Spray coating, spraying powder, spraying powder manufacturing method and spray coating manufacturing method

A manufacturing method and coating technology, which can be applied in the direction of fusion spraying, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., and can solve the problems of life reduction and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

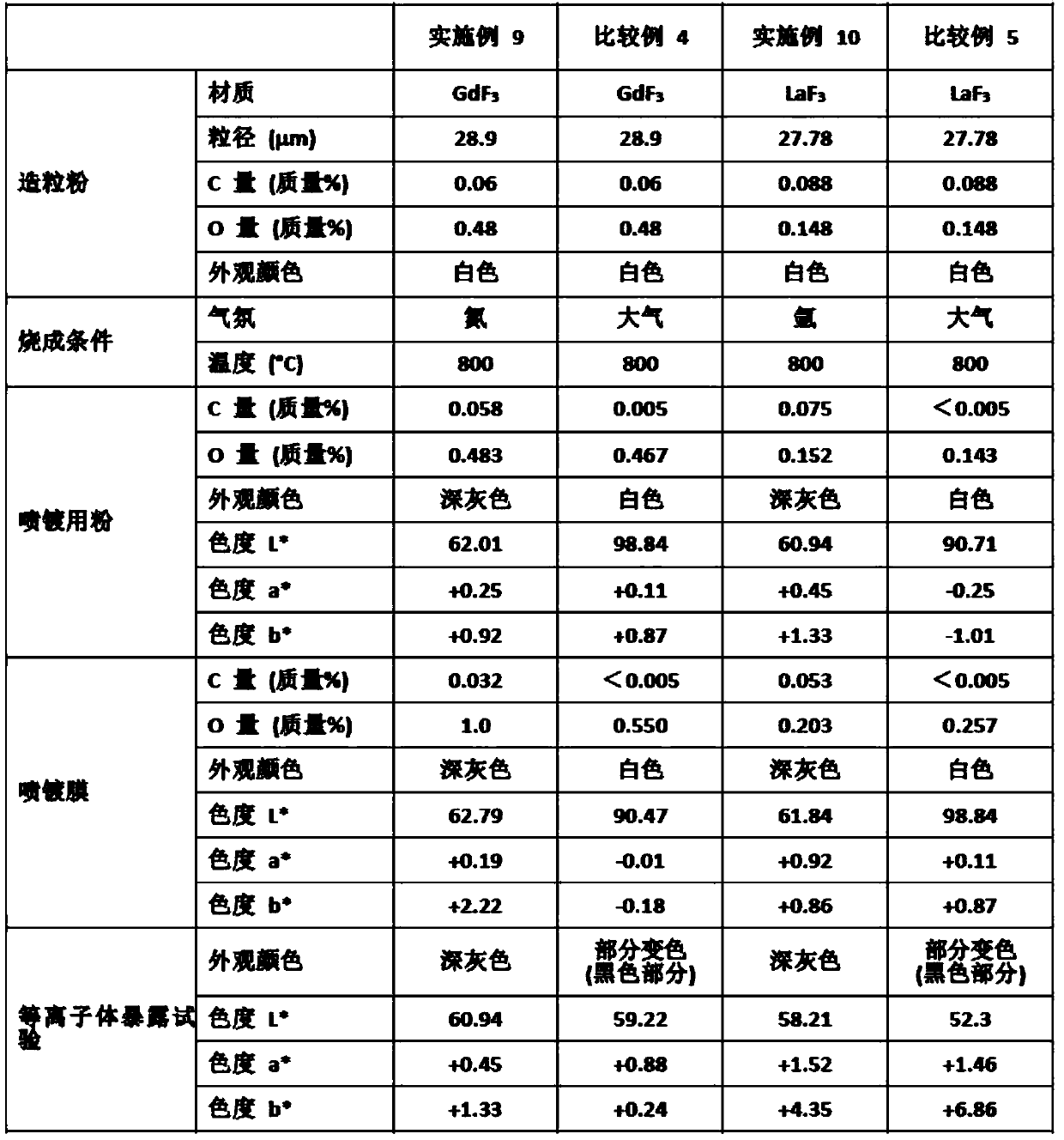

Embodiment 1

[0129] Add 1 liter of phenol solution diluted to 3% with ethanol to 1 kg of ytterbium fluoride (average particle size: 40 μm) powder with an oxygen concentration of 3.4%, mix for 5 minutes, dry, and bake for 2 hours with a nitrogen flow at 800°C. Furthermore, the granulated powder was subjected to reduced pressure (1×10 -2 torr or less) at 1000°C for 2 hours to produce powder for thermal spraying. The spraying powder is L * a * b * L in chromaticity representation * : 42.3, a * : -0.30, b * : Black at -0.65, the carbon concentration in the powder is 1.3%. In addition, the oxygen concentration was 2.9%.

[0130] Using this thermal spraying powder, a film was deposited on an aluminum alloy member by plasma spraying using argon or hydrogen gas to form a film having a thickness of about 200 μm. The L of the sprayed coating was measured * a * b * Chroma, the result is L * : 45.2, a * : -0.53, b * : -0.62, the carbon concentration is 1.1%. In addition, the oxygen conc...

Embodiment 2

[0136] Yttrium fluoride (average particle size: 40 μm) powder having an oxygen concentration of 0.2% was immersed in a 30% sucrose aqueous solution, stirred for 10 minutes, filtered, and dried. This yttrium fluoride powder was calcined for 2 hours in a nitrogen flow at 800° C., and sieved through a #100 sieve to obtain a powder for thermal spraying. The spraying powder is L * a * b * L in chromaticity representation * : 72.23, a * : -0.02, b * : 3.12 gray, the carbon concentration in the powder is 0.235%. In addition, the oxygen concentration was 0.75%.

[0137] Using this thermal spraying powder, a film was deposited on an aluminum alloy member by plasma spraying using argon or hydrogen gas to form a film having a thickness of about 200 μm. The L of the sprayed coating was measured * a * b * Chroma, the result is L * : 76.18, a * : 0.04, b * : 3.77, the carbon concentration is 0.015%. In addition, the oxygen concentration was 1.1%.

[0138] The sputtering membe...

Embodiment 3

[0140] Add 4 liters of 2% aqueous solution of acrylic binder to 150 g of white yttrium oxide (average particle diameter 1.1 μm) powder and 850 g of yttrium fluoride (average particle diameter 3 μm) powder and mix to prepare a slurry, and use a spray dryer This was granulated and dried, and then sieved through a #100 sieve to obtain yttrium fluoride (average particle diameter: 36 μm) powder, thereby obtaining a powder for thermal spraying. The spraying powder is L * a * b * L in chromaticity representation * : 88.46, a * : 3.63,b * : The gray color of -2.85, the carbon concentration in the powder is 1.46%, and the oxygen concentration is 3.37%. In addition, X-ray diffraction of the powder was carried out, and it was observed that YF 3 and Y 2 o 3 peak.

[0141] Using this thermal spraying powder, a film was deposited on an aluminum alloy member by plasma spraying using argon or hydrogen gas to form a film having a thickness of about 200 μm. The L of the sprayed coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com