Method for rapid in-situ preparation of rare earth fluoride-rare earth oxide heterojunction micro-nano material

A technology of rare earth fluorides and rare earth oxides, applied in the direction of rare earth metal oxyhalides, rare earth metal compounds, rare earth metal halides, etc., can solve the problems of irregular product shape, limited application, complex synthesis process, etc., and achieve exciting The effect of low optical power density, simple and easy method, and excellent optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Preparation of Gold Nanoislands

[0037] A gold nano film with a thickness of 20nm was vapor-deposited on a pre-cleaned glass sheet by a thermal evaporation coater, and then the gold nano film was annealed at 400°C for 30s to form gold nano islands (see Figure 5 ).

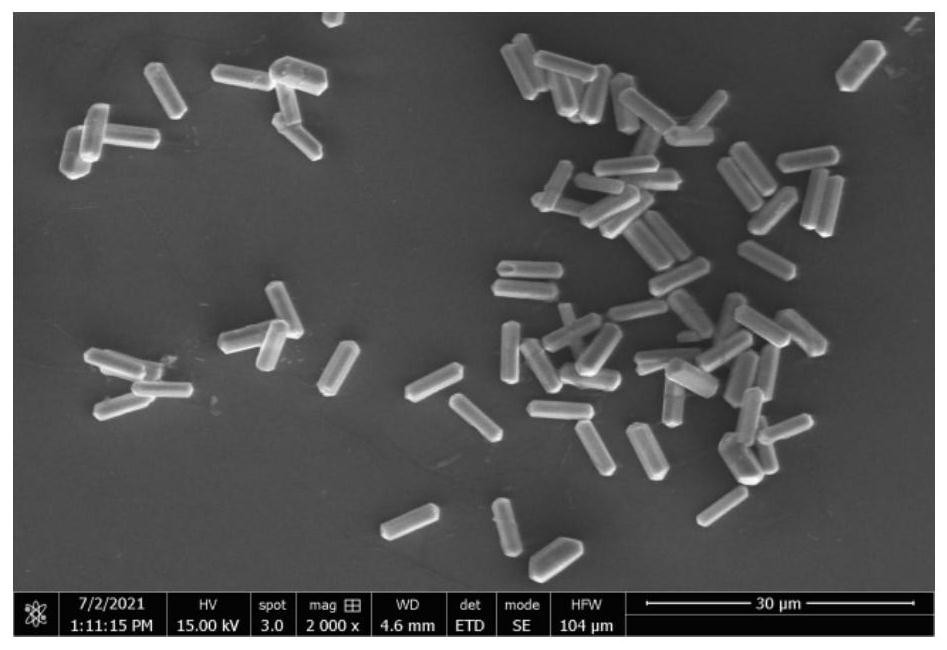

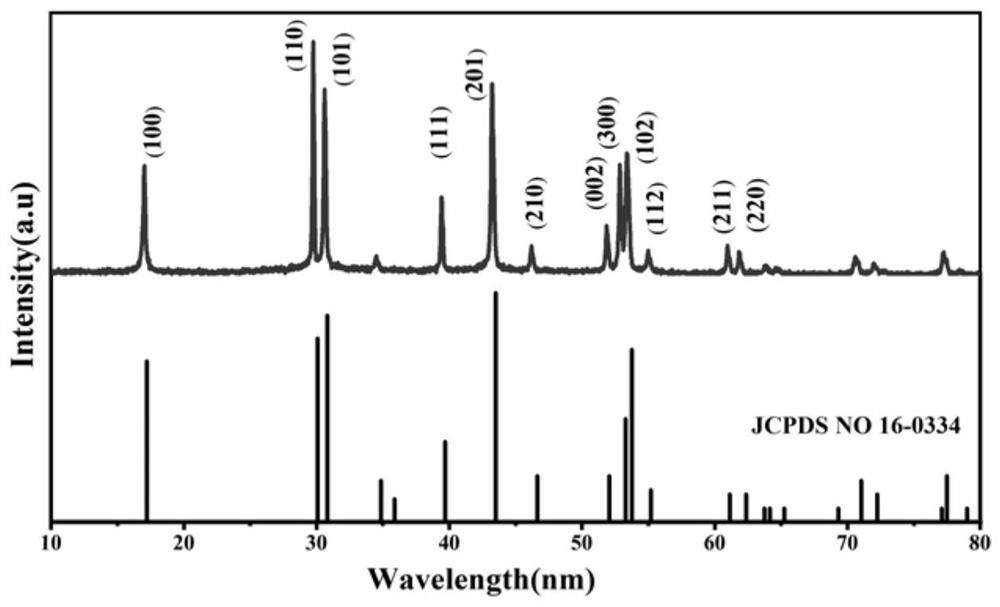

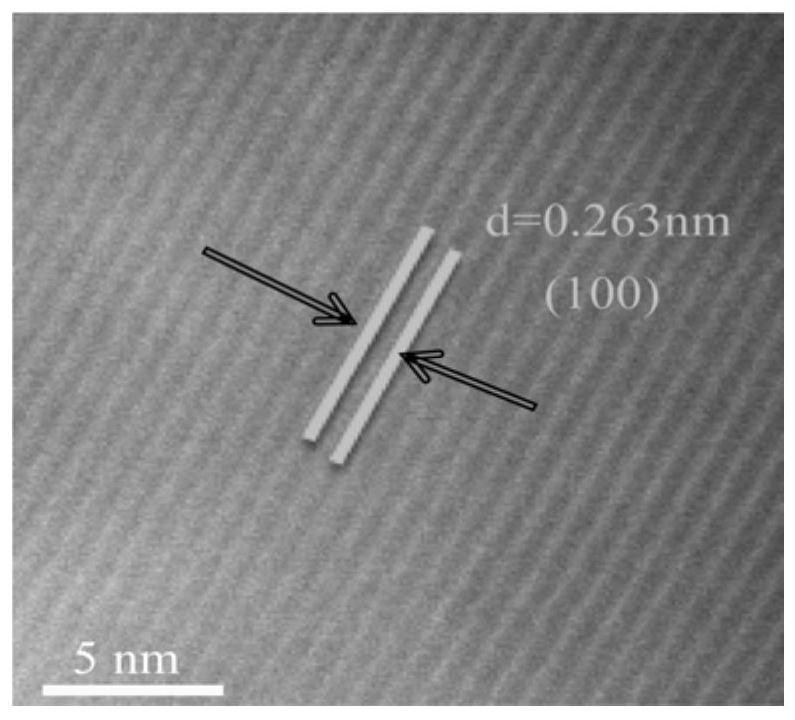

[0038] 2. NaYF 4 :Eu 3+ -YOF:Eu 3+ Preparation of heterojunction micro-nano materials

[0039] 1g NaYF 4 :Eu 3+ Micron rod-shaped crystal powder was added to 10 mL of deionized water, and then it was sonicated at room temperature for 10 minutes and dropped on the surface of the gold nano-islands, and then placed in a drying oven at a temperature of 50°C until the deionized water was completely dried. Then