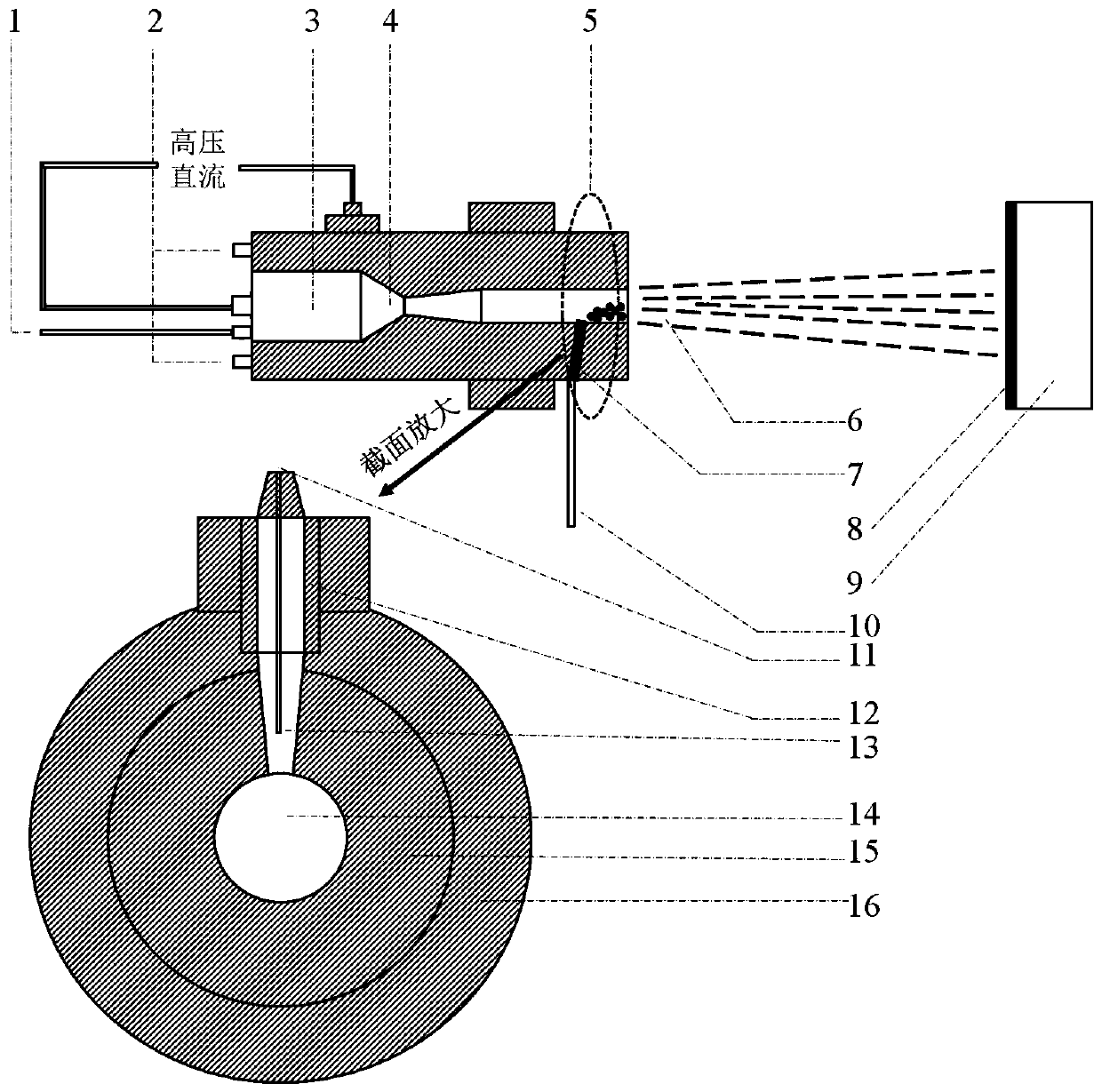

A micron-scale supersonic suspension plasma spraying device and spraying method

A spraying device and plasma technology, applied in coating, fusion spraying, metal material coating process, etc., can solve the problems of low coating preparation efficiency, improve coating preparation efficiency, ensure effective melting, and increase melting degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

