Silicon crystal pulling process method for monocrystalline silicon

A process method, single crystal silicon technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of limited effective length range of resistivity, low minority carrier lifetime, fast attenuation speed, etc., and achieve improvement The effect is obvious, the effect of reducing oxygen is obvious, and the effect of increasing the lifespan of the minority

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0139] The single crystal silicon crystal growth process (CZ method) doped with gallium is as follows:

[0140] During the melting stage, keep the furnace pressure at 11-15Torr (pressure unit, 1Torr is 1mmHg), and the argon gas flow at 100slpm (stard liter per minute, that is, the standard liter per minute flow value).

[0141] In the stages of temperature adjustment, seeding, and shouldering, keep the furnace pressure at 11-15torr.

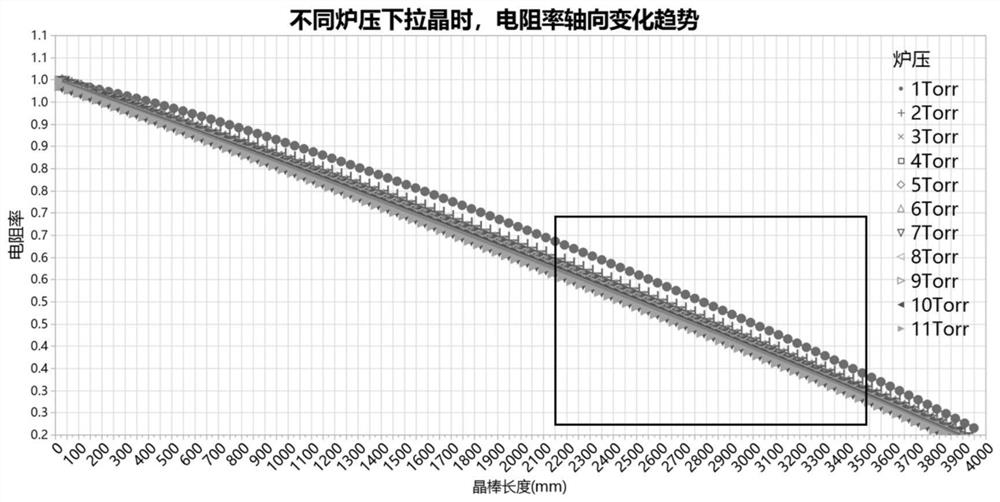

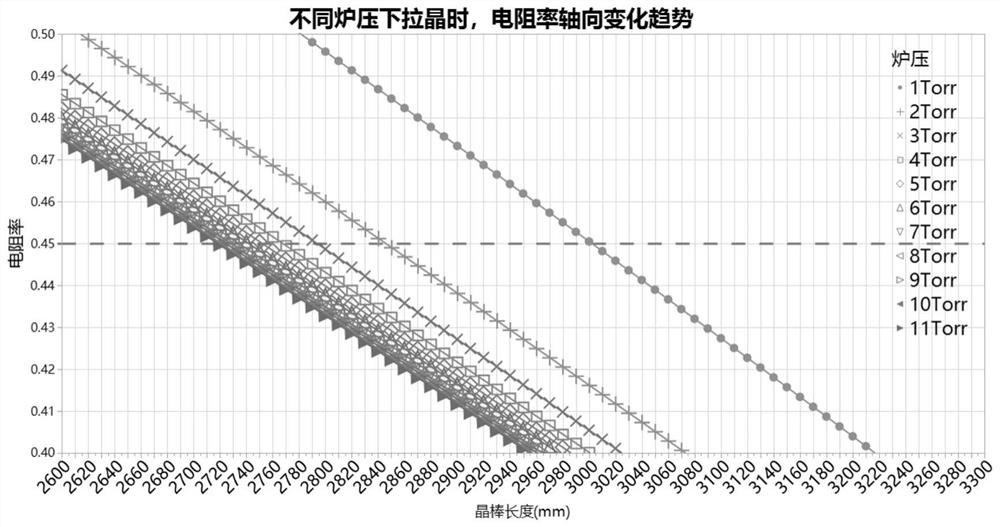

[0142] In the equal-diameter stage, the furnace pressure is gradually reduced to 0-10Torr as the length of the ingot increases. The entire isometric process is automatically controlled by the system, and the furnace pressure is controlled by adjusting the argon flow and / or the frequency of the dry pump. The parameters are shown in Table 1 below:

[0143] Table 1

[0144] Equal diameter length (mm) Furnace pressure (Torr) 0 11-15 150 10-14 250 8-12 350 6-10 600 4-8 1500 3-7 2500 2-6 3250 2-6 ...

