A kind of samarium oxychloride nanosheet and its preparation method and application

A technology of samarium oxychloride and nanosheets, which is applied in the field of photocatalytic synthesis of ammonia, can solve the problems of hindering photocatalyst electron transfer and limiting efficiency, and achieve the effects of simple separation and drying, promotion of adsorption and activation, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Preparation of Graphene Oxide (GO):

[0034] 1) Mix 1.2g of flake graphite powder with 6.0g of potassium permanganate and grind together for at least 30min until they are evenly mixed.

[0035] 2) Put the mixed powder into a 100ml hydrothermal kettle, add 40ml of concentrated sulfuric acid, immediately tighten the hydrothermal kettle and put it in an ice-water bath for 24 hours of reaction.

[0036] 3) Turn the reaction kettle into an electric heating constant temperature blast drying oven, keep it warm at 80°C for 2 hours, and take out the hydrothermal kettle when it cools down to room temperature with the instrument.

[0037] 4) Put the obtained solid-liquid mixture into a 1000ml large beaker, add 40ml of 30% hydrogen peroxide solution to react the excess potassium permanganate in the solution until no bubbles come out, then pour it out after standing for 12 hours supernatant.

[0038] 5) Add 500ml of hydrochloric acid solution with a mass fraction of 5% and stir, a...

Embodiment 1

[0044] 1) Put 5mmol tris(hydroxymethyl)aminomethane, 4mmol concentrated hydrochloric acid into a beaker and add 50ml of H 2 O is made into a buffer solution without solid suspension, and its pH is about 7.5;

[0045] 2) Add 1 mmol of samarium chloride and 5 ml of graphene oxide solution, add a stirrer, cover with plastic wrap, and sonicate for 15 minutes;

[0046] 3) Put the beaker into an oil bath preheated to 60°C, and react for 3 hours;

[0047] 4) Pour the solution into a centrifuge tube, centrifuge, pour off the liquid, wrap the mouth of the centrifuge tube with plastic wrap and pierce the hole;

[0048] 5) Put the centrifuge tube into the refrigerator, freeze it for at least 6 hours, then put it into a freeze dryer, and freeze it for 24 hours;

[0049] 6) Put the obtained solid into a small porcelain boat and burn it at 550°C for 2 hours to generate amorphous smoky two-dimensional SmOCl nanosheets, which are denoted as A-SmOCl.

