Method for suspending liquid plasma spraying preparation of hydroxyapatite bioactivity coatings

A technology of hydroxyapatite and biological activity, which is applied in the direction of coating, metal material coating process, fusion spraying, etc., can solve the problems of uneven coating structure, low production efficiency, increased production cost, etc., and achieve reduction The effect of production cost, production efficiency improvement and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

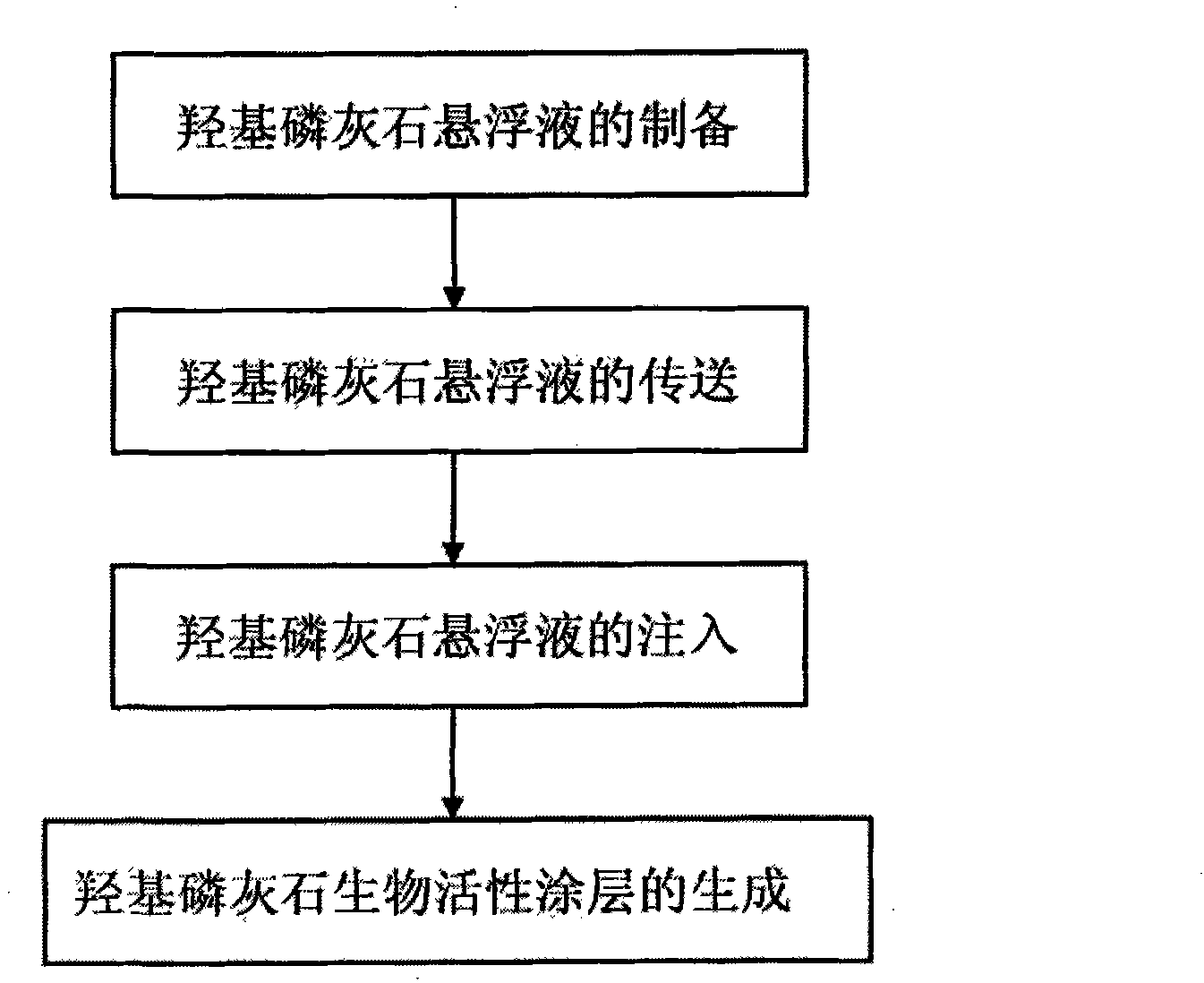

[0039] (1) Preparation of hydroxyapatite suspension;

[0040] (2) Transmission of hydroxyapatite suspension;

[0041] (3) injection of hydroxyapatite suspension;

[0042] (4) Generation of hydroxyapatite bioactive coating.

