System and method for utilization of shrouded plasma spray or shrouded liquid suspension injection in suspension plasma spray processes

A plasma and suspension technology, which is applied in the direction of liquid injection device, metal material coating process, injection device, etc., can solve the problem of reducing deposition efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

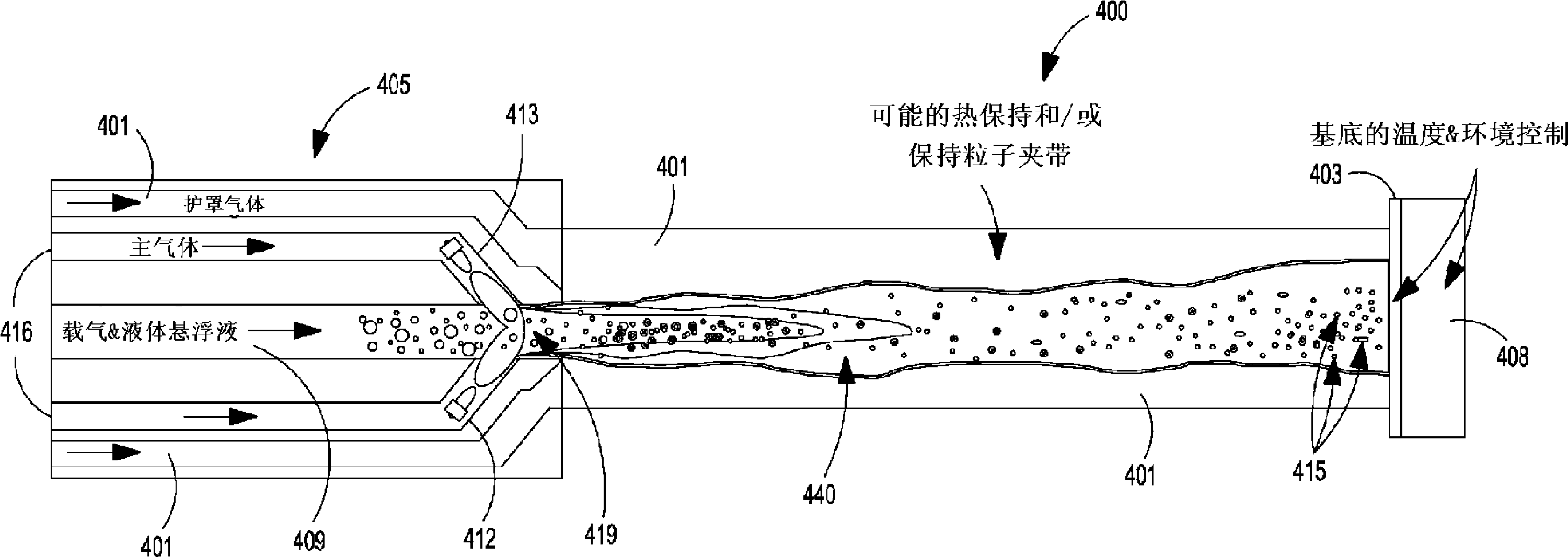

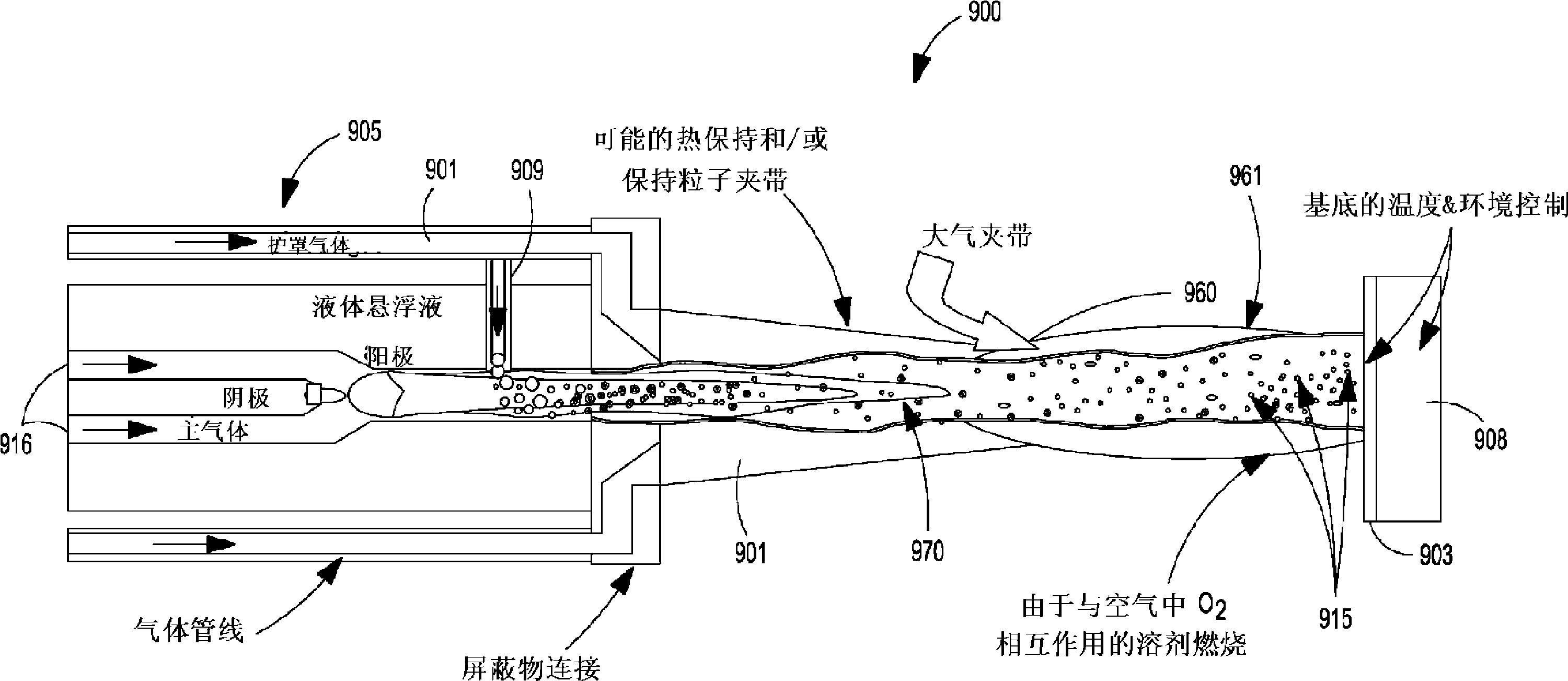

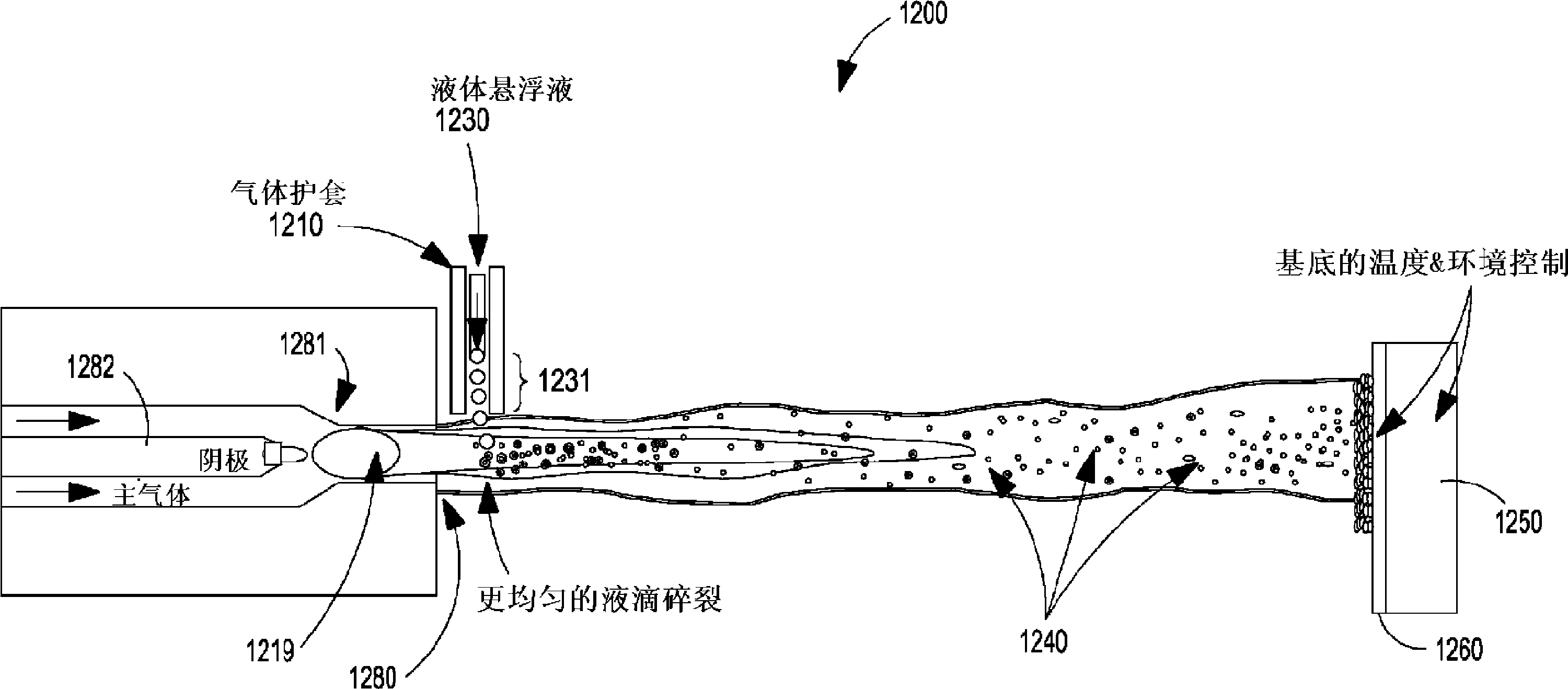

[0032] The present invention relates to novel SPS systems and processes for depositing coating materials. The SPS system and process of the present invention are particularly suitable for depositing submicron particles. The invention is described herein in various embodiments and in conjunction with various aspects and features of the invention.

[0033] The relationship and function of the various elements of the invention are better understood from the following detailed description. The detailed description contemplates various permutations and combinations of features, aspects, and embodiments, which are all within the scope of the invention. The disclosure may thus be recited as comprising, consisting of or consisting essentially of the particular features, aspects and embodiments, or any such combination and permutation of selected one or more of them.

[0034] The present invention recognizes the shortcomings of current SPS systems and processes. See attached Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com