Mold and technology for forming composite T-shaped stringer stiffened wallboard

A composite material and reinforced wall panel technology is applied in the field of molds and processes for forming composite T-shaped truss reinforced wall panels, and achieves the effects of promoting fiber compaction, avoiding pores, and facilitating disassembly and demoulding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

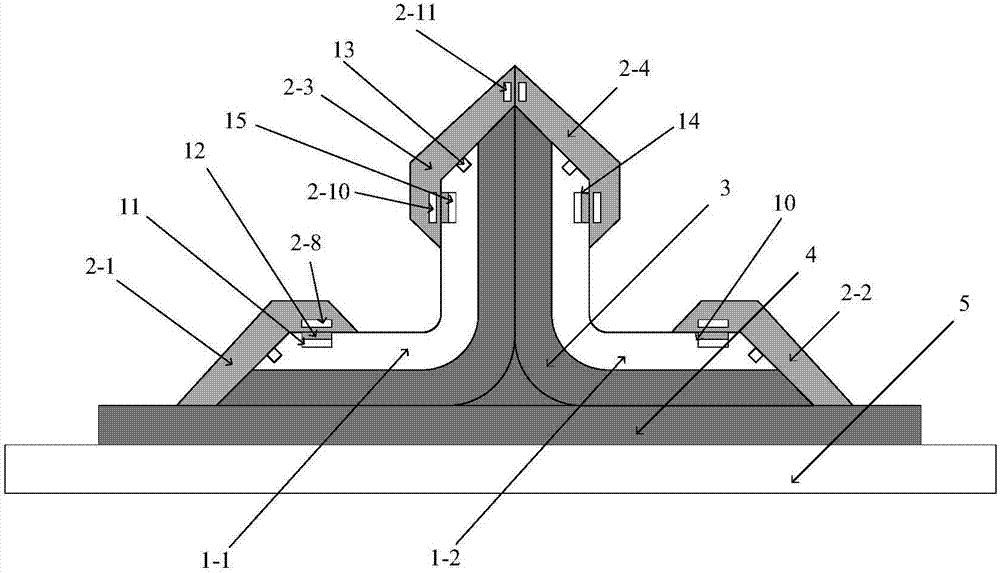

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

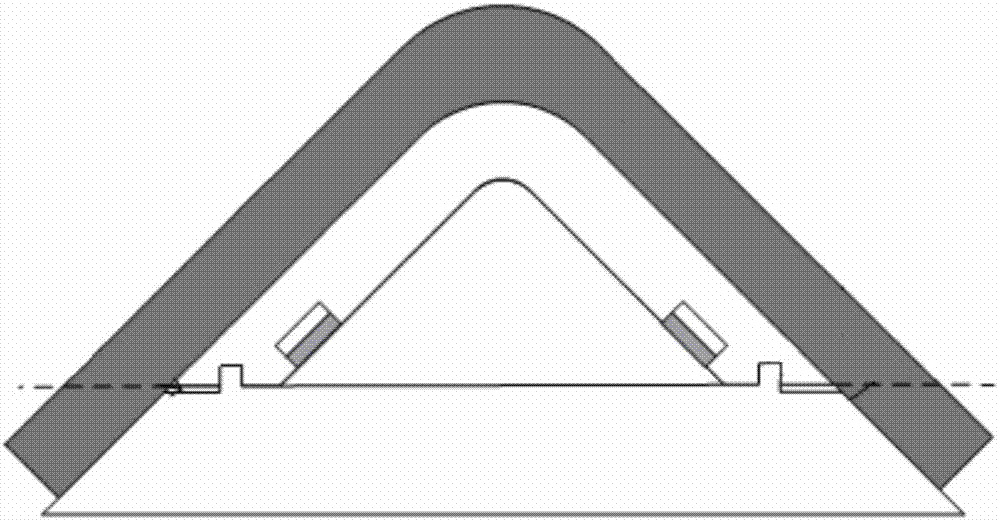

[0038] like figure 1 As shown, the present invention is a mold for molding composite T-shaped long truss reinforced wall panels, which is characterized in that the mold includes a rigid module 1 and a flexible module 2, and the rigid module 1 and the flexible module 2 are positioned by magnetic force and fixed;

[0039] The rigid module 1 is used for the preforming of the L-shaped prepreg layup on one side of the T-shaped stringer, the assembly and curing of the T-shaped stringer, and ensures the positional degree, axis degree and surface quality of the T-shaped stringer;

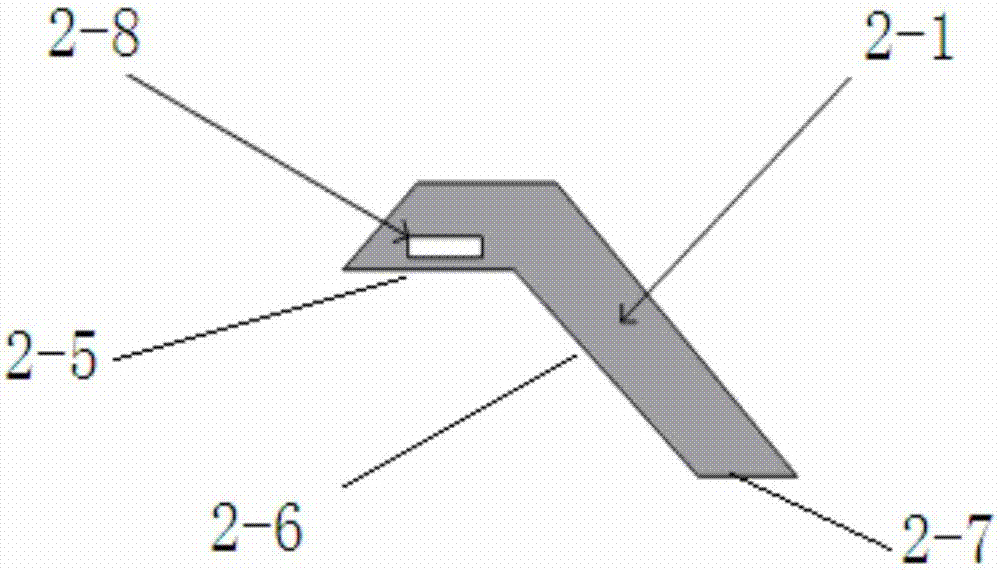

[0040] The flexible module 2 is used to promote the effective transfer of the applied pressure to the T-shaped stringer corner area and the triangular area through the flexible module 2 respectively along the flange and the web, so as to ensure the prepreg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com