Method for separating and recovering rare earth elements

A rare earth element, separation and recovery technology, applied in the fields of rare earth metal compounds, rare earth metal halides, chemical instruments and methods, etc., can solve the problems of difficult separation and purification of elements, high cost, and time required for practical application, and achieves effective utilization of resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

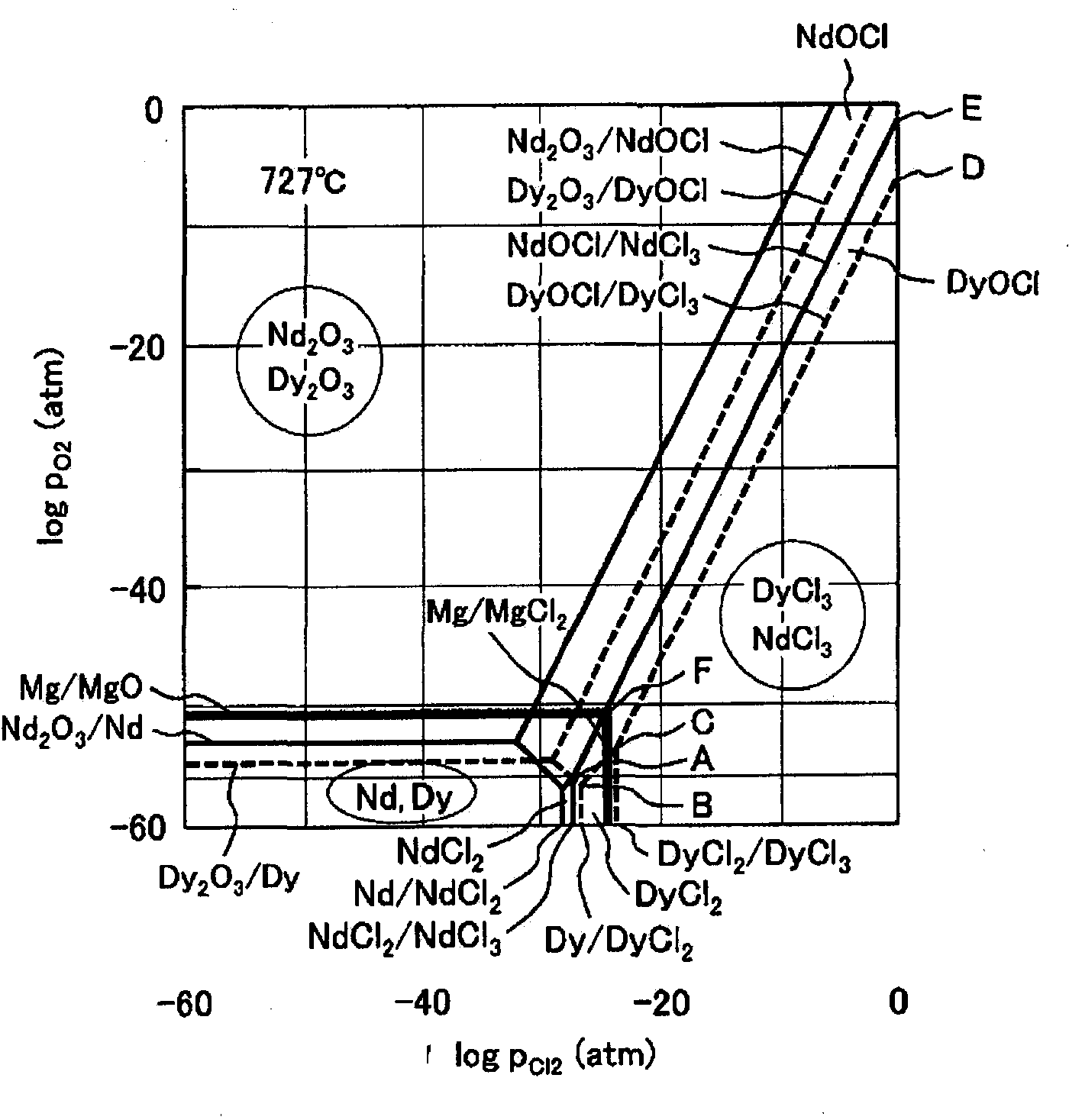

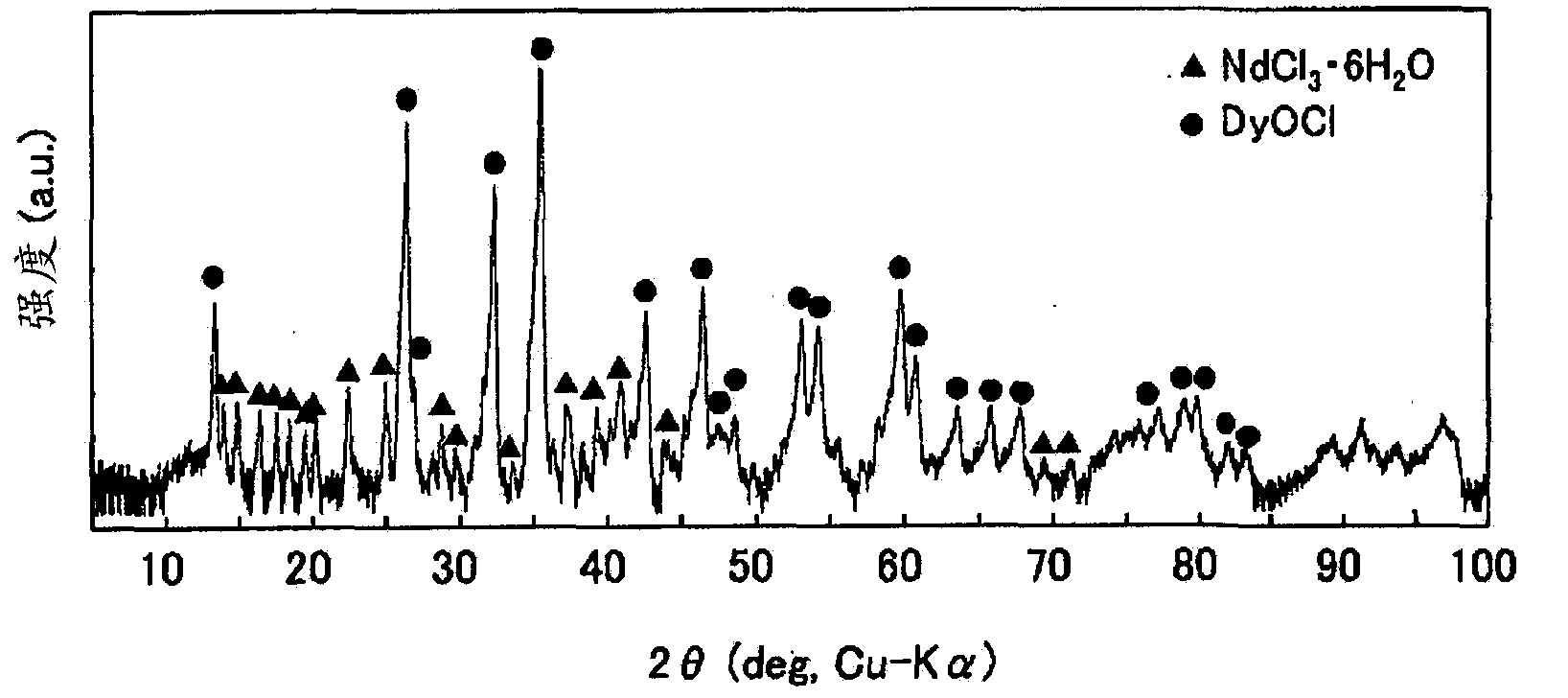

[0063] Separation and recovery from rare earth oxide mixtures are considered. As the starting material of rare earth oxides, neodymium oxide (Nd 2 o 3 ) powder with dysprosium oxide (Dy 2 o 3 ) powder, as a starting material for the chlorine source, anhydrous dysprosium chloride (DyCl 3 )powder. For the powdered reagents of the starting materials, all of them were 3N-grade reagents manufactured by High Purity Chemical Research Institute Co., Ltd. In the drying chamber, put 2.5mmol (0.84g) of Nd 2 o 3 Powder, 2.5 mmol (0.93 g) of Dy 2 o 3 powder, with 5.0 mmol (1.34 g) of DyCl 3 The powders were weighed and mixed, and charged and sealed in a stainless steel reaction vessel under a nitrogen atmosphere. Sealing was performed by argon welding with a cap on a stainless steel reaction container.

[0064] Put the reaction container sealed with the raw material powder into an electric furnace, heat treatment at 800° C. for 6 hours to allow the chemical reaction to proceed, ...

