Method for preparing magnesium alloy with micro-arc oxidation ceramic membrane

A micro-arc oxidation and magnesium alloy technology, applied in the direction of anodic oxidation, can solve the problems that the micro-arc discharge cannot be carried out smoothly, the dense crystalline MgO cannot be obtained, the color of the yellow ceramic film is light, etc. Simple preparation method and smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

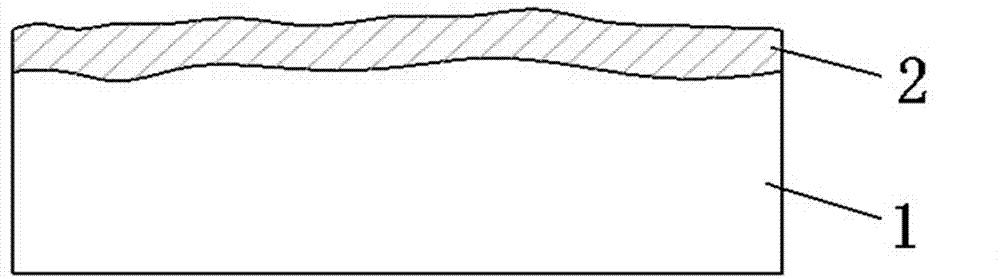

[0023] refer to figure 1 , the present invention is a magnesium alloy with a yellow micro-arc oxidation ceramic film on the surface, which is composed of a magnesium alloy substrate 1 and a yellow ceramic film 2 coated on the surface of the magnesium alloy substrate 1 .

[0024] Magnesium alloy substrate: AZ31B magnesium alloy is used, and the size is 30mm×20mm×3mm.

[0025] The preparation method of the present invention is:

[0026] (1) Prepare the electrolyte: weigh 20g / L of sodium metaaluminate, 1g / L of sodium hydroxide, 2g / L of disodium edetate, 15ml of hydrogen peroxide and 1g / L of potassium permanganate, and use a glass Stir with a rod to make it fully dissolved, and the pH value of the electrolyte is 10.0;

[0027] (2) Grinding, cleaning and drying the surface of the magnesium alloy substrate;

[0028] (3) Micro-arc oxidation: the magnesium alloy is used as the anode, and the stainless steel sheet is used as the cathode, and is completely immersed in the...

Embodiment 2

[0032] Preparation of a magnesium alloy with a yellow micro-arc oxidation ceramic film on the surface, the magnesium alloy substrate: AZ31B type magnesium alloy is used, and the size is 30mm×20mm×3mm.

[0033] Prepare electrolyte: weigh 25g / L of sodium metaaluminate, 1.5g / L of sodium hydroxide, 3g / L of disodium edetate, 15ml of hydrogen peroxide and 2g / L of potassium permanganate, stir with a glass rod Make it fully dissolved, the pH value of the electrolyte is 10.0; the micro-arc oxidation time is 30min, and the current density is 12A / dm 2 , the rest of the method is the same as in Example 1, the thickness of the prepared ceramic film is 25.7 μm, and the microhardness is 1550HV.

Embodiment 3

[0035] Preparation of a magnesium alloy with a yellow micro-arc oxidation ceramic film on the surface. The magnesium alloy substrate: AZ31B type magnesium alloy is used, and the size is 25mm×15mm×2mm.

[0036] Prepare electrolyte: weigh 40g / L of sodium metaaluminate, 3g / L of sodium hydroxide, 3.5g / L of disodium edetate, 10ml of hydrogen peroxide and 3g / L of potassium permanganate, stir with a glass rod Make it fully dissolved, the pH value of the electrolyte is 10.0; the micro-arc oxidation time is 30min, and the current density is 8A / dm 2 , the rest of the method is the same as in Example 1, the thickness of the prepared ceramic film is 21.1 μm, and the microhardness is 1500HV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com