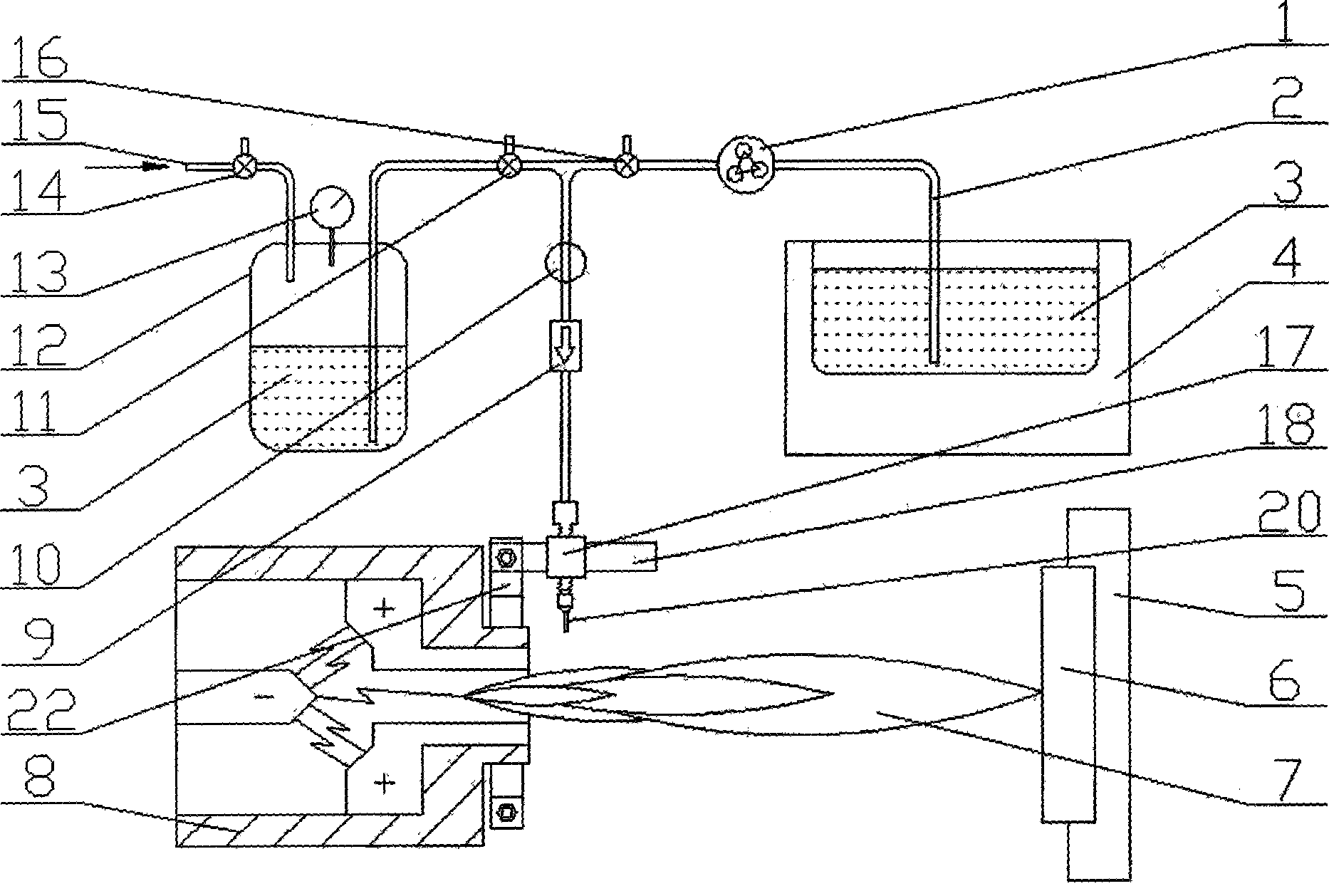

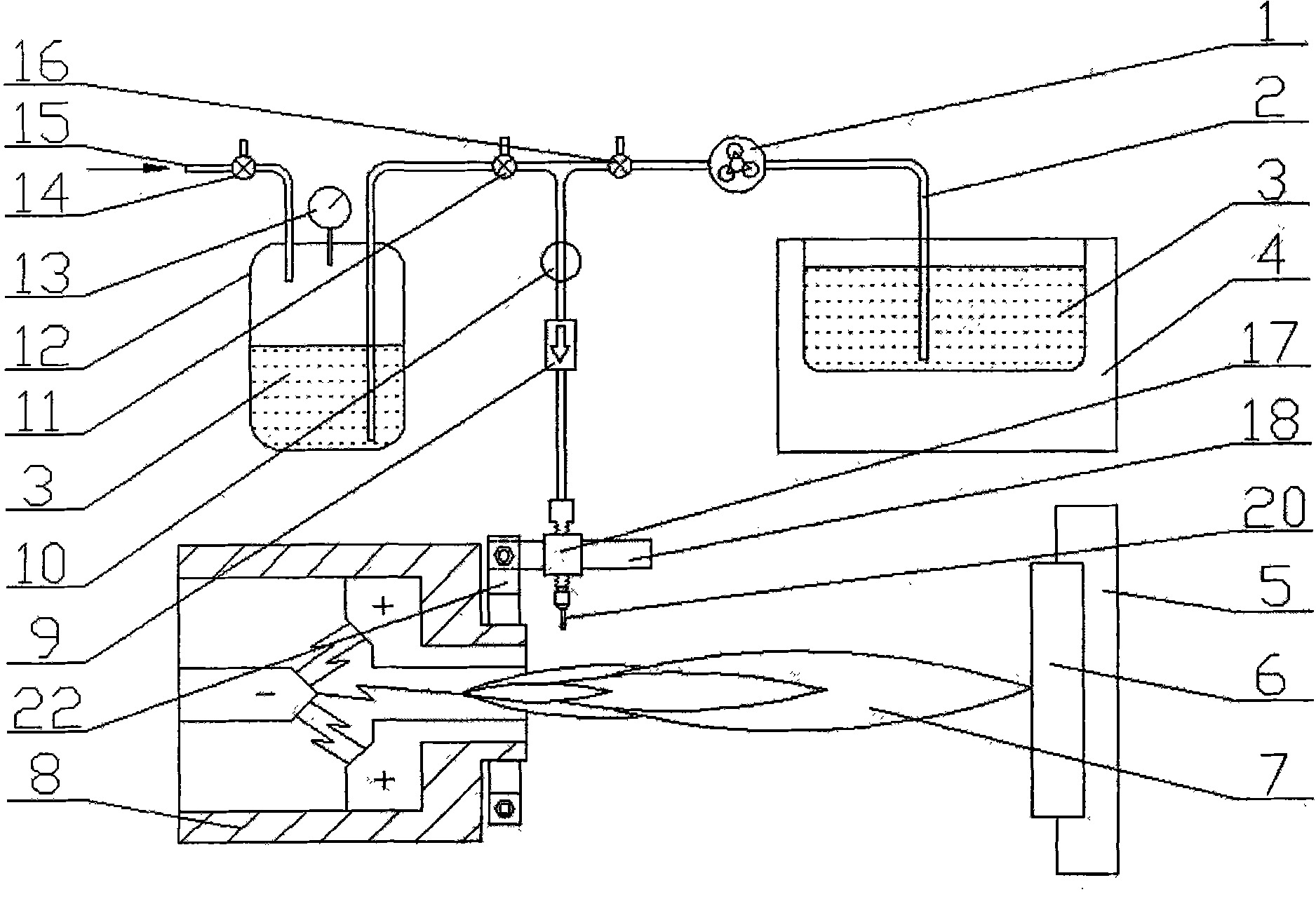

[0043] Among Fig. 2, realize that the device that the inventive method provides adopts direct current plasma spraying equipment, plasma spray gun 8 is connected with fixed seat 22, and an adjusting support 18 is installed on the fixed seat, is installed on the adjusting support and can slide along the horizontal direction with The adjustment bracket is matched with the adjustment slider 17 connected, and the small-diameter conduit 20 is installed under the adjustment slider.

[0044] When the compressed air charged in the pressure tank 12 is used as the transmission power of the hydroxyapatite suspension 3 in the transmission system, the third valve 16 is closed, and the first valve 11 on the pressure-resistant pipe 2 and the first valve 11 on the pressu...

Embodiment 1

[0048] Arrange and connect each component according to the device structure shown in Fig. 3, in the present embodiment, the plasma flame 7 that plasma torch 8 ejects is produced by the direct current plasma spraying equipment used, and its spraying power is 20 kilowatts, and metal substrate 6 is biomedical Titanium metal, the distance between the titanium metal and the plasma spray gun is 8 centimeters, and the pressure vessel used is a pressure tank 12.

