Mixed crystal Ti (C, N)-based metal ceramic material and preparation method thereof

A base metal and mixed crystal technology, applied in the field of Ti-based cermet, can solve the problems of poor inherent toughness, increased production cost, and difficulty in controlling the preparation process of cermet materials, and achieves the effect of increased activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

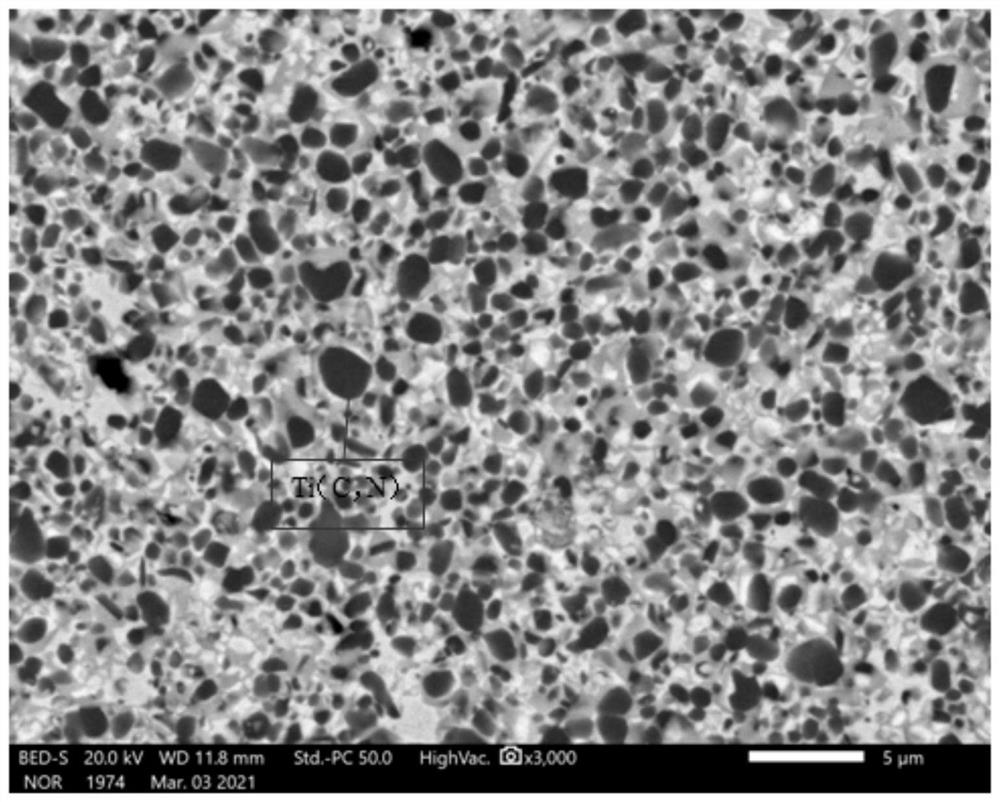

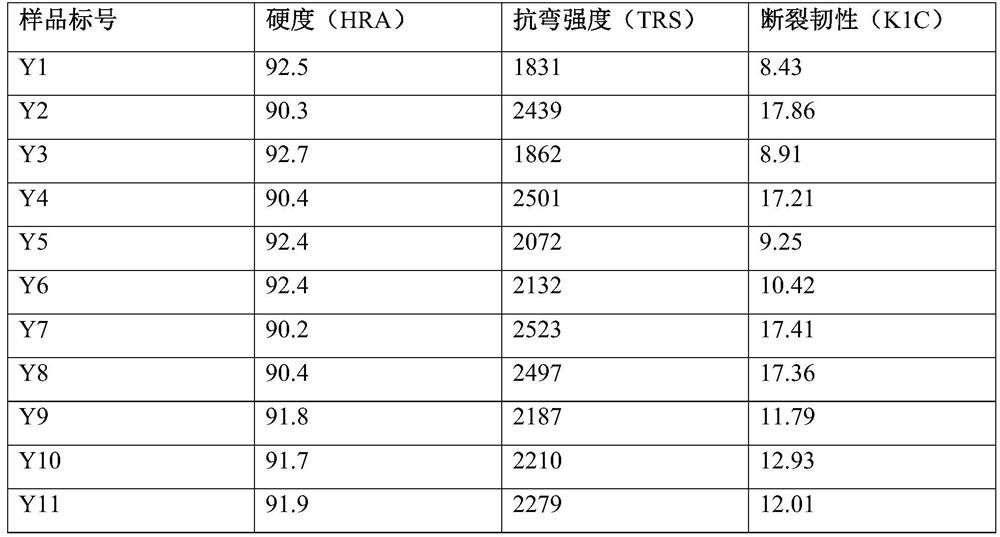

[0029] Example 1: Mixed crystal Ti(C,N)-based cermet The Ti(C,N)-based cermet product obtained through the steps of ball milling, molding, vacuum dewaxing, and vacuum sintering is denoted as Y1.

[0030] Ball mill mixing step: Co and Ni with a particle size of 0.8-3 μm are used as the bonding phase, and the content (wt%) thereof is 14%. The weight ratio of Co and Ni: Co / Ni is 1.

[0031] Ti (C, N) is used as the hard phase, and its content (wt%) is 42%; the hard phase Ti (C, N) is selected from Ti (C 0.5 , N 0.5 ) and Ti(C 0.7 , N 0.3 ) combination, Ti(C 0.5 , N 0.5 ) particle size of 1.4 ~ 2.0μm, Ti (C 0.7 , N 0.3 ) particle size of 0.7 ~ 1.1μm, Ti (C 0.5 , N 0.5 ) / Ti(C 0.7 , N 0.3 ) = 0.6.

[0032] Additives are (Ti, W) C solid solution, WC, TaC, NbC, Mo, Mo 2 C, Cr 2 C 3 , VC, etc., the content (wt%) is 44%, the particle size is 0.8-1.8 μm, the Ni / (the total amount of Mo and Mo2C or Mo2C)=1-2 in the additive, and the TaC content (wt%) is 0-2 5%, the NbC conte...

Embodiment 2

[0037] Embodiment 2: The components of ball milling and mixing are different from those in Example 1 except for the ball milling and mixing step. The other process parameters are the same as in Example 1. The prepared Ti(C,N)-based cermet product is marked as Y2.

[0038] The ball mill mixture components are: 24wt% binder phase, Co / Ni=1; 58wt% hard phase, Ti(C 0.5 , N 0.5 ) / Ti(C 0.7 , N 0.3 )=0.6, 18wt% additive.

Embodiment 3

[0039] Example 3: Except that the ball milling mixing components in the ball milling mixing step are different from those in Example 1, other process parameters are the same as in Example 1, and the prepared Ti(C,N)-based cermet product is denoted as Y3.

[0040] The ball mill mixture components are: 14wt% binder phase, Co / Ni=1; 42wt% hard phase, Ti(C 0.5 , N 0.5 ) / Ti(C 0.7 , N 0.3 )=1, 44wt% additive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com