Process for coating the surface of a solid substrate with a layer comprising a ceramic compound and the coated substrate obtained

A technology of solid substrates and compounds, applied in the direction of plating, coating, support elements of blades, etc. of superimposed layers, capable of solving different problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

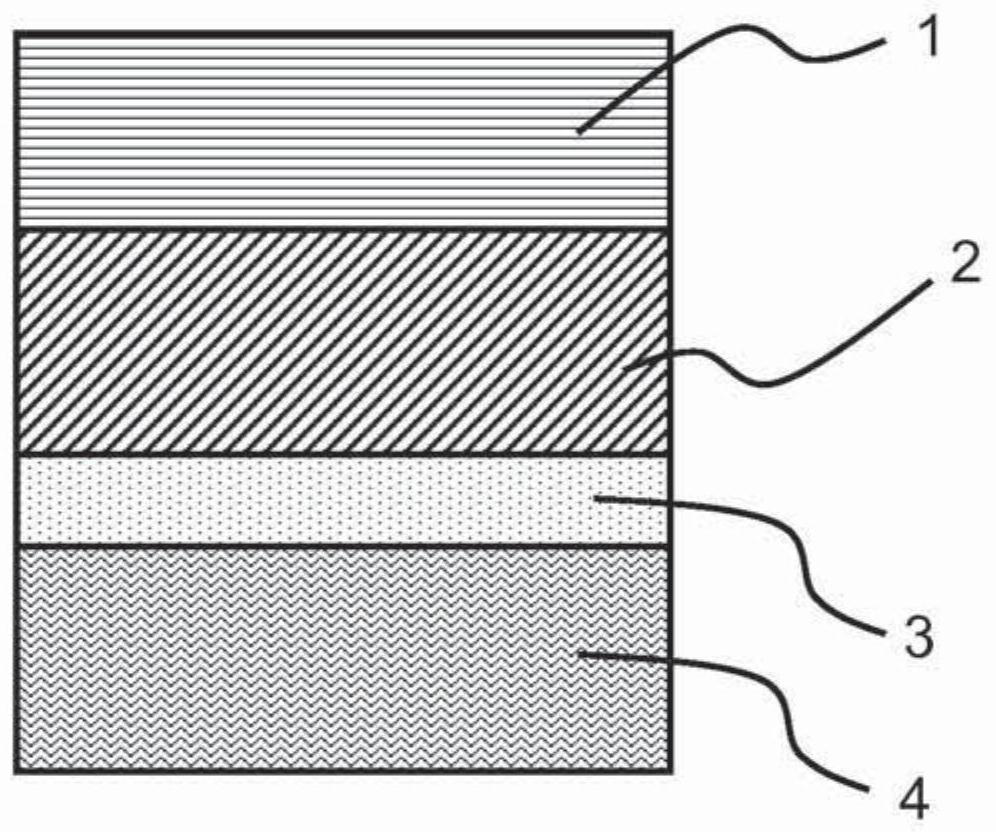

[0155] According to a first embodiment, a layer 1 according to the invention can be applied to a layer 2 obtained by SPS with a porous columnar microstructure ( image 3 Layer 6) in the middle.

[0156] According to a second embodiment, a layer 1 according to the invention can be applied to a layer 2 obtained by SPS with a porous dense columnar microstructure ( Figure 4 Layer 7) in the middle.

[0157] According to a third embodiment, a layer 1 according to the invention can be applied to a layer 2 with a columnar microstructure obtained by EB-PVD ( Figure 5 on layer 8) in

[0158] Advantageously, layer 2 can have a thermal and / or environmental insulation function. This layer can also (but is not limited to) guarantee good properties in terms of service life, thermal insulation or protection against oxidation and moisture corrosion.

[0159] Advantageously, layer 3 acts as an adhesive layer.

[0160] Layer 3 may be selected from metals; metal alloys such as β-NiAl metal a...