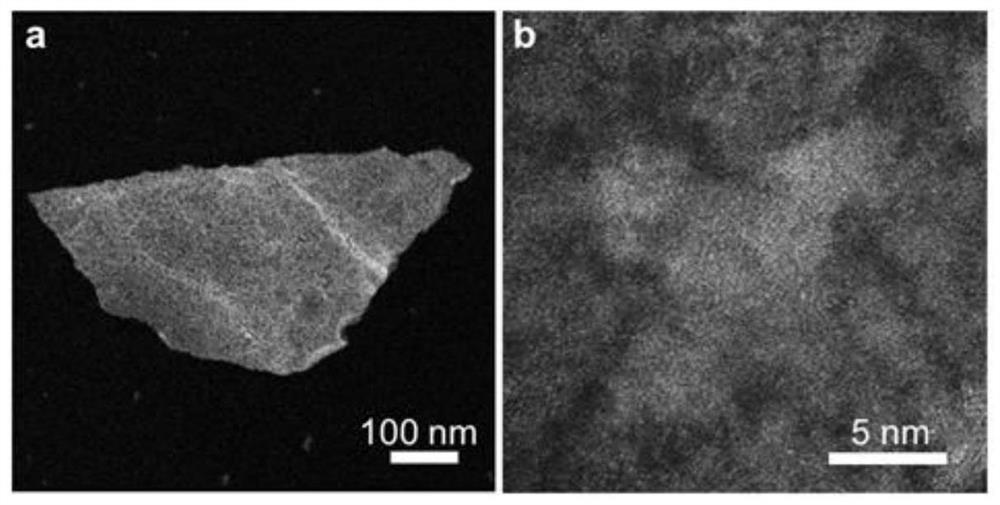

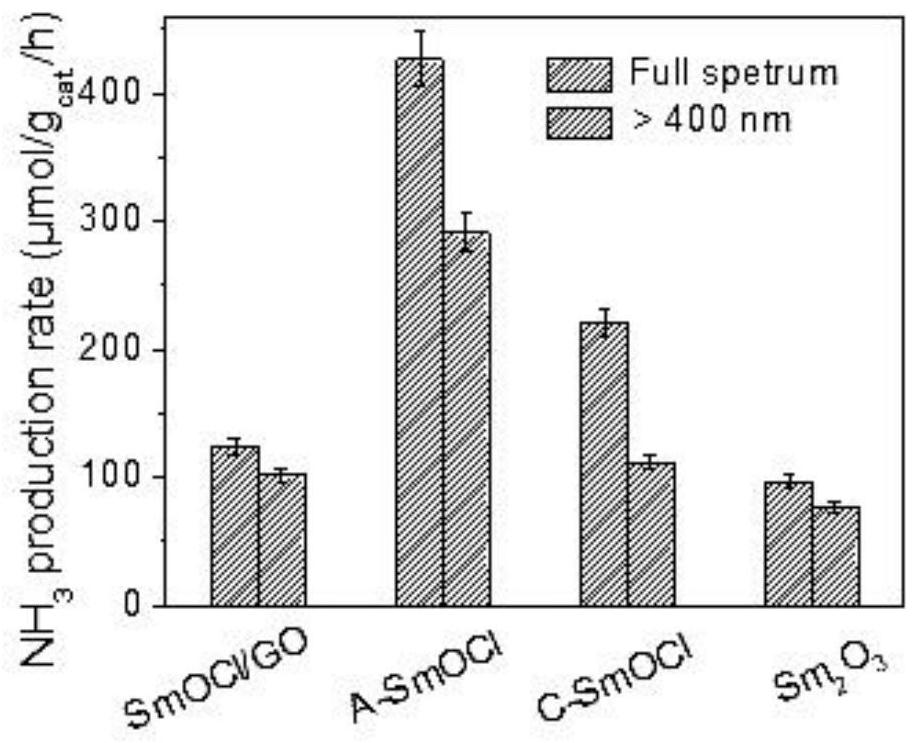

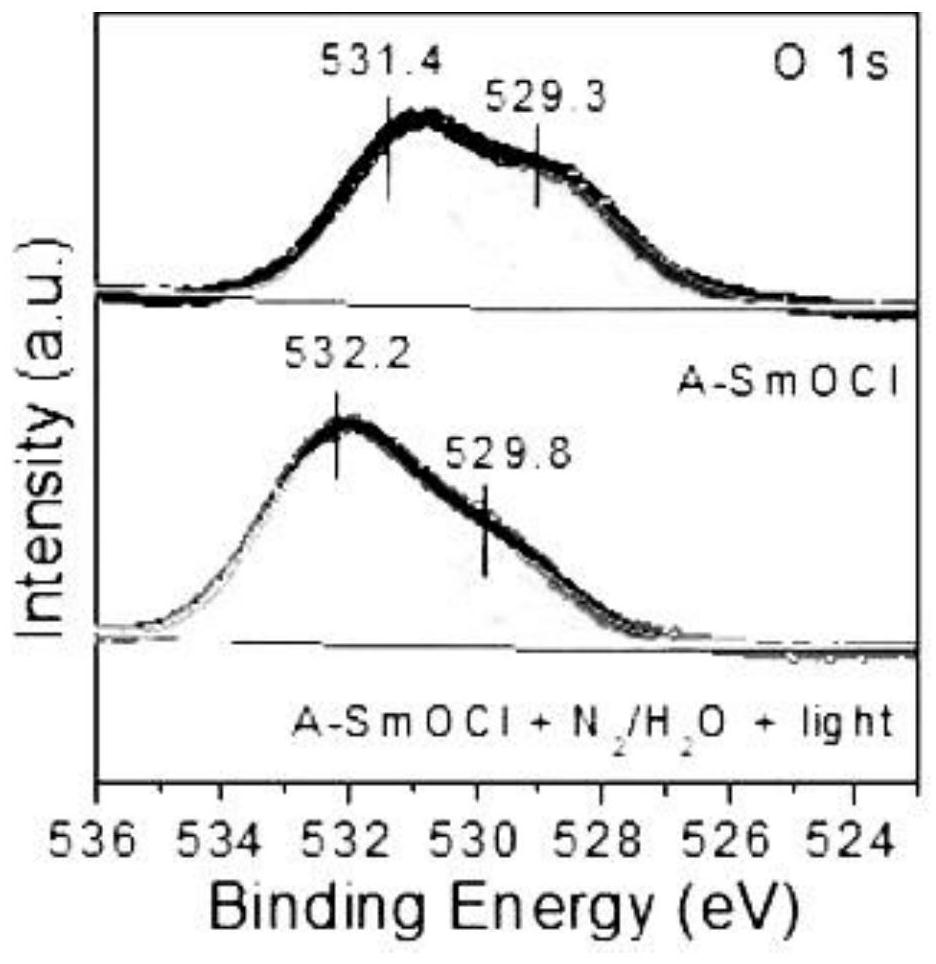

[0050] The sample that present embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com