Mullite anti-oxidation coating for composite material and preparation method of mullite anti-oxidation coating

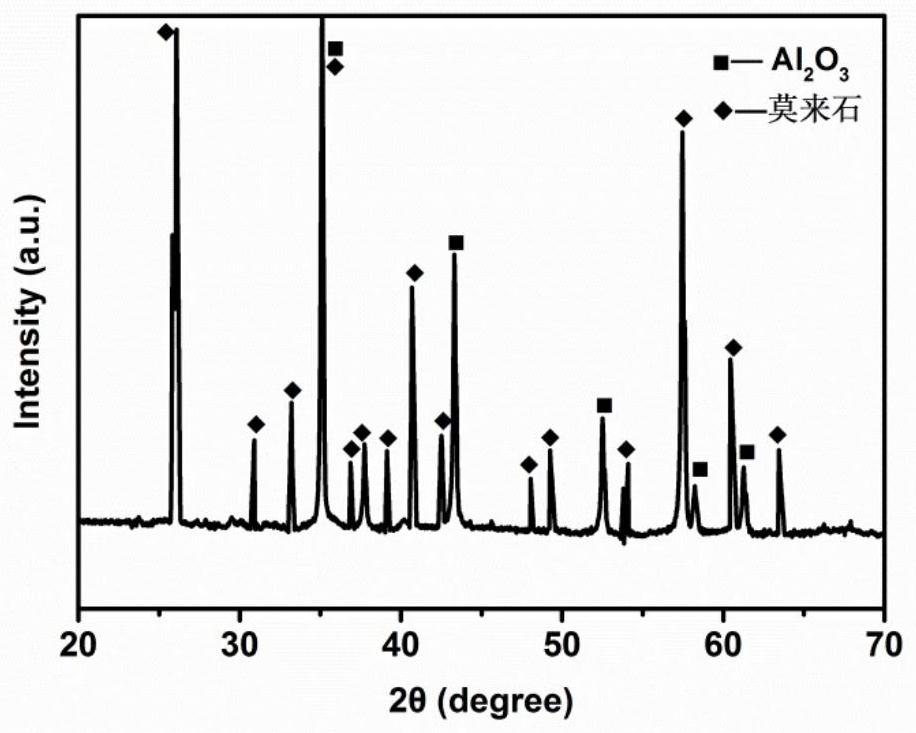

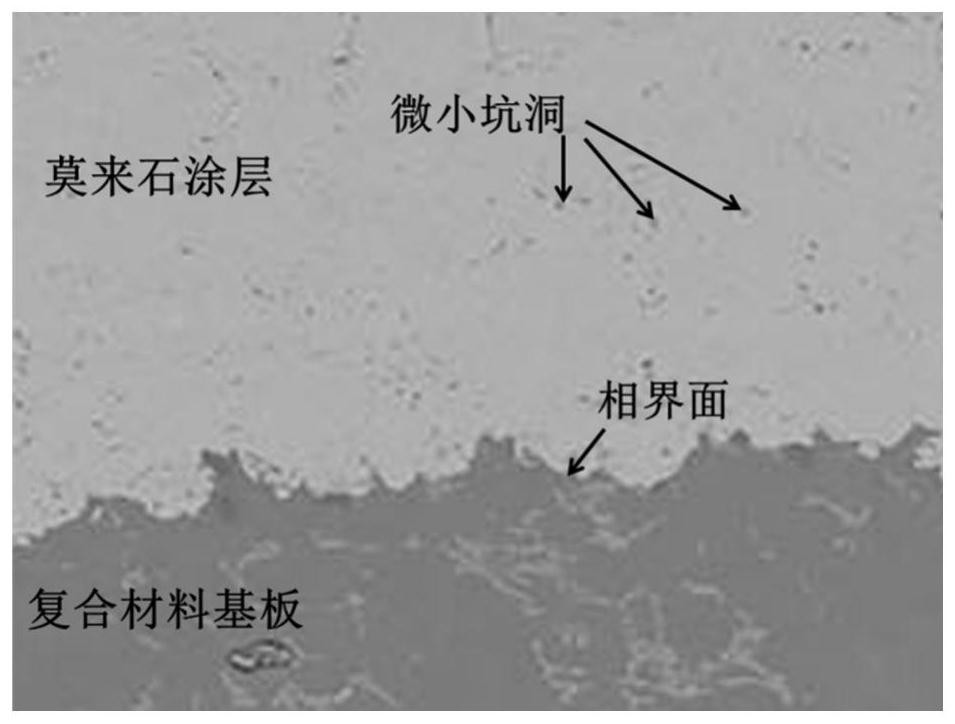

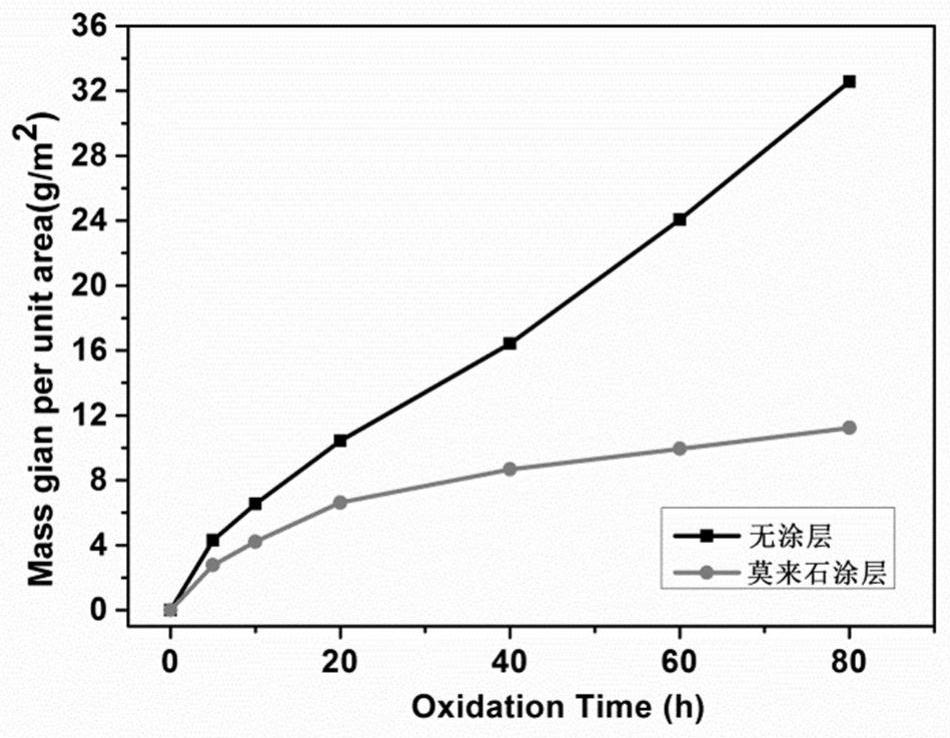

A composite material and mullite technology, which is applied in the field of mullite anti-oxidation coating for composite materials and its preparation, can solve problems such as thermal expansion coefficient mismatch, complex process, coating cracks, etc., and achieve good high temperature stability and high temperature stability. Oxidation resistance, coating surface smoothing, reduction in oxidative weight gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0037] Step 1, prepare Al(NO 3 ) 3 9H 2 O solution, the volume is 2000mL, Al(NO 3 ) 3 9H 2 The mass fraction of O is 20wt.%;

[0038] Step 2, Al(NO 3 ) 3 9H 2 The O solution is placed in a hot water pot, continuously stirred and an appropriate amount of ammonia water is added drop by drop to generate Al(OH) 3 Transparent sol, wherein the temperature of the water bath is 60°C, and the concentration of ammonia water is 5%;

[0039]Step 3, to the Al(OH) of Step 2 3 A certain amount of transparent silica sol is added to the transparent sol, the concentration of the silica sol is 30wt%, and the volume of the silica sol is 500 mL;

[0040] Step 4, placing the mixed sol in step 3 on a roller ball mill for ball milling, the rotational speed of the roller ball mill is 60r / min, and the working time is 4h;

[0041] Step 5, place the composite material substrate and the mixed sol in step 4 on a liquid-phase plasma spraying equipment, and use the suspension plasma spraying equip...

Embodiment example 2

[0044] Step 1, prepare the Al(NO) of the set concentration 3 ) 3 ·9H 2 O solution, the volume is 2000mL, Al(NO 3 ) 3 ·9H 2 The mass fraction of O is 40wt.%;

