Multi-station rotating wheel type small material semi-automatic distributing system

A batching system and multi-station technology, which is applied in the field of multi-station rotary wheel-type semi-automatic batching system for small materials, can solve the problems of being unable to serve foreign trade customers, not being able to load into containers, and potential safety hazards, etc., and achieve compact structure and weighing The effect of high efficiency and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the purpose, structure and function of the present invention, a multi-station rotary wheel-type semi-automatic batching system for small materials of the present invention will be further described in detail below in conjunction with the accompanying drawings.

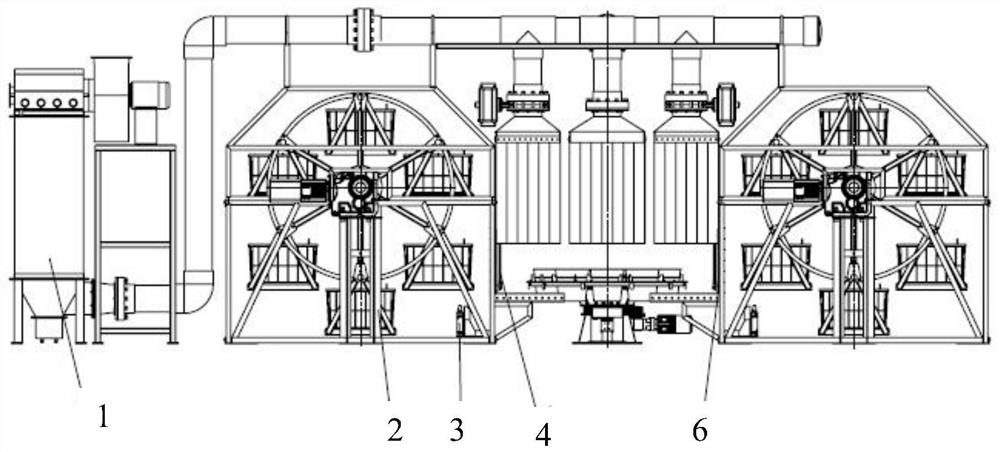

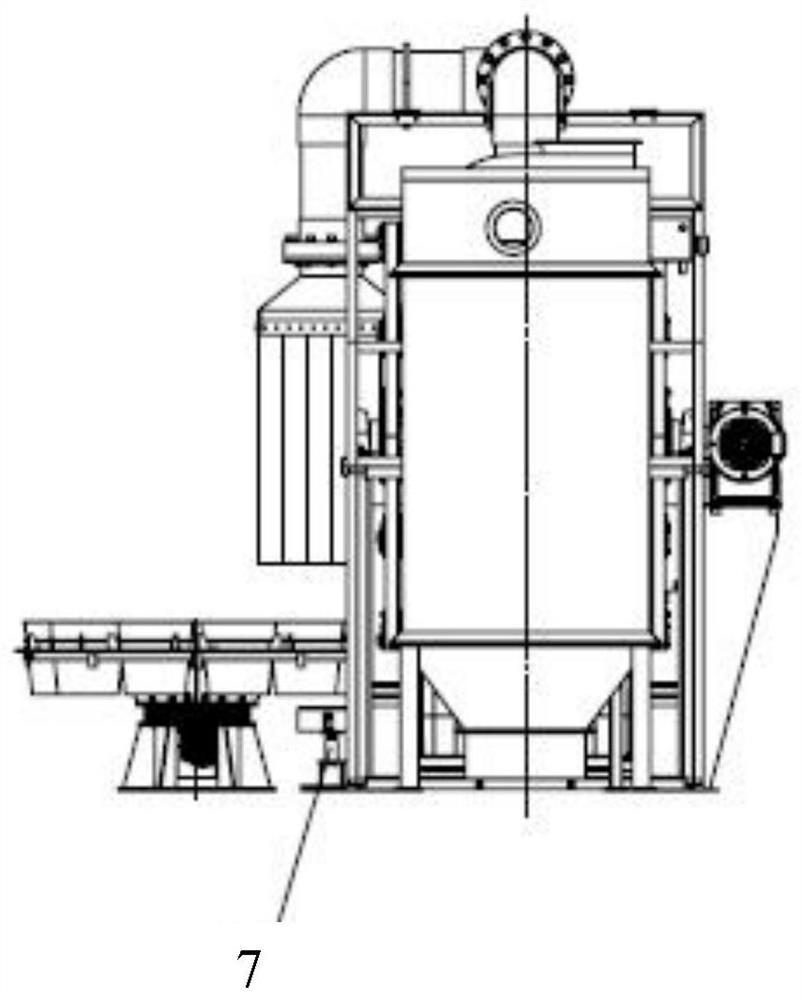

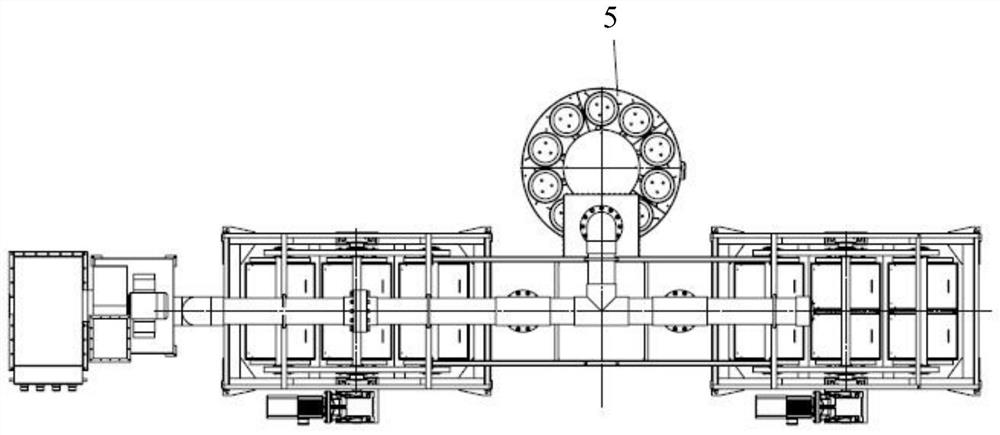

[0031] Such as Figure 1 to Figure 3 As shown, it is shown as a multi-station rotary small material semi-automatic batching system of the present invention, especially for 24-station double disc small material weighing, including dust removal system 1, at least two multi-station vertical turntables 2. Thrust cylinder 3, door opening cylinder 4, multi-station weighing turntable 5, safety light curtain 6, weighing mechanism 7, and the control system is compatible with the thrust cylinder, multi-station weighing turntable and each multi-station vertical It is connected with the multi-station vertical turntable, and is used to control the small and medium-sized materials in the multi-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com