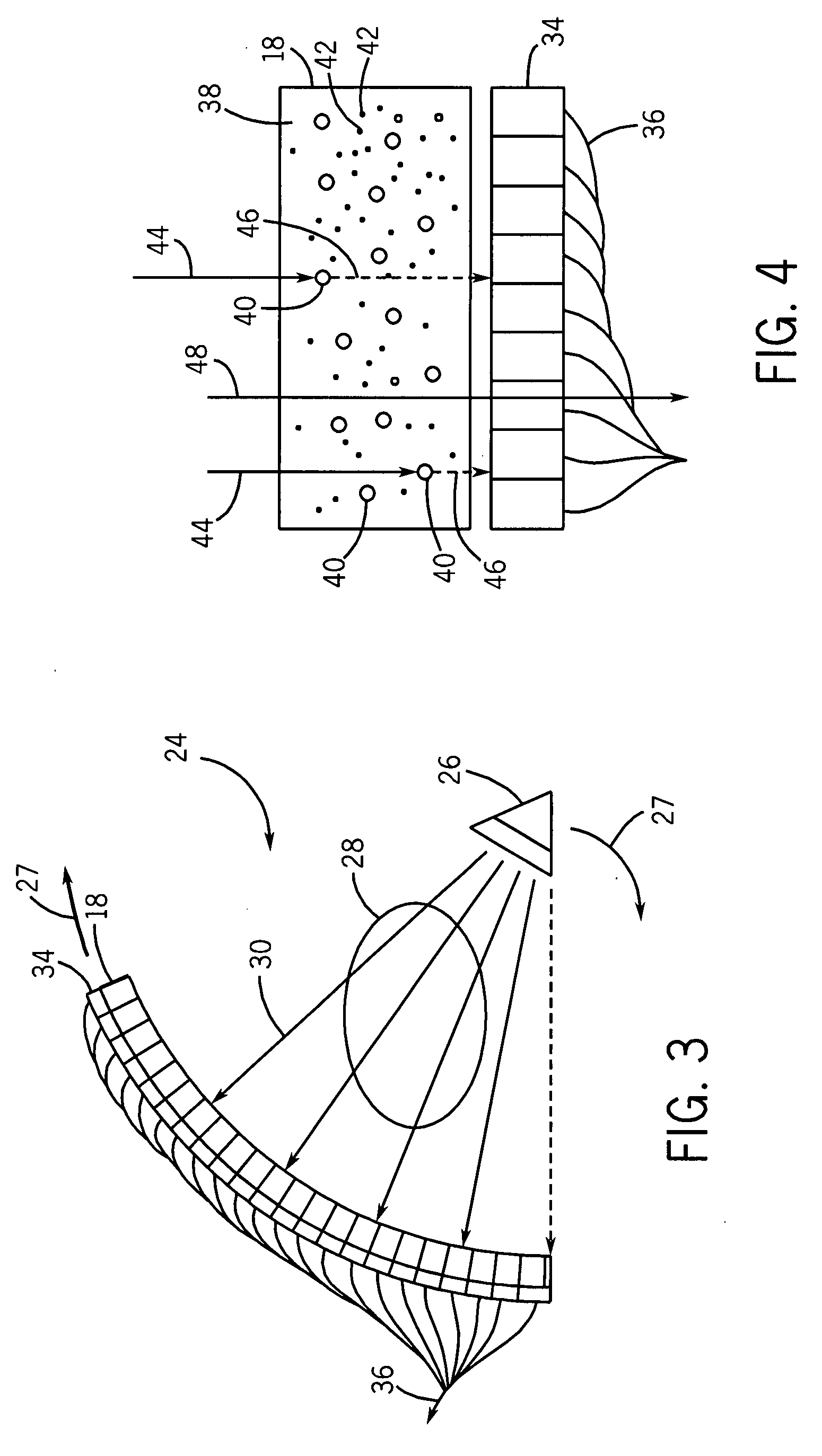

Nano-scale metal oxyhalide and oxysulfide scintillation materials and methods for making same

InactiveUS20080241041A1Rare earth metal oxides/hydroxidesMaterial nanotechnologyEmulsionNanoparticle

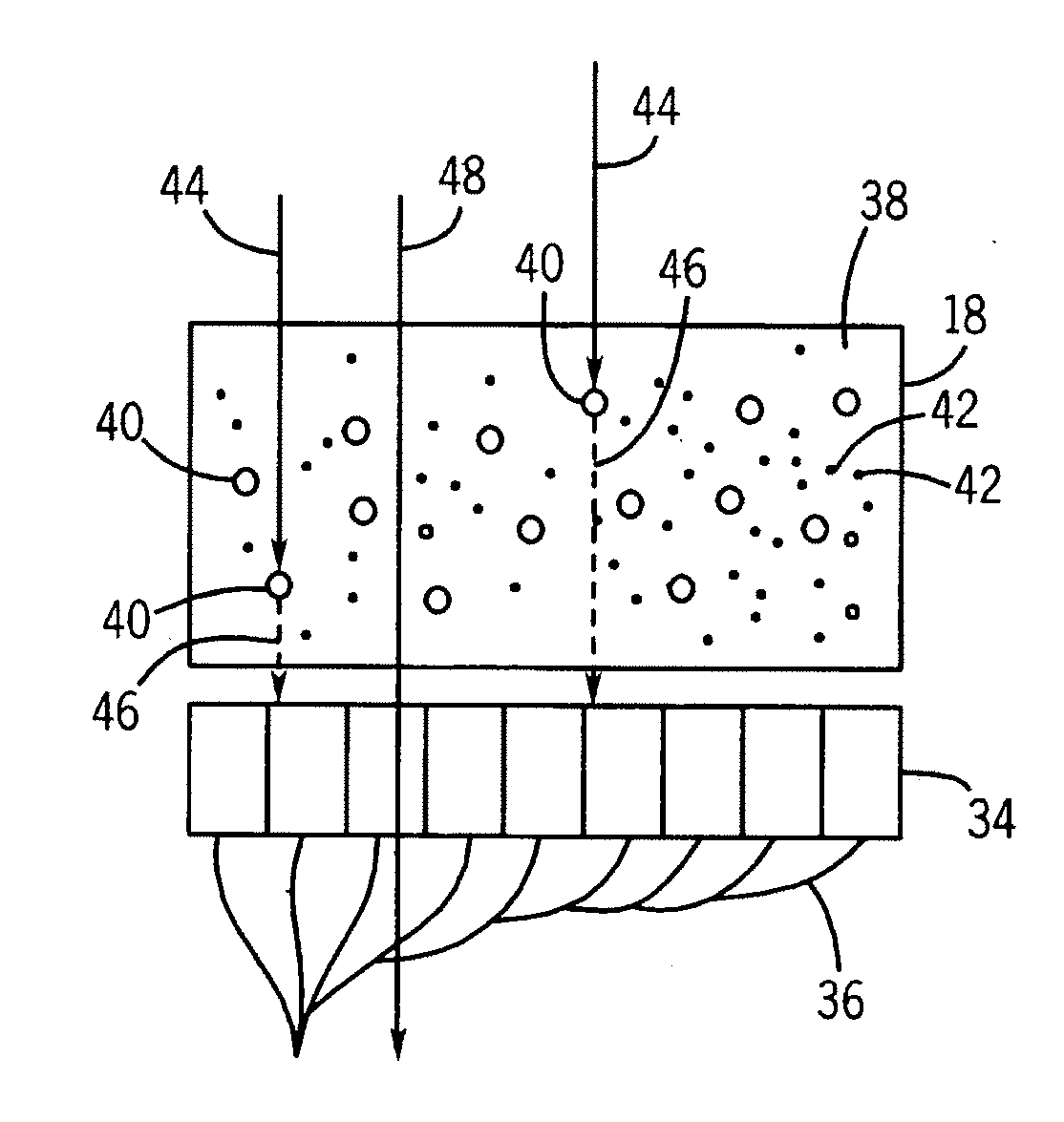

Crystalline scintillator materials comprising nano-scale particles of metal oxides, metal oxyhalides and metal oxysulfides are provided. The nano-scale particles are less than 100 nm in size. Methods are provided for preparing the particles. In one method, used to form oxyhalides and oxysulfides, metal salts are dissolved in water, and then precipitated out as fine particles using an aqueous base. After the particles are separated from the solution, they are annealed under a flow of a water saturated hydrogen anion gas, such as HCl or H2S, to form the crystalline scintillator particles. The other methods take advantage of the characteristics of microemulsion solutions to control droplet size, and, thus, the particle size of the final nano-particles. For example, in one method, a first micro-emulsion containing metal salts if formed. The first micro-emulsion is mixed with an aqueous base in a second micro-emulsion to form the final nano-scale particles.

Owner:GENERAL ELECTRIC CO

Nano-scale metal oxyhalide and oxysulfide scintillation materials and methods for making same

InactiveUS20110024685A1Rare earth metal oxides/hydroxidesMaterial nanotechnologyEmulsionMicroemulsion

Crystalline scintillator materials comprising nano-scale particles of metal oxides, metal oxyhalides and metal oxysulfides are provided. The nano-scale particles are less than 100 nm in size. Methods are provided for preparing the particles. In one method, used to form oxyhalides and oxysulfides, metal salts are dissolved in water, and then precipitated out as fine particles using an aqueous base. After the particles are separated from the solution, they are annealed under a flow of a water saturated hydrogen anion gas, such as HCl or H2S, to form the crystalline scintillator particles The other methods take advantage of the characteristics of microemulsion solutions to control droplet size, and, thus, the particle size of the final nano-particles. For example, in one method, a first micro-emulsion containing metal salts if formed. The first micro-emulsion is mixed with an aqueous base in a second micro-emulsion to form the final nano-scale particles.

Owner:GENERAL ELECTRIC CO

Nano-scale metal halide scintillation materials and methods for making same

Crystalline scintillator materials comprising nano-scale particles of metal halides are provided. The nano-scale particles are less than 100 nm in size. Methods are provided for preparing the particles. In these methods, ionic liquids are used in place of water to allow precipitation of the final product. In one method, the metal precursors and halide salts are dissolved in separate ionic liquids to form solutions, which are then combined to form the nano-crystalline end product. In the other methods, micro-emulsions are formed using ionic liquids to control particle size.

Owner:GENERAL ELECTRIC CO

Preparation method of cerium dioxide fluoride polishing powder under microwave condition

ActiveCN112266730AReduce reunionGranularityOther chemical processesRare earth metal compounds preparation/treatmentCerium(IV) oxidePhysical chemistry

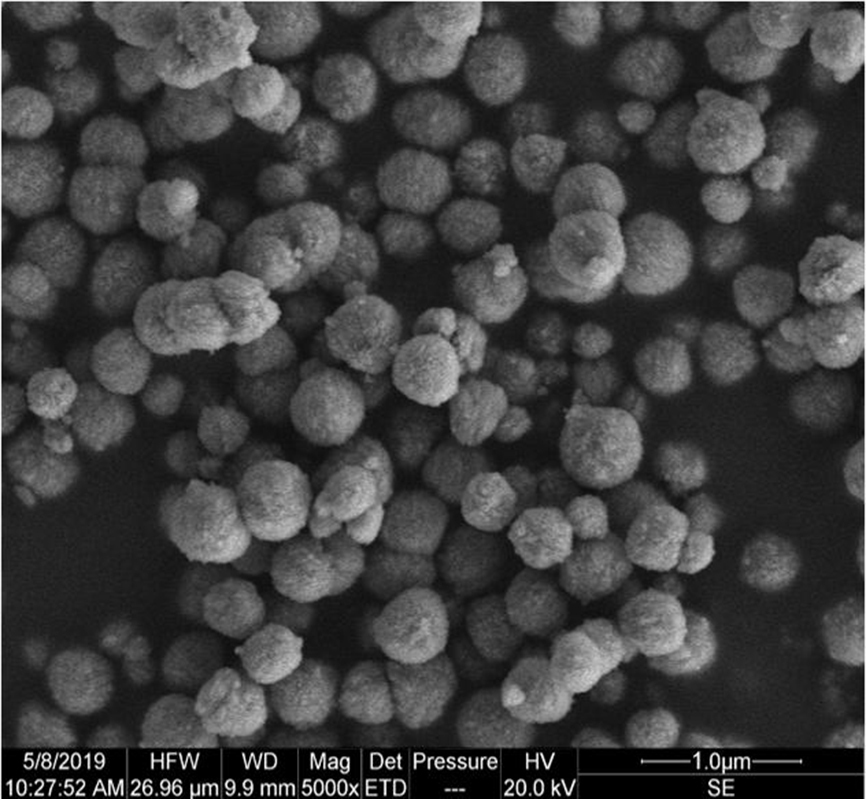

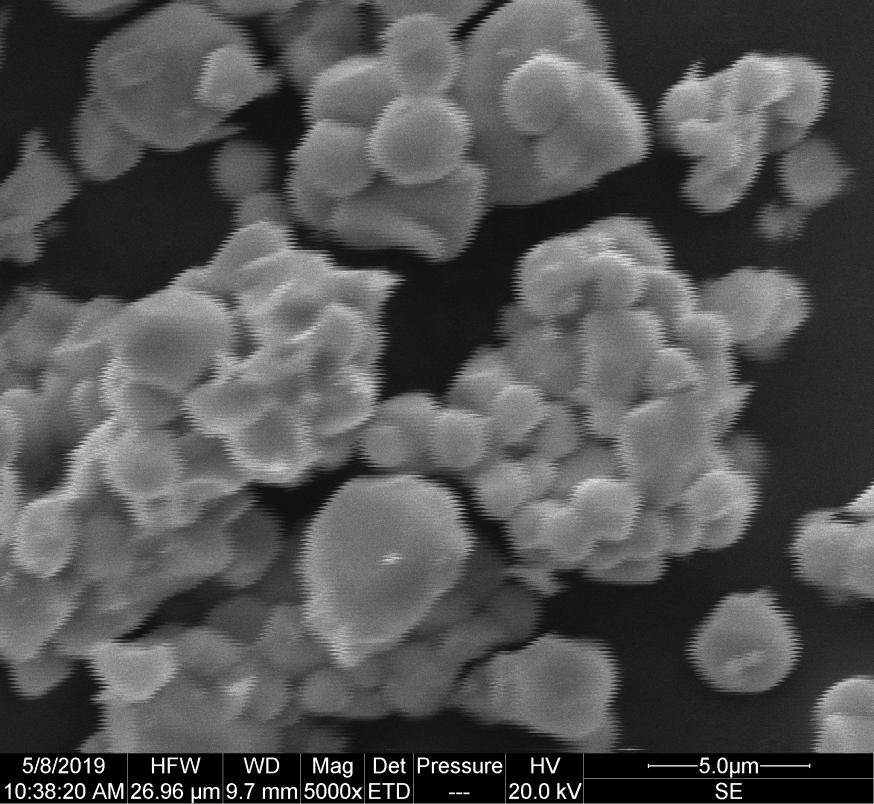

The invention discloses a preparation method of cerium dioxide fluoride polishing powder under a microwave condition, which belongs to the technical field of nano rare earth material preparation. Thepreparation method comprises the following steps: dissolving Ce(NO3)3.6H2O in deionized water, preheating in a microwave mode, and adding NH4F; dissolving NH4HCO3 in deionized water, adding a preheated Ce(NO3)3.6H2O and NH4F mixed solution into the deionized water, carrying out a constant-temperature precipitation reaction under a microwave condition to generate a Ce2(CO3)3 precursor, and continuing to age the Ce2(CO3)3 precursor; filtering the precursor reaction solution to obtain a precipitate, drying at a constant temperature, and grinding into powder; and roasting the precursor powder to prepare cerium dioxide fluoride polishing powder. The cerium dioxide powder prepared by the method disclosed by the invention is high in particle crystallinity, regular and spherical in morphology, uniform in particle size distribution and good in dispersity, and the polishing efficiency and the polishing precision of the fluorinated cerium dioxide powder are further improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