[0045] Step 2, Al(NO 3 ) 3 ·9H 2 The O solution was placed in a hot water pot, stirred continuously and an appropriate amount of ammonia water was added dropwise to form Al(OH) 3 Transparent sol, wherein the temperature of the water bath is 80°C, and the concentration of ammonia water is 10%;

[0046] Step 3, to the Al(OH) of Step 2 3 A certain amount of transparent silica sol is added to the transparent sol, the concentration of the silica sol is 40wt%, and the volume of the silica sol is 1000 mL;

[0047] Step 4, placing the mixed sol in step 3 on a roller ball mill for ball milling, the rotational speed of the roller ball mill is 80r / min, and the working time is 8h;

[0048] Step 5, place the composite material substrate and the mixed sol in step 4 on a liquid-phase plasma spraying equipment, and use the su...

Embodiment example 3

[0051] Step 1, prepare the Al(NO) of the set concentration 3 ) 3 ·9H 2 O solution, the volume is 2000mL, Al(NO 3 ) 3 ·9H 2 The mass fraction of O is 30wt.%;

[0052] Step 2, Al(NO 3 ) 3 ·9H 2 The O solution was placed in a hot water pot, stirred continuously and an appropriate amount of ammonia water was added dropwise to form Al(OH) 3 Transparent sol, wherein the temperature of the water bath is 70°C, and the concentration of ammonia water is 8%;

[0053] Step 3, to the Al(OH) of Step 2 3 A certain amount of transparent silica sol is added to the transparent sol, the concentration of the silica sol is 35wt%, and the volume of the silica sol is 800 mL;

[0054] Step 4, placing the mixed sol in step 3 on a roller ball mill for ball milling, the rotational speed of the roller ball mill is 70r / min, and the working time is 6h;

[0055] Step 5, place the composite material substrate and the mixed sol in step 4 on a liquid-phase plasma spraying equipment, and use the susp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com