A method for recovering rare earth elements by utilizing low-purity silicon and rare earth-containing oxide materials

A technology of rare earth oxides and rare earth elements, which is applied in the preparation/processing of rare earth metal oxyhalides, rare earth metal compounds, and rare earth metal fluorides, etc., and can solve problems such as the limitation of recycling and utilization of silicon cutting waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

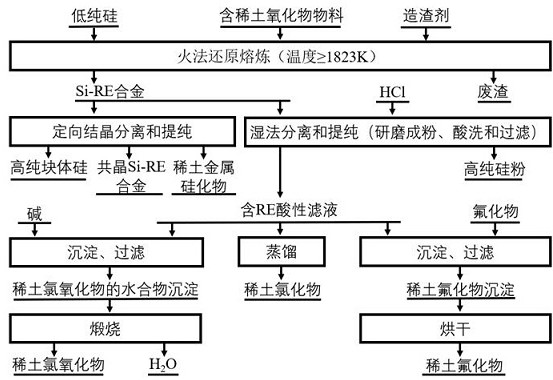

[0025] like figure 1 As shown, the specific steps of the method for recovering rare earth elements by utilizing low-purity silicon and rare earth-containing oxide materials are as follows:

[0026] Step 1. Combine industrial silicon (purity 99.3%), oxide slag containing lanthanum oxide (La 2 O 3 , CaO, SiO 2 , MgO, Al 2 O 3 The content of slag is 33.52wt.%, 16.76wt.%, 23.8wt.%, 11.17wt.% and 14.75wt.%, respectively) and slag-forming agent (the amount of CaO added is 11.73wt.% of the total slag) to reduce together For smelting, the mass ratio of industrial silicon to total slag is 0.6:1, the smelting temperature is 1823K, and the smelting time is 2 hours. After separation of the slag and gold, a Si-La alloy and waste slag with a La content of 15.9wt.% are obtained;

[0027]Step 2. Separate and purify the Si-La alloy obtained in step 1 in a directional crystallization furnace heated by electromagnetic induction to obtain high-purity bulk silicon with a purity of 99.99% (the...

Embodiment 2

[0029] like figure 1 As shown, the specific steps of the method for recovering rare earth elements by utilizing low-purity silicon and rare earth-containing oxide materials are as follows:

[0030] Step 1. Combine industrial silicon (industrial silicon, purity 99.3%), oxide slag containing lanthanum oxide (La 2 O 3 , CaO, SiO 2 , MgO, Al 2 O 3 The content of slag is 33.52wt.%, 16.76wt.%, 23.8wt.%, 11.17wt.% and 14.75wt.%, respectively) and slag-forming agent (the amount of CaO added is 11.73wt.% of the total slag) to reduce together Smelting, the mass ratio of industrial silicon to total slag is 0.2:1, the smelting temperature is 1973K, and the smelting time is 3 hours. After the slag and gold are separated, a Si-La alloy and waste slag with a La content of 55.2 wt.% are obtained;

[0031] Step 2. Separate and purify the Si-La alloy obtained in step 1 in a directional crystallization furnace heated by electromagnetic induction to obtain high-purity LaSi with a purity of 9...

Embodiment 3

[0033] like figure 1 As shown, the specific steps of the method for recovering rare earth elements by utilizing low-purity silicon and rare earth-containing oxide materials are as follows:

[0034] Step 1. Silicon cutting waste (Si content 86.9wt.%, in which the content of main impurities C, O and Al are 0.83mass%, 3.85mass% and 0.87mass%, respectively), oxide slag containing neodymium oxide (Nd 2 O 3 , CaO, SiO 2 , MgO, Al 2 O 3 The contents of slag-forming agents (CaO and SiO) were 2 , the addition amount is 17.8wt.% and 13.8wt.% of the total slag, respectively) for reduction smelting, the mass ratio of silicon cutting waste to the total slag is 0.8:1, the smelting temperature is 1823K, and the smelting time is 3 hours. After slag gold separation, Si-Nd alloy and waste slag with Nd content of 11.3wt.% were obtained;

[0035] Step 2. Grind the Si-Nd alloy obtained in step 1 into powder with a particle size of less than 74 microns, and pickle it with HCl. The pickling co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com