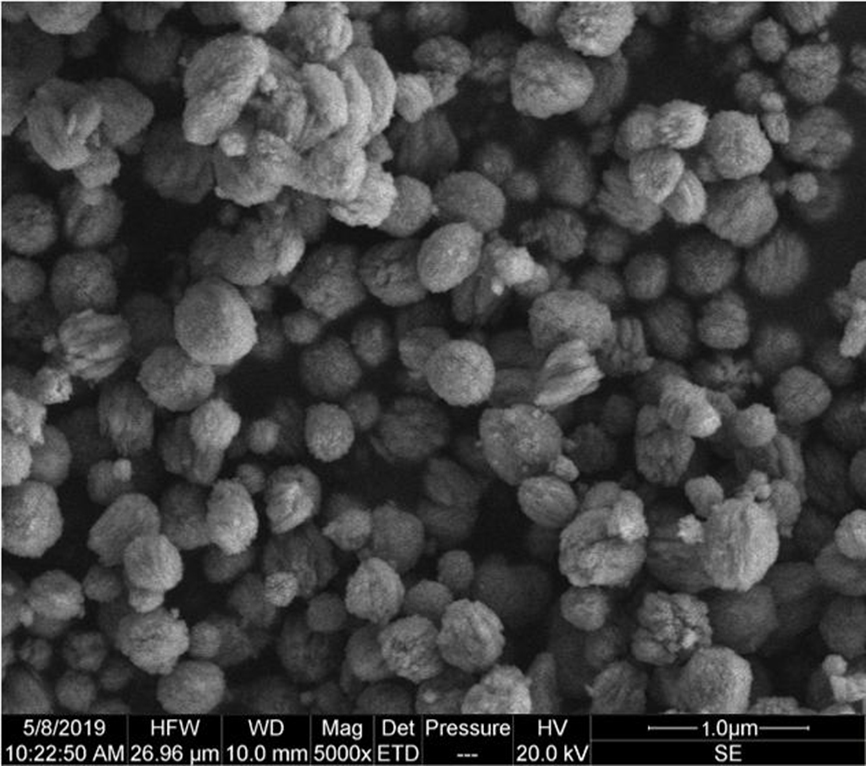

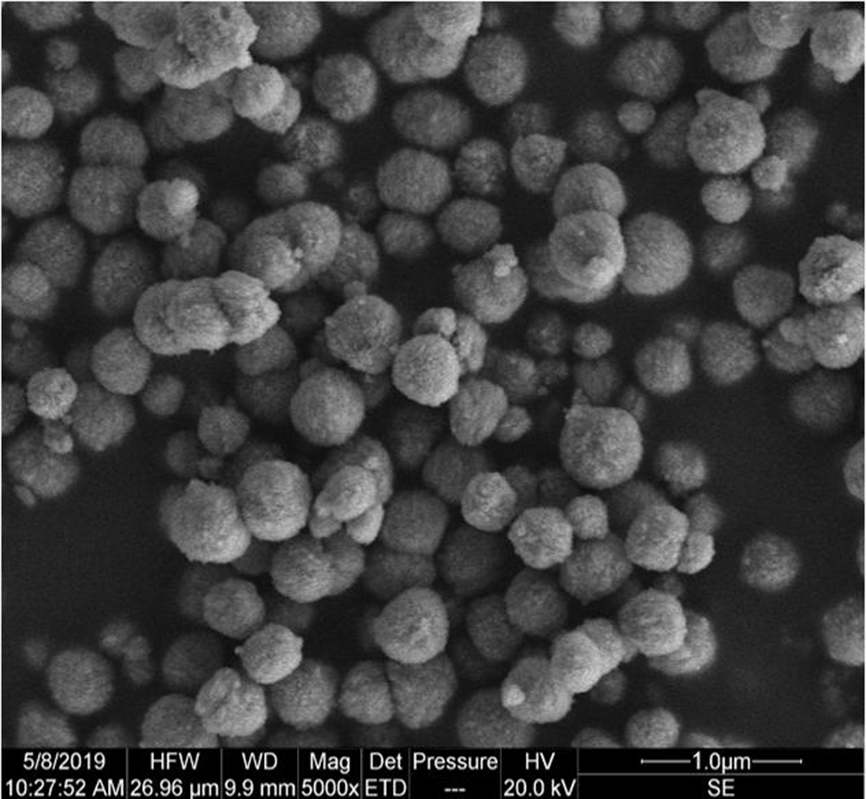

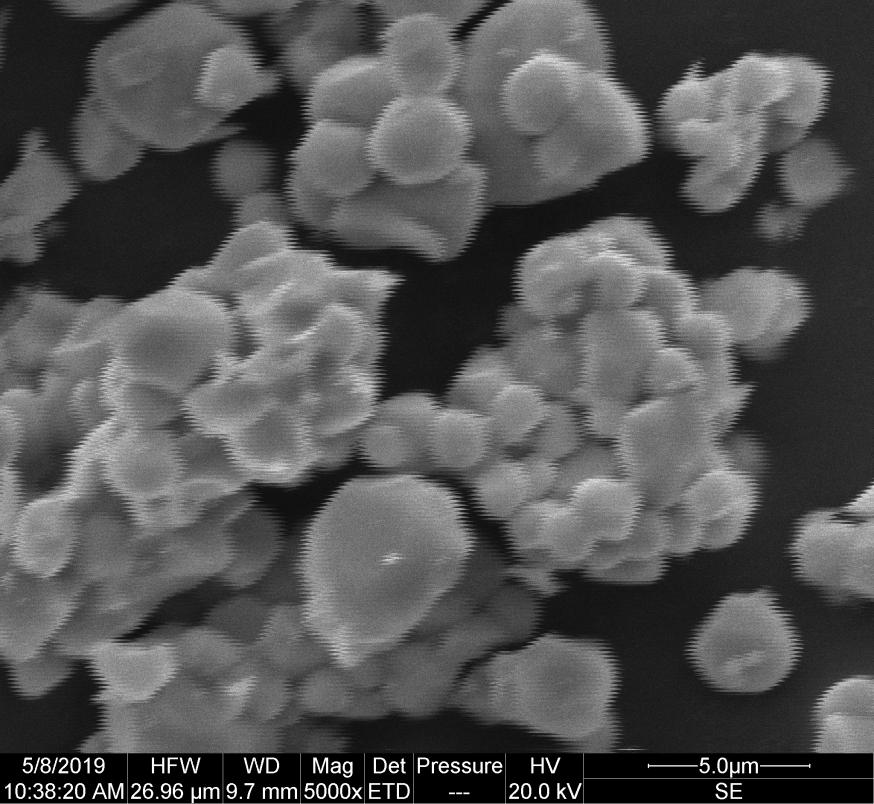

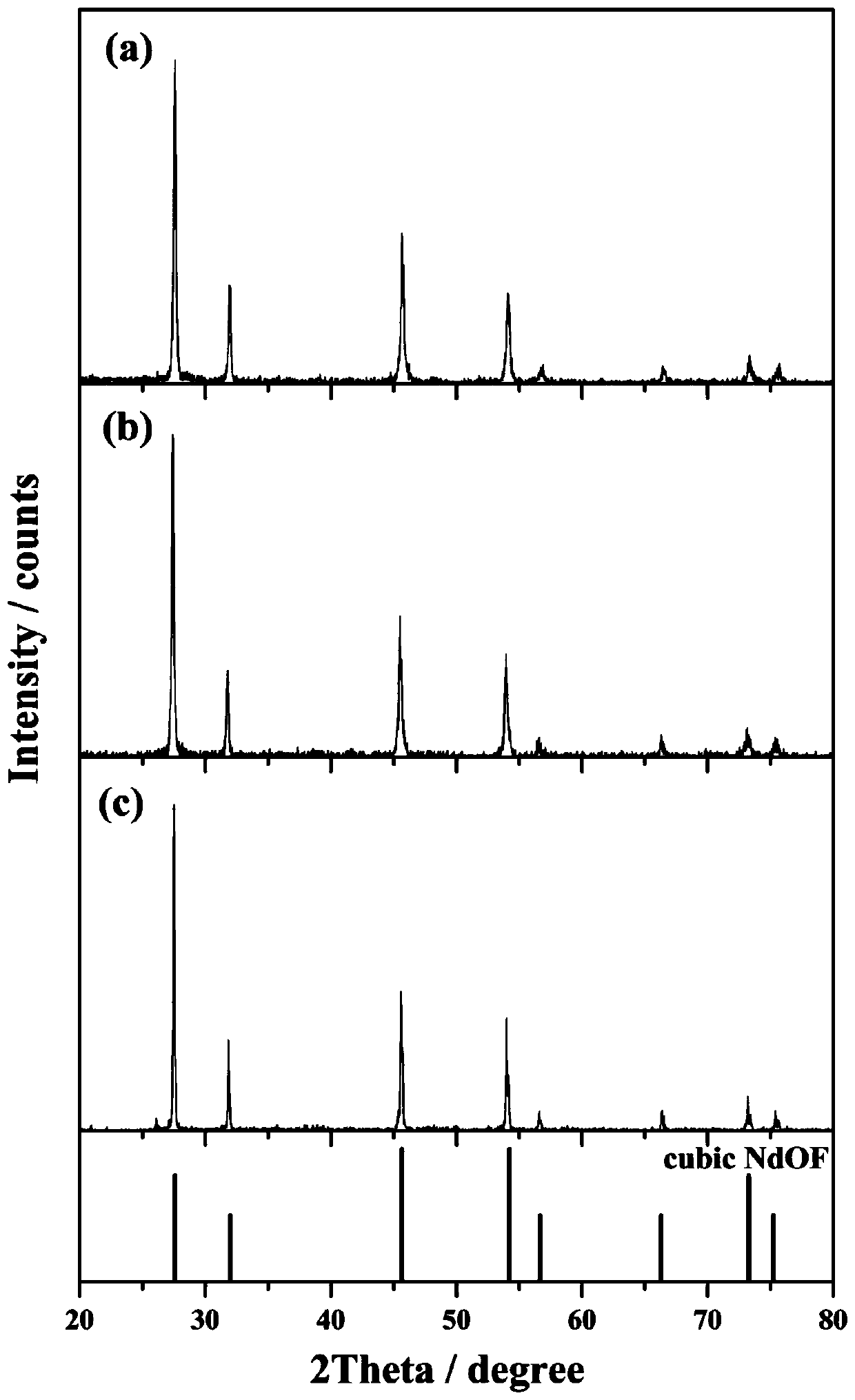

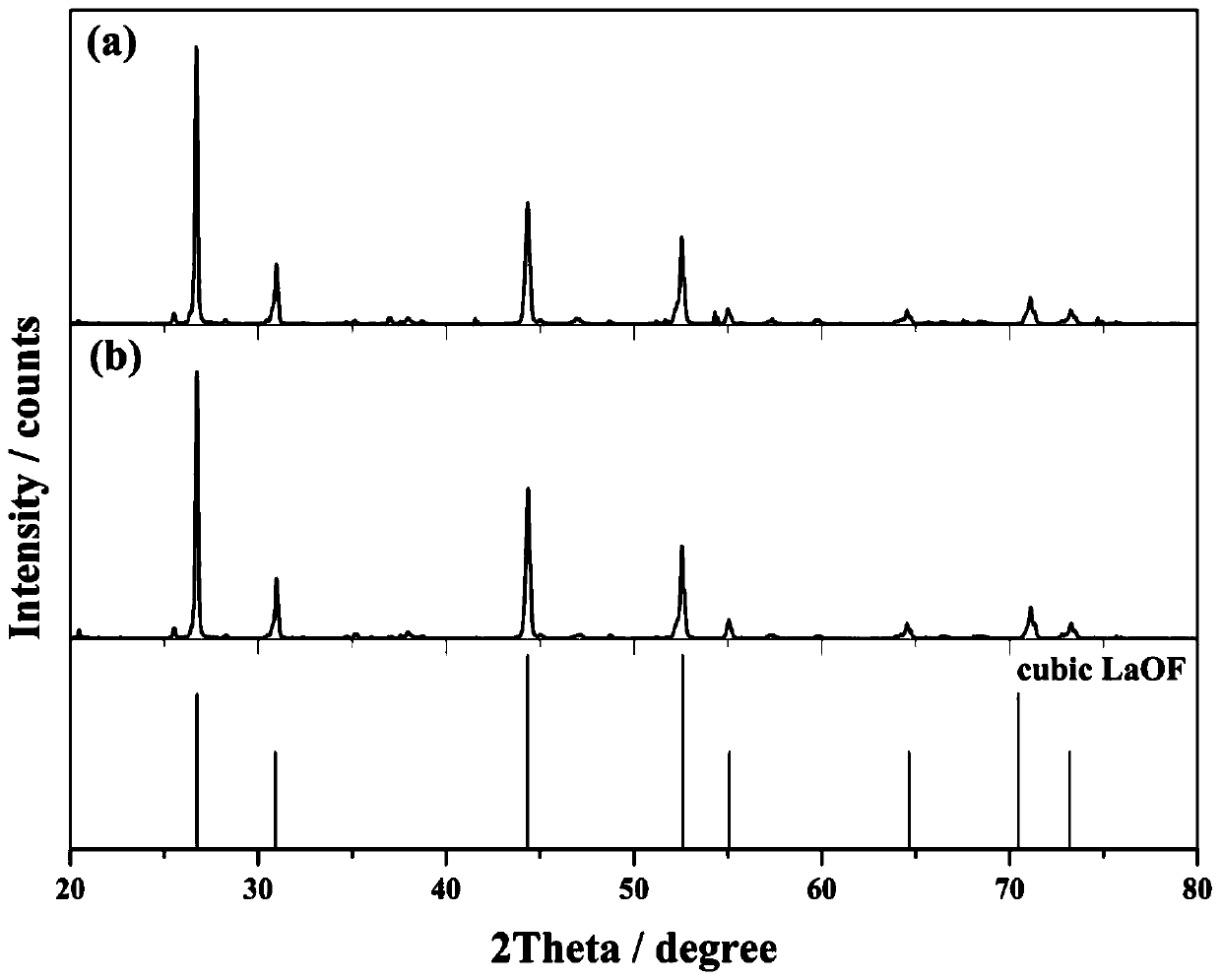

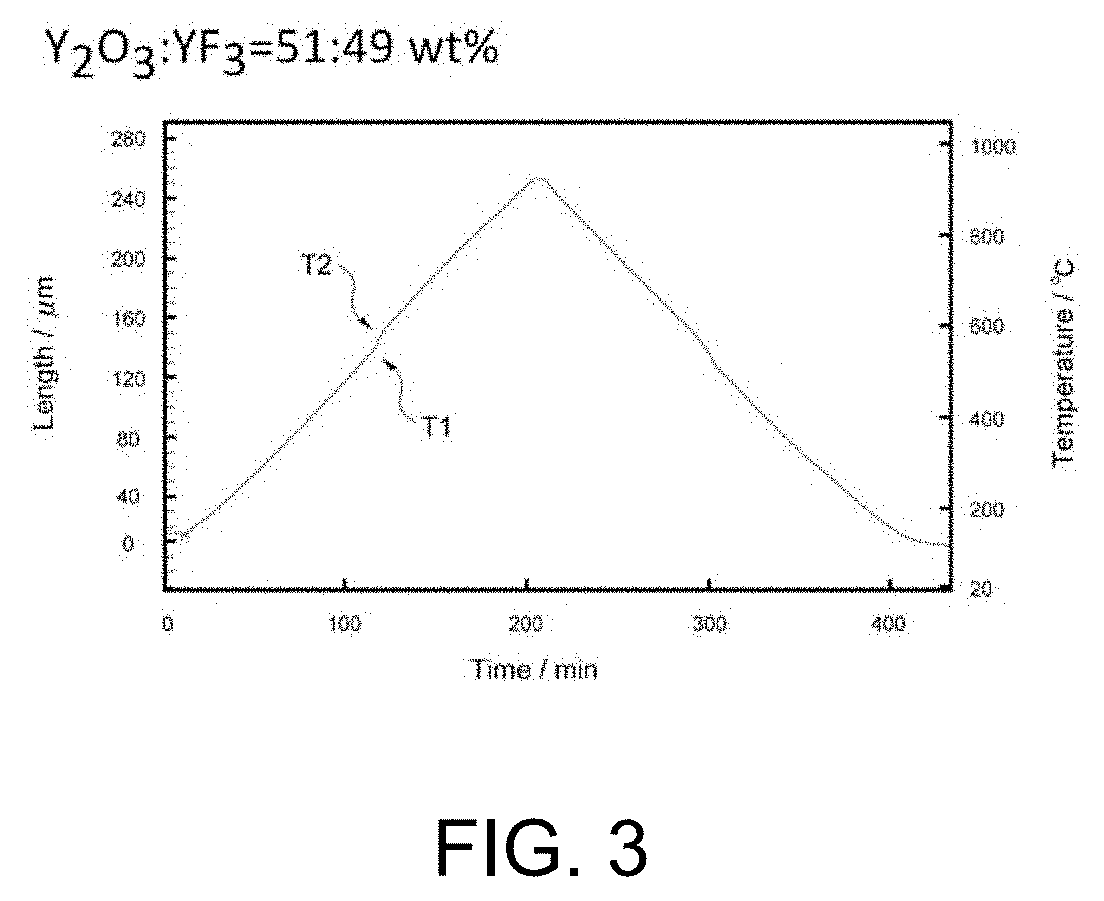

Molten salt synthesis method of rare earth oxyfluoride with cubic crystal form

ActiveCN111268715AIncrease reaction rateSynthetic conditions are not harshRare earth metal oxyhalidesAlkaline earth metalReaction rate

The invention discloses a molten salt synthesis method of rare earth oxyfluoride with a cubic crystal form. The method comprises the following steps: mixing rare earth oxide and rare earth fluoride toobtain a rare earth mixture, uniformly mixing the rare earth mixture with alkali metal fluoride and / or alkaline-earth metal fluoride, heating to a temperature higher than the melting point of the mixed fluoride, keeping the temperature for a preset time, and cooling to obtain the rare earth oxyfluoride with the cubic crystal form. According to the synthesis method of rare earth oxyfluoride, the cubic crystal structure of the rare earth oxyfluoride at high temperature can be reserved without quenching, inert atmosphere or reducing atmosphere is not needed as protective atmosphere, the molten salt synthesis reaction rate is far higher than the traditional solid-phase synthesis reaction rate, and the method has the characteristics of simple synthesis process, high synthesis efficiency and low cost.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

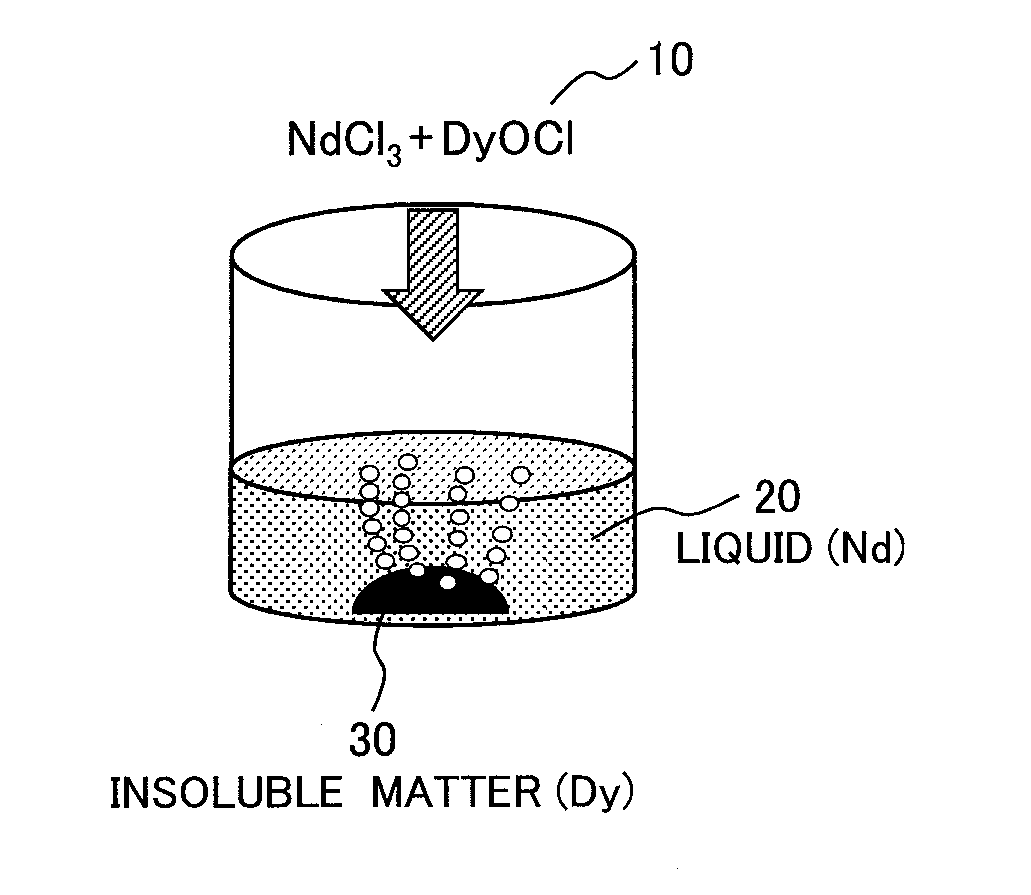

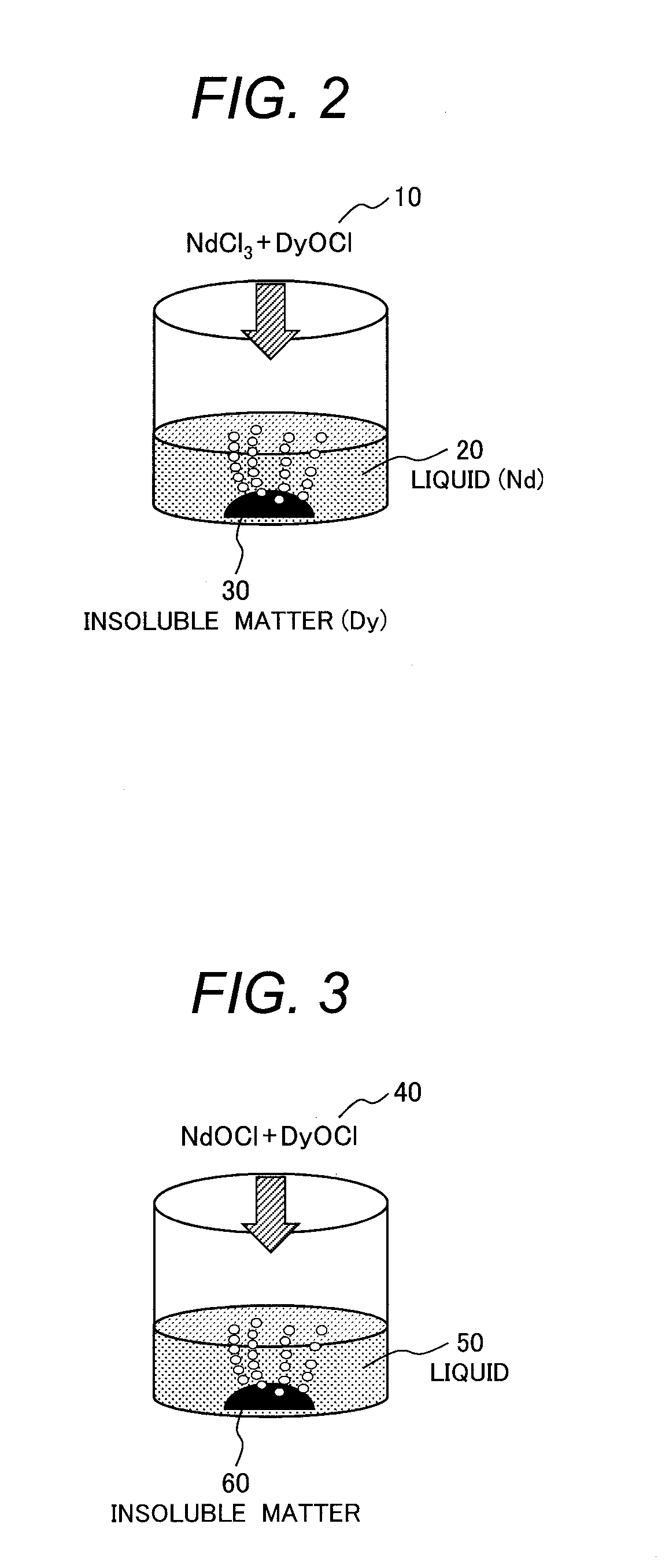

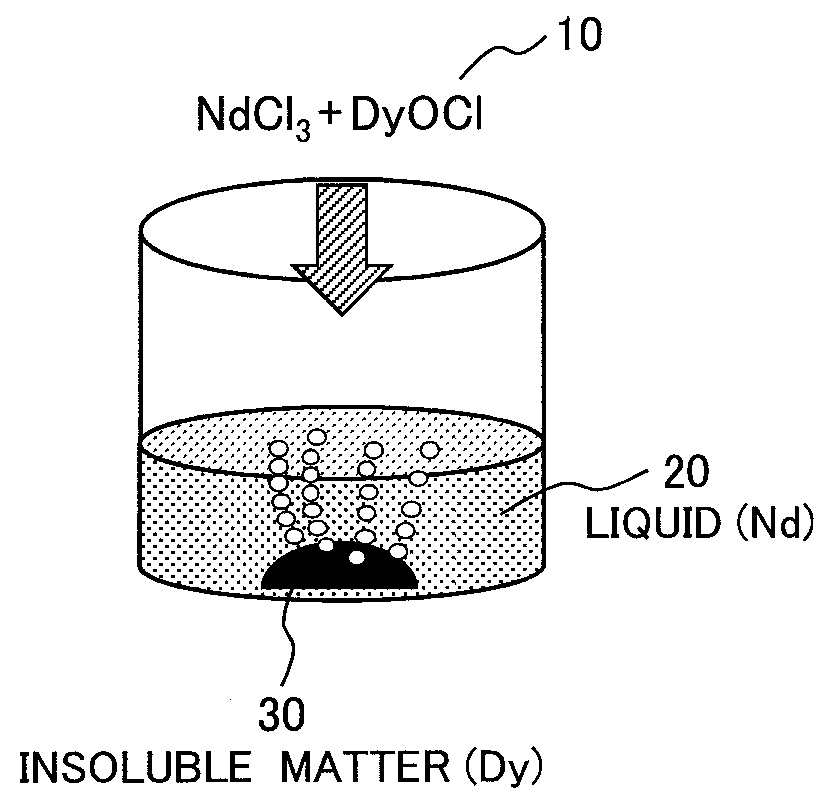

Method for Separating and Recovering Rare-Earth Elements

ActiveUS20140356258A1Less effectHigh separation rateRare earth metal chloridesLanthanide oxides/hydroxidesRare-earth elementTrace element

A method for separating and recovering a plurality of rare-earth elements, the method including a step of introducing, into a liquid, a mixture containing a rare-earth oxychloride and a rare-earth chloride, the rare-earth oxychloride constituted from a rare-earth element different from a rare-earth element constituting the rare-earth chloride, thereby obtaining an insoluble matter containing the rare-earth oxychloride and a liquid in which the rare-earth chloride is dissolved, a step of recovering the rare-earth oxychloride from the insoluble matter, and a step of recovering the rare-earth chloride from the liquid in which the rare-earth chloride is dissolved.

Owner:HITACHI METALS LTD

Method of manufacturing nanoparticle dispersion liquid

InactiveUS20130338304A1Small particle sizeMaterial nanotechnologyRare earth metal chloridesSolventViscosity

The present invention provides a method of producing a nanoparticle dispersion liquid, including: altering a surface of a nanoparticle in the presence of an ion by contacting a complex that includes the nanoparticle and a solid material present around the nanoparticle with a surface altering agent-containing liquid, that includes a surface altering agent for altering the surface of the nanoparticle and a solvent for dissolving the solid material and that has a viscosity of 1.10 mPa·s or more at 25° C.; and a dispersing step of dispersing the surface-altered nanoparticle in the solvent.

Owner:TOKYO UNIVERSITY OF SCIENCE

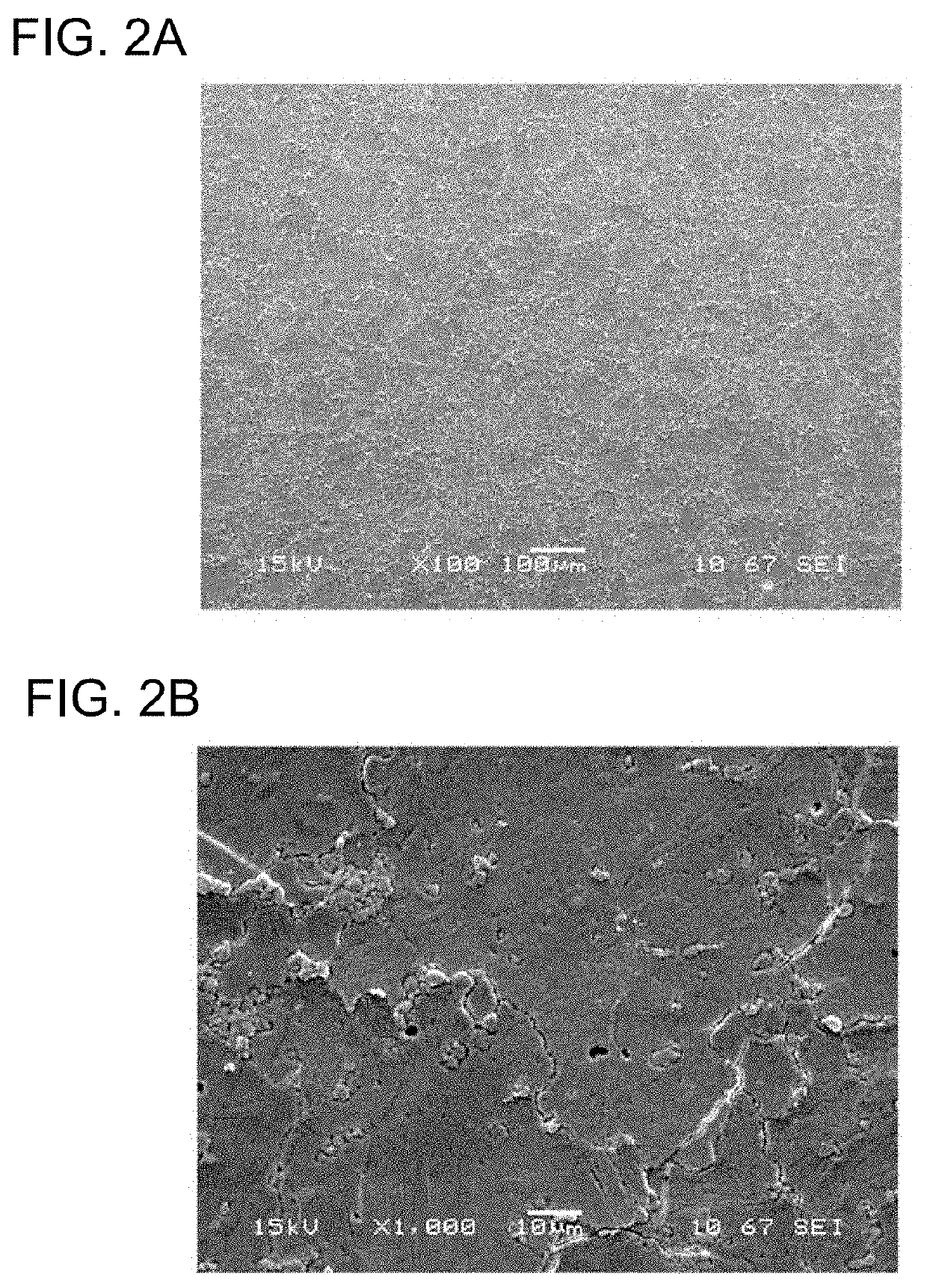

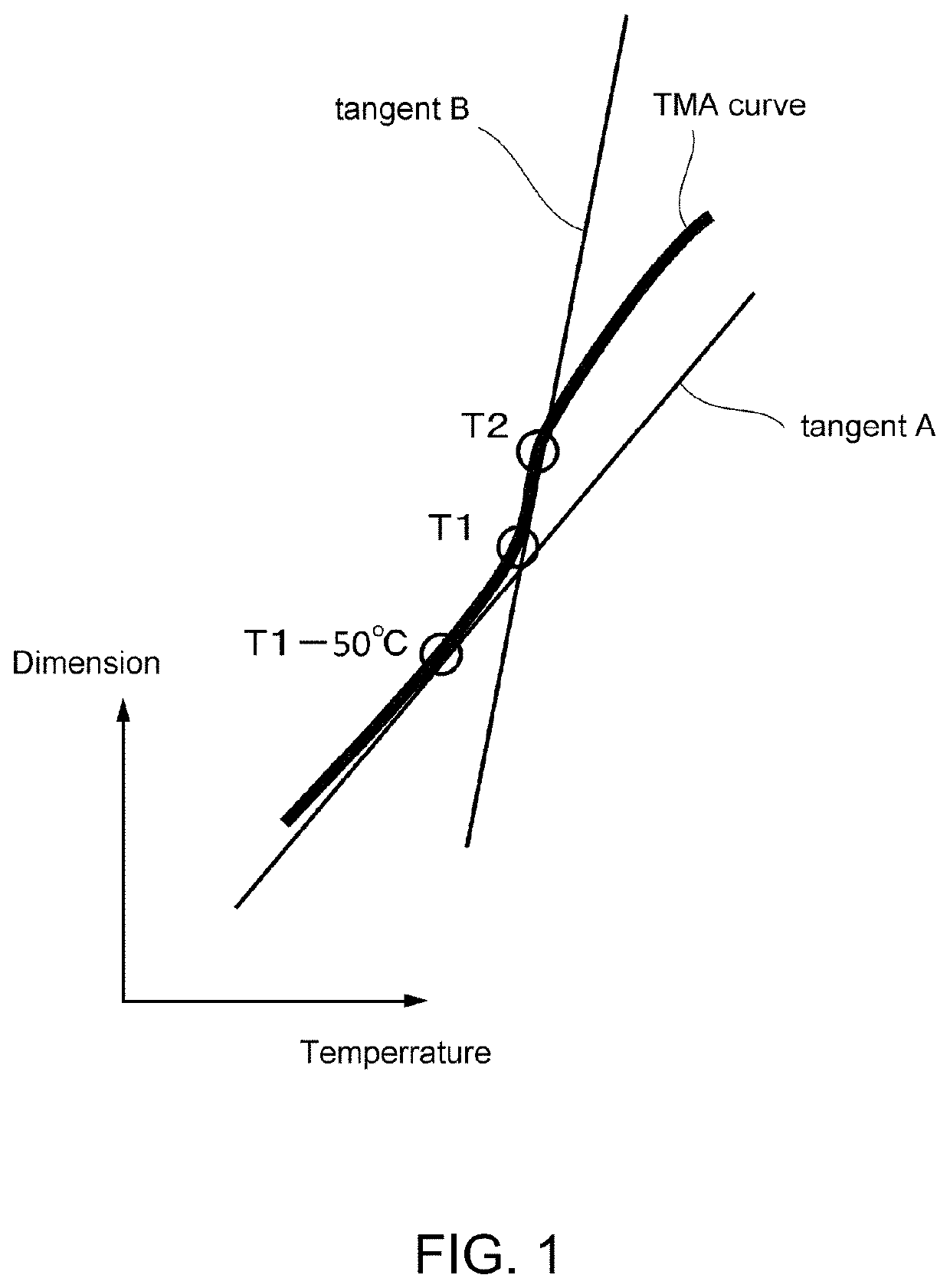

Rare earth oxyfluoride sintered body and method for producing same

ActiveUS20190345069A1High strengthYittrium oxides/hydroxidesRare earth metal oxyhalidesRare-earth elementMaterials science

A sintered rare earth oxyfluoride compact is composed of LnaObFc (wherein Ln is a rare earth element; and a, b, and c each independently represent a positive number, provided that they are not equal to each other) or Ca-stabilized LnOF as a primary phase and LnOF unstabilized with Ca as a secondary phase. The intensity ratio of the XRD peak of the (018) or (110) plane of the unstabilized LnOF to the highest XRD peak of LnaObFc is preferably 0.5% to 30%.

