Suspension plasma spraying high-purity Y2O3 erosion-resistant coating and preparation method and application thereof

A plasma spray gun and suspension technology, applied in coating, metal material coating process, fusion spraying, etc., can solve the problems of uneven microstructure of the coating, many structural defects, high porosity of the coating, etc., and achieve improvement Anti-plasma erosion performance, lower processing cost, and excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

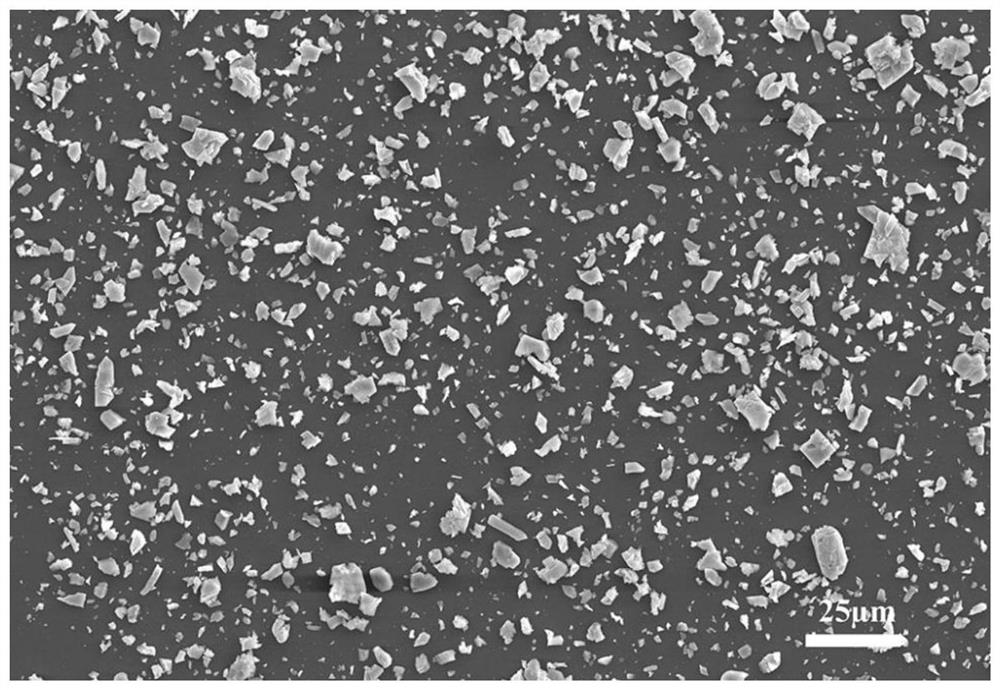

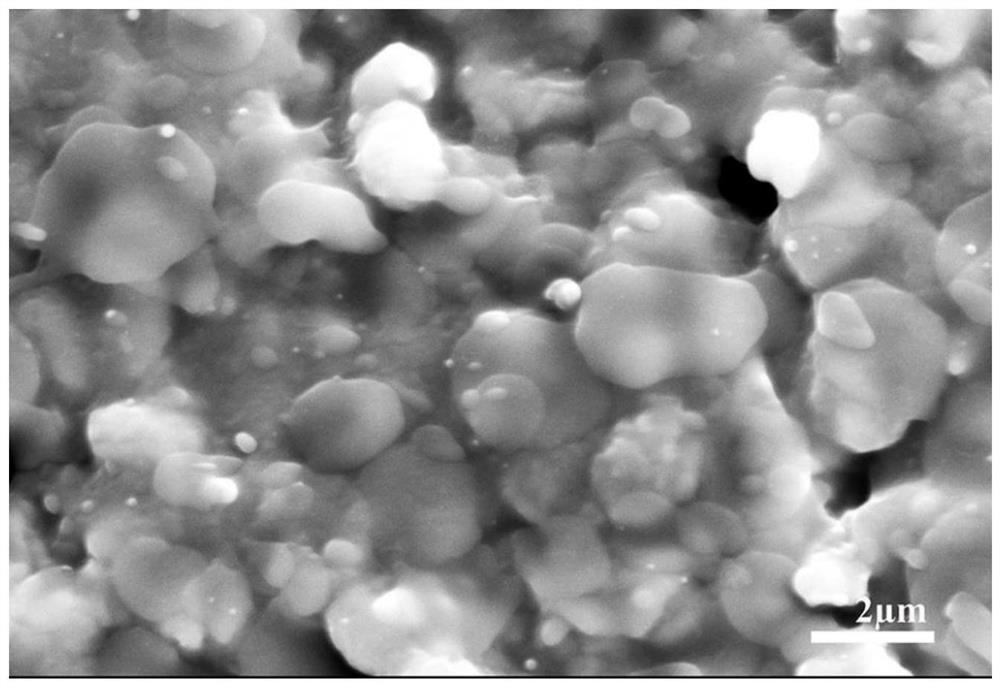

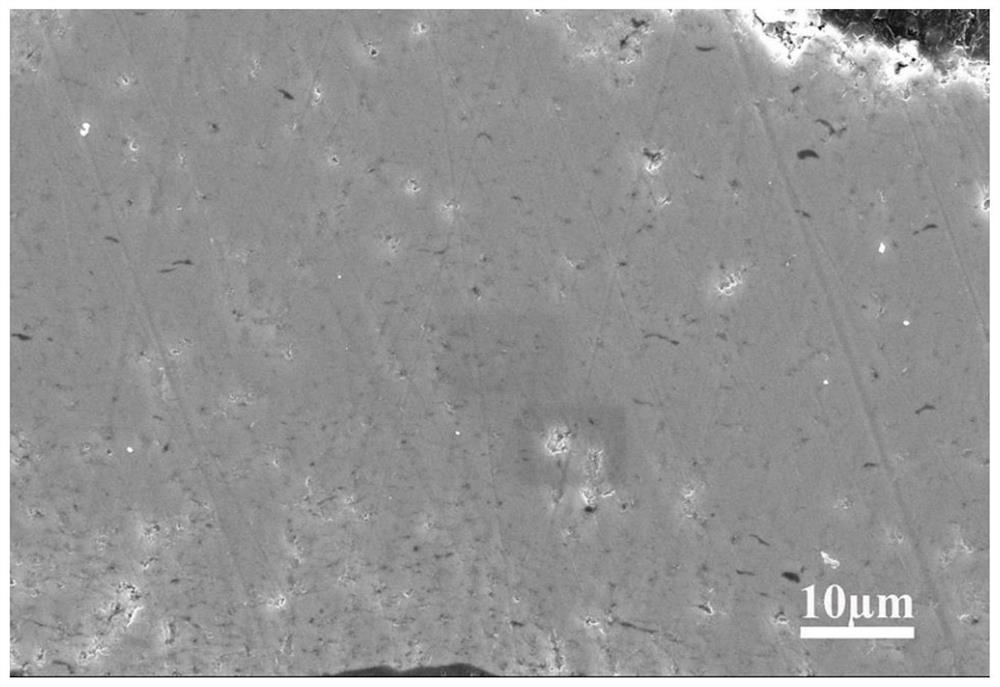

[0033]Using aluminum alloy as the substrate, it is processed into a 50mm×50mm sample by wire cutting and grinding. The surface of the sample is sandblasted with 360 mesh corundum sand under compressed air, and then the sample is placed in acetone and anhydrous Ultrasonic cleaning was carried out in alcohol to fully remove the contamination impurities and corundum fine sand remaining on the surface of the sample and then dried; the suspension plasma was sprayed on the surface of aluminum alloy to prepare high-purity Y with a thickness of 100 μm 2 o 3 Coating: Y 2 o 3 The particle size of the powder is D50=1μm (the microscopic appearance of the powder is as follows figure 1 shown), the concentration of the suspension is 15wt.%, the surfactant is polyethyleneimine, and the addition amount is 2wt.%. The flow rate of the suspension injected into the plasma jet was 35g / min, the spraying distance was 50mm, the moving speed of the spray gun was 700mm / s, and the preheating temperatu...

Embodiment 2

