Silicone based adhesive protective film and optical member comprising the same

An adhesive and protective film technology, used in optical components, optics, film/sheet adhesives, etc., can solve problems such as deformation, increase peel strength, damage to adherends, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

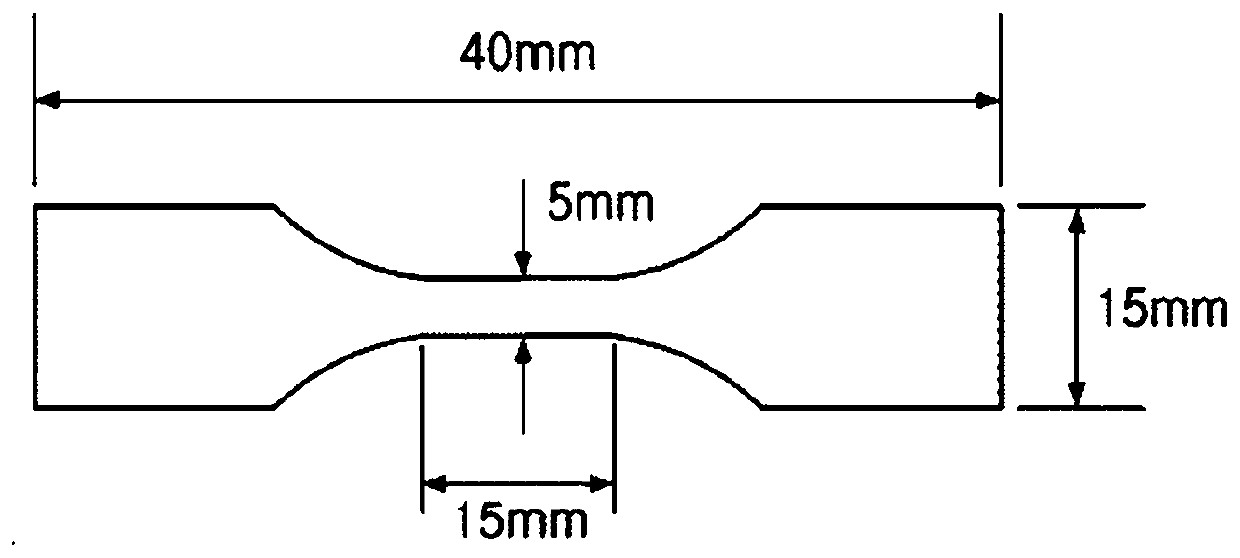

Method used

Image

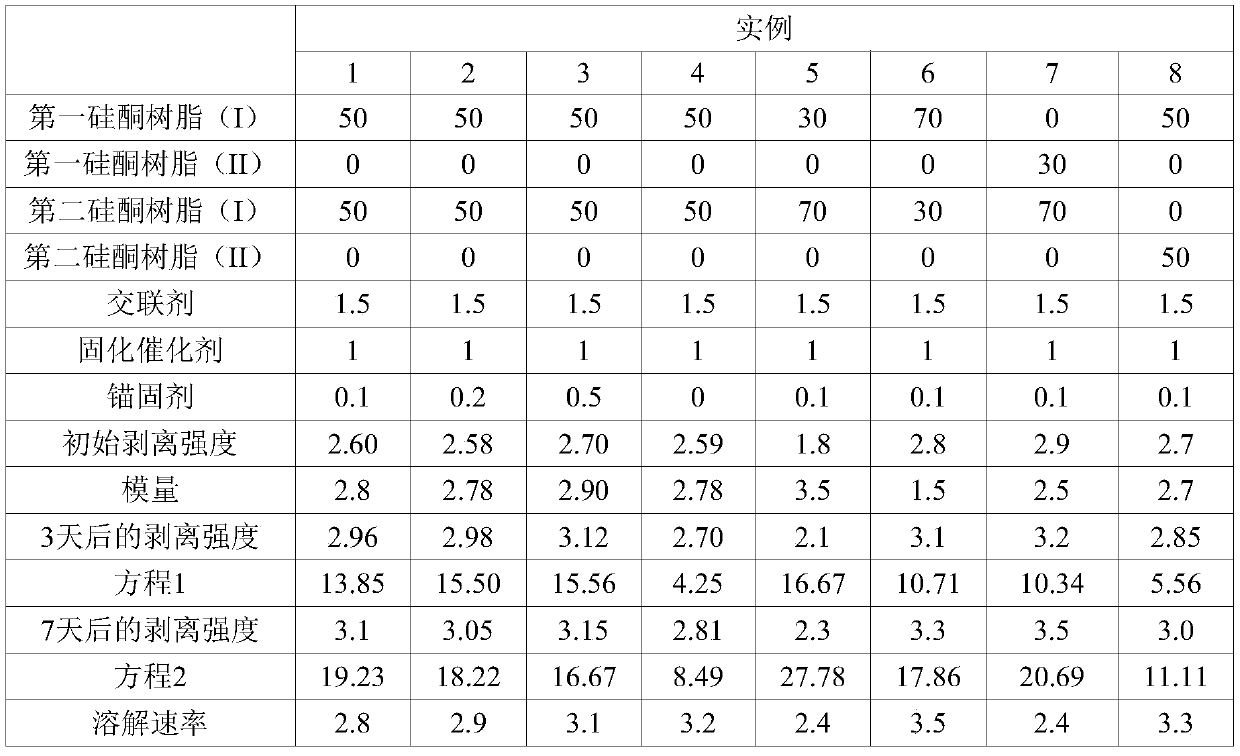

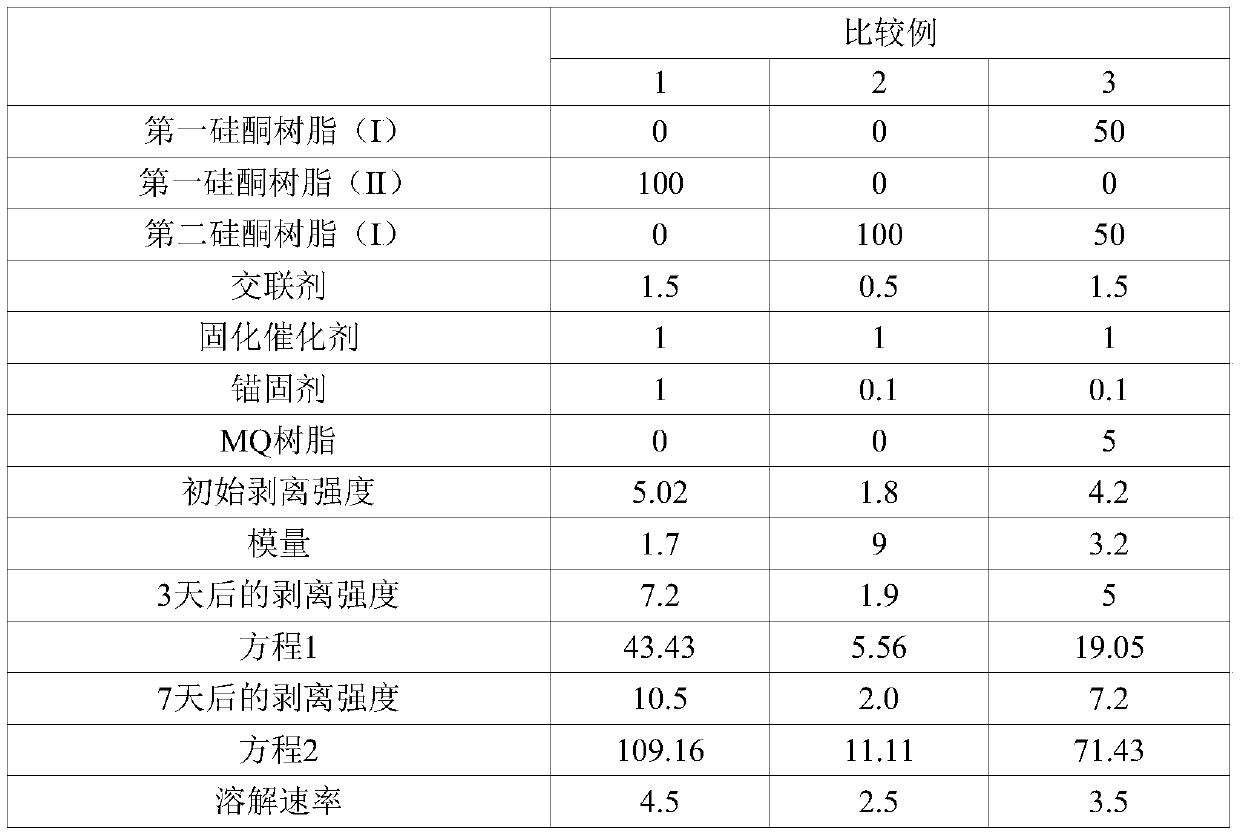

Examples

example 1

[0137] (1) Preparation of the first silicone resin (I)

[0138] As the first silicone resin, a dimethylvinylsiloxane-dimethylsiloxane-dimethylvinylsiloxane resin whose molecular chains are both terminated with dimethylvinylsiloxane was used. The first silicone resin contained 900 dimethylsiloxane units and had a weight average molecular weight of 65,000.

[0139] First, 21.6g of [Vi(Me) 2 SiO 1 / 2 ] SiO 4 / 2 and 592.6 g of octamethylcyclotetrasiloxane were introduced into a nitrogen-filled reactor, followed by heating to 150°C. Next, 50 ppm of linear polyaminophosphazenium hydroxide catalyst ([Py3-N-(P=NPy 2 )1.8-PPy 3 ] + Oh - (where Py is pyrrolidine)), followed by neutralization for 1 min with stirring. Next, the reactor was cooled to room temperature, followed by removal of volatile substances, thereby preparing a first silicone resin (I).

[0140] (2) Preparation of the second silicone resin (1)

[0141] Dimethylvinylsiloxane-Dimethicone-Methylhexenylsiloxane-Dime...

example 7

[0152] Except using 7646 silicone resin (II) (Dow Chemical, molecular weight: 124,000) as shown in Table 1 instead of the first silicone resin (I) as the first silicone resin and changing the first silicone resin Except the amount of (II) and the second silicone resin (I), a silicone-based adhesive protective film was prepared in the same manner as in Example 1.

example 8

[0154] A silicone-based adhesive was prepared in the same manner as in Example 1, except that 7664 silicone resin (II) (Dow Chemical, molecular weight: 554,000) was used instead of the second silicone resin (I) as the second silicone resin. protective film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com