Embodiment 2

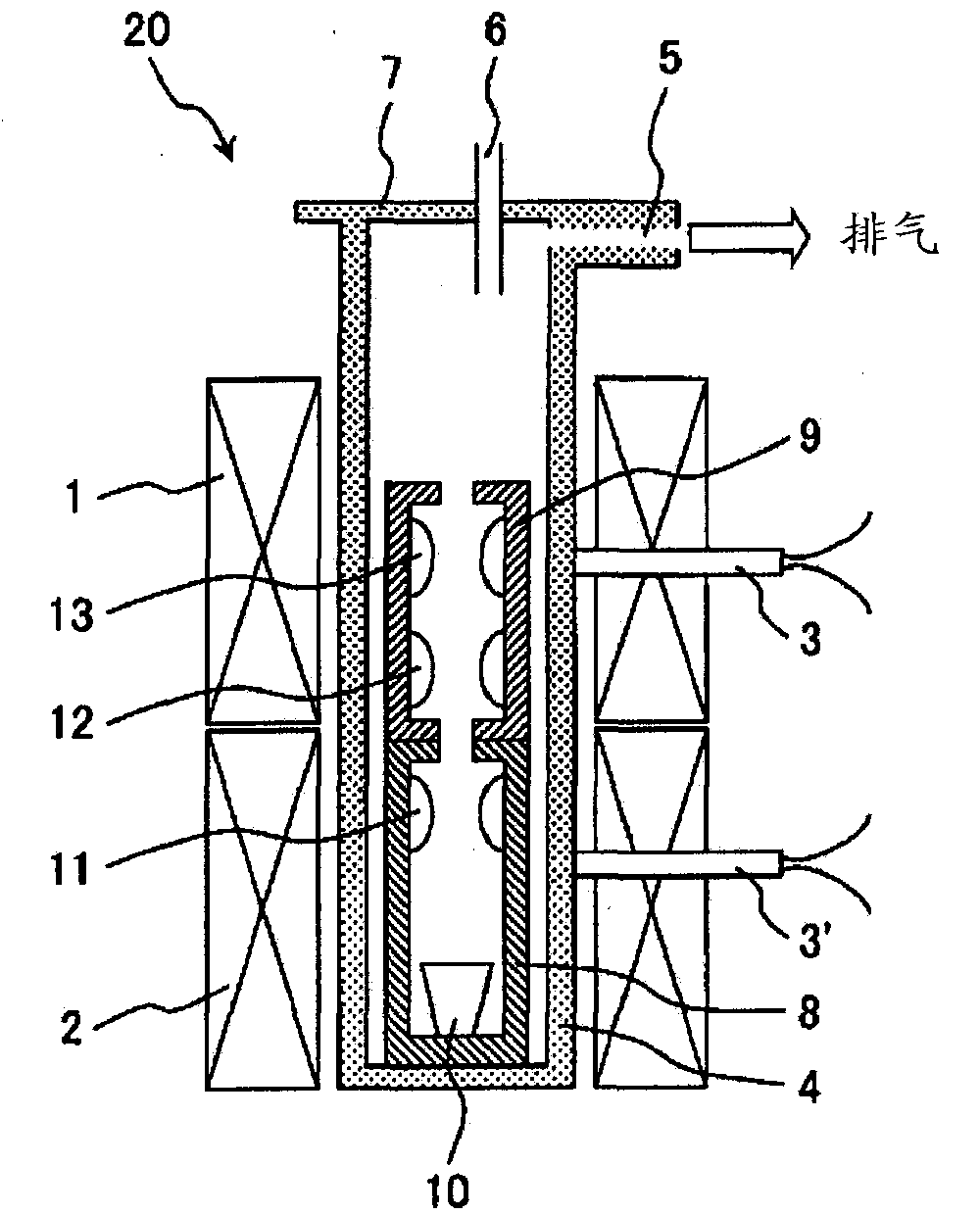

[0068] Separation and recovery from rare earth chloride mixtures are investigated. As the starting material of rare earth chlorides, anhydrous NdCl manufactured by High Purity Chemical Research Institute Co., Ltd. is used 3 powder with anhydrous DyCl 3 As the powder, metal Mg powder (particle size: about 0.5 mm, purity: 99.93%) manufactured by Wako Pure Chemical Industries, Ltd. was used as the starting material of magnesium. In the drying room, weigh the NdCl 3 Powder and DyCl 3 Each powder was 2.5 g, 5.0 g of Mg powder was weighed, and it filled in the molybdenum crucible 10. After stirring and mixing these powders with a medicine spoon, 0.2 g of high-temperature-treated graphite powder was separately weighed and put into the crucible 10 so as to coat the previously charged rare earth chloride powder. A desiccator is prepared in advance in the drying chamber, and the crucible filled with the raw material powder is sealed in the desiccator at one time.

[0069] The dryer...

Embodiment 3

[0076] Discussion on rare earth magnets containing neodymium, dysprosium, praseodymium, iron and boron (RE 2 Fe 14 B) Waste materials, separation and recovery of rare earth elements. The mass composition of the rare earth magnet used is 61.2% Fe-23.1% Nd-3.5% Dy-2.0% Pr-1.0% B. This scrap magnet is a defective product due to cracks, chipping, etc. after electroplating nickel in the manufacturing process.

[0077] First, the scrap magnets were coarsely pulverized by heating at 800° C. in a hydrogen atmosphere using an electric furnace. As mentioned above, nickel electroplating is performed on the scrap magnet, and since the electroplated nickel film can be peeled off through the hydrogen crushing process, the stripped electroplated film is separated from the magnet powder by screening.

[0078] For the obtained magnetite powder, with FeCl as chlorine source 2 The powders are mixed, put into the crucible 10 made of iron, and are arranged in figure 2 Inside the distillation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com