Acid solution spray dry-process flue gas desulfurization and modulating intensification method

A technology of dry flue gas desulfurization and acid solution, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles. It can solve problems such as unstable chemical properties, unfavorable volume expansion, and waste of effective desulfurization components, and achieve activation effects. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

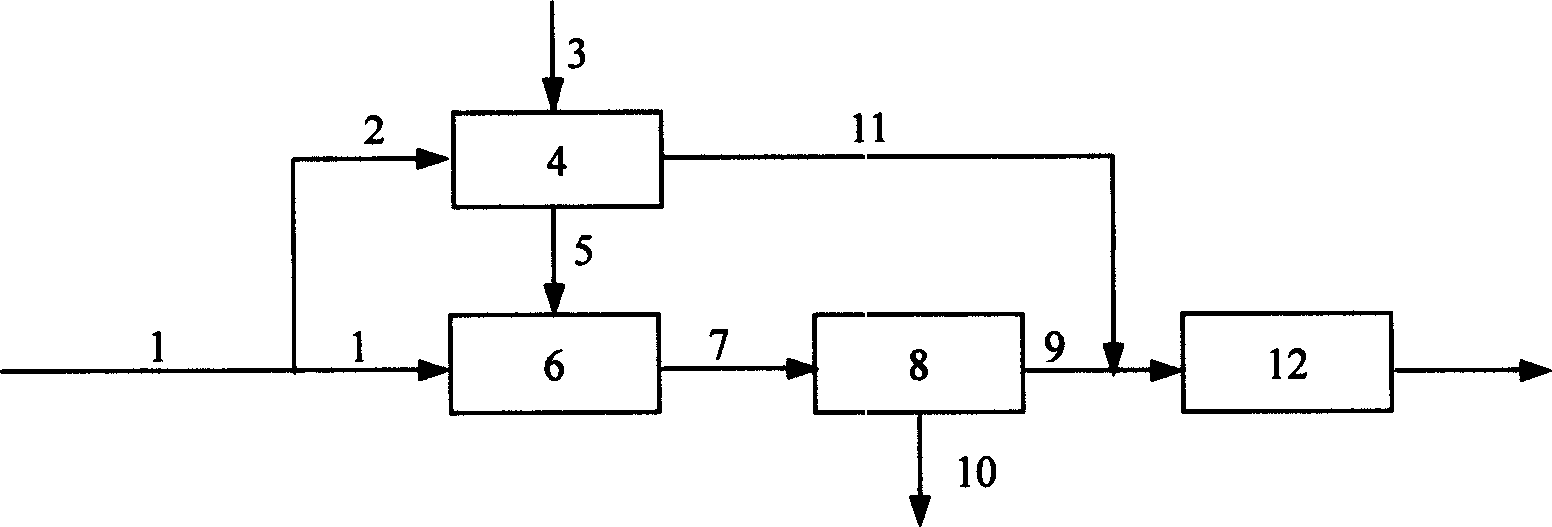

[0070] Such as figure 1 As shown, a small amount of flue gas is taken from undesulfurized or undesulfurized flue gas 1 as acid flue gas 2, and the acid flue gas 2 is utilized through the adsorption desulfurization acid plant 4 and ordinary industrial water or waste water 3 of the prior art SO contained in 2 Obtain dilute sulfuric acid, and further dilute it into an acidic solution 5 of PH=5, and spray the acidic solution 5 into the flue through which the undesulfurized or incompletely desulfurized flue gas 1 containing fly ash / desulfurizing agent particles passes or In the desulfurization reactor 6, the droplet diameter is less than or equal to 50 μm, and the acidic droplets can effectively capture the particles in the flue gas through the reasonable organization of the flow field. With the rapid evaporation of water in the acidic droplets, the acidity of the liquid film on the surface of the particles is stronger, The pH tends to be lower, so that the desulfurization active ...