[0036] Using aluminum alloy as the matrix, the sample of 100mm×100mm is finished by wire cutting and grinding, and the surface of the sample is sandblasted with 240 mesh corundum sand under compressed air, and then the sample is placed in acetone and anhydrous Ultrasonic cleaning was carried out in alcohol to fully remove the contamination impurities and corundum fine sand remaining on the surface of the sample and then dried; the suspension plasma was sprayed on the surface of aluminum alloy to prepare high-purity Y with a thickness of 200 μm 2 o 3 Coating: Y 2 o 3 The particle size of the powder is D50=60nm, the concentration of the suspension is 30wt.%, the surfactant is sodium polyacrylate, and the addition amount is 1wt.%. The flow rate of the suspension injected into the plasma jet was 65g / min, the spraying distance was 100mm, the moving speed of the spray gun was 700mm / s, and the preheating temperature of the aluminum alloy substrate was 100℃. Using Axial III TM (No...

Embodiment 3

[0039] Using aluminum alloy as the matrix, it is processed into a 50mm×50mm sample by wire cutting and grinding. The surface of the sample is sandblasted with 120 mesh corundum sand under compressed air, and then the sample is placed in acetone and anhydrous Ultrasonic cleaning was carried out in alcohol to fully remove the contamination impurities and corundum fine sand remaining on the surface of the sample and then dried; the suspension plasma was sprayed on the surface of aluminum alloy to prepare high-purity Y with a thickness of 300 μm 2 o 3 Coating: Y 2 o 3 The particle size of the powder is D50=300nm, the concentration of the suspension is 20wt.%, the surfactant is polyvinylpyrrolidone, and the addition amount is 3wt.%. The flow rate of the suspension injected into the plasma jet is 57g / min, the spraying distance is 70mm, the moving speed of the spray gun is 1000mm / s, and the preheating temperature of the aluminum alloy substrate is less than 100℃. 100HE (Progressiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com