Embodiment 2

[0158] The single crystal silicon crystal growth process (CZ method) doped with gallium is as follows:

[0159] During the melting stage, temperature adjustment stage, seeding stage, and shouldering stage of crystal growth, the furnace pressure of the single crystal furnace is kept at 11-15 Torr, and the flow rate of argon gas is 100 slpm.

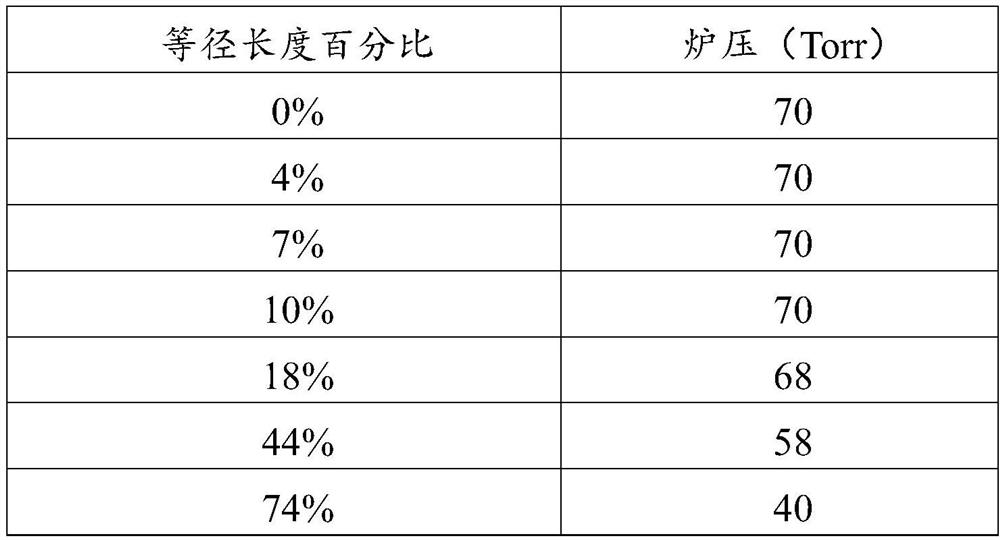

[0160] In the equal diameter stage, the percentage of the equal diameter length of the ingot and the furnace pressure of the single crystal furnace are controlled according to Table 2 below, and the furnace pressure is controlled to correspond to each other by adjusting the flow rate of argon gas and / or the frequency of the dry pump.

[0161] Table 2

[0162] Percentage of isometric length Furnace pressure (Torr) 0% 10 4% 7 7% 5 10% 4 18% 3 44% 2 74% 2 96% 2 100% 2

Embodiment 3

[0169] The single crystal silicon crystal growth process (CZ method) doped with gallium is as follows:

[0170] During the melting stage, temperature adjustment stage, seeding stage, and shouldering stage of crystal growth, the furnace pressure of the single crystal furnace is maintained at 11-15 Torr, and the argon gas flow rate is 100 slpm.

[0171] In the equal-diameter stage, according to the following table 3, the percentage of the equal-diameter length of the ingot is controlled to be L, the furnace pressure U of the single crystal furnace, the flow rate of argon gas P, and the frequency of the dry pump to make them correspond to each other, and always maintain that they meet U=A *L+B*P+D*F+C,

[0172] Among them, 5≤A≤10, 0.01≤B≤0.02, -0.6≤D≤-0.2, 15≤C≤20.

[0173] Among them, the value of furnace pressure is in the range of 2Torr≤U≤10Torr, the value of argon gas flow is in the range of 50slpm≤P≤70slpm; the value of dry pump frequency is in the range of 20HZ≤F≤60HZ

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com