[0049] First prepare hydroxyapatite suspension 3, according to calcium phosphorus molar ratio 1.67, configuration molar concentration is the calcium nitrate aqueous solution of 0.5mol / L and the diammonium hydrogen phosphate aqueous solution that molar concentration is 0.5mol / L; Under constant stirring, will The diammonium hydrogen phosphate aqueous solution of configuration is added dropwise in the calcium nitrate aqueous solution with 5ml / min rate and reacts, and then the ammoniacal liquor of percentage concentration 10% is ...

Embodiment 2

[0051] Arrange and connect each component according to the device structure shown in Fig. 3, in the present embodiment, plasma flame 7 is produced by used DC plasma spraying equipment, and its spraying power is 30 kilowatts, and metal base 6 is biomedical titanium alloy, titanium alloy and The distance between the plasma nozzles is 10 centimeters, and the pressure vessel used is a pressure tank 12 .

[0052] First prepare the hydroxyapatite suspension 3, according to the calcium-phosphorus molar ratio of 1.67, configure the calcium nitrate aqueous solution with a molar concentration of 2.5mol / L and the diammonium hydrogen phosphate aqueous solution with a molar concentration of 3mol / L; The diammonium hydrogen phosphate aqueous solution is added dropwise in the calcium nitrate aqueous solution with 15ml / min speed to react, and then the ammoniacal liquor of percentage concentration 30% is added dropwise in the reaction solution with 20ml / min speed, and the control reaction soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com