High-dispersity edible instant thickener and preparation method thereof

A technology of high dispersibility and thickener, which is applied in the direction of food ingredients as thickeners, food ingredients as taste improvers, applications, etc. It can solve the problems of bad taste, bitter taste, insufficient dispersibility, etc., and achieve dispersibility Effect of improving and slowing down the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0031] 1. Thickener preparation.

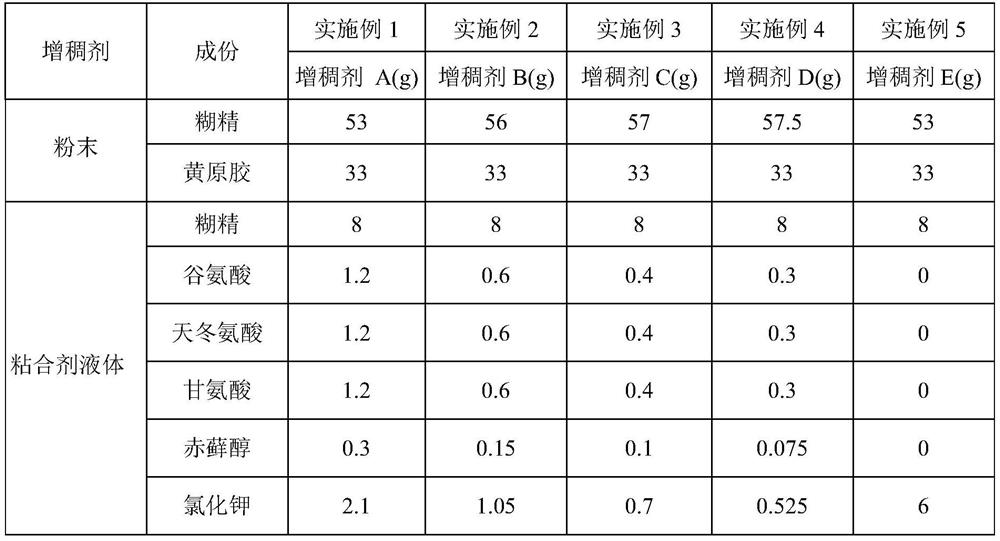

[0032] Prepare a highly dispersible edible instant thickener, as shown in Table 1, mix 53g dextrin and 33g xanthan gum to obtain mixed powder. Separately, 8 g of dextrin was dissolved in 15 ml of water, after which 6 g of a composition consisting of glutamic acid, aspartic acid, glycine, erythritol, and potassium chloride were added to produce a binder. The mixed powder of dextrin and xanthan gum is granulated, the binder solvent is sprayed onto the mixed powder of dextrin and xanthan gum, and the thickener A is prepared by fluidized bed granulation. According to table 1, change the part according to the manufacture method in thickener A, obtain thickener B, C, D, E.

[0033] Table 1, the composition of thickener.

[0034]

[0035]