Embodiment 2

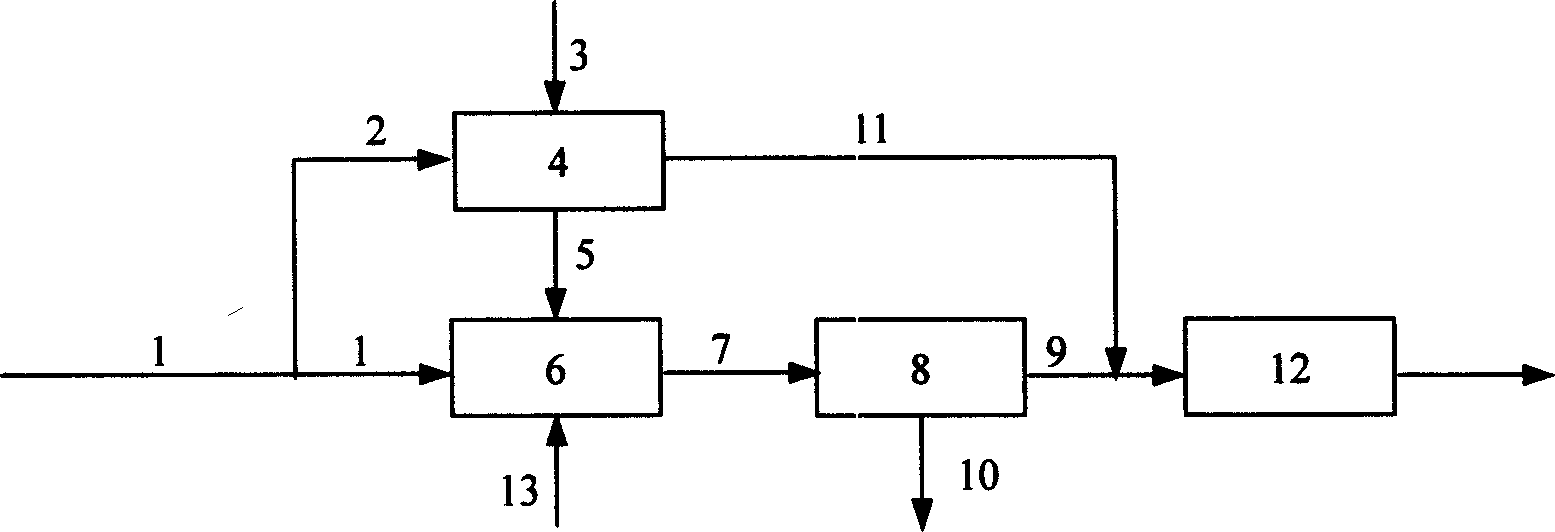

[0074] Such as figure 2 As shown, on the basis of Example 1, dry desulfurization agent 13 is sprayed into the flue or desulfurization reactor 6 to obtain higher desulfurization efficiency.

Embodiment 3

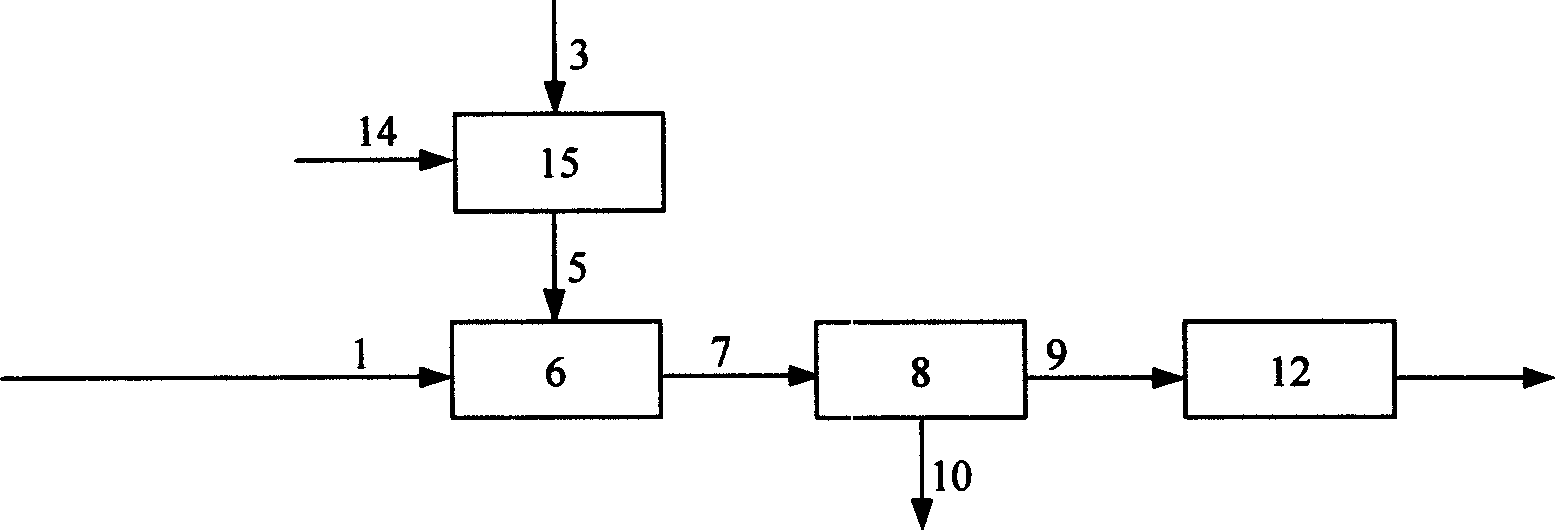

[0076] Such as image 3 As shown, the mother liquor required for preparing acidic solution 5 in this embodiment is directly prepared by diluting waste sulfuric acid solution or industrial sulfuric acid 14 with common industrial water or waste water 3 through a dilution buffer container 15, and the pH of acidic solution 5 is 5.0, spray the acidic solution 5 in the form of mist into the flue or desulfurization reactor 6 through which the undesulfurized or incompletely desulfurized flue gas 1 containing fly ash / desulfurizing agent particles passes, the diameter of the droplets is ≤50 μm, The rational organization of the field enables the acidic mist to effectively capture the particles in the flue gas. With the rapid evaporation of water in the acidic mist, the stronger the acidity of the liquid film on the surface of the particles, the lower the pH, so that the desulfurization active ingredients contained in the particles Rapid activation and dissolution, and with the SO in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com