Owner:MITSUI MINING & SMELTING CO LTD

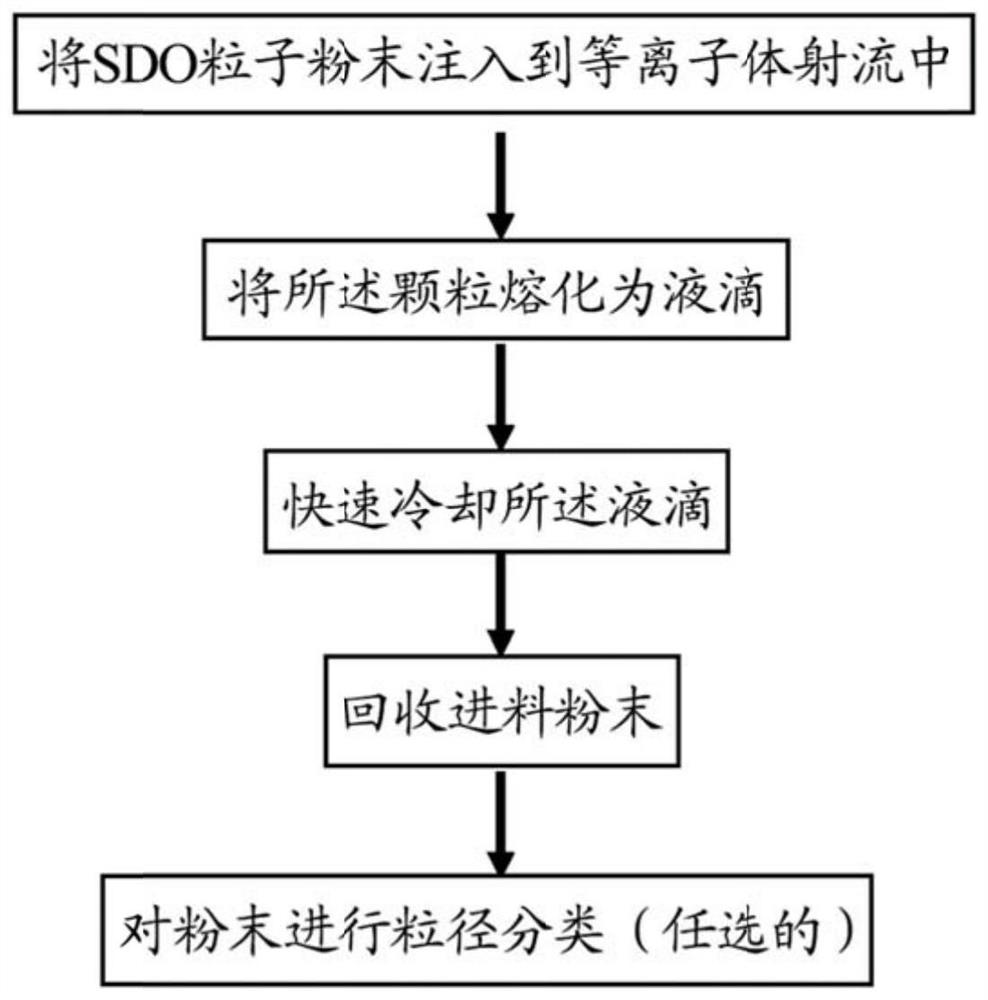

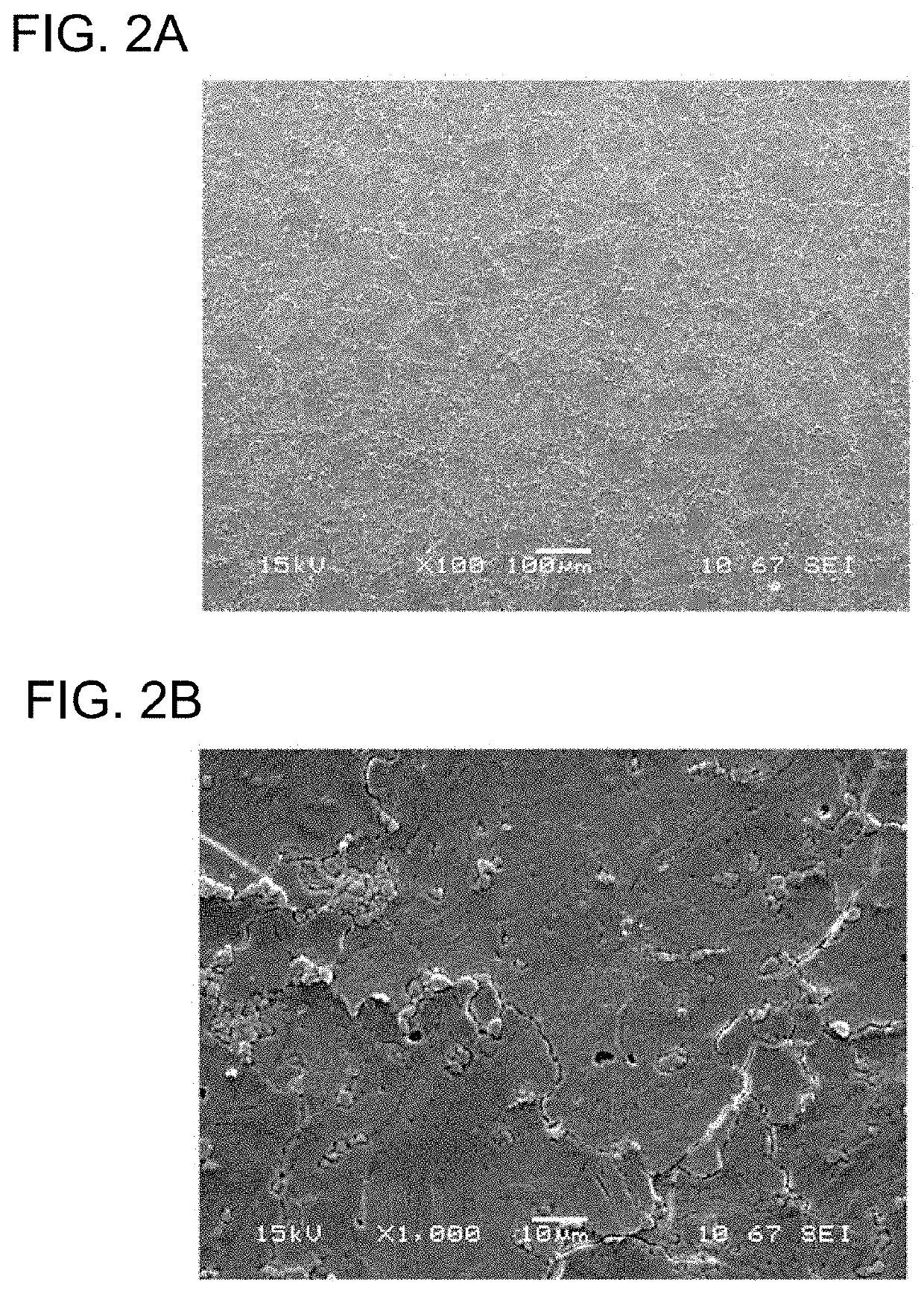

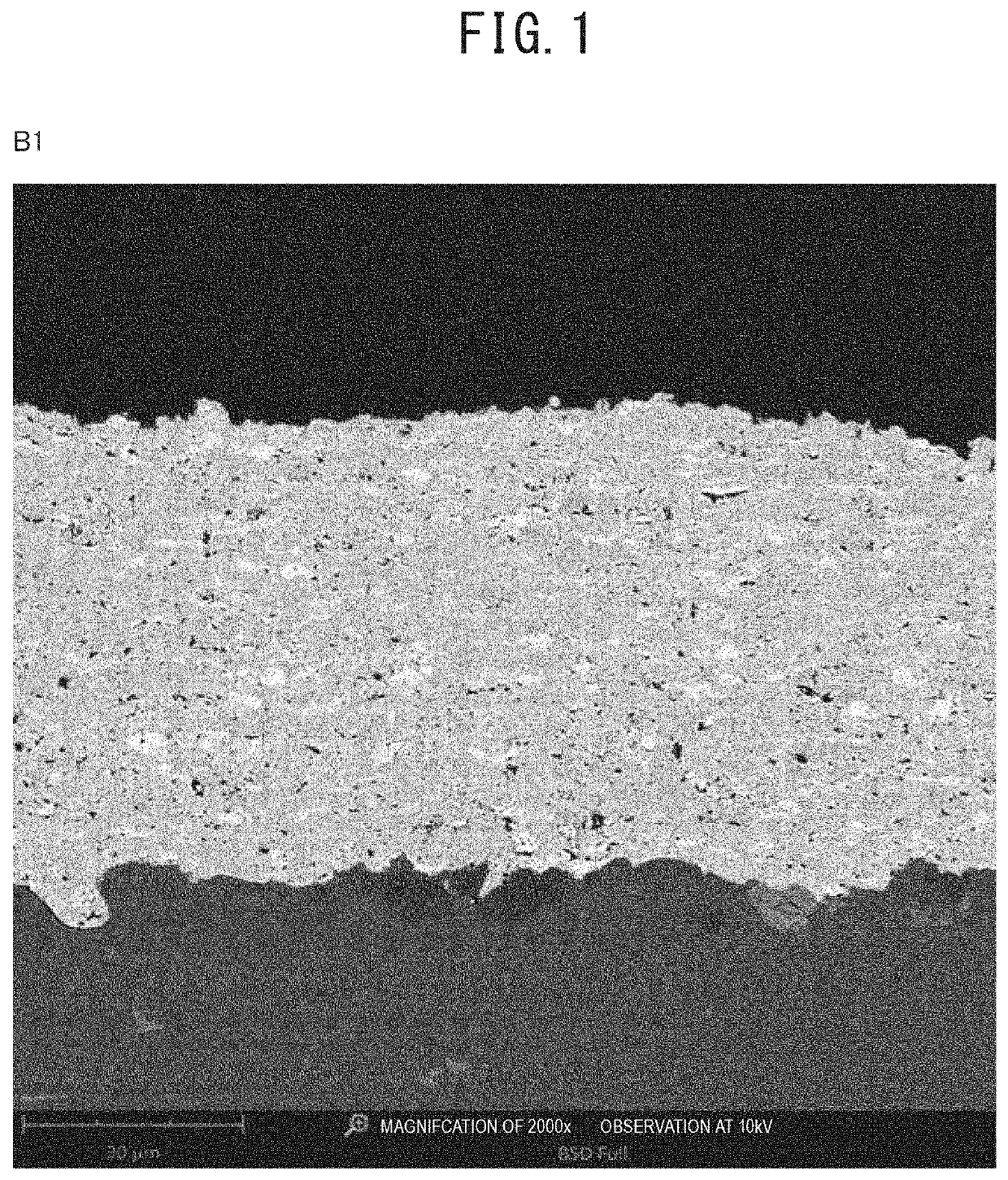

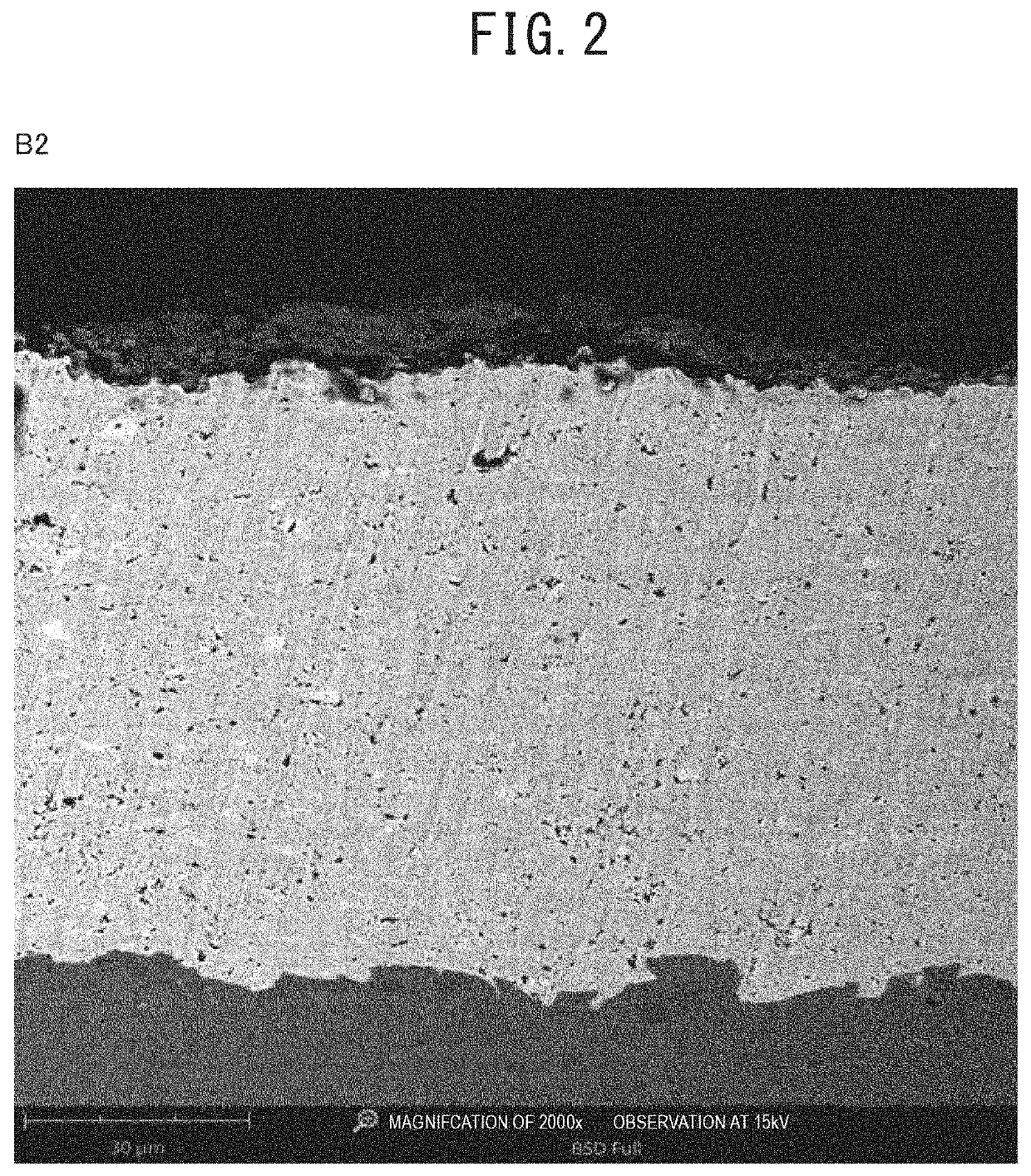

Powder for coating an etch chamber

ActiveCN111670164AImprove liquidityMeet needsLanthanide oxides/hydroxidesMolten spray coatingAluminium oxidesHafnium oxide

Particle powder, a number greater than 95% of the particles having a circularity greater than or equal to 0.85, the powder containing more than 99.8% of a rare earth oxide and / or a hafnium oxide and / or an aluminium oxide, as a percentage by weight on the basis of the oxides, and having: a median particle size D50 less than 15 [Mu]m, a 90th percentile of the particle sizes D90 less than 30 [Mu]m, and a size dispersion index (D90 -D10) / D10 less than 2; and a relative density greater than 90%.

