Preparation method of cerium dioxide fluoride polishing powder under microwave condition

A technology of fluorinated cerium dioxide and polishing powder, which is applied in the preparation/treatment of rare earth metal compounds, chemical instruments and methods, rare earth metal oxyhalides, etc., and can solve the problems of increasing equipment, consuming time, and reducing product purity. , to achieve the effects of weakening agglomeration, reducing surface scratches, and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1 (no microwave control group)

[0038] A preparation method of fluorinated ceria polishing powder under a water bath condition, comprising the following steps:

[0039] (1) Take Ce (NO 3 ) 3 ·6H 2 O, NH 4 HCO 3 and NH 4 F was dissolved in deionized water, and 500 mL of 0.0582 mol / L cerium nitrate aqueous solution, 125 mL of 1.047 mol / L ammonium bicarbonate aqueous solution and 125 mL of 0.126 mol / L ammonium fluoride aqueous solution were prepared; The influence of polishing powder preparation does not study the influence of the above-mentioned component content on the polishing powder. The above-mentioned component dosage is a preferred solution in the research process of the present invention, and its selection range satisfies the following conditions:

[0040] A.NH 4The amount of F is 5% to 7% of the quality of the final product as the fluorine element;

[0041] B.NH 4 HCO 3 and Ce(NO 3 ) 3 ·6H 2 The molar ratio of O is more than 4.5:1;

[0042]...

Embodiment 2

[0054] A preparation method of fluorinated ceria polishing powder under microwave conditions, comprising the following steps:

[0055] (1) Take Ce (NO 3 ) 3 ·6H 2 O, NH 4 HCO 3 and NH 4 F was dissolved in deionized water, and 500 mL of 0.0582 mol / L cerium nitrate aqueous solution, 125 mL of 1.047 mol / L ammonium bicarbonate aqueous solution and 125 mL of 0.126 mol / L ammonium fluoride aqueous solution were prepared;

[0056] (2) get the cerium nitrate solution configured in the above (1) and put it into the microwave reactor for microwave heating, the heating temperature is to 65 ° C, and get the ammonium fluoride solution in the above (1) and add it, and stir magnetically evenly;

[0057] (3) get the ammonium bicarbonate solution configured in the above-mentioned (1), add the cerium nitrate and ammonium fluoride mixed solution obtained in the above-mentioned (2), stir magnetically and react 75min at a constant temperature of 65 ℃ in a microwave mode;

[0058] In steps (2)...

Embodiment 1、2

[0065] Embodiment 1,2 comparative analysis is as follows:

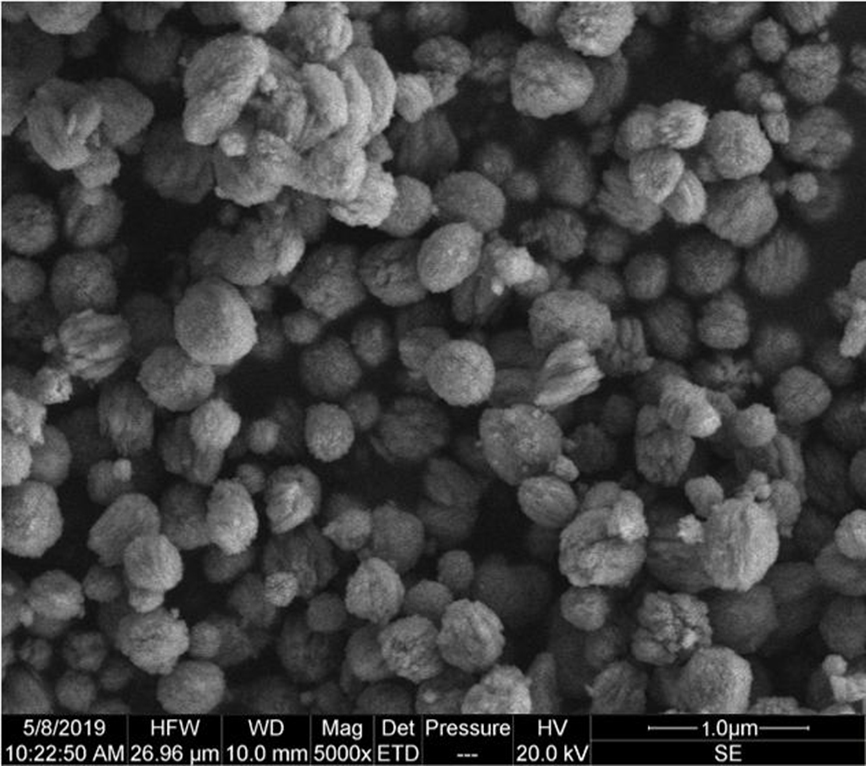

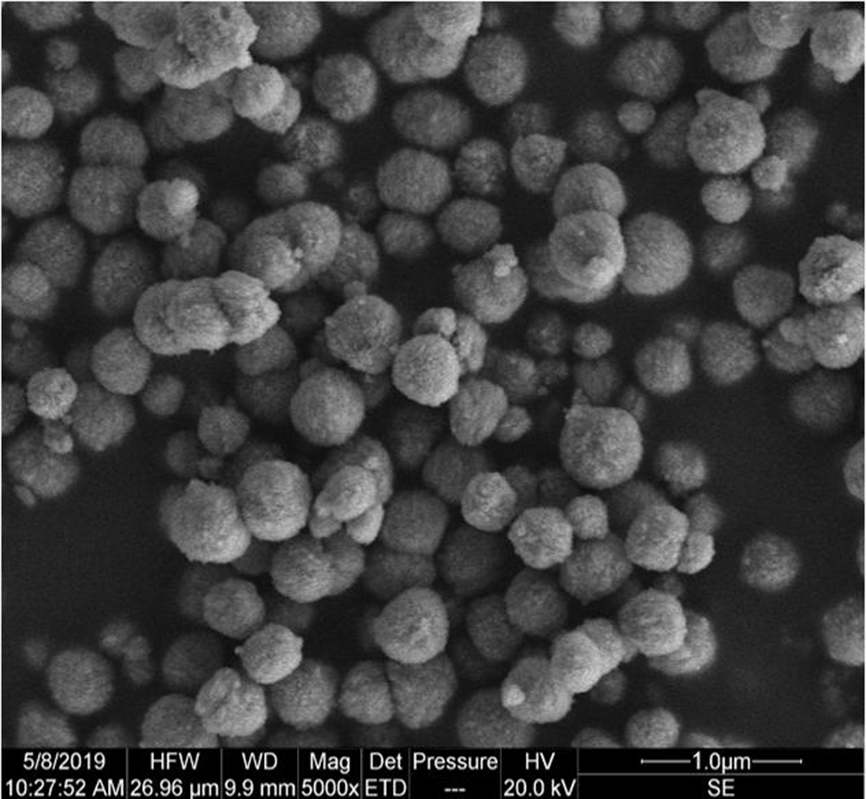

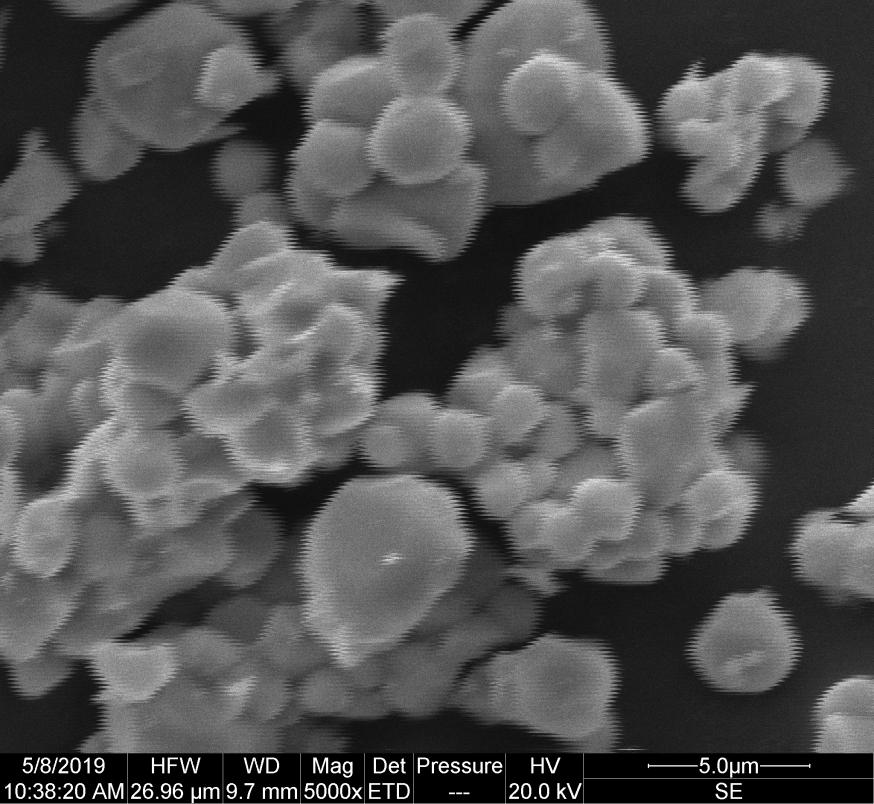

[0066] (1) as figure 1 Shown is the SEM image of the precursor cerium carbonate under the water bath condition prepared in Example 1, such as figure 2 Shown is the SEM image of the precursor cerium carbonate under microwave conditions prepared in Example 2; the comparison of the two SEM images shows that the cerium carbonate particles prepared under microwave conditions are more rounded and have better particle dispersibility.

[0067] (2) as image 3 Shown is the SEM image of fluorinated ceria under the water bath condition prepared in Example 1, such as Figure 4 Shown is the SEM image of fluorinated ceria under microwave conditions prepared in Example 2; by comparison, it can be seen that the ceria particles prepared under water bath conditions have large-scale agglomeration, while the ceria particles prepared under microwave conditions The dispersibility of cerium dioxide particles is good, indicating that mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com