Powder for coating an etch chamber

A powder and coating technology, applied in the coating field of semiconductor etching chamber, can solve the problems of increasing corrosion resistance of semiconductor etching chamber coating and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0164] The following examples are provided by way of illustration, not limitation of the scope of the invention.

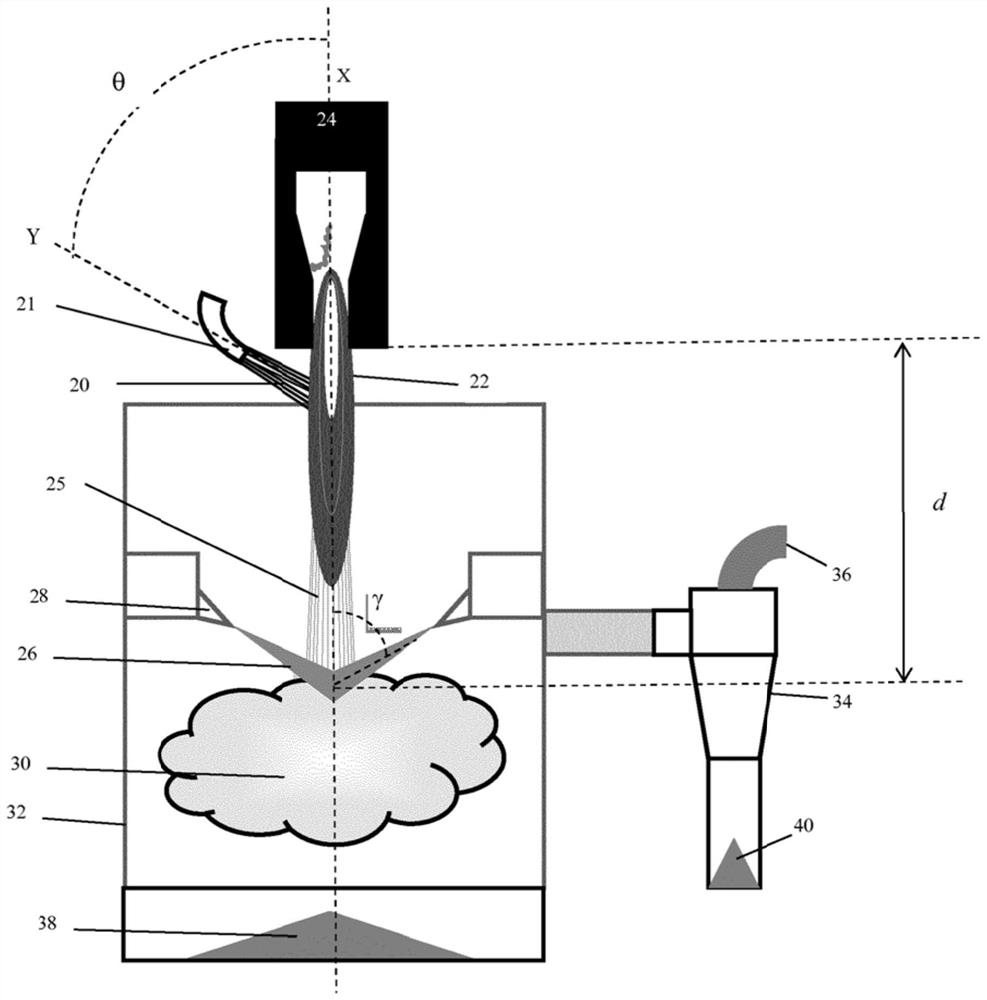

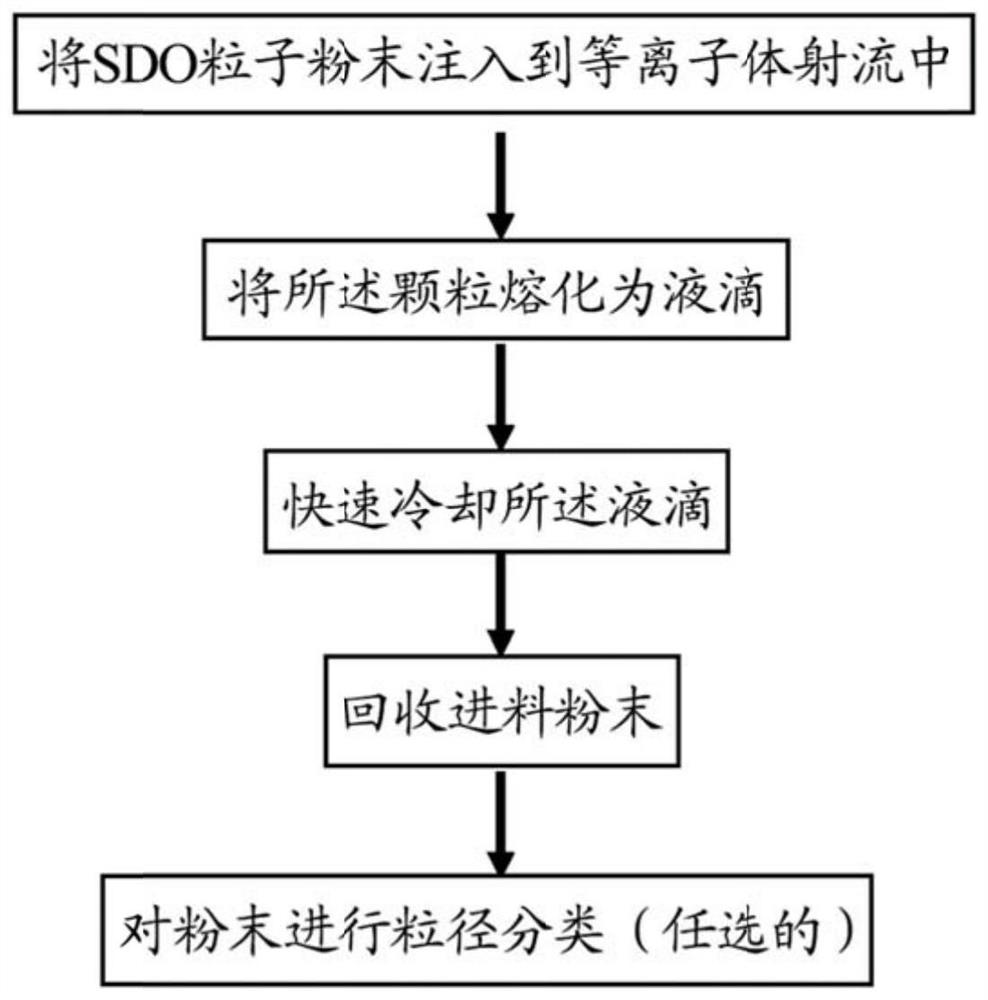

[0165] Feed powder H1, feed powder I1 (comparative example) and feed powder C1 (comparative example) are used in WO2014 / 083544 figure 2 The plasma torch shown in the similar plasma torch has a median particle size D measured with a Horiba laser particle analyzer. 