Preparation method of neodymium-iron-boron magnet surface suspension plasma spraying coating

A suspension and NdFeB technology, which is applied in coating, metal material coating process, inductance/transformer/magnet manufacturing, etc., can solve the problem of low utilization rate of target material and evaporation material, high manufacturing cost of target material, coating Low binding force and other problems, to achieve the effect of fine microstructure, high production efficiency and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

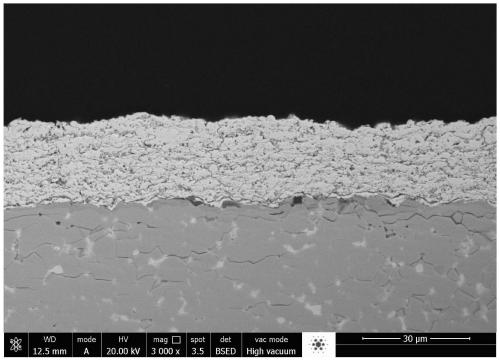

[0032] Embodiment 1: The rare earth powder is Dy 2 o 3 pink

[0033] 1. Preparation of rare earth suspension: Dy 2 o 3 Mix the powder and deionized water in proportion, stir evenly to obtain a rare earth powder suspension, the solid content of the rare earth powder suspension is 15wt%, after ball milling for 1.5h, the median diameter of the rare earth powder is 0.45 μm, add a dispersant to polymerize Acrylic acid, the amount of dispersant added is Dy 2 o 3 1 wt% of the powder mass, adjust the pH of the suspension to 7-9 to obtain a uniform and stable rare earth suspension, ready for use.

[0034] 2. Double-sided spraying of NdFeB magnets:

[0035] 2.1. The surface of the sintered NdFeB magnet is sequentially degreased, pickled, and vacuum dried. The degreasing adopts ultrasonic cleaning of acetone solution, and the ultrasonic cleaning time is 30 min, and the pickling adopts nitric acid solution with a mass fraction of 4 wt%, and the pickling time is 30 s.

[0036] 2.2....

Embodiment 2

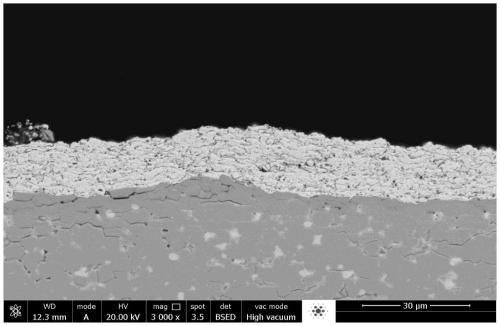

[0043] 1. Preparation of rare earth suspension: Dy 2 o 3 Mix the powder and deionized water in proportion, and stir evenly to obtain a rare earth powder suspension. The solid content of the rare earth powder suspension is 15wt%. After ball milling for 2.5 hours, the median diameter of the rare earth powder is 0.28 μm. Acrylic acid, the amount of the dispersant added is 1wt% of the mass of the rare earth powder, the pH of the suspension is adjusted to 7-9, and a uniform and stable rare earth suspension is obtained, which is ready for use.

[0044] 2. Double-sided spraying of NdFeB magnets:

[0045] 2.1. The surface of the sintered NdFeB magnet is sequentially degreased, pickled, and vacuum dried. The degreasing adopts ultrasonic cleaning of acetone solution, and the ultrasonic cleaning time is 30 min, and the pickling adopts nitric acid solution with a mass fraction of 4 wt%, and the pickling time is 30 s.

[0046] 2.2. Use suspension plasma spraying technology to spray on t...

Embodiment 3

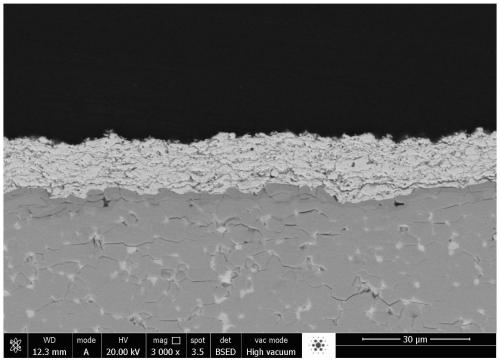

[0053] 1. Preparation of rare earth suspension: mix Tb 2 o 3 The powder and deionized water are mixed in proportion, and stirred evenly to obtain a rare earth powder suspension. The solid content of the rare earth powder suspension is 20wt%. After ball milling for 2.5 hours, the median diameter of the rare earth powder is 0.36 μm. Acrylic acid, the amount of the dispersant added is 1.5wt% of the mass of the rare earth powder, and the pH of the suspension is adjusted to 7-9 to obtain a uniform and stable rare earth suspension, which is ready for use.

[0054] 2. Double-sided spraying of NdFeB magnets:

[0055] 2.1. The surface of the sintered NdFeB magnet is sequentially degreased, pickled, and vacuum dried. The degreasing adopts ultrasonic cleaning of acetone solution, and the ultrasonic cleaning time is 30 min, and the pickling adopts nitric acid solution with a mass fraction of 4 wt%, and the pickling time is 30 s.

[0056] 2.2. Use suspension plasma spraying technology t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com