Method for preparing transparent ceramic through one-time forming based on photocuring 3D printing technology

A 3D printing, transparent ceramic technology, applied in ceramic molding machines, manufacturing tools, rare earth metal halides, etc., can solve problems such as the inability to meet the molding requirements of large-sized ceramic components, the limitation of light-curing 3D printing technology, and the uneven size control. Achieve the effect of small internal curing shrinkage stress, ensure printing efficiency, and reduce the possibility of deformation and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

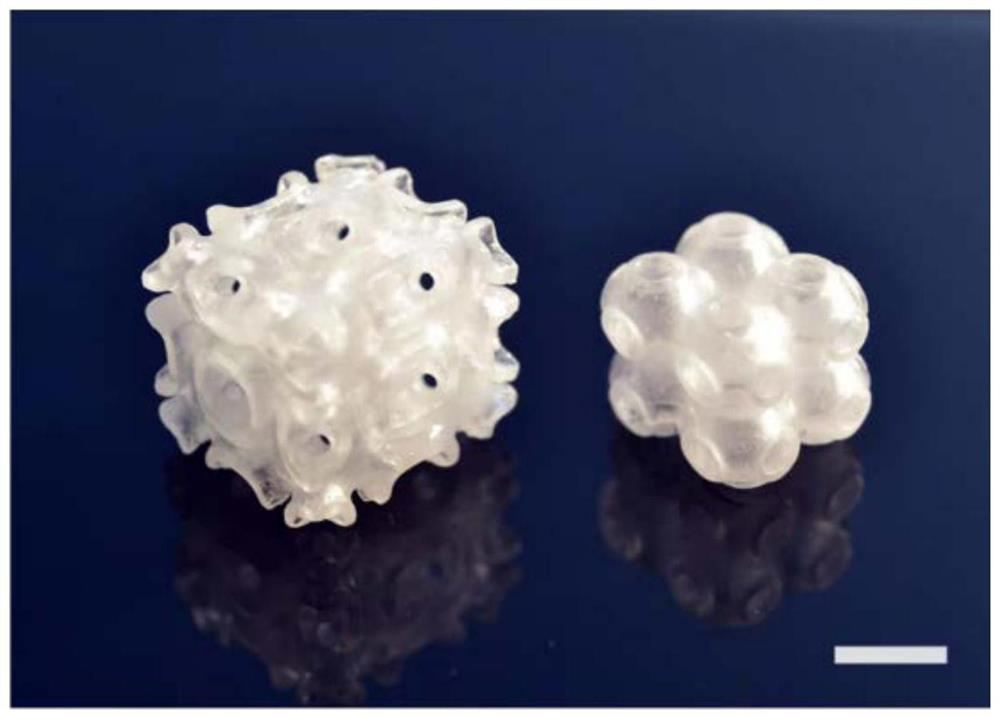

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described in further detail below. It should be understood that the descriptions of the embodiments of the present invention herein are not intended to limit the protection scope of the present invention.

[0027] The method for preparing transparent ceramics by one-time molding based on photocuring 3D printing technology provided by the present invention comprises the following steps:

[0028] STEP101: Provide oxide ceramic powder raw materials, the purity of the oxide ceramic powder is greater than 99.99%;

[0029] STEP102: Provide photosensitive resin, photoinitiator, dispersant, sintering aid, and grinding ball, wherein the photosensitive resin is an ethoxylated low-viscosity compound system and the viscosity of the photosensitive resin below 25°C is not high At 1000cps, the dispersant is a polymer-based dispersant with a pigment affinity group;

[0030]STEP103: Put the oxide ceramic powder raw materials, as we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com