50 1.2 micron pure Y 2 o 3 Powder (Y with a chemical purity of 99.999% 2 o 3 ) made of.

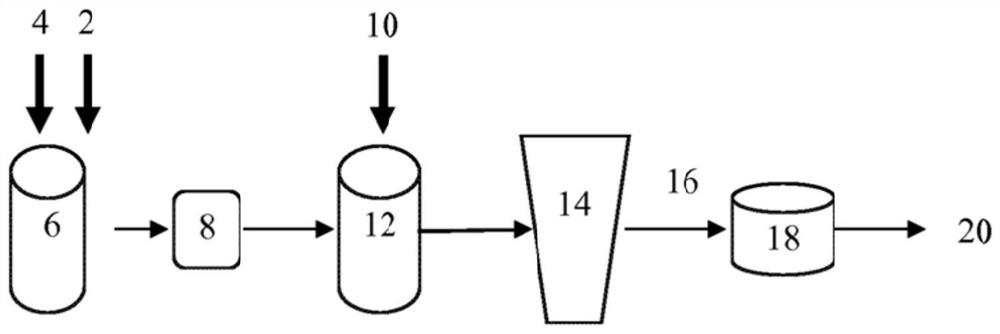

[0166] In step a), by applying PVA (polyvinyl alcohol) adhesive 2 (see figure 1 ) was added to deionized water 4 to prepare the binder mixture. The binder mixture is then filtered through a 5 μm filter 8 . Yttrium oxide powder 10 is mixed into the filtered binder mixture to form slip 12 . The slip was made to contain 55% by mass of yttrium oxide and 0.55% of PVA, the balance to 100% being deionized water. Mix the slip vigorously using a high shear speed mixer.

[0167] The particles G3 are subsequently ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com