NaYF uniformly dispersed on the surface of gold nano islands 4 :Eu 3+ Select a single microrod, focus the excitation light spot on one end of the microrod and irradiate it for 20ms. The wavelength of the excitation light is 532nm (coupled with the wavelength of the Au nanoparticle plasmon reson...

Embodiment 2

[0042] 1. Preparation of Gold Nanoislands

[0043] A gold nano film with a thickness of 20nm was evaporated on a pre-cleaned glass plate by a thermal evaporation coating device, and then the gold nano film was annealed at 400°C for 30s to form gold nano islands.

[0044] 2. NaYF 4 :Eu 3+ -Y 2 o 3 :Eu 3+ Preparation of heterojunction micro-nano materials

[0045] 1g NaYF 4 :Eu 3+ Micron rod-shaped crystal powder was added to 10 mL of deionized water, and then it was sonicated at room temperature for 10 minutes and dropped on the surface of the gold nano-islands, and then placed in a drying oven at a temperature of 50°C until the deionized water was completely dried. Then NaYF uniformly dispersed on the surface of gold nano islands 4 :Eu 3+ Select a single microrod, focus the excitation light spot on one end of the microrod and irradiate for 60ms, the wavelength of the excitation light is 532nm (coupled with the wavelength of the Au nanoparticle plasmon resonance peak),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com