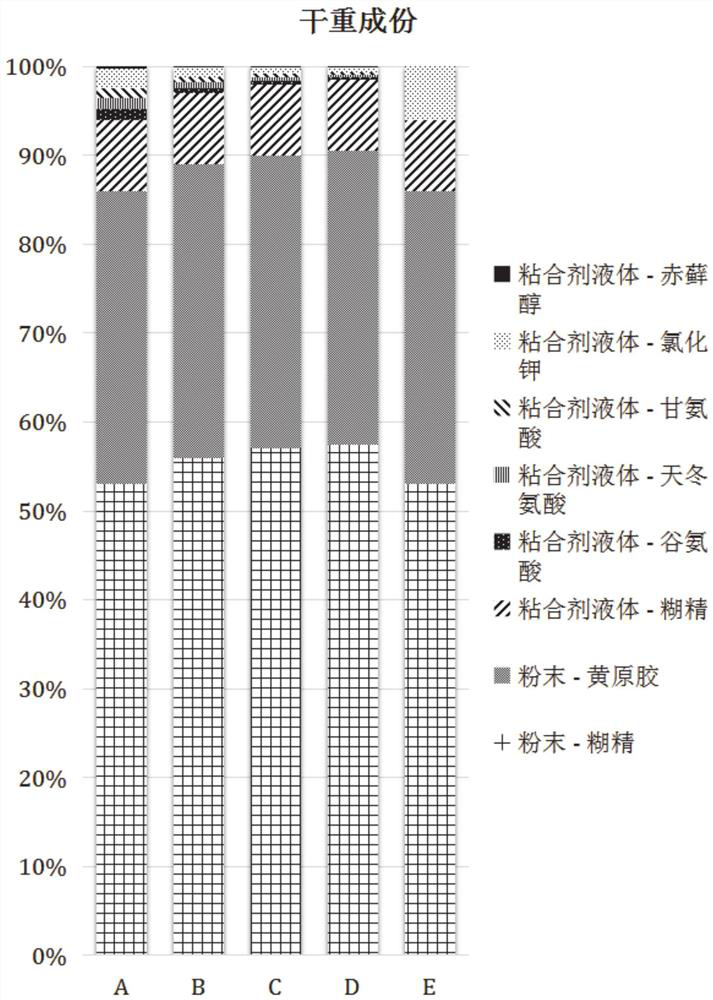

[0036] The dry weight of the thickener is figure 1 shown.

[0037] Second, performance comparison.

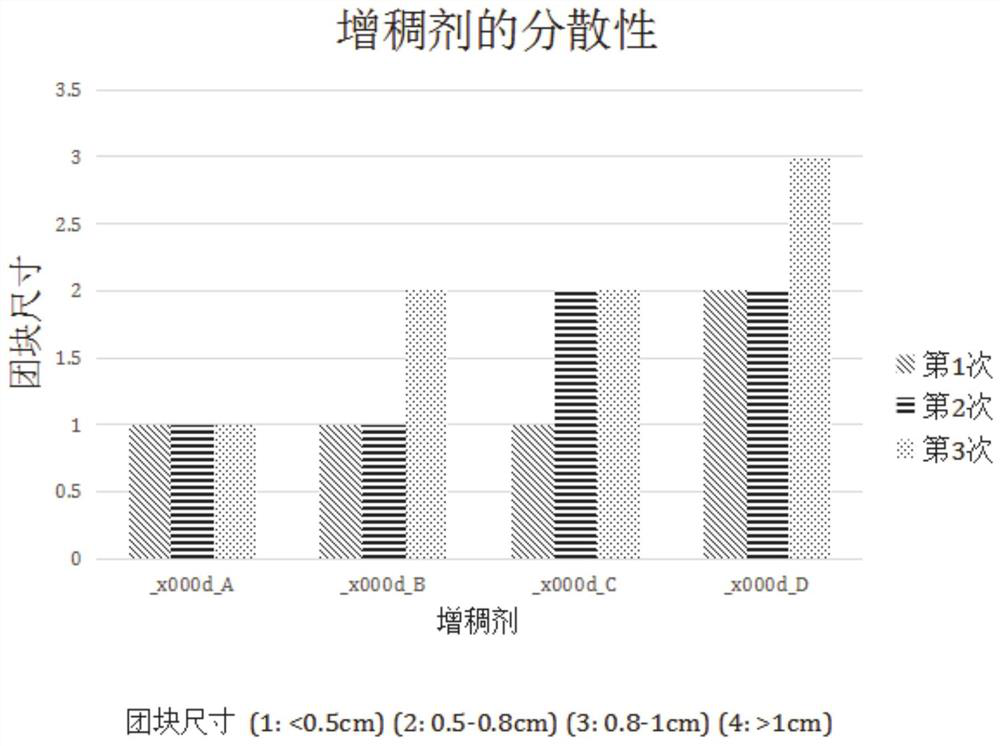

[0038] 1. Dispersion and viscosity.

[0039] 100 g of salt solution (0.025% by weight) were prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com