Embodiment 1

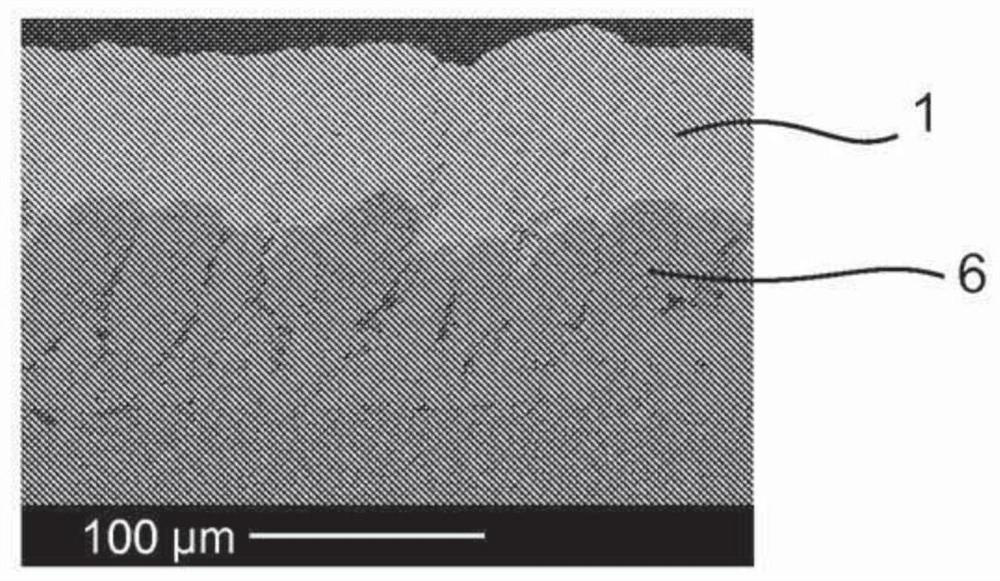

[0187] In this embodiment, the anti-CMAS layer according to the invention is prepared by the method according to the invention (see image 3 ).

[0188] by Gd 2 Zr 2 o 7 The compositional anti-CMAS layer 1 is prepared on the surface of the porous columnar YSZ layer 6 obtained by the SPS method. By the SPS method using d 90 Less than 10μm (ie d 90 is 7μm) and d 50 A suspension of primary particles greater than or equal to 1 μm (ie 3 μm) was used to prepare the anti-CMAS layer.

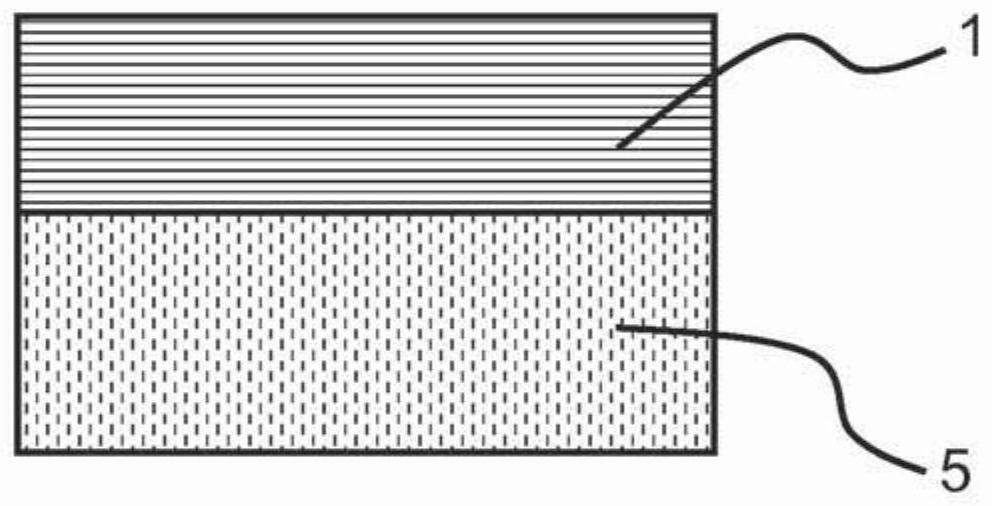

[0189] A sample thus prepared consisting of an anti-CMAS layer on a substrate fell into figure 1 and figure 2 within the range of the system shown.

[0190] image 3 A scanning electron microscope (SEM) micrograph using backscattered electrons using a polished portion of the sample prepared in this example is shown.

Embodiment 2

[0192] In this example, the anti-CMAS layer according to the invention was produced by the method according to the invention.

[0193] by Gd 2 Zr 2 o 7 The compositional anti-CMAS layer 1 was prepared on the surface of the columnar dense porous YSZ layer 7 obtained by the SPS method. By the SPS method using d 90 Less than 10μm (ie d 90 is 7μm) and d 50 A suspension of primary particles greater than or equal to 1 μm (ie 3 μm) was used to prepare the anti-CMAS layer.

[0194] A sample thus prepared consisting of an anti-CMAS layer on a substrate fell into figure 1 and figure 2 within the range of the system shown.

[0195] Figure 4 A scanning electron microscope (SEM) micrograph using backscattered electrons using a polished portion of the sample prepared in this example is shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com