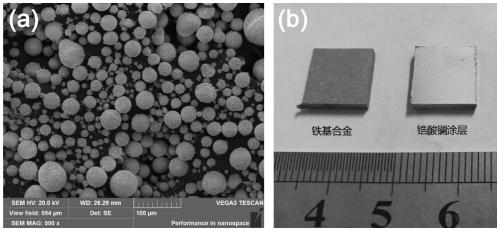

[0034] Step 1: Preparation of suspended lanthanum zirconate slurry: Weigh spherical lanthanum zirconate powder with a particle size of 7-90 μm, absolute ethanol, polyethyleneimine, and deionized water with an electronic balance, according to the mass ratio of 0.20: 0.20:0.05:0.55 is placed in an open beaker, fully stirred with a fully automatic mechanical stirring device to form a suspension slurry. After testing, the pH of the suspension slurry is 8, and the stability and dispersibility are good;

[0035] Step 2: Surface pretreatment of the iron-based substrate: cutting the iron-based substrate into 10×10×2mm by wire cutting method 3 There are several block samples, and they are roughened with 60-mesh corundum sand with a pressure of 0.3-0.5 MPa to remove impurities such as oil stains on the surface of the substrate. The sandblasting angle is 60-90°, and the sandblasting distance is 5-10cm; after sandblasting, it is cleaned with anhydrous ethanol for 30 minutes, and the ultr...

Embodiment example 2

[0039] Step 1: Preparation of suspended lanthanum zirconate slurry: Weigh spherical lanthanum zirconate powder with a particle size of 7-90 μm, absolute ethanol, polyethyleneimine and deionized water with an electronic balance, and weigh them in a mass ratio of 0.22: 0.22:0.05:0.51 is placed in an open beaker, fully stirred with a fully automatic mechanical stirring device to form a suspension slurry. After testing, the pH of the suspension slurry is between 7 and 8, and the stability and dispersibility are good;

[0040] Step 2: Surface pretreatment of the iron-based substrate: cutting the iron-based substrate into 10×10×2mm by wire cutting method 3 There are several block samples, and they are roughened with 60-mesh corundum sand with a pressure of 0.3-0.5 MPa to remove impurities such as oil stains on the surface of the substrate. The sandblasting angle is 60-90°, and the sandblasting distance is 5-10cm; after sandblasting, it is cleaned with anhydrous ethanol for 30 minut...

Embodiment example 3

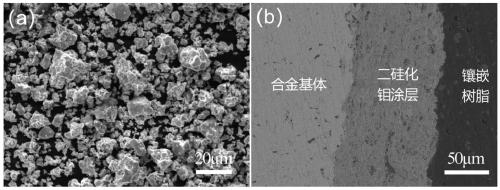

[0044] Step 1: Preparation of suspended molybdenum silicide slurry: weigh molybdenum silicide powder, absolute ethanol, polyvinyl alcohol, and deionized water with a particle size of 0.5-25 μm with an electronic balance, and weigh them in a mass ratio of 0.20:0.20:0.05:0.55 Put it in an open beaker, and fully stir it with a fully automatic mechanical stirring device to form a suspension slurry;

[0045] Step 2: Surface pretreatment of the niobium alloy substrate: cutting the niobium alloy substrate into 10×10×3mm 3 A number of block samples were pickled with 40wt.% nitric acid for 10 minutes to remove oil stains and other impurities on the surface of the substrate; roughened with 60-mesh corundum sand with a pressure of 0.3-0.5MPa. During the sandblasting process, control the corundum sand speed direction to be perpendicular to the sample surface, and the sandblasting distance is 10-20cm; after sandblasting, use absolute ethanol for ultrasonic cleaning for 20-30min, and the ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com