Owner:SAINT GOBAIN CENT DE RES & DEVS & DETUD EUROEN

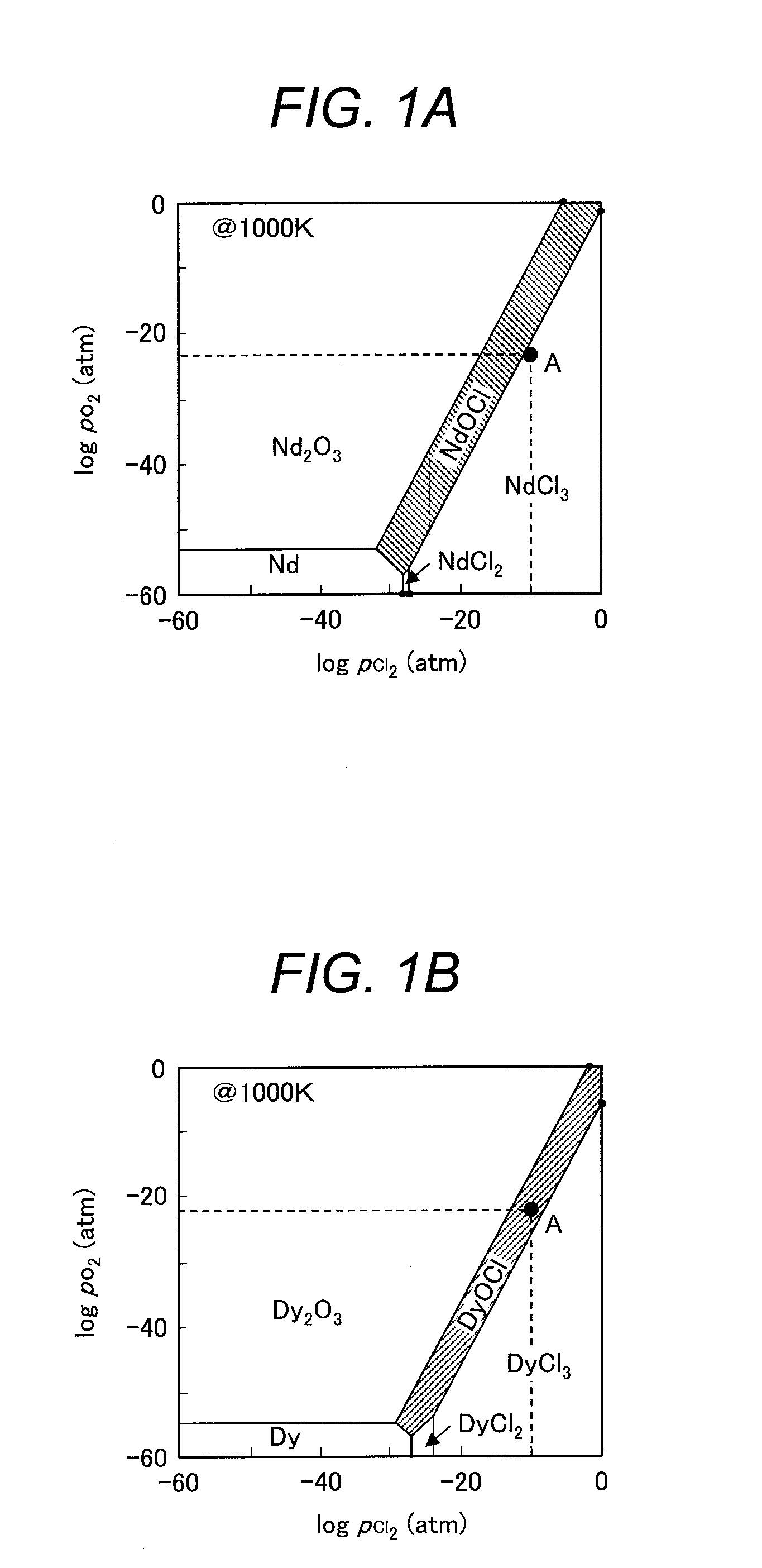

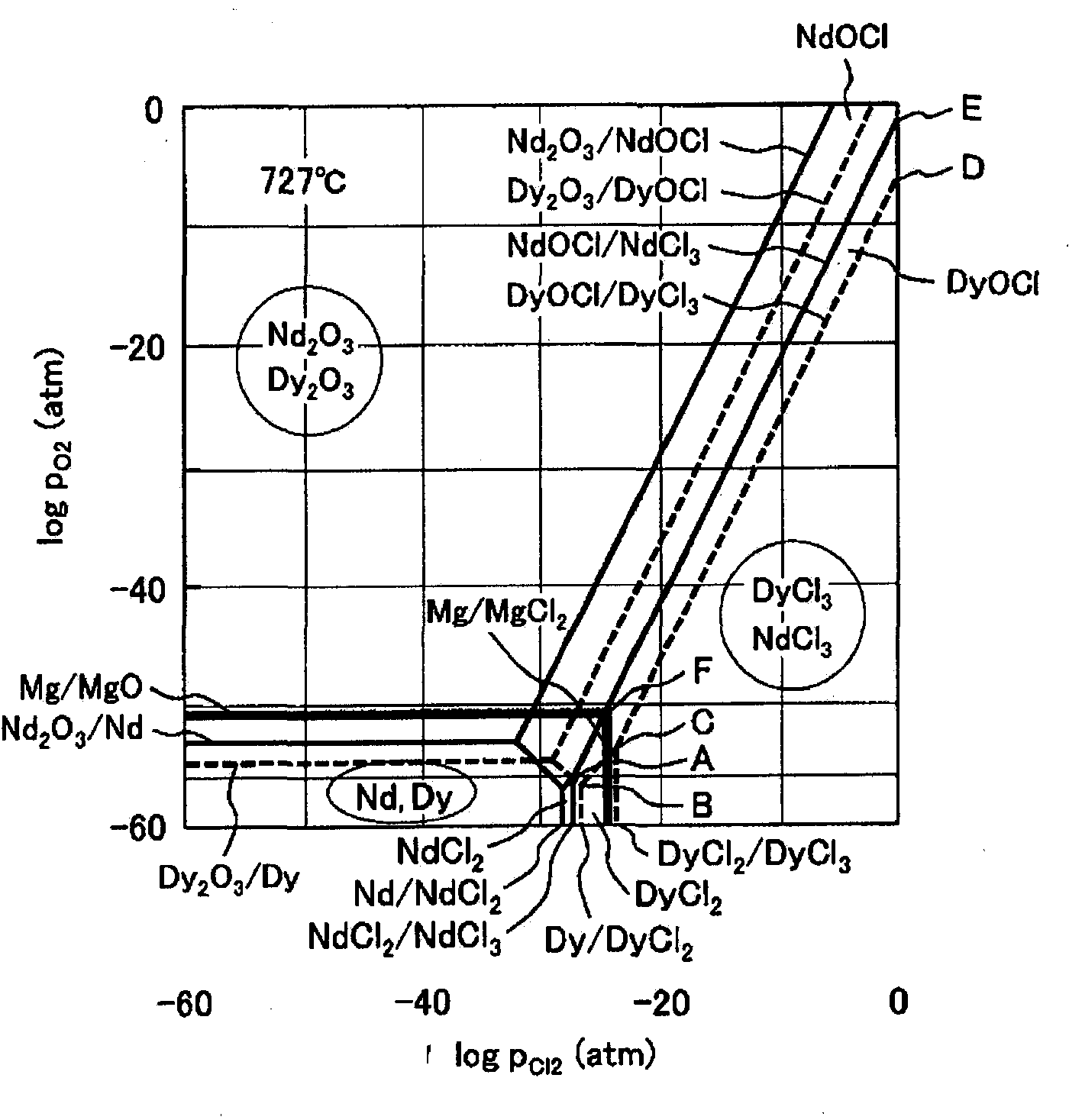

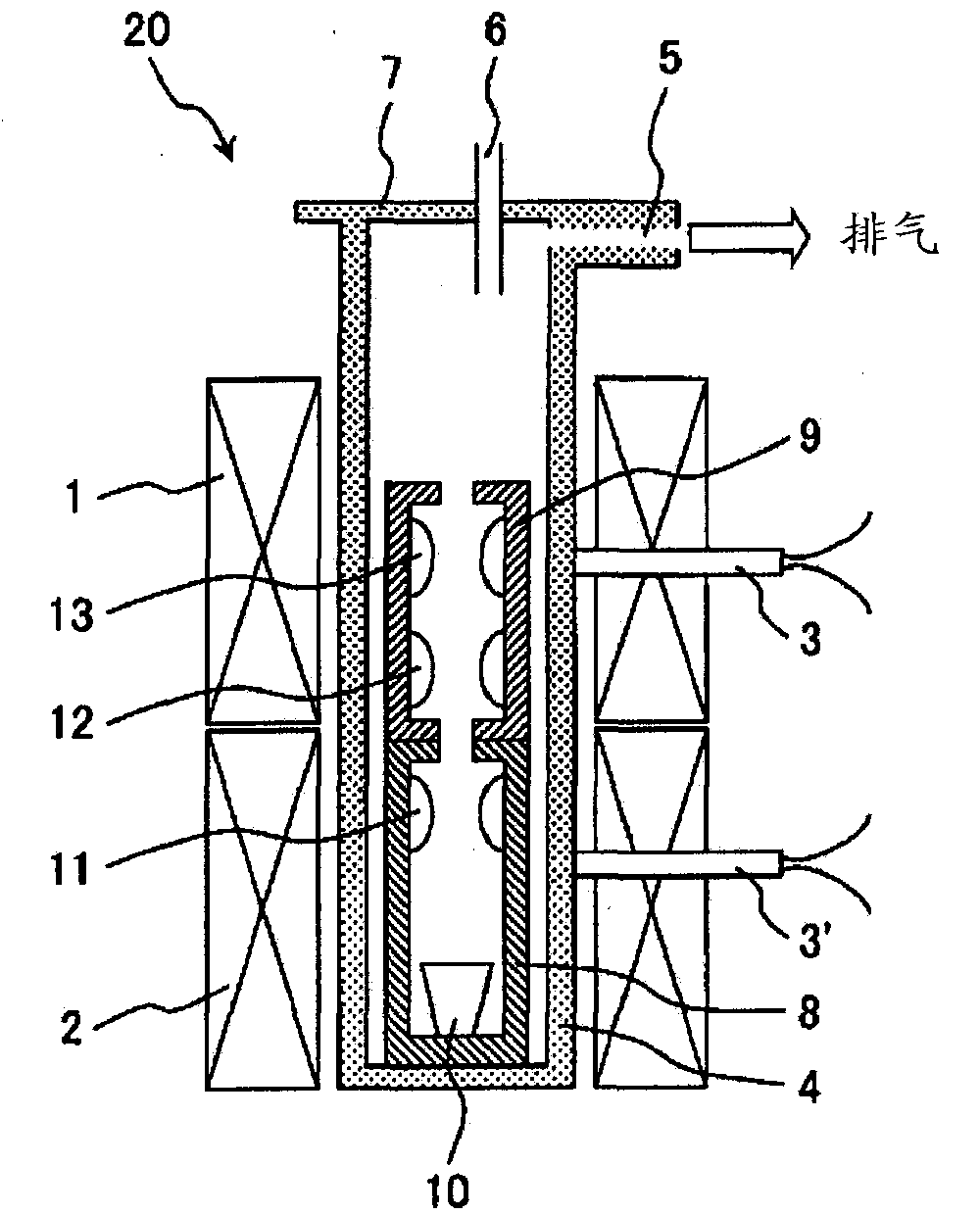

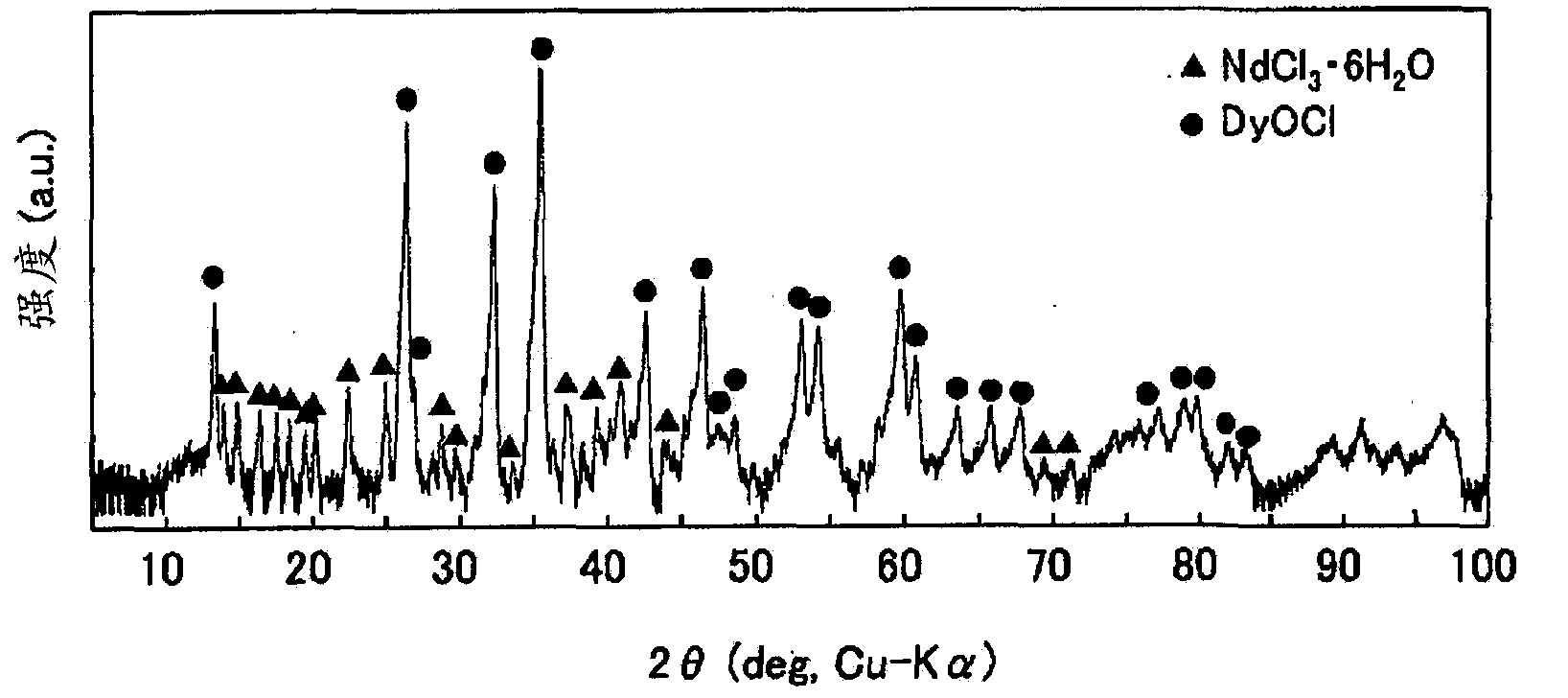

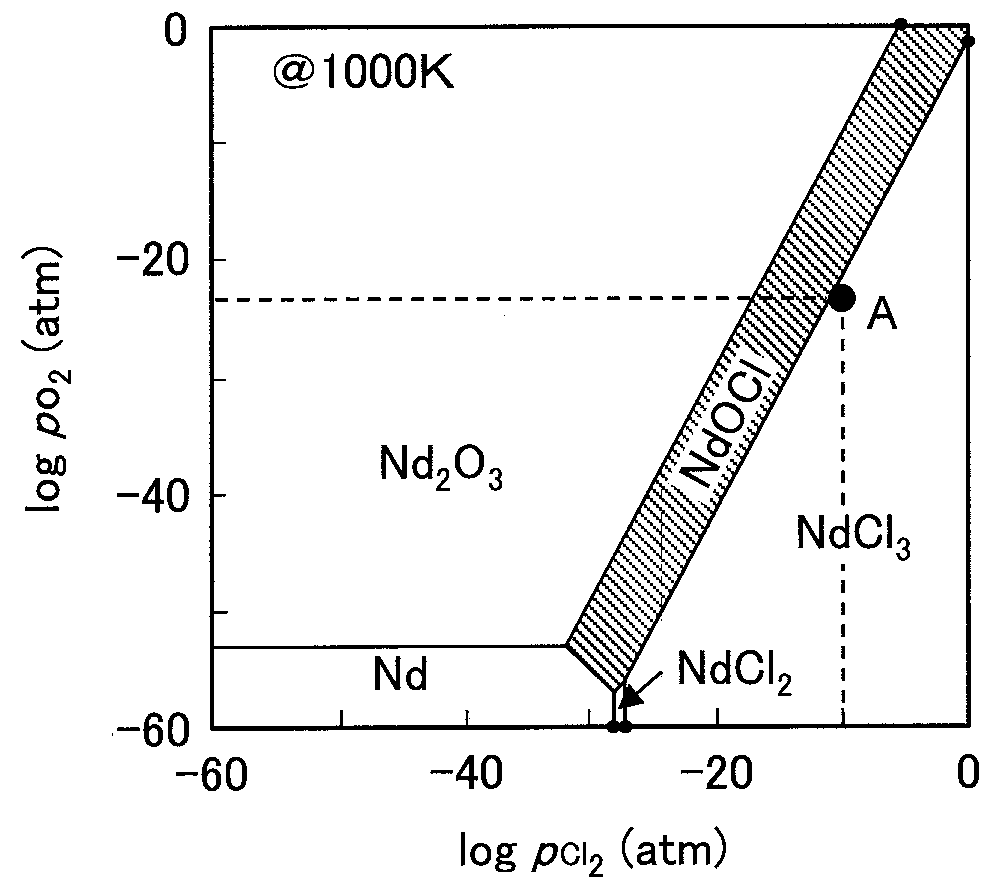

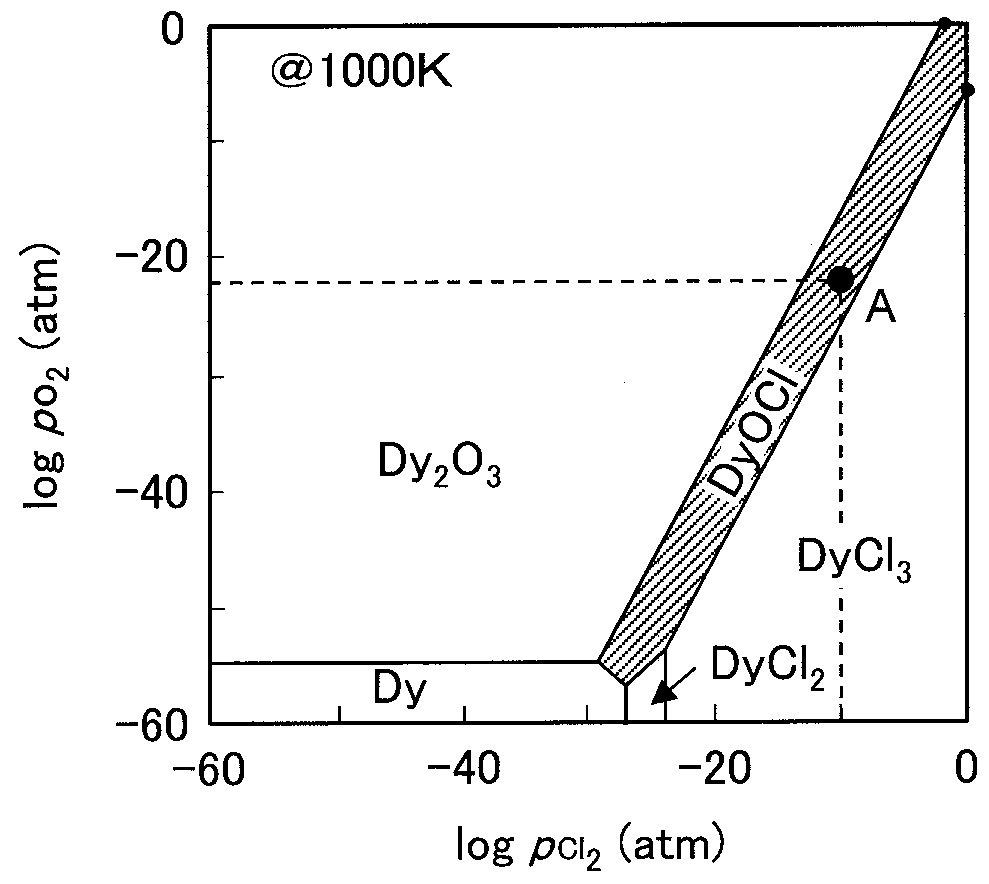

Method for separating and recovering rare earth elements

InactiveCN103443304ATo achieve stabilityProcess efficiency improvementRare earth metal oxyhalidesRare-earth elementChemical reaction

The purpose of the present invention is to provide a method whereby rare earth elements can be separated and recovered at a higher yield than by conventional techniques. The method for separating and recovering rare earth elements, whereby multiple kinds of rare earth elements are separated and recovered, comprises: a step for achieving chemical equilibrium among rare earth halides of rare earth elements of group 1 and rare earth oxyhalides of rare earth elements of group 2, by chemically reacting a mixture, said mixture containing halides of the multiple kinds of rare earth elements, in the presence of an oxygen source, or by chemically reacting a mixture, said mixture containing oxides of the multiple kinds of rare earth elements, in the presence of a halogen source; a step for pouring the rare earth halides and the rare earth oxyhalides into water to selectively dissolve the rare earth halides in water, and thus extracting the rare earth halides into a liquid phase while allowing the rare earth oxyhalides to remain as a solid phase; and a step for subjecting the liquid phase, which contains the rare earth halides extracted therein, and the solid phase of the remaining rare earth oxyhalides to solid / liquid separation to thereby separate the rare earth elements of group 1 from the rare earth elements of group 2.

Owner:HITACHI LTD

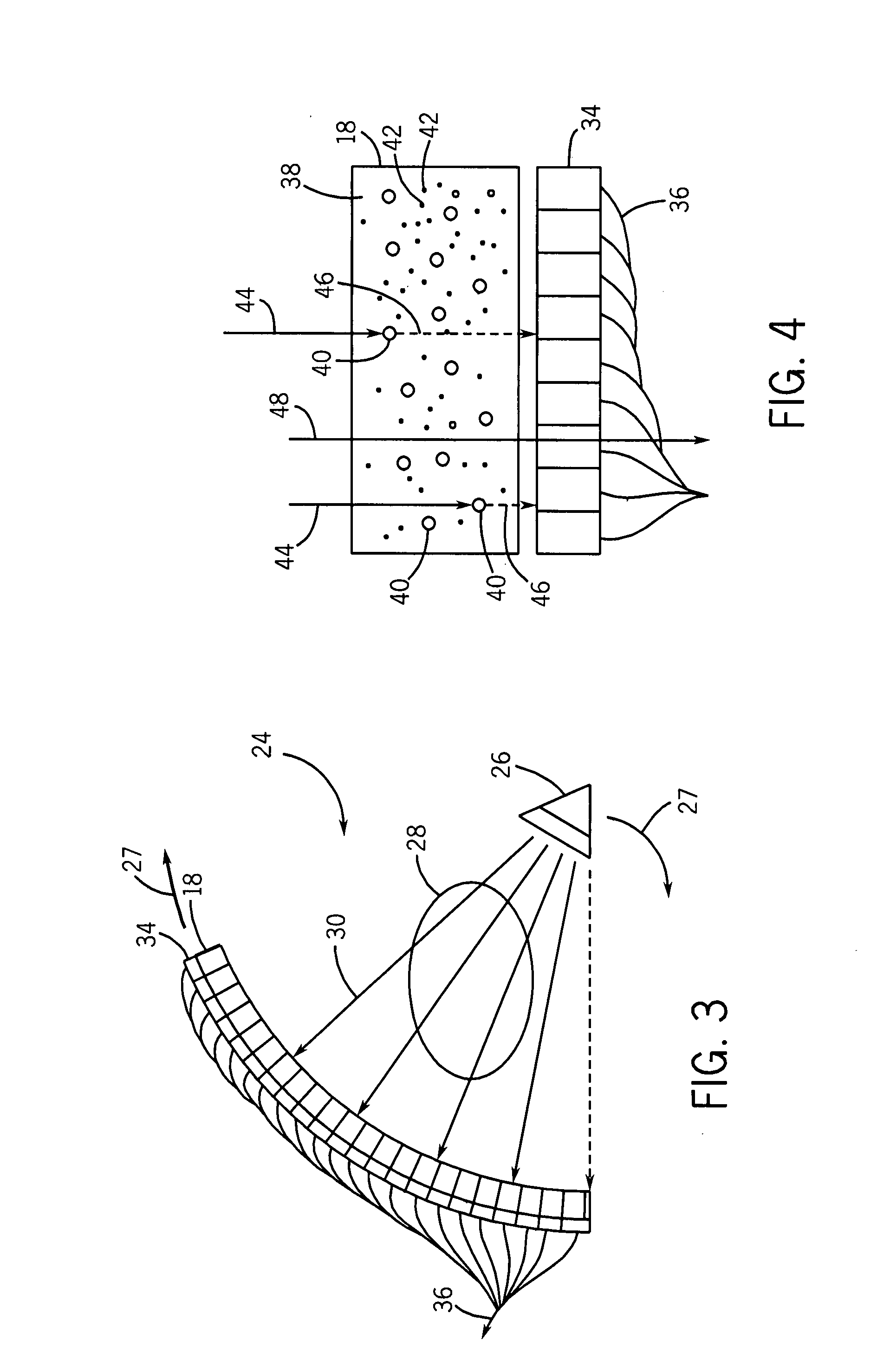

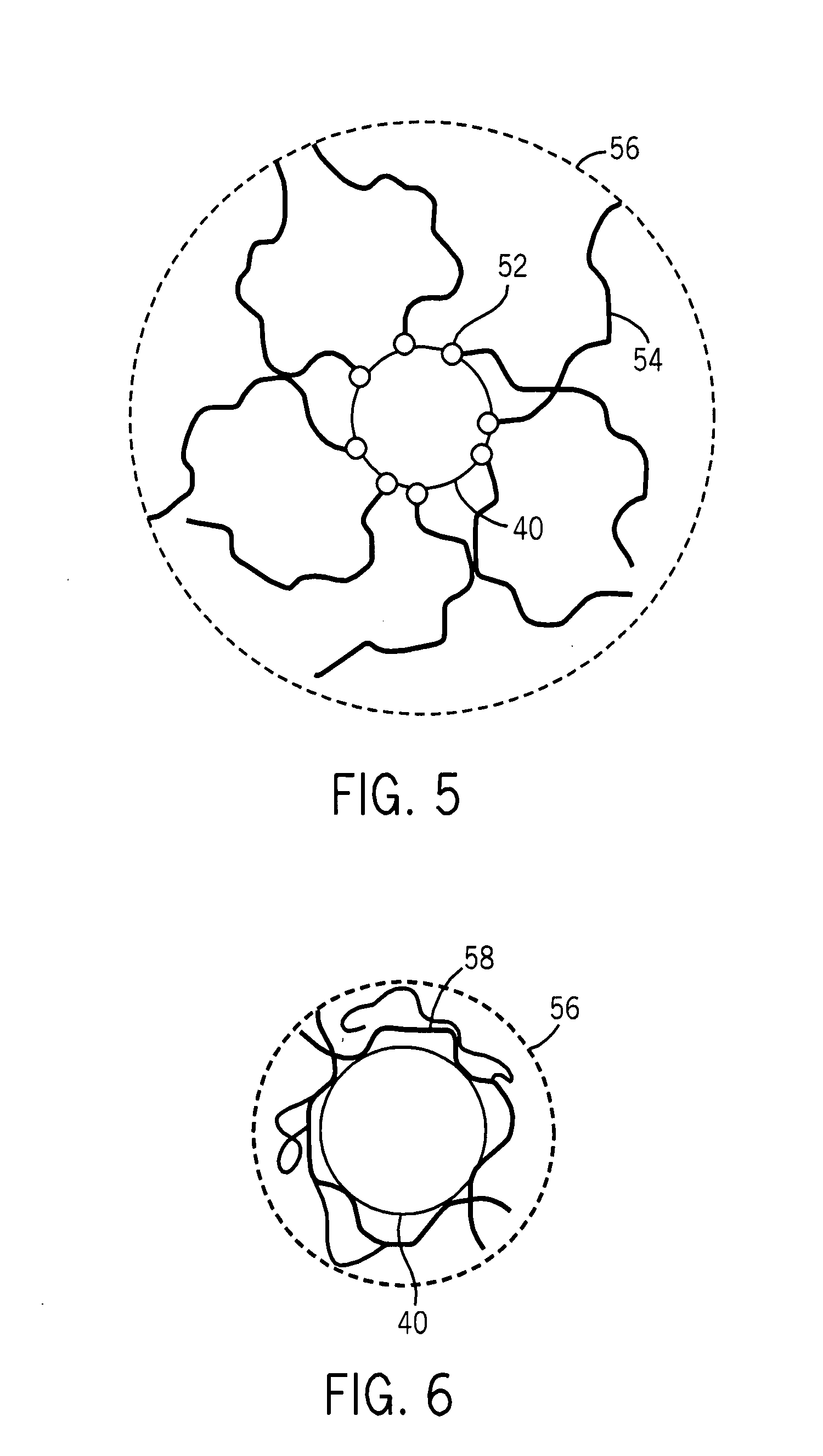

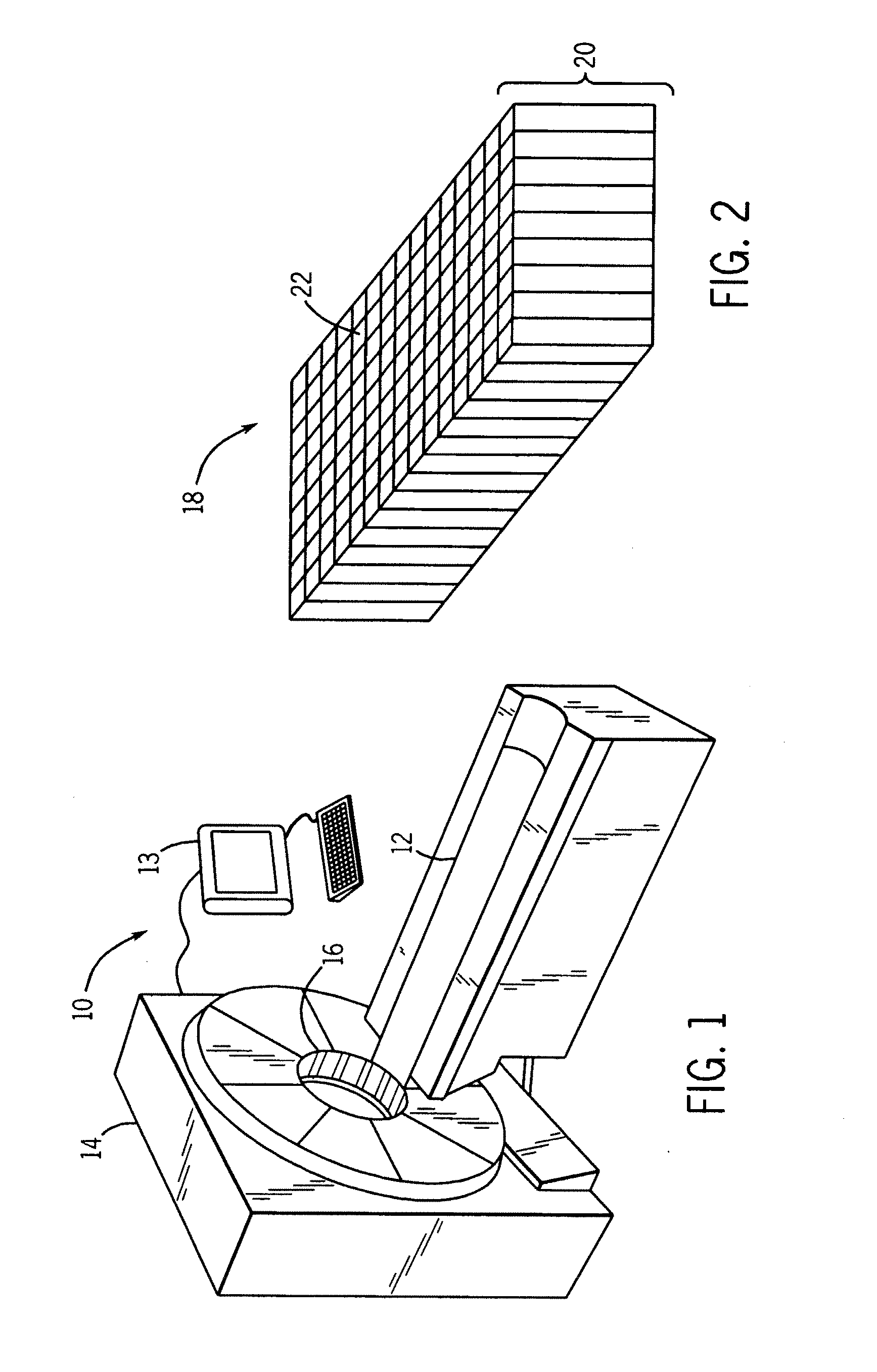

Nano-scale metal oxide, oxyhalide and oxysulfide scintillation materials and methods for making same

Crystalline scintillator materials comprising nano-scale particles of metal oxides, metal oxyhalides and metal oxysulfides are provided. The nano-scale particles are less than 100 nm in size. Methods are provided for preparing the particles. In one method, used to form oxyhalides and oxysulfides, metal salts are dissolved in water, and then precipitated out as fine particles using an aqueous base. After the particles are separated from the solution, they are annealed under a flow of a water saturated hydrogen anion gas, such as HCl or H2S, to form the crystalline scintillator particles. The other methods take advantage of the characteristics of microemulsion solutions to control droplet size, and, thus, the particle size of the final nano-particles. For example, in one method, a first micro-emulsion containing metal salts if formed. The first micro-emulsion is mixed with an aqueous base in a second micro-emulsion to form the final nano-scale particles.

Owner:GENERAL ELECTRIC CO

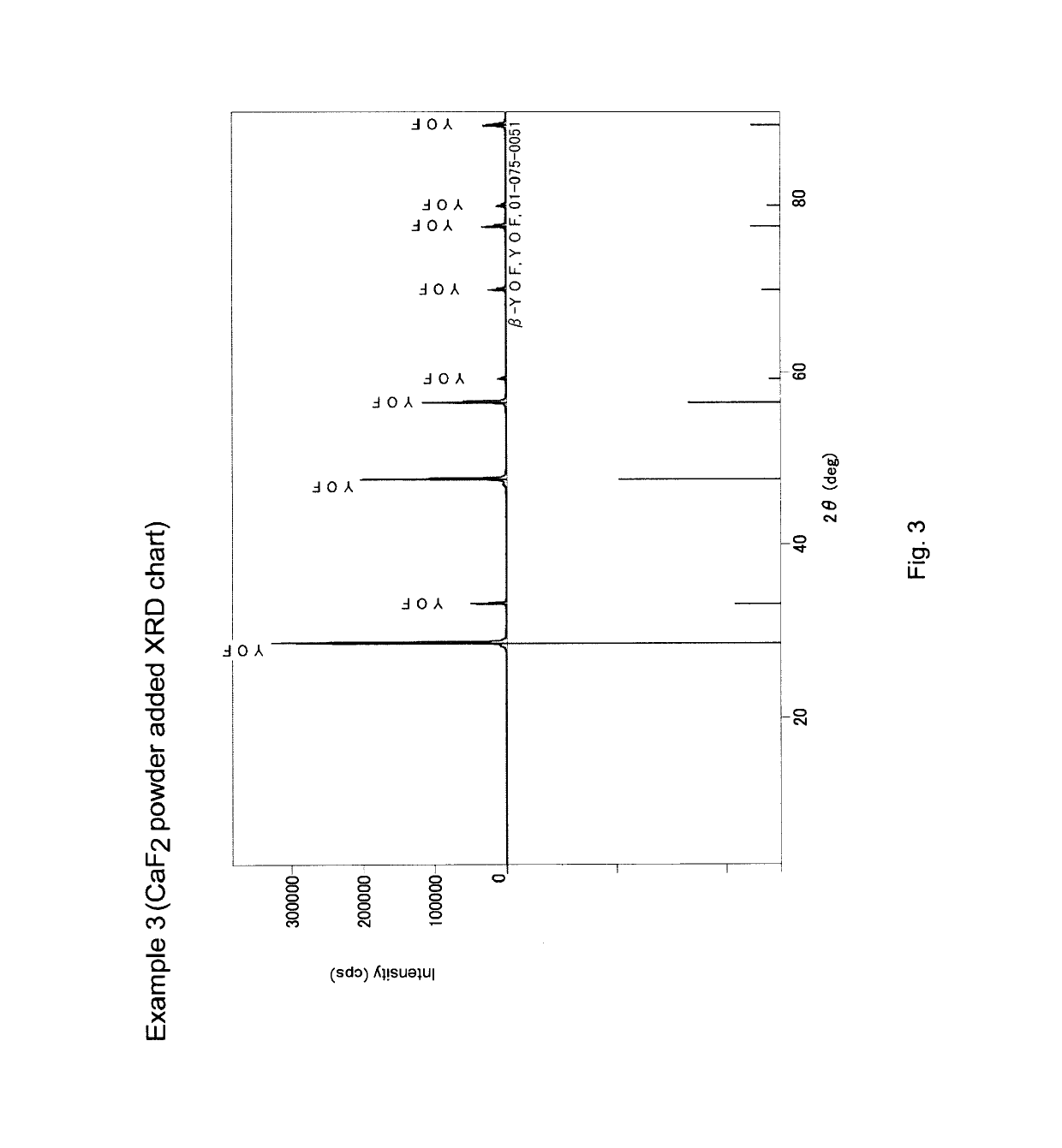

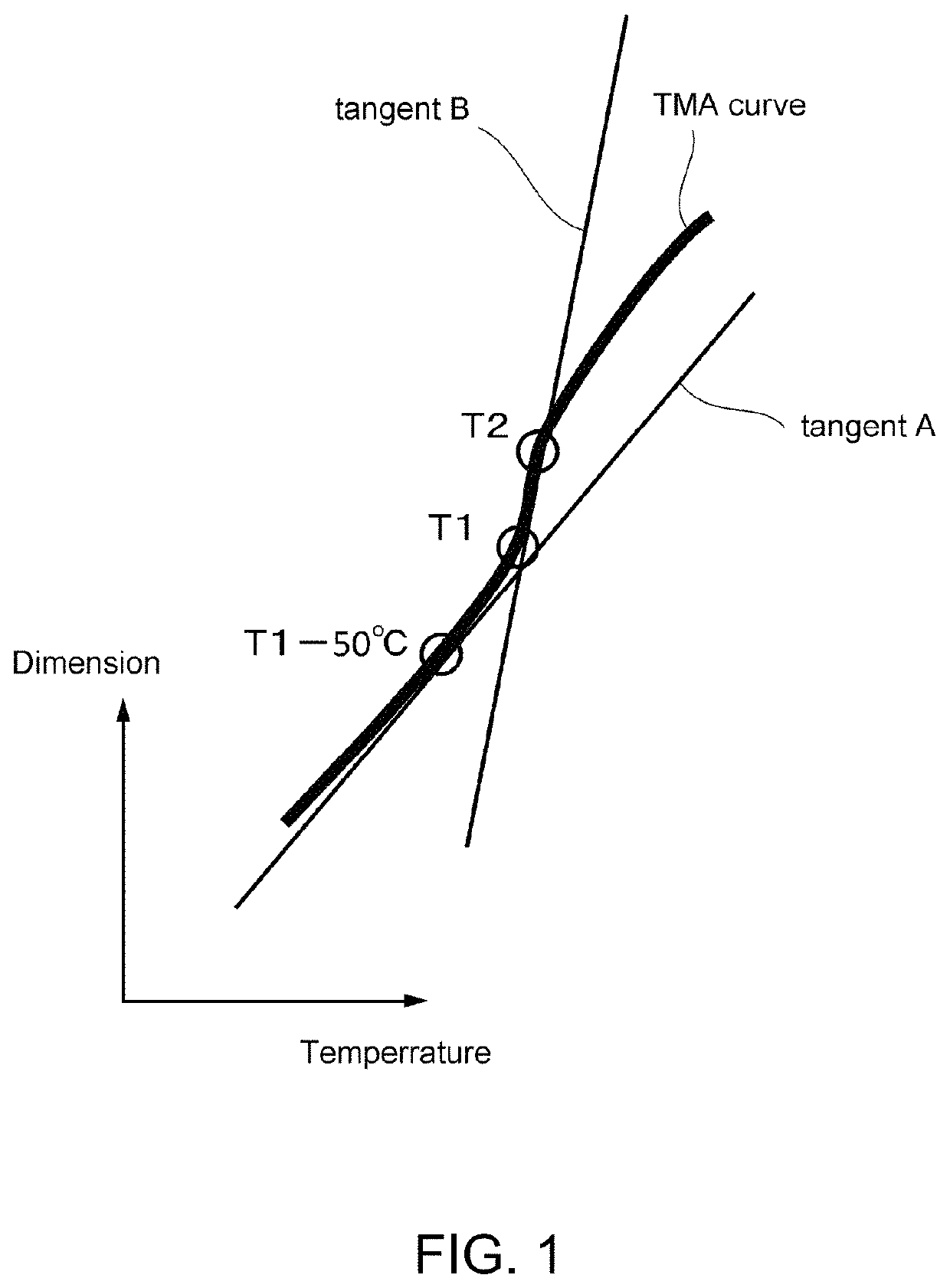

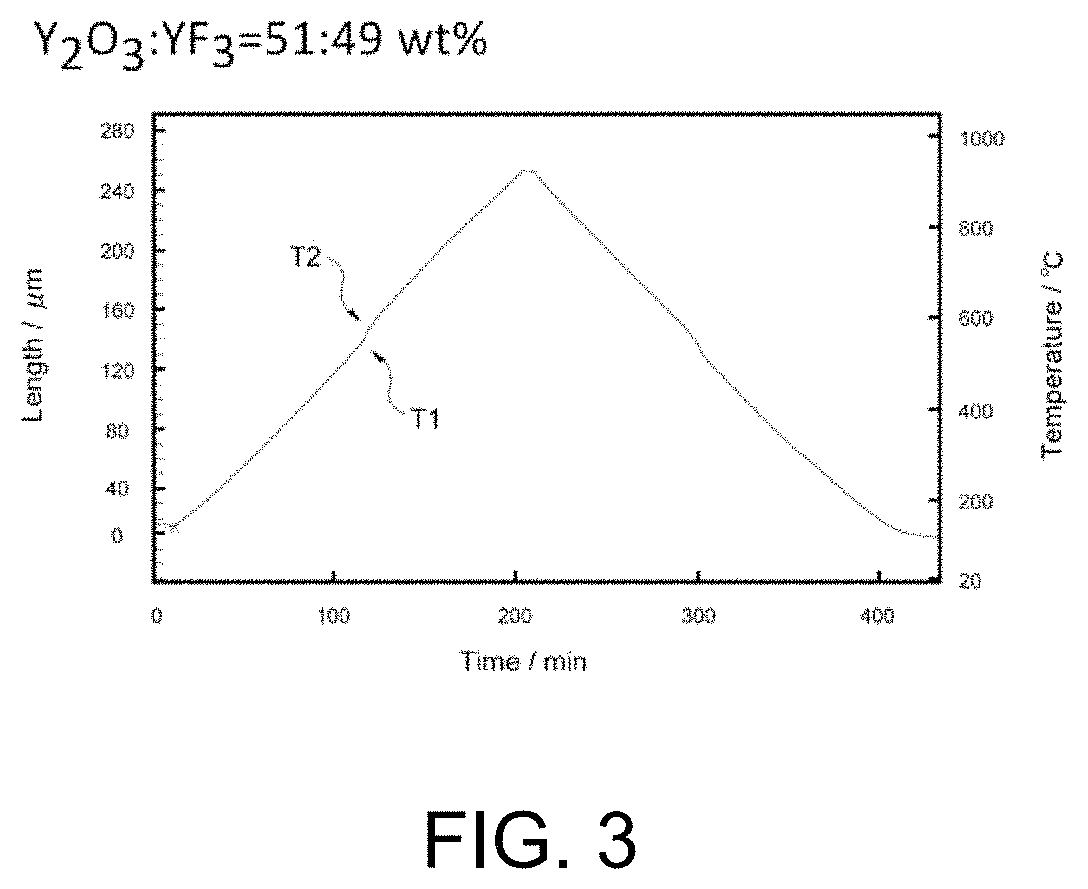

Yttrium oxyfluoride, starting material powder for production of stabilized yttrium oxyfluoride, and method for producing stabilized yttrium oxyfluoride

ActiveUS20180230022A1Effectively prevents fracture/crackingCalcium/strontium/barium fluoridesFluorine oxygen compoundsPowder mixtureMaterials science

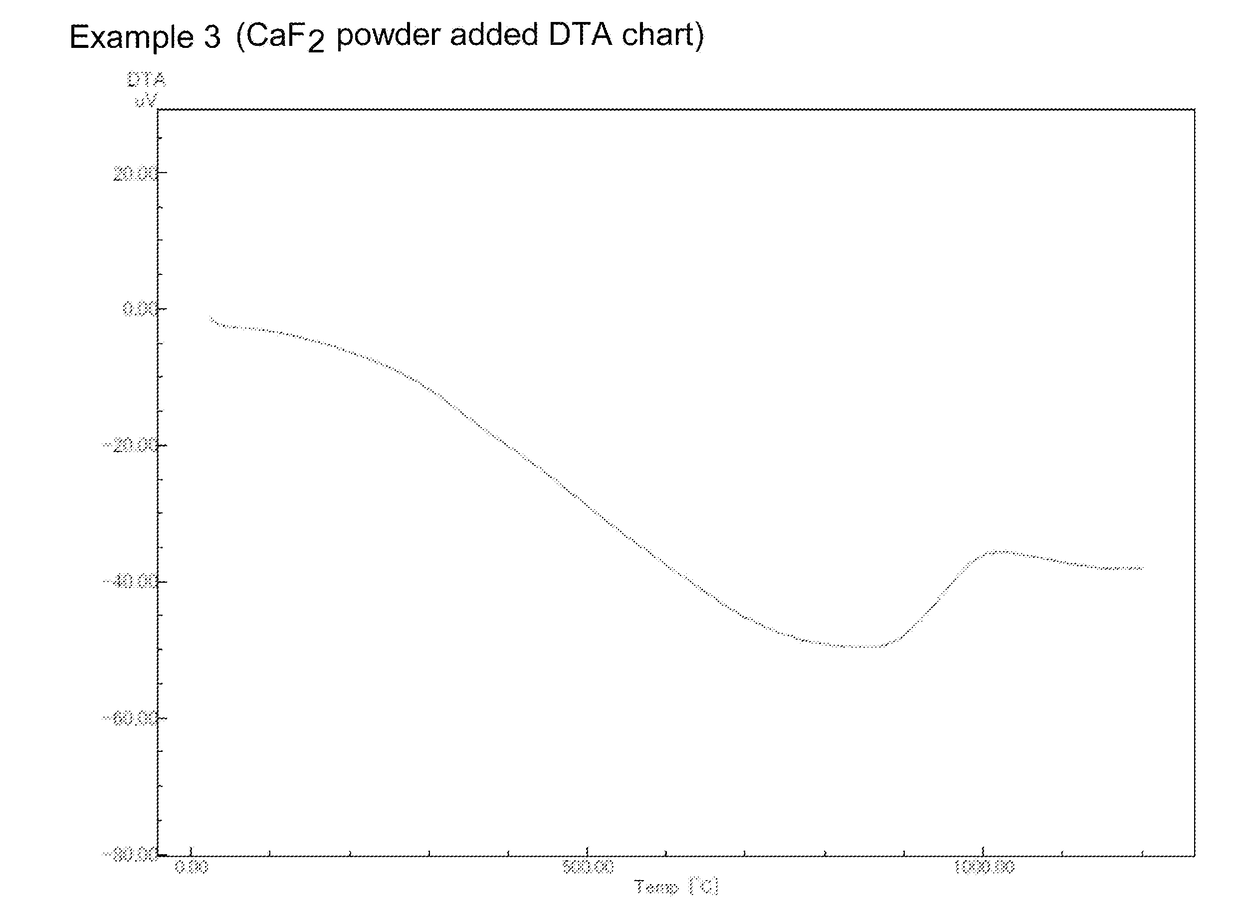

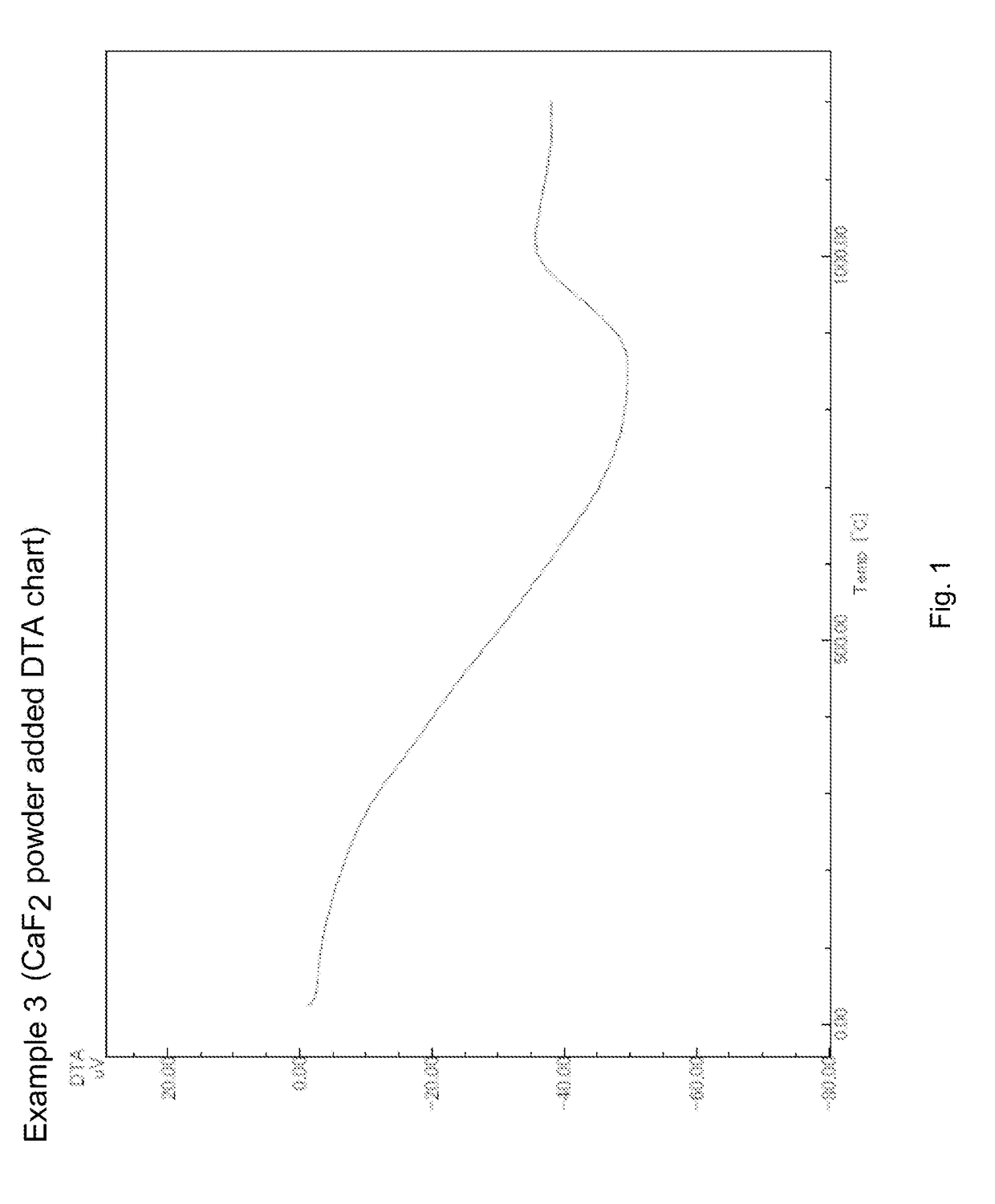

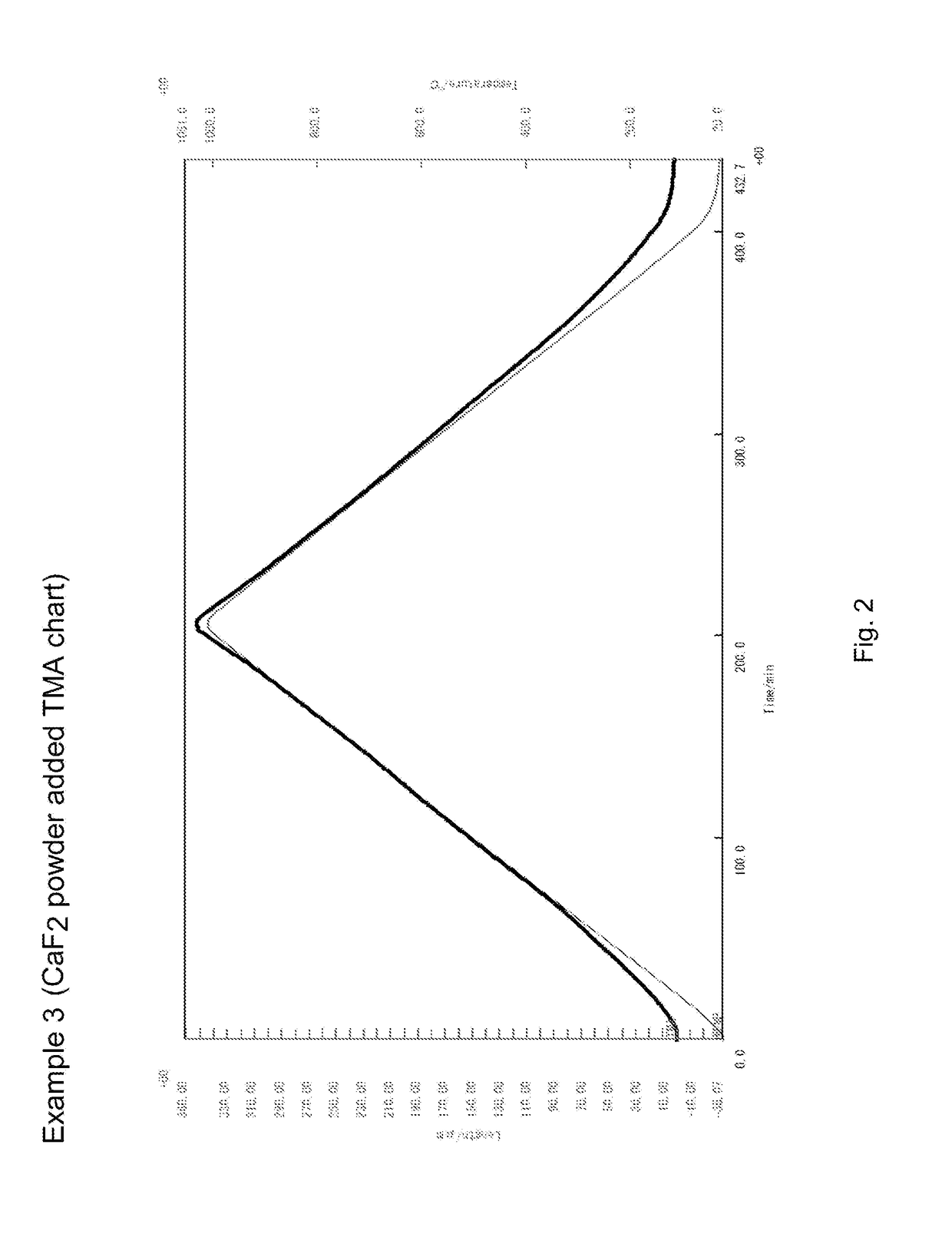

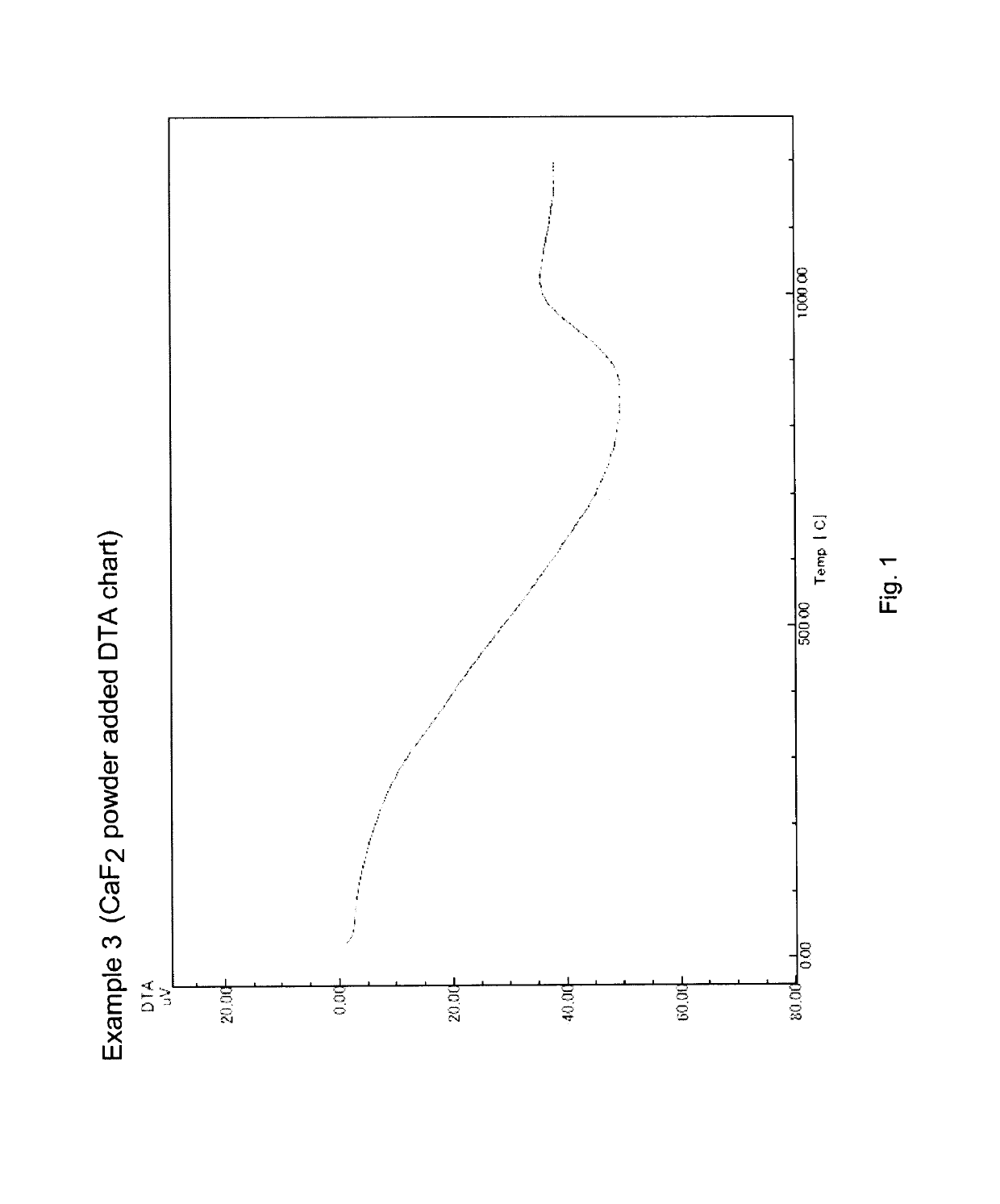

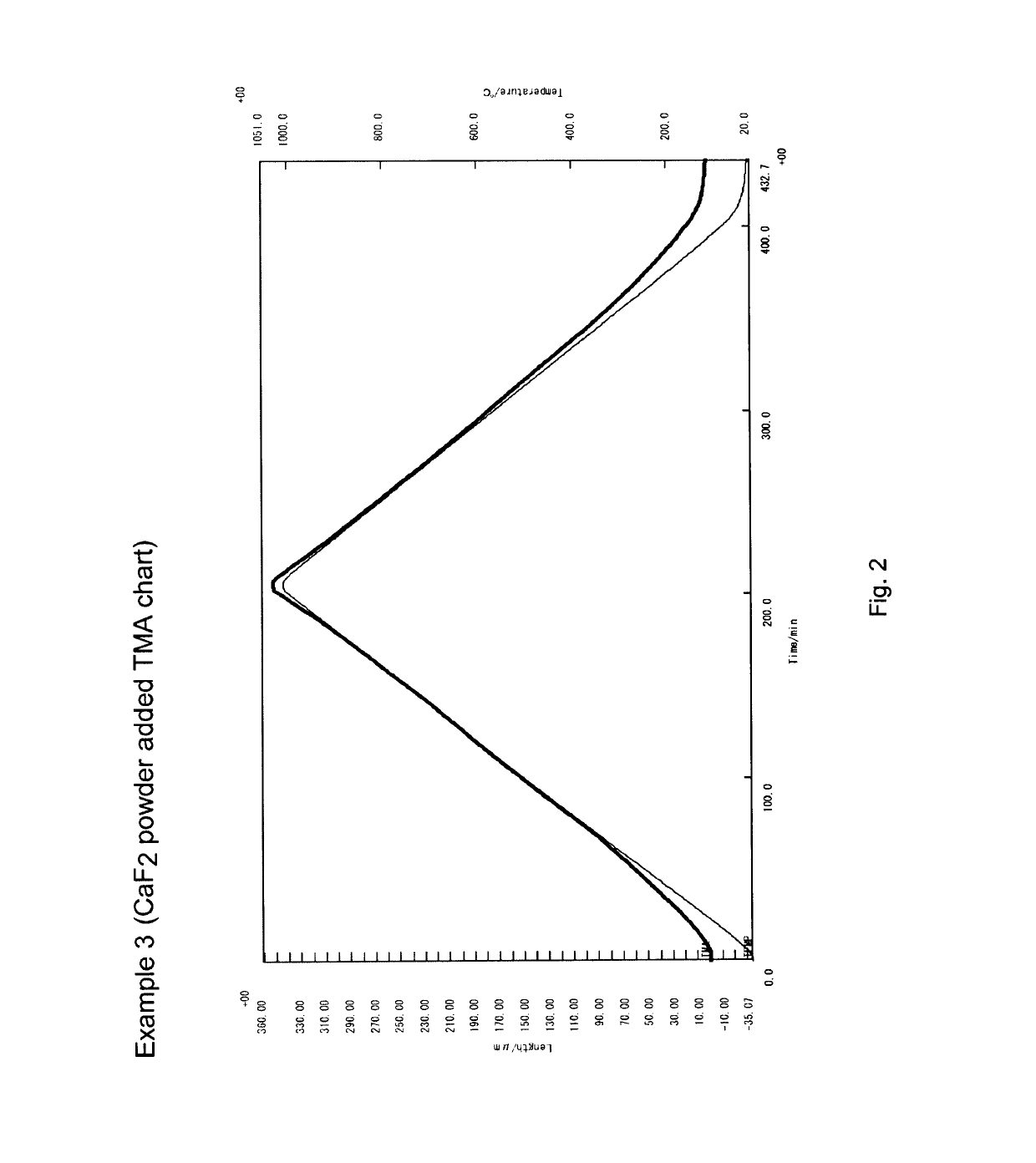

An yttrium oxyfluoride is represented by YOF and is stabilized by a fluoride represented by CaF2. Preferably, the number of moles of Ca with respect to 100 mol of yttrium is from 8 to 40 mol. A powder material is made of a first powder mixture including a calcium fluoride powder represented by CaF2 and an yttrium oxyfluoride powder represented by YOF, or a second powder mixture including a calcium fluoride powder represented by CaF2, an yttrium fluoride powder represented by YF3, and an yttrium oxide powder represented by Y2O3. A production method involves firing a molded product of the first or second powder mixture under predetermined conditions.

Owner:MITSUI MINING & SMELTING CO LTD

Yttrium oxyfluoride, starting material powder for production of stabilized yttrium oxyfluoride, and method for producing stabilized yttrium oxyfluoride

ActiveUS10280091B2Effectively prevents fracture/crackingCalcium/strontium/barium fluoridesFluorine oxygen compoundsPowder mixturePhysical chemistry

An yttrium oxyfluoride is represented by YOF and is stabilized by a fluoride represented by CaF2. Preferably, the number of moles of Ca with respect to 100 mol of yttrium is from 8 to 40 mol. A powder material is made of a first powder mixture including a calcium fluoride powder represented by CaF2 and an yttrium oxyfluoride powder represented by YOF, or a second powder mixture including a calcium fluoride powder represented by CaF2, an yttrium fluoride powder represented by YF3, and an yttrium oxide powder represented by Y2O3. A production method involves firing a molded product of the first or second powder mixture under predetermined conditions.

Owner:MITSUI MINING & SMELTING CO LTD

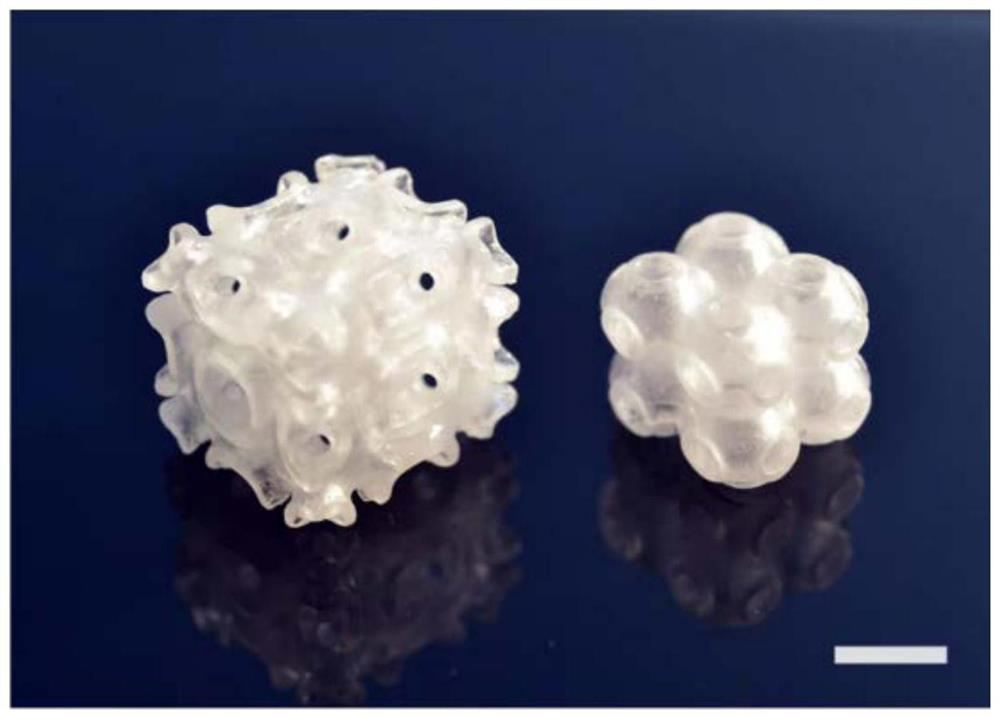

Method for preparing transparent ceramic through one-time forming based on photocuring 3D printing technology

PendingCN114800767AImprove compactnessHigh strengthAdditive manufacturing apparatusCeramic shaping apparatusOxide ceramicSlurry

Owner:嘉兴饶稷科技有限公司

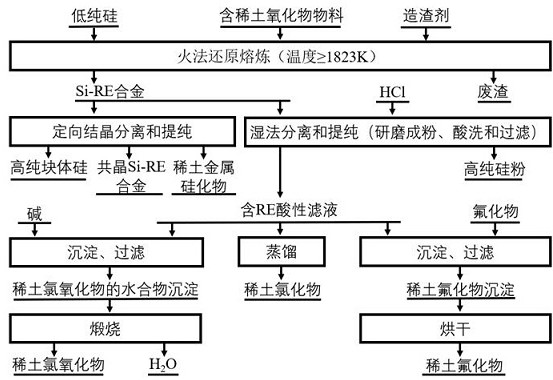

A method for recovering rare earth elements by utilizing low-purity silicon and rare earth-containing oxide materials

ActiveCN112981123BLow costImprove efficiencyRare earth metal chloridesIncreasing energy efficiencyRare-earth elementSlag

The invention relates to a method for recovering rare earth elements by using low-purity silicon and rare earth oxide materials, and belongs to the technical field of solid waste resource recycling and material preparation. Reduce and smelt low-purity silicon, rare earth-containing oxide materials and slagging agents together, and separate slag and gold to obtain Si-RE alloy and waste slag respectively; grind the obtained Si-RE alloy into powder and use HCl-containing leaching solution After pickling, high-purity silicon powder and RE-containing acidic filtrate are obtained; alkali or fluoride is added to the obtained RE-containing acidic filtrate to obtain hydrate precipitation of rare earth oxychlorides or rare earth fluoride precipitation; or the obtained rare earth-containing acidic filtrate The rare earth chlorides are obtained after distillation; the obtained precipitates are calcined to obtain high-purity rare earth oxychlorides, or dried to obtain rare earth fluorides. The present invention is a technology with no waste gas generation, low cost, environmental friendliness and high efficiency.

Owner:KUNMING UNIV OF SCI & TECH

Process for preparing an oxyhalogenide and/or oxide of actinide(s) and/or of lanthanide(s) from a medium comprising at least one molten salt

ActiveUS20140219900A1Easy to recycleRare earth metal chloridesPlutonium oxides/hydroxidesMolten saltLanthanide

The invention relates to a process for manufacturing an oxychloride or oxide of actinide(s) and / or of lanthanide(s) from a chloride of actinide(s) and / or of lanthanide(s) present in a medium comprising at least one molten salt of chloride type comprising a step of bringing said chloride of actinide(s) and / or lanthanide(s) present in said medium comprising at least one molten salt of chloride type into contact with a wet inert gas.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

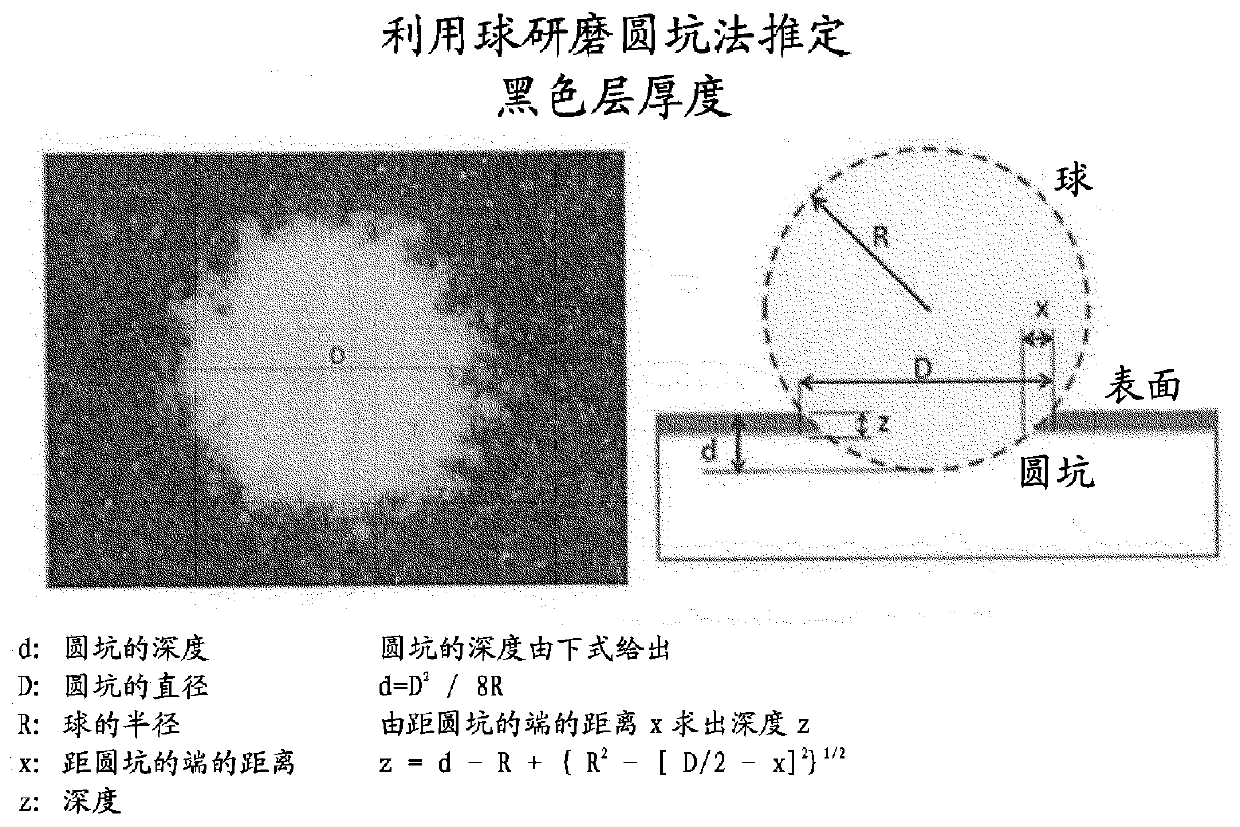

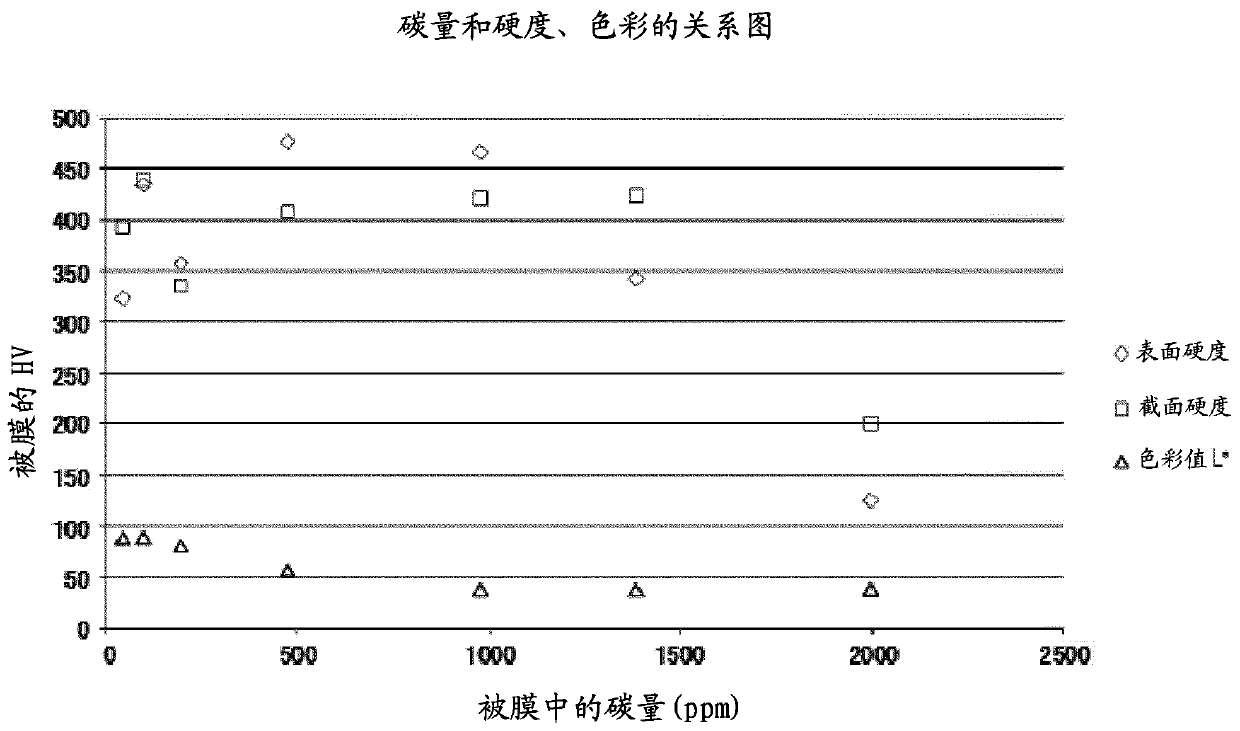

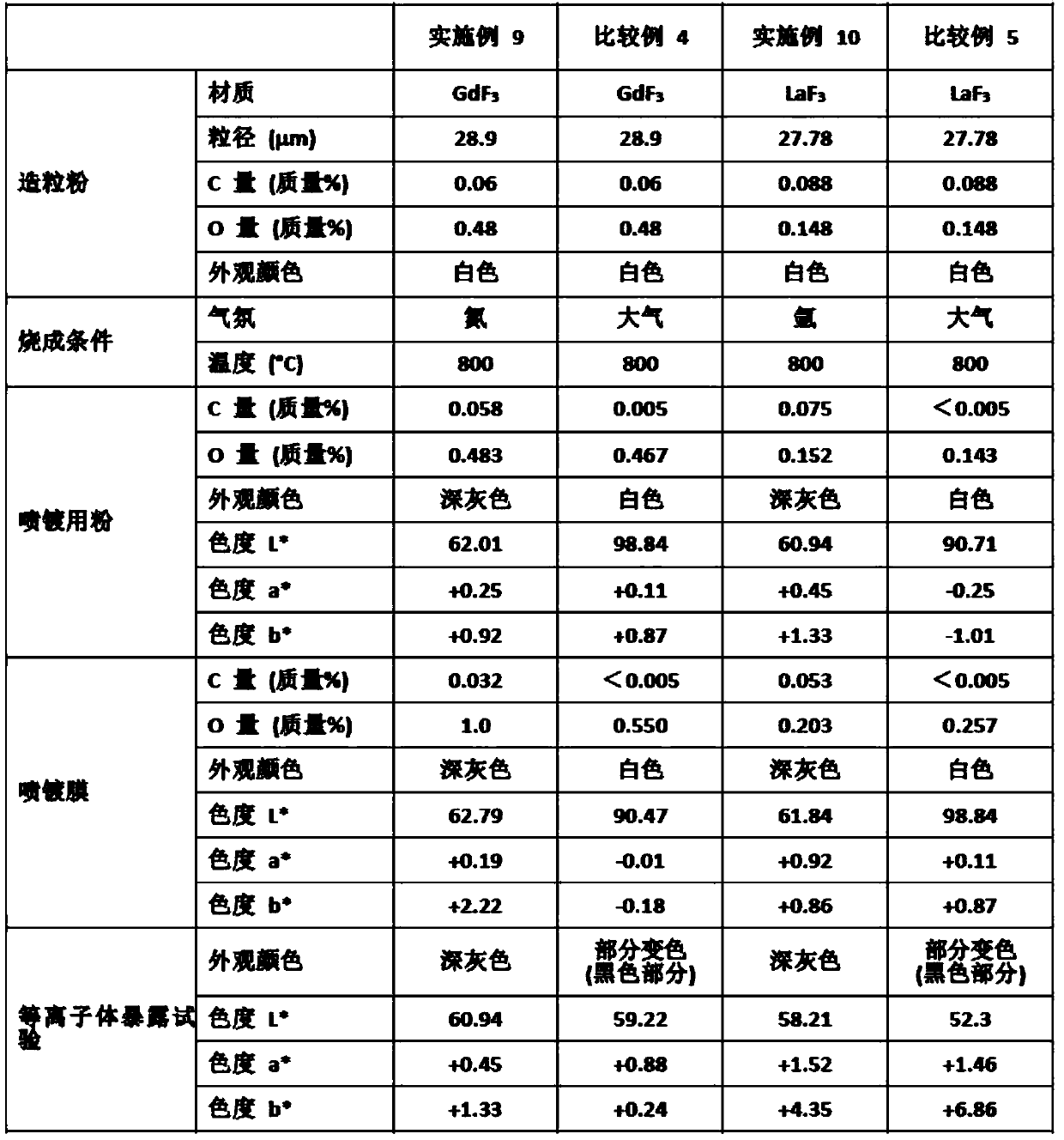

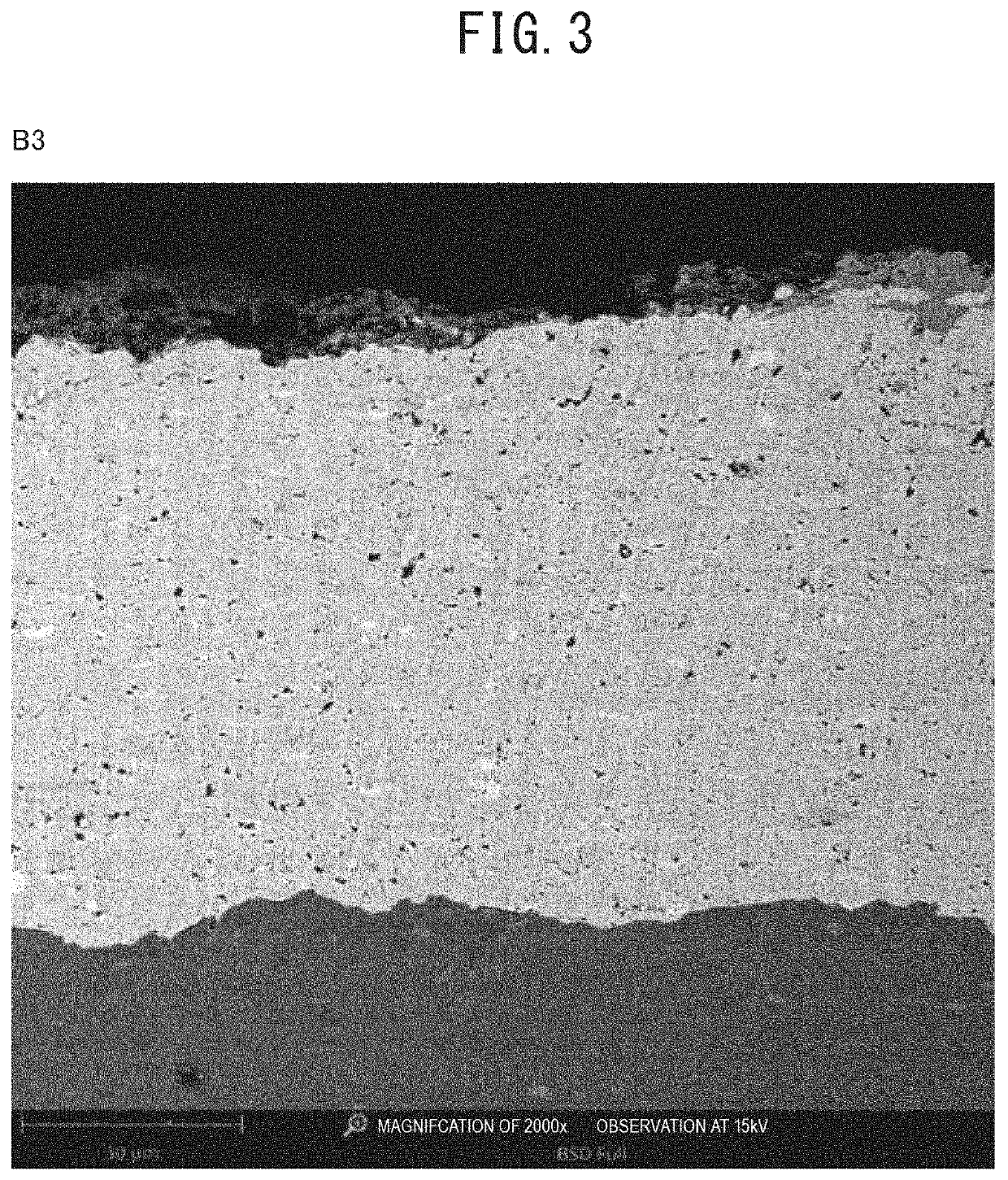

Spray coating, spraying powder, spraying powder manufacturing method and spray coating manufacturing method

ActiveCN110382730AAchieve long lifeLow costRare earth metal oxides/hydroxidesMolten spray coatingSpray coatingTitanium

Provided is a spray coating containing a rare earth fluoride and / or a rare earth acid fluoride, wherein carbon is contained therein at 0.01-2% by mass or titanium or molybdenum is contained therein at1-1000 ppm, and wherein, in the case in which an acid fluoride is not contained therein, the spray coating is gray to black in which, in terms of the L*a*b* chromaticity, L* is 25-64, a* is -3.0 to +5.0, and b* is -4.0 to +8.0, and, in the case in which an acid fluoride is contained therein, the spray coating is white or gray to black in which, in terms of the L*a*b* chromaticity, L* is equal toor greater than 25 and less than 91, a* is -3.0 to +5.0, and b* is -6.0 to +8.0. By forming this coating on a plasma resistant member, a partial color change is reduced, the situation in which said member is washed in a manner that causes partial deterioration thereof when being removed and washed is eliminated, and thus, a member that is capable of reliably realizing the original longevity thereof is obtained.

Owner:SHIN ETSU CHEM IND CO LTD

Method for separating and recovering rare-earth elements

ActiveUS9376736B2Less effectHigh rateRare earth metal chloridesLanthanide oxides/hydroxidesRare-earth elementTrace element

A method for separating and recovering a plurality of rare-earth elements, the method including a step of introducing, into a liquid, a mixture containing a rare-earth oxychloride and a rare-earth chloride, the rare-earth oxychloride constituted from a rare-earth element different from a rare-earth element constituting the rare-earth chloride, thereby obtaining an insoluble matter containing the rare-earth oxychloride and a liquid in which the rare-earth chloride is dissolved, a step of recovering the rare-earth oxychloride from the insoluble matter, and a step of recovering the rare-earth chloride from the liquid in which the rare-earth chloride is dissolved.

Owner:HITACHI METALS LTD

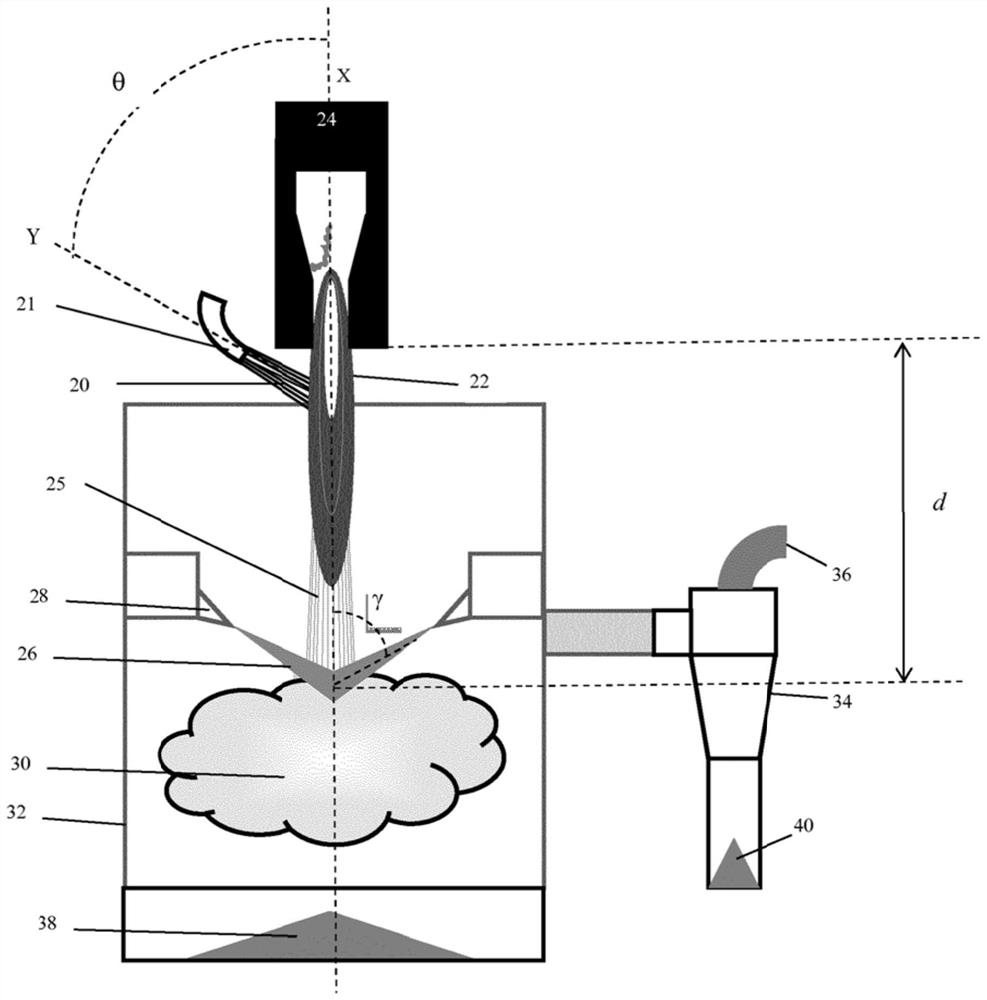

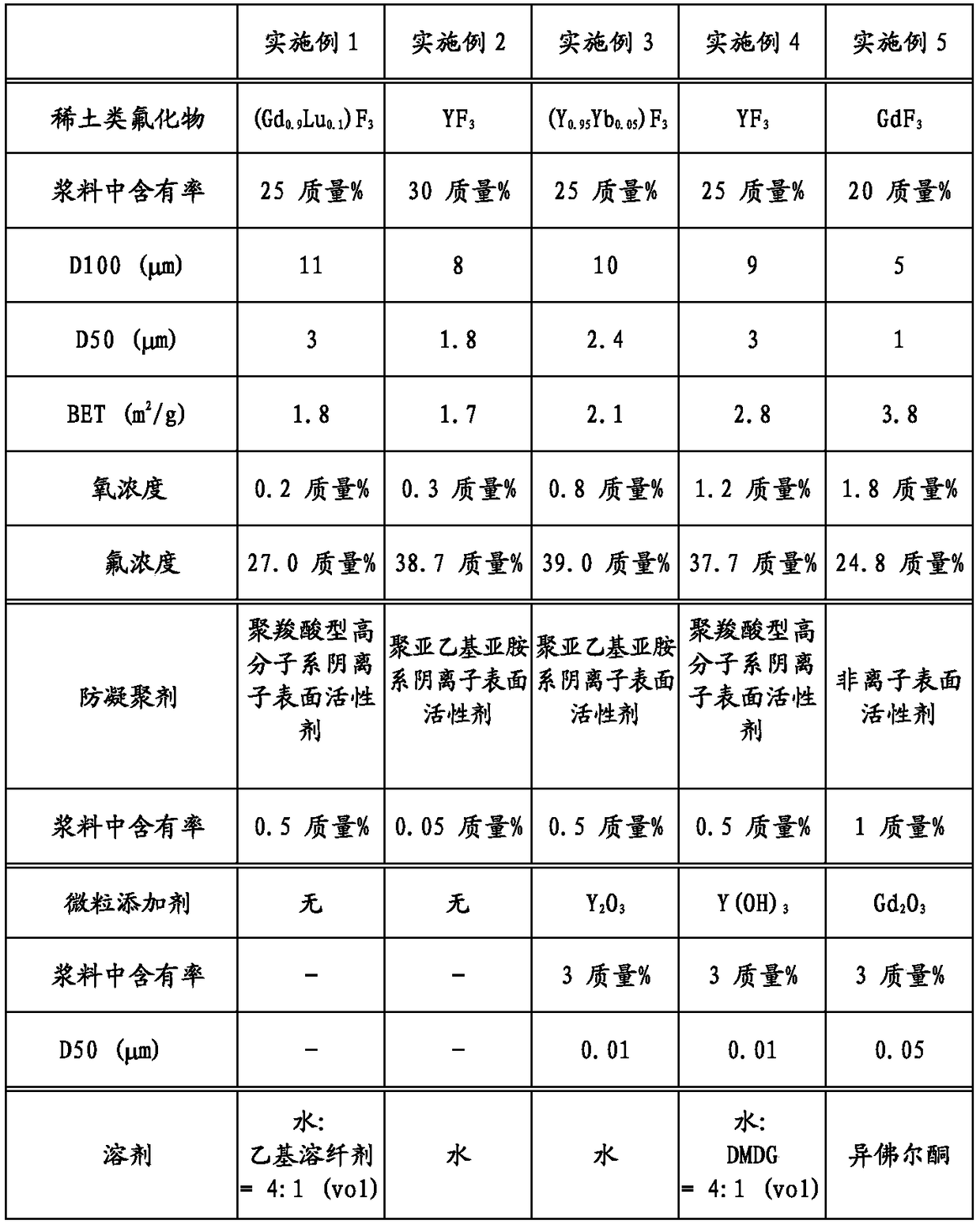

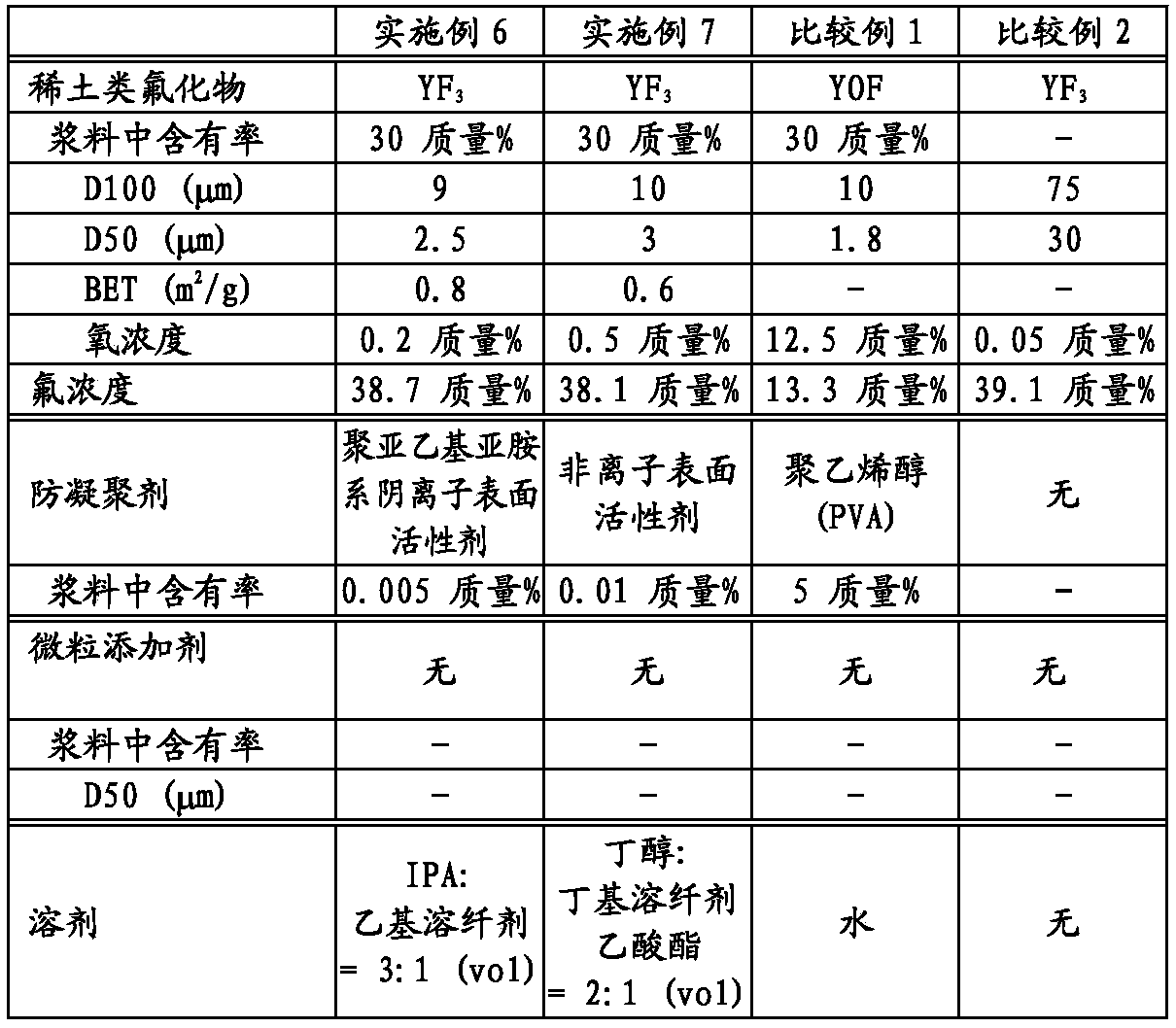

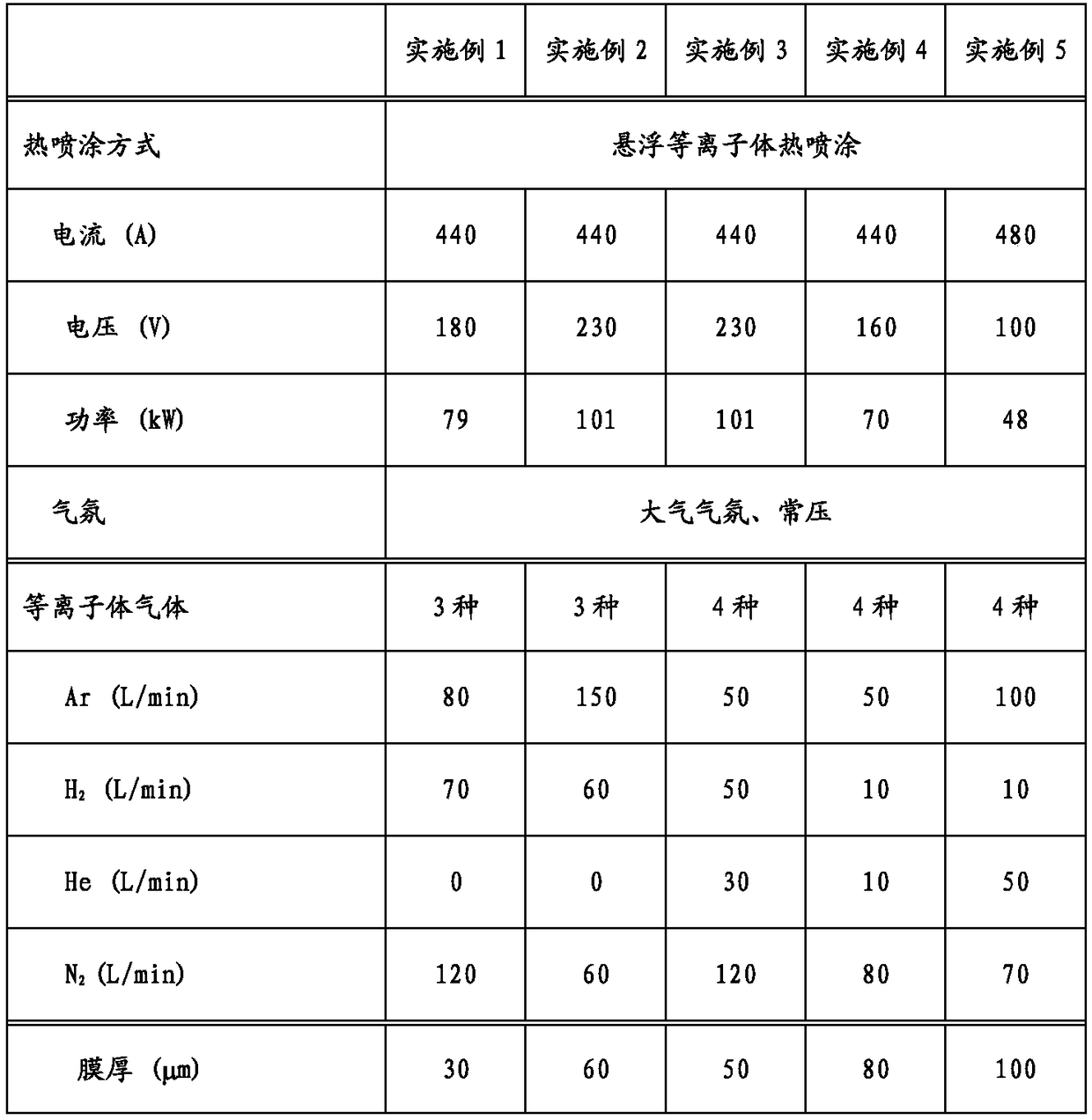

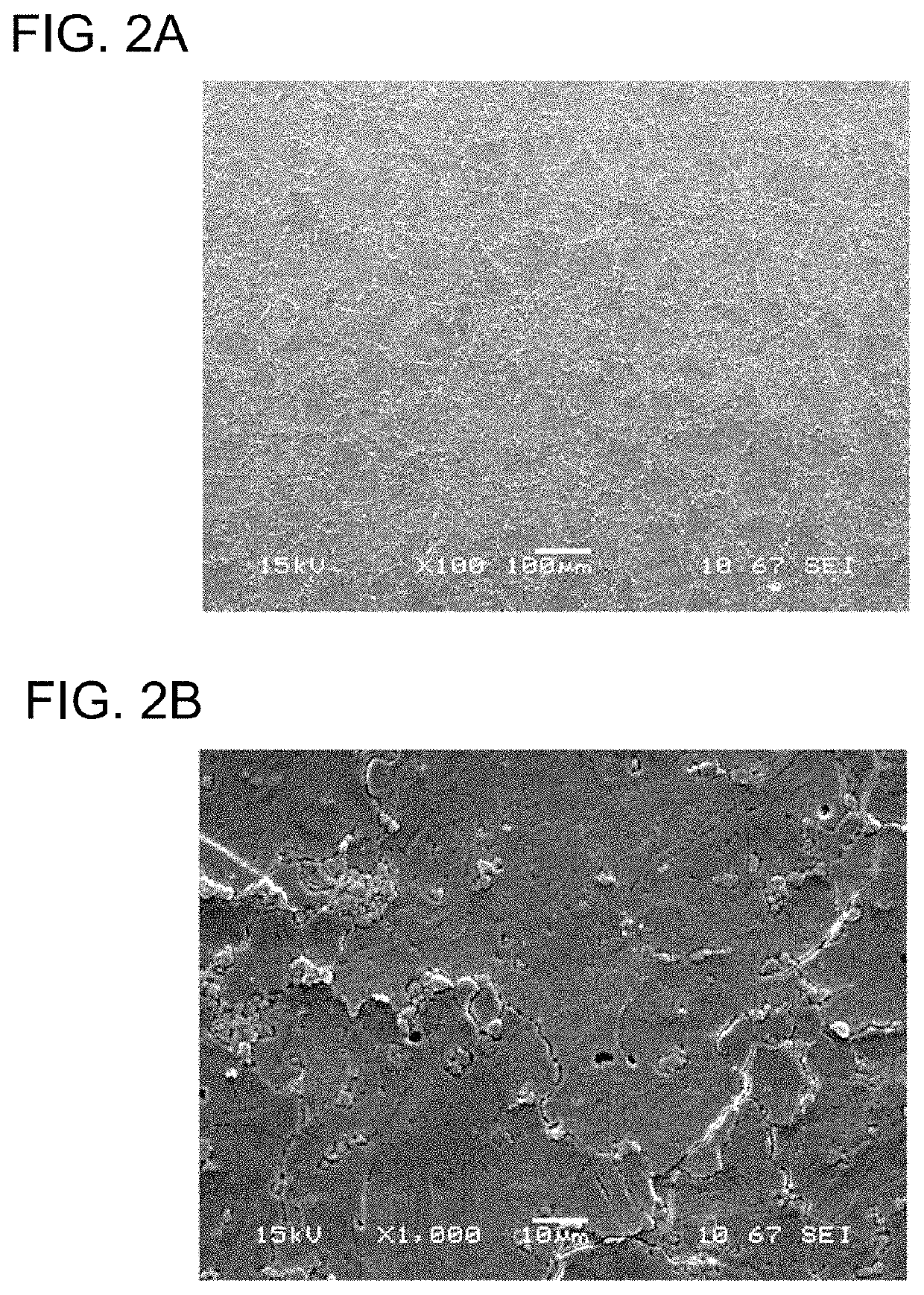

Slurry for suspension plasma spraying, method for forming rare earth acid fluoride sprayed film, and spraying member

ActiveCN109477199AImprove corrosion resistanceSmall particlesMolten spray coatingYittrium oxides/hydroxidesThermal sprayingHalogen

Provided is a slurry for suspension plasma spraying, which is a spray material used for suspension plasma spraying in an atmosphere including an oxygen-containing gas, contains 5-40 mass% of rare earth fluoride particles having a maximum particle diameter (D100) of 12 mum or less, and contains one or more types of solvent selected from among water and organic solvents. A rare earth acid fluoride-containing sprayed film, in which process shift and particle generation hardly occur, can be stably formed on a base material by carrying out suspension plasma spraying in an atmosphere including an oxygen-containing gas. A spraying member provided with this sprayed film exhibits excellent corrosion resistance to halogen-based gas plasma.

Owner:SHIN ETSU CHEM CO LTD

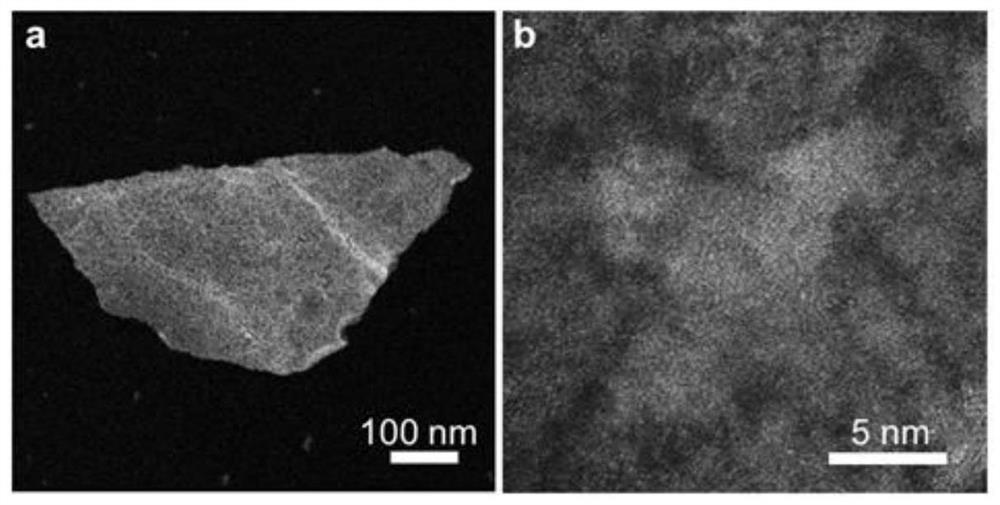

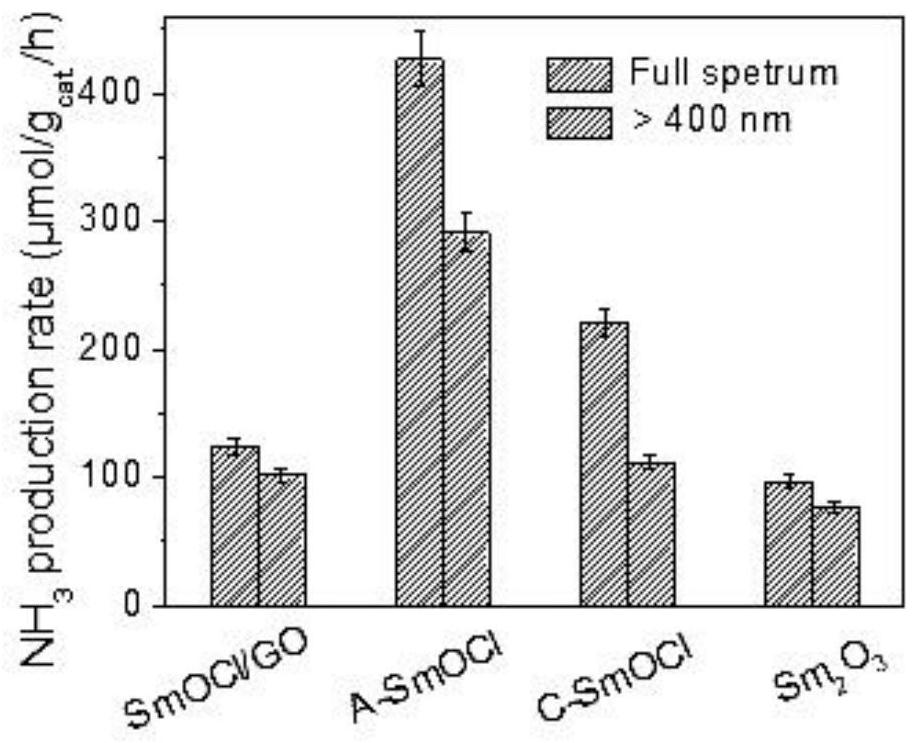

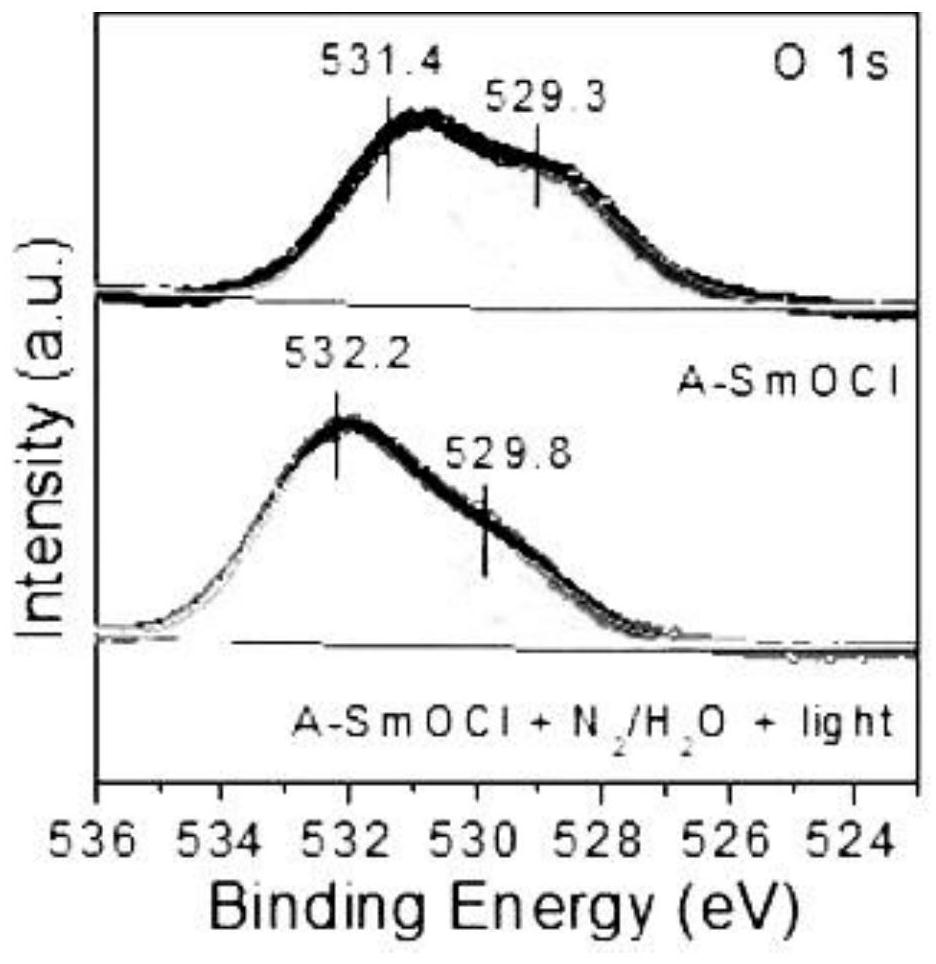

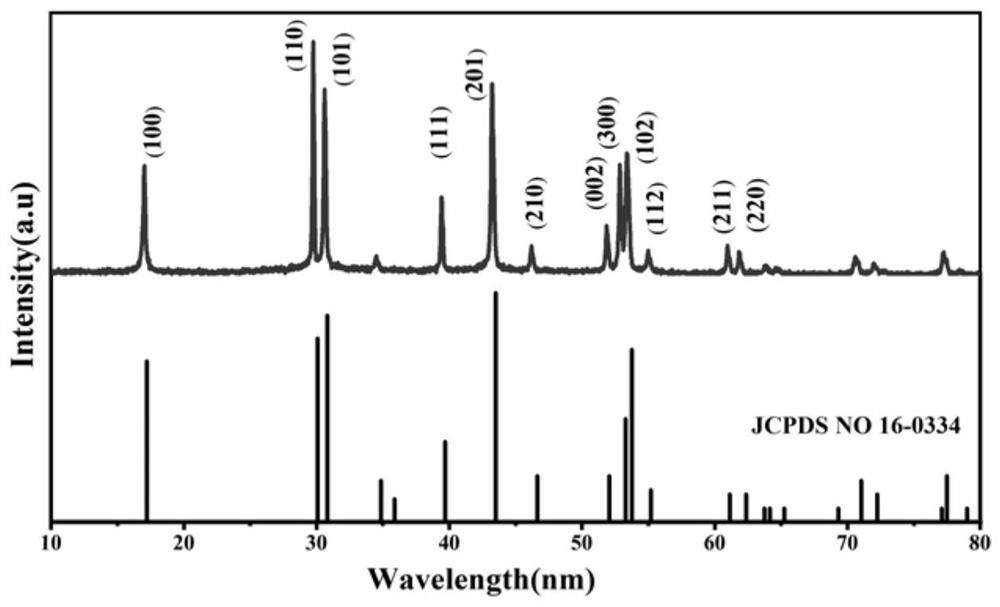

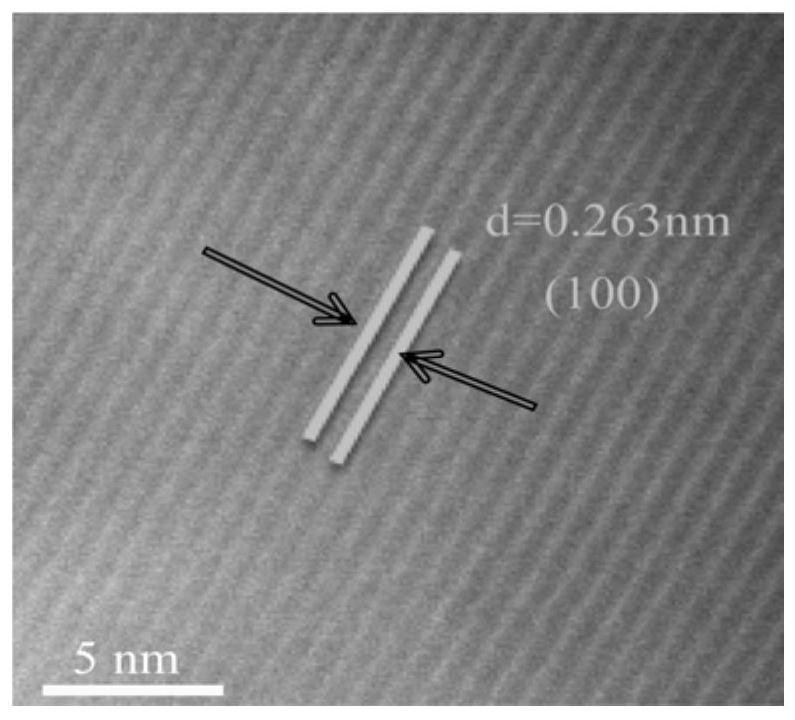

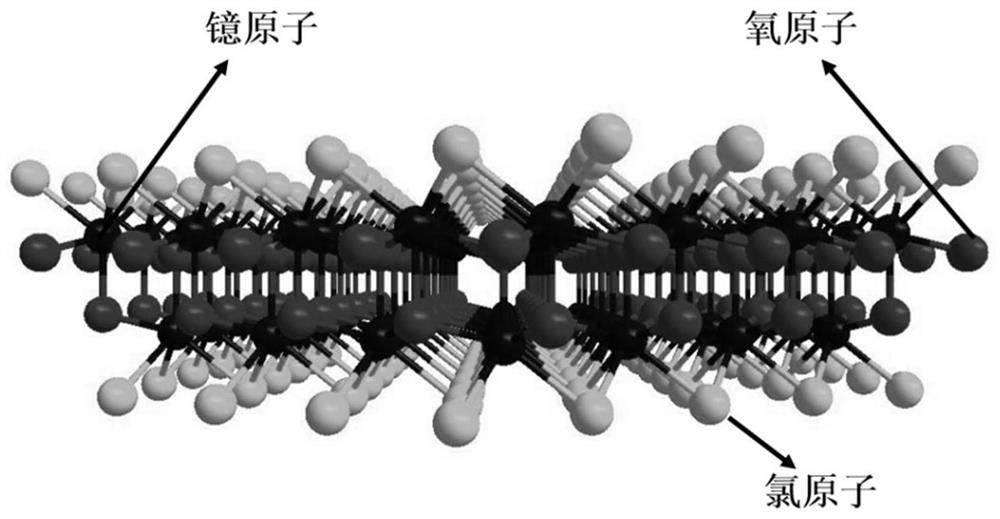

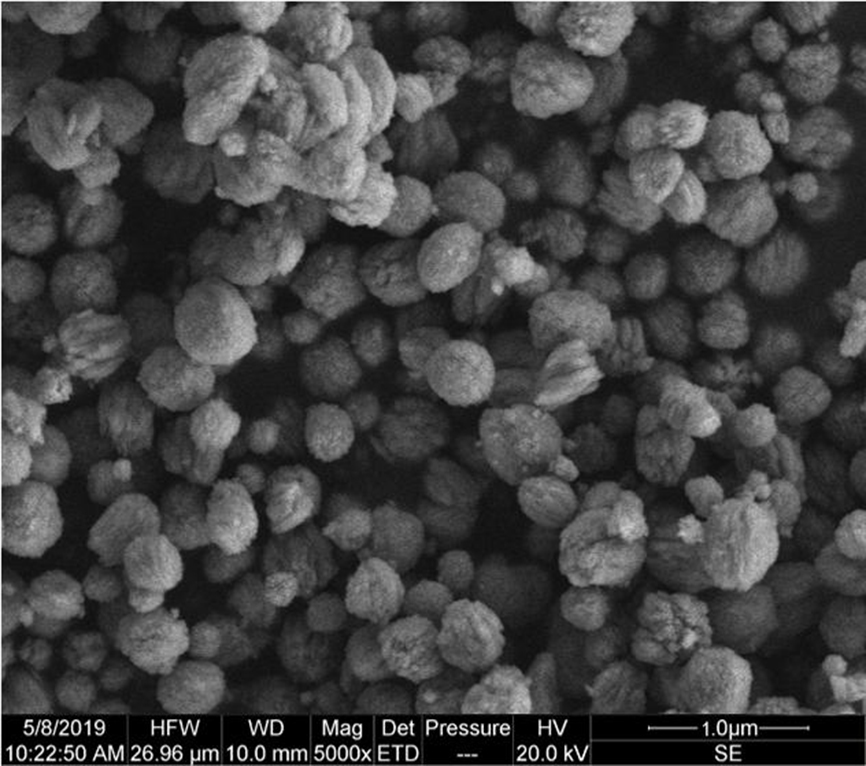

A kind of samarium oxychloride nanosheet and its preparation method and application

ActiveCN110467214BNovel structureSimple preparation processPhysical/chemical process catalystsNanotechnologyPtru catalystPhysical chemistry

The invention discloses a samarium oxychloride nanosheet and its preparation method and application. Its structure is an amorphous smoky two-dimensional samarium oxychloride nanosheet. The preparation process is as follows: (1) first trishydroxymethylaminomethane and Mix hydrochloric acid to obtain a buffer solution, then add a soluble samarium source and graphene oxide for ultrasonic treatment to obtain a uniformly dispersed suspension, and obtain a precursor after solid-liquid separation and drying after the reaction; (2) the precursor is burned at 500-600°C Burn to get samarium oxide nanosheets. The inventive amorphous smoky two-dimensional samarium oxychloride nanosheets are used as photocatalytic N 2 and H 2 When O reacts to synthesize ammonia, it does not need to add any sacrificial agent, and reacts NH at room temperature 3 The yield reached 426μmol·g cat. –1 h –1 , for the rational design of photocatalytic N 2 Fixed high-efficiency catalysts improve new ideas.

Owner:CENT SOUTH UNIV

Method for rapid in-situ preparation of rare earth fluoride-rare earth oxide heterojunction micro-nano material

PendingCN113772716AGood optical performanceSimple methodMaterial nanotechnologyRare earth metal compounds preparation/treatmentHeterojunctionNano structuring

The invention discloses a method for rapid in-situ preparation of a rare earth fluoride-rare earth oxide heterojunction micro-nano material, which utilizes the plasmon heat effect of a noble metal nano structure, takes a small-size gold nano island structure with a large absorption interface as a heat source, under the action of an external light field with resonant wavelength, the gold nano island structure generates an extremely high temperature in an extremely short time, and the extremely high temperature is transmitted to the rare earth luminescent material, so that the local temperature of the rare earth luminescent material is instantly increased; meanwhile, hot electrons generated by surface plasmon relaxation catalyze oxygen molecules adsorbed on the surface of the luminescent material to activate the oxygen molecules, so that oxidation reaction of the luminescent material is promoted, and the luminescent material is instantaneously phase-changed into rare earth oxide under the dual effects of instantaneous high temperature and activated oxygen. The surface plasmon heat effect is utilized, preparation of the heterojunction micro-nano material formed by combining the rare earth fluoride and the rare earth oxide which are not matched in crystal lattices is achieved on the single-particle level, the method is simple and easy to implement, the method can be carried out at the room temperature, the reaction time is short, and the needed exciting light power density is small.

Owner:SHAANXI NORMAL UNIV

Rare Earth Oxyfluoride Sintered Body And Method For Producing Same

InactiveUS20200407280A1High strengthYittrium oxides/hydroxidesRare earth metal oxyhalidesRare-earth elementMetallurgy

A sintered rare earth oxyfluoride compact is composed of LnaObFc (wherein Ln is a rare earth element; and a, b, and c each independently represent a positive number, provided that they are not equal to each other) or Ca-stabilized LnOF as a primary phase and LnOF unstabilized with Ca as a secondary phase. The intensity ratio of the XRD peak of the (018) or (110) plane of the unstabilized LnOF to the highest XRD peak of LnaObFc is preferably 0.5% to 30%.

Owner:MITSUI MINING & SMELTING CO LTD

Method of manufacturing nanoparticle dispersion liquid

InactiveUS8809437B2Small particle sizeMaterial nanotechnologyRare earth metal chloridesSolventViscosity

The present invention provides a method of producing a nanoparticle dispersion liquid, including: altering a surface of a nanoparticle in the presence of an ion by contacting a complex that includes the nanoparticle and a solid material present around the nanoparticle with a surface altering agent-containing liquid, that includes a surface altering agent for altering the surface of the nanoparticle and a solvent for dissolving the solid material and that has a viscosity of 1.10 mPa·s or more at 25° C.; and a dispersing step of dispersing the surface-altered nanoparticle in the solvent.

Owner:TOKYO UNIVERSITY OF SCIENCE

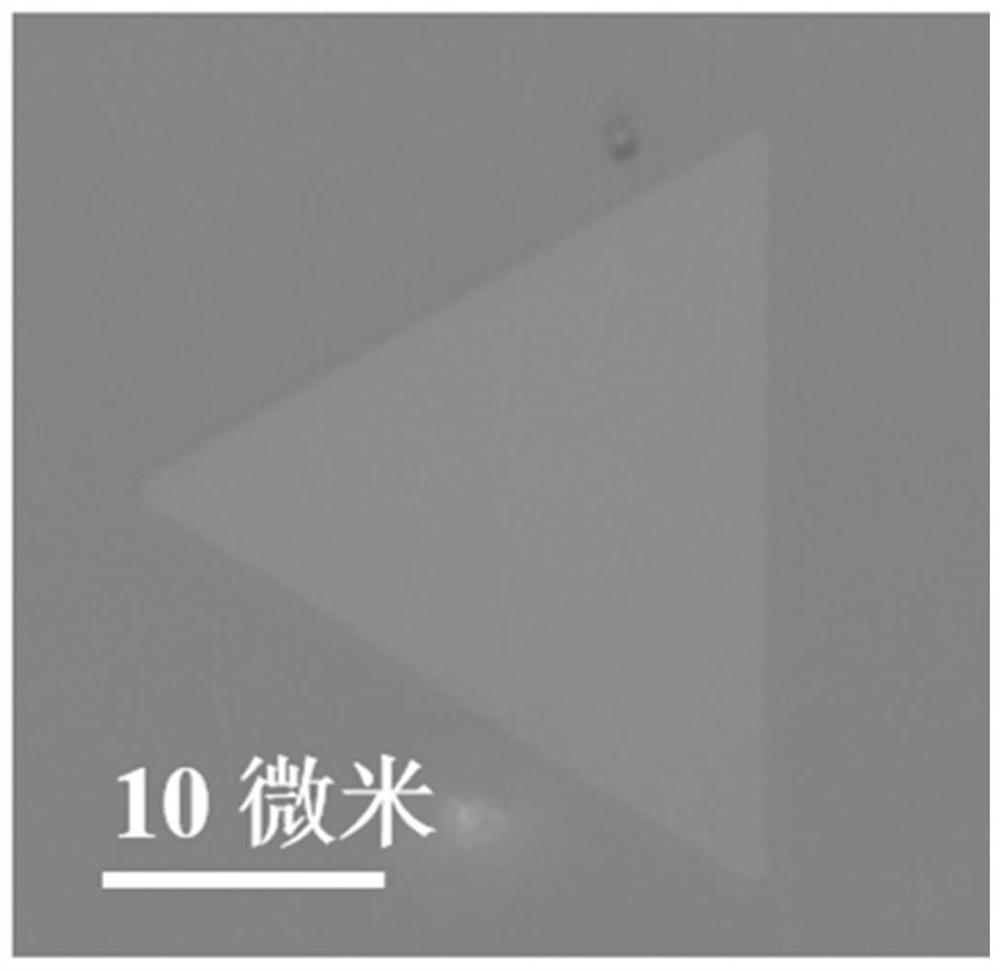

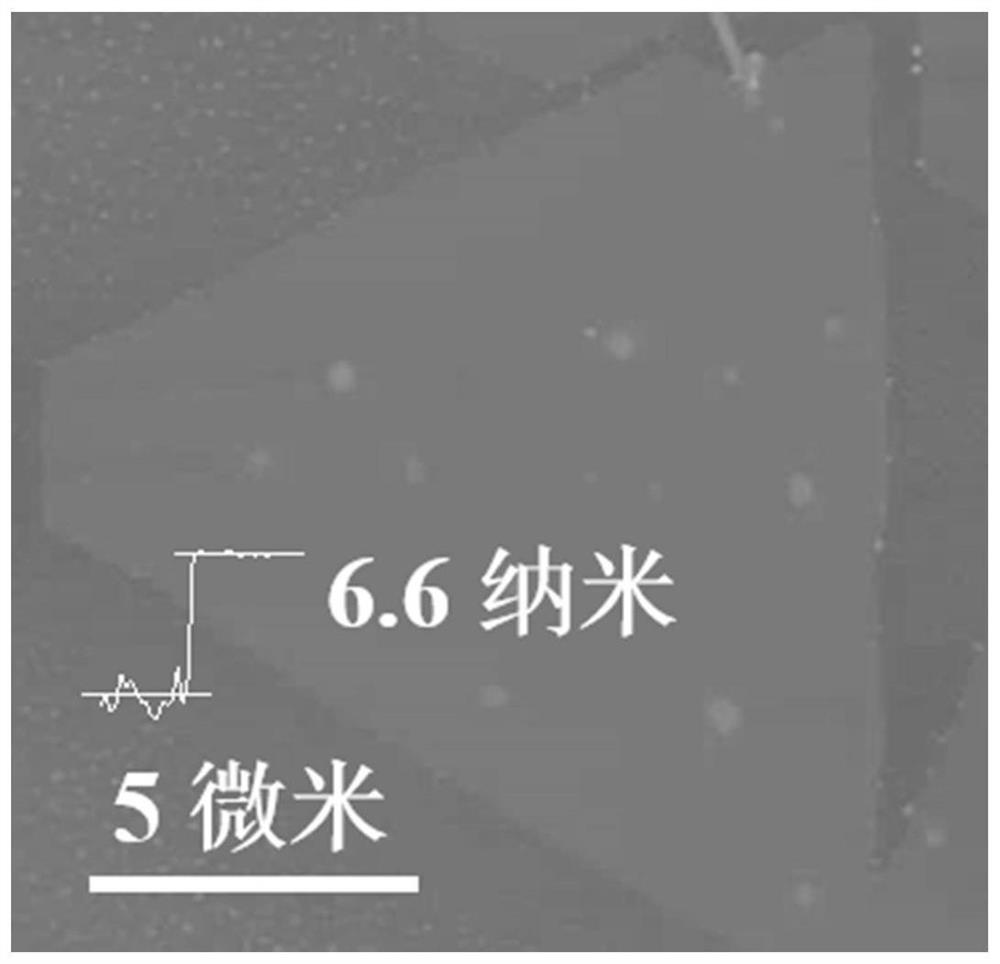

A kind of ytterbium oxychloride nanosheet and its preparation method and application

ActiveCN110316752BSimple preparation processEasy to operateCell electrodesNanotechnologyYTTERBIUM OXIDEElectrical battery

The present invention provides a nanosheet of ytterbium oxychloride and its preparation method and application. The preparation method comprises: taking ytterbium oxide and ytterbium chloride hexahydrate as raw materials, adding sodium chloride, and performing a chemical vapor deposition reaction to obtain the chlorine Ytterbium oxide nanosheets. The preparation method of the invention has simple process, fast reaction speed and low cost, and the prepared ytterbium oxychloride (YbOCl) nano sheet has large area, high purity, good crystallinity and stable chemical properties. The ytterbium oxychloride (YbOCl) nanosheets prepared by the present invention can be applied in aspects such as battery electrode materials or intercalation materials.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

A kind of preparation method of fluorinated ceria polishing powder under microwave condition

ActiveCN112266730BReduce reunionGranularityOther chemical processesRare earth metal compounds preparation/treatmentPhysical chemistryCerium

The invention discloses a preparation method of fluorinated ceria polishing powder under microwave condition, belonging to the technical field of nano rare earth material preparation, comprising the following steps: 3 ) 3 ·6H 2 O was dissolved in deionized water, preheated by microwave, and NH was added to it 4 F; will NH 4 HCO 3 Dissolve in deionized water, add preheated Ce(NO3) to it 3 ·6H 2 O and NH 4 F mixed solution, under microwave conditions, isothermal precipitation reaction generates Ce 2 (CO 3 ) 3 the precursor, and continue to age; the precursor reaction solution is filtered to obtain precipitate, dried at constant temperature, and ground into powder; the precursor powder is calcined to obtain ceria fluoride polishing powder; preparation by the method of the present invention The crystallinity of the fluorided ceria powder particles is high, the morphology is regular (like) spherical, the particle size distribution is uniform, and the dispersibility is good, which further improves the polishing efficiency and polishing accuracy of the fluorided ceria powder.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

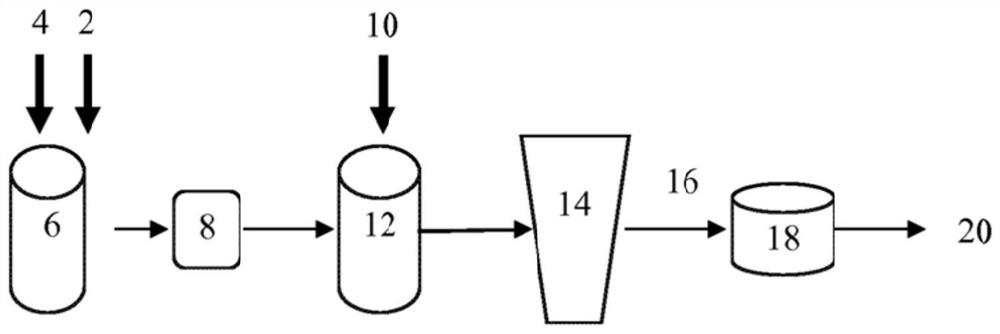

Thermal spray material and method for forming thermal sprayed coating using same

PendingUS20220064014A1Easy to getMolten spray coatingRare earth metal fluoridesThermal spray coatingCoating

A thermal spray material that enables a thermal sprayed coating, which is capable of exhibiting the same performances as those of the related art, to be obtained more easily than the related art, and a method for forming a thermal sprayed coating using the thermal spray material are provided.A thermal spray material which for forming a thermal sprayed coating containing a rare-earth oxyhalide includes a rare-earth halide powder and a rare-earth oxide powder.

Owner:FUJIMI INCORPORATED

Rare earth oxyfluoride sintered body and method for producing same

ActiveUS11034622B2High strengthYittrium oxides/hydroxidesRare earth metal oxyhalidesRare-earth elementMetallurgy

A sintered rare earth oxyfluoride compact is composed of LnaObFc (wherein Ln is a rare earth element; and a, b, and c each independently represent a positive number, provided that they are not equal to each other) or Ca-stabilized LnOF as a primary phase and LnOF unstabilized with Ca as a secondary phase. The intensity ratio of the XRD peak of the (018) or (110) plane of the unstabilized LnOF to the highest XRD peak of LnaObFc is preferably 0.5% to 30%.

Owner:MITSUI MINING & SMELTING CO LTD

Process for preparing an oxyhalogenide and/or oxide of actinide(s) and/or of lanthanide(s) from a medium comprising at least one molten salt

ActiveUS9302918B2Easy to recycleNuclear fuel reprocessingRare earth metal chloridesLanthanideMolten salt

The invention relates to a process for manufacturing an oxychloride or oxide of actinide(s) and / or of lanthanide(s) from a chloride of actinide(s) and / or of lanthanide(s) present in a medium comprising at least one molten salt of chloride type comprising a step of bringing said chloride of actinide(s) and / or lanthanide(s) present in said medium comprising at least one molten salt of chloride type into contact with a wet inert gas.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Slurry for suspension plasma spraying, method for forming rare earth acid fluoride sprayed film, and spraying member

PendingUS20210277509A1Improve corrosion resistanceMinimal processingMolten spray coatingYittrium oxides/hydroxidesOrganic solventHalogen

Provided is a slurry for suspension plasma spraying, which is a spray material used for suspension plasma spraying in an atmosphere including an oxygen-containing gas, contains 5-40 mass % of rare earth fluoride particles having a maximum particle diameter (D100) of 12 μm or less, and contains one or more types of solvent selected from among water and organic solvents. A rare earth acid fluoride-containing sprayed film, in which process shift and particle generation hardly occur, can be stably formed on a base material by carrying out suspension plasma spraying in an atmosphere including an oxygen-containing gas. A spraying member provided with this sprayed film exhibits excellent corrosion resistance to halogen-based gas plasma.

Owner